Cincinnati CL-7 Use and care manual

-

DPERATIDN

1

SAFETY

AND

MAINTENANCE

MANUAL

EM-355

(2

APR

92)

CNC

LASER

CENTER

CINCINNATI

INCORPORATED

CINCINNATI,

OHIO

45211

INTRODUCTION

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECT~ON

6

~DENTIFICATION

~-----~-------------------

1-1

iNSTAllATION

liFTING

AND

MOVING

---------------------------

2-1

FOUNDATION

--------------------

_

---

_

----

___

----

2-1

ERECTION OF

MACHINE--------------------------

2-2

ERECTION OF

COMPONENTS--------------------

2-2

LEVELING----

___

---------

________

-----_----

__

---

2-2

iNITIAL

LUBRICATION----------------------------

2-2

ELECTRICAL CONNECTION______________________ 2-2

SAFETY

SAFETY

IS

EVERYONE'S

JOB

_____________________

3-1

HAZARDS----

______

------_-----_________________

3-4

ASSOCIATED

HAZARDS--------------------------

3-5

GAS STORAGE

----------------------------------

3-5

PRECAUTIONS

----------------------------------

3-8

SAFETY

SIGNS----------------------------------

3-8

SAFETY

GUIDELINES----------------------------

3-10

SAFETY MAINTENANCE CHI;:CK_______

~-----~----

3-iO

SPECIFICATIONS

DIMENSIONS

__

---

___

----

___

-----

___

---__________

4-1

SPECIFICATIONS ________________________

-----

__

_ 4-i

PIPING CONNECTIONS__________________________

4-1

EXTERNAL OPTICAL

ELEMENTS-----------------

4-2

GAS

REQUIREMENTS---------------------------

4-2

CONTOURING ACCURACY________________________ 4-3

AMBIENT TEMPERATURE

------------------------

4-4

CAPACITIES

_________

------_---

___

---

__

----

___

---

4-4

PRINCIPAL OF OPERATION

----------------------

4-4

SETaUP

AND

USE

LOADING

MATERIAL-----------------------------

5-1

GAGING

------

___________

---------------------

__

5-1

MACH~NE

CONTROlS

OPERATOR

CONTROL

CONSOLE _________________

6-1

REMOTE STATION

-------------------------------

6-6

lASER

HEAD

CONTROl

PANEL___________________ 6-7

COPYRIGHT©

1991

CINCINNATI INCORPORATED

SECTION 7

SECTION 8

SECTION 9

SECTION 10

OPERATION

DAILY

START-UP---------------------------------

7-1

NORMAL SHUTDOWN

---------------------------

7·1

LENS

CENTERING----------------------------·--

7·1

LENS

FOCAL

POINT

LOCATION

PROCEDURE

-----

7·2

ASSIST

GAS

PRESSURE

ADJUSTMENT-----------

7-5

COOLANT •

-----.-------------------.

__

••

-----

••

-7·5

POWER

CONTROL

------------------------------

7-6

PROGRAMMING

---------------------------------

7·9

SPECIAL

CODE

LIST-----------------------------

7·9

OPTIONS

BALL

TRANSFER

LOAD

STATION

-----------------

8-1

SCRAP

CONVEYOR

-----------------------------

8·1

HeNe

LASER-------------·-----------------------

8-1

NON-CONTACT

HEAD

---------------------------

8-1

PROGRAMMABLE ASSIST

GAS

PRESSURE-------

8·2

TOUCH

SENSOR

PROBE

-------------------------

8-2

MAINTENANCE AND ADJUSTMENTS

LUBRICATION

REQUIREMENTS-------------------

9-1

PALLET

DRIVE

MAINTENANCE

-------------------

9-1

OPTICS-----------------------------------------

9-2

BEAM

DELIVERY

ALIGNMENT---------------------

9·3

WHEN

REQUIRED------------------------

9·3

TOOLS

REQUIRED------------------------

9·4

COMPLETE

SYSTEM

ALIGNMENT----------

9-4

LASER

HEAD

ALIGNMENT

TO

MACHINE---- 9-4

X-AXIS

BEAM

ALIGNMENT----------------

9-5

Y-AXIS

BEAM

ALIGNMENT-----------------

9·6

Z-AXIS

ALIGNMENT-----------------------

9-7

FINAL ALIGNMENT

CHECK----------------

9-8

1/4

WAVE

PHASE

RETARDER

COOLING-----------

9-9

POWER

LEVEL CONTROL

••

----------------------

9-9

STAND

ALONE OPERATION-

LASER

HEAD--------

9-10

TROUBLESHOOTING

----------------------------

9-11

ALARM

AND

OPERATOR

MESSAGES

-------------

9-11

PREVENTATIVE

MAINTENANCE-------------------

9·13

SERVICE AND PARTS

SERVICE----------------------------------------

10-1

TRAINING---------------------------------------

10-1

ORDERING

REPAIR

PARTS-----------------------

10·1

RETURNING

PARTS

FOR

CREDIT-----------------

10·1

2

INTRODUCTION

CINCINNATI

CL-7

CNC

LASER

CENTER

The

Laser

Center

produces

two-dimensional

contoured

shapes

from fiat

matertal

by

mov-

ing

a

focussed

laser

beam

along

a

programmed

path.

The

beam

from

a

stationary

laser

resonator

is

directed

to

a

moving

lens

by

two

mirrors

mounted

on

a

moving

gantry.

The

workpiece

remains

stationary

while

a

narrow

strip

of

matertal

is

removed

along

the

path

made

by

the

lens.

Matertal

is

removed

by

vaporization

and

melting

where

the

lens

con-

centrates

laser

power

into

a

small

spot

on

the

workpiece.

Assist

gas

and

coolant

are

also

used

to

control

the

cutting

process.

The

mirrors

and

lens

are

positioned

by

the

gantry

to

produce

the

programmed

workpiece

geometry. A CNC

is

used

to

command

servo

dlives,

which

control

the

gantly

motion.

The

CNC

program

is

provided

by

the

user

and

also

includes

commands

to

specify fee-

drate,

laser

power,

assist

gas

and

coolant.

The

Laser

Center

is

equipped

'With

an

exhaust

system,

which

draws

air

down

from

the

cutting

area

to

assist

in

the

removal

of

process

by-products.

PART

QUALITY

The

follovving

factors

affect

part

quality:

.,

Machine

condition

e

Operator

ability

•

Setup

and

Programming

.,

Quality

and

type

of

material

CINCINNATI

machines

are

designed

to

be

rugged

and

durable.

However,

improper

adjustment

or

lack

of

maintenance

can

reduce

the

quality

of

parts

produced

on

the

machine.

The

quality

of

a

laser-cut

edge

depends

on

the

combination

of

a

uniform

laser

beam

of

adequate

power,

properly

focused

on

the

workpiece 'With

an

adequate

supply

of

the

correct

assist

gas,

traveling

at

a

speed

compatible

'With

the

material

removal

rate.

Uniform

beam

quality

and

power

level

are

most

influenced

by

the

alignment

and

cleanli-

ness

of

the

optical

elements

(internal

resonator

mirrors,

external

beam

delivery

mirrors

and

the

focusing lens).

Critical

manual

adjustments

are:

Lens

focal

point

location,

lens-to-nozzle

centertng,

and

the

assist

gas

pressure,

unless

programmable

gas

pressure

option

is

included.

Part

quality

depends

on

the

CNC

program

to

command

the

correct

combination

of

laser

power,

assist

gas,

feedrate

and

coolant

for

the

material

type

and

thickness

being

pro-

cessed.

Part

accuracy

depends

on

the

CNC

program

for

proper

use

of

kerf

width

compen-

sation

and

for selection

of

feedrate

'Within

radius

contouring

accuracy

limits.

Material

quality

can

affect

the

repeatability

of

process

parameters.

Matertal

which

has

uniform

composition

and

thickness

and

a

smooth,

clean

surface

'Will

minimize

variations

in

part

quality.

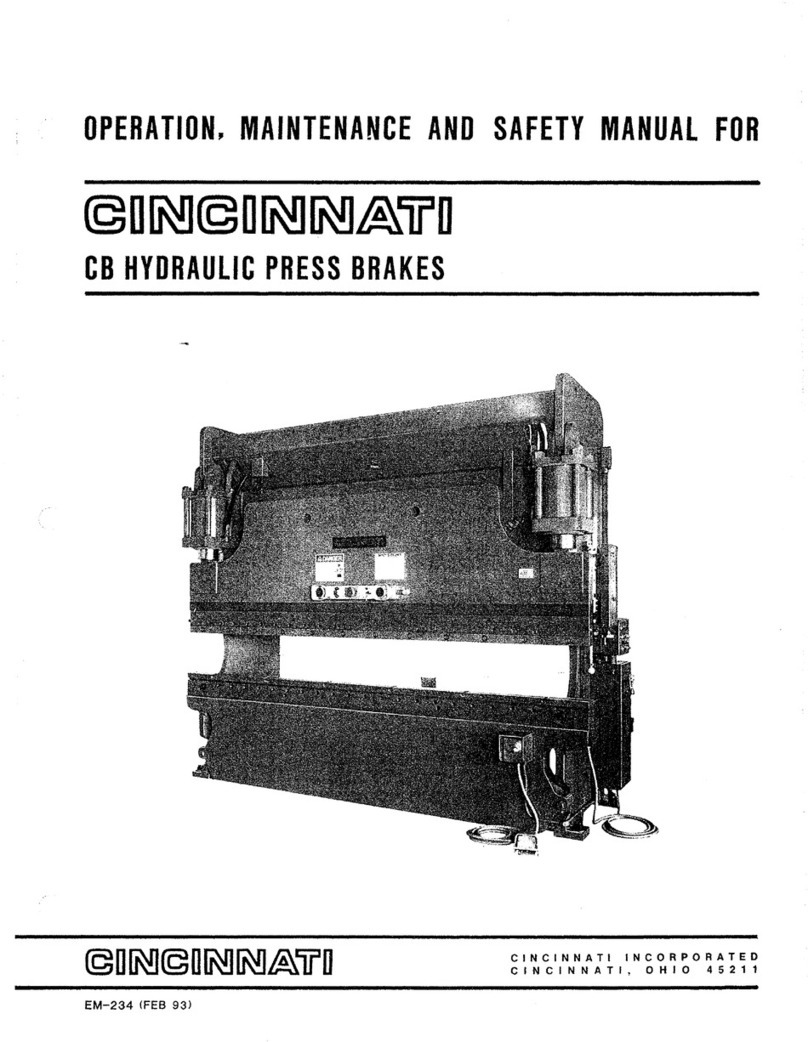

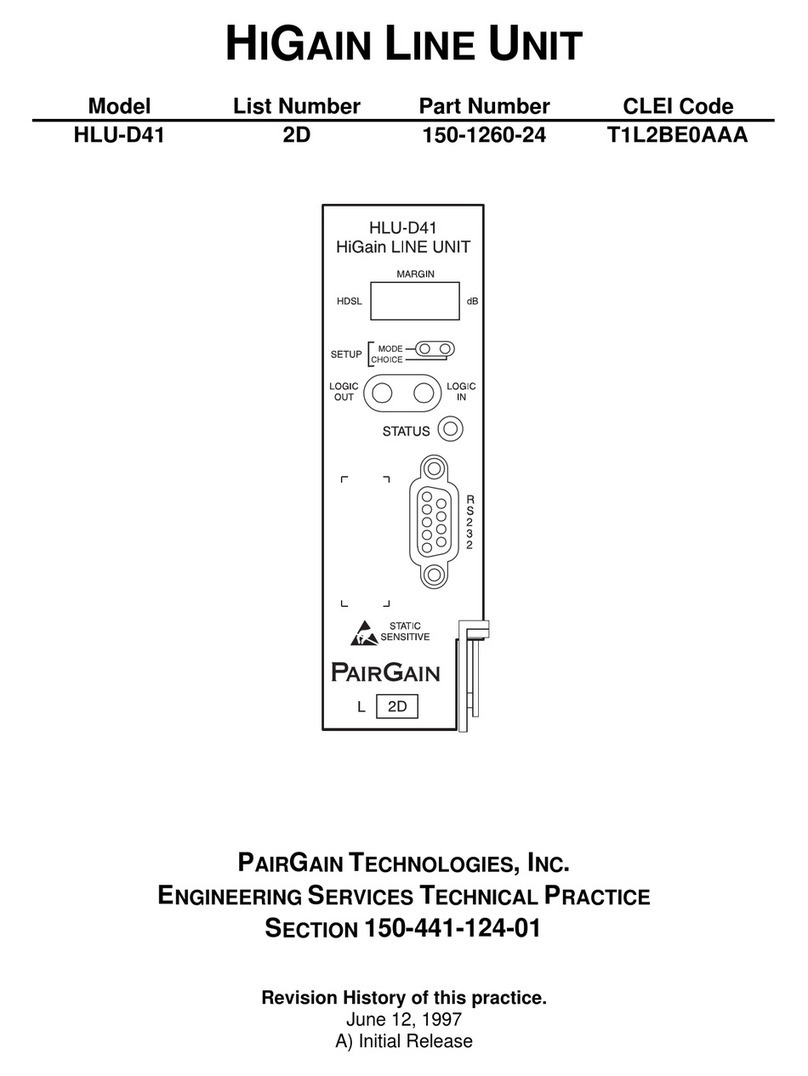

SECTION 1 IDENTIFICATION

CL-7

CNC

LASER

CENTER

FIGURE

1-1

1. LASER HEAD CONTROL

2. LASER WARNING LIGHT

3.

HIGH VOLTAGE WARNING

4.

LASER HEAD

5. Z-AXIS PROTECTIVE HOUSING

6.

CUTTING HEAD ASSEMBLY

7. GANTRY

8.

X-AXIS BEAM DELIVERY MIRROR BOX

9.

UPPER WORK PALLET

10. X-AXIS GUIDE AND X-AXIS BALLSCREW

(Covered by bellows)

11.

X-AXIS BEAM TUBE

12. SUPPORT GRID

13. LOWER WORK PALLET

14. FEED HOLD BUTTON (Pallet drive adjustment

located underneath plate on both sides of frame)

15. LOAD STATION PENDANT

16. LOAD FRAME

17. FUME/COOLANT

PAN

18. OPERATOR'S MANUAL

19. SAFETY MAT

20. OPERATOR CONTROL CONSOLE

21. MAIN FRAME

1-1

22. ASSIST GAS PRESSURE SWITCH

23. Z-AXIS DRIVE MOTOR (Behind bellows)

24. MATERIAL CONTACT SWITCH

25. COUNTERBALANCE SPRING

26. PROGRAMMABLE ASSIST GAS

27. 5.0" FOCAL LENGTHLENS HOLDER

28. BLANK LENS HOLDER

29. LENS PURGE GAS LINE

30. LENS COOLING WATER LINE

31. TOUCH PROBE

32. MAGNETIC BREAKAWAY COUPLING

33. COOLANT LINE (Cutting

fli.l,id)

34. HINGED COVER (Shown removed)

35. MATERIAL FOLLOWER/ADJUSTING

RING

FIGURE

1-2

1-2

FIGURE

1-3

36. FUME DUCT (Exits to axial flow fan attached to 41. PALLET DRIVE MOTORS (2)

outside of frame) 42. OPTICS COOLANT FILTERS (2)

37. PALLET DRIVE CABLE 43. FUME PLENUM

38. X-AXIS SERVO MOTOR 44. SCRAP TRAY

39. SCRAP CONVEYORS (Optional) 45. COOLANT PUMP AND RESERVOIR

40. X-AXIS OVERTRAVEL BUMPER 46. COOLANT RESERVOIR FILTER

1-3

LIFTING &MOVING

Machine

weights

as

shipped

are

approximately:

MAINFRAME

LOAD

FRAME

5 X

10-

22,000

lbs.

8,000

lbs.

(9,977

Kg.)

(3,628

kg.)

6 X

12-

25,000

lbs.

9,500

lbs.

(11,338

kg.)

(4,308

kg.)

Variations

of

plus

or

minus

500

pounds

(227

Kg)

from

these

figures

are

possible,

depending

on

optional

equipment

installed.

The

Main

Frame

is

lifted

by

using

the

four

lifting

locations

provided.

There

are

two

1-l/4"

diameter

holes

located

in

front

of

the

Resonator.

These

holes

are

for

standard

lifting

devises.

There

are

also

two

1

"-8 UNC

tapped

holes

for swivel clevises

located

at

the

front

of

the

Main

Frame.

See

Figure

2-1.

CAUTION

WHEN

liFTING

MAIN FRAME BE SURE THAT

SWIVEL

ClEVISES

(C.I. PART #525462) ARE

INSTAllED

AS MEANS TO

liFT

THE

FRONT

(lOAD

FRAME END). USING

AN

EYEBOlT

OR

ANY

OTHER

DEVICE

NOT

DESIGNED

FOR

EXCESSIVE SIDE

lOADS

COUlD

RESULT IN

SERIOUS INJURY

OR

DEATH

TO

BYSTANDERS

AND/OR CAUSE EXTENSIVE DAMAGE TO

THE

MAIN FRAME AND RESONATOR.

FIGURE

2~1

=

lifting

Main Frame

IMPORTANT:

Extreme

cue

must

be

taken

not

to

subject

the

machine

to

shock

loads.

The

machine

must

be

lifted

and.

set

down

gently.

2-1

The

Load

Frame

is

lifted

by

placing

four

chain

hooks

at

each

of

the

four

outer

machine

corners.

The

chain

hooks

are

hooked-in

the

access

holes

at

these

locations.

See

Figure

2-2.

FIGURE 2=2-

lifting

load

Frame

FOUNDATION

This

section

applies

only

to

machines

installed

in

an

area

not

affected

by

shock

inducing

equipment,

such

as

punch

presses,

turret

punches,

etc.

Installations

involving

this

type

of

equipment

in

close

proximity

to

the

machine

require

special

considerations

and

CINCINNATI INCORPORATED

must

be

consulted.

A

Foundation

Plan

drawing

is

provided

when

the

machine

is

ordered.

This

drawing

will

provide

the

user

with

~11

the

detailed

information

required

to

locate

the

equipment

and

the

eight

machine

anchors.

The

eight

anchor

locations,

each

approx-

imately

6" x 6"

(152

x

152

rum),

should

be

prepared

by

the

customer

prior

to

arrival

of

the

equipment.

These

eight

pads

must

be

pre-leveled

to lie

in

the

same

plane

within

.50

inches

(12.7 mm);

and

eight

anchor

holes

should

be

drilled

as

specified

on

Foundation

Plan

drawing.

Shims

for final leveling,

anchors,

studs,

nuts

and

isolation

pads

are

provided

by

CINCINNATI

INCORPORATED.

Optional

wedge

type

adjustable

mounts

are

available.

These

provide

a

secure

footing

for

the

machine,

limited

isolation

from

shock

and

will

considerably

speed

the

installation

process.

Floor

should

be

concrete,

have

a

minimum

thick-

ness

of

6

inches

(

152

mm),

and

be

free

from

cracks.

ERECTION OF MACHINE

After

setting

the

machine

on

the

anchor

studs,

place

washers

and

nuts

on

studs

but

do

not

tighten.

Erection

consists

of

the

following

steps:

l.

Be

sure

lifting

devises

are

removed.

2.

Remove

all

steel

banding

and

protective

wrappings.

3.

Install

fume

fan

and

duct

connecting

to

fume

pan

with

flange

and

fasteners

provided.

Be

sure

to

seal

connection

with

a

bead

of

RTV silicone.

Make

the

electrical

connection

to

the

fan

drive

motor

with

wiring

provided.

4.

Install

the

operator's

control

console

with

the

fasteners

provided.

Refer

to

Electrical

Section

for

connection.

5.

Refer

to

Laser

Manufacturer's

manual

provided

for

preparation

of

the

laser

resonator.

ERECTION OF COMPONENTS

The

water

chiller

is

a free-standing

unit

requiring only

floor

support.

It

is

connected

at

a

central

location

with

hoses

furnished

with

machine

(for

chiller

location

shown

on

Foundation

Plan)

on

the

drive side

at

the

laser

end

of

the

frame. The chiller

should

be

positioned

as

shown

on

the

Foundation

Plan drawing.

Consult

CINCINNATI

INCORPORATED

if

an

alternative chiller location

is

required.

After

chiller

(and

transformer)

installation,

wiring

and

final leveling,

the

safety

cable

on

the

drive

side

of

the

machine

should

be

installed

as

shown

on

the

Foundation

Plan

drawing.

Likewise,

the

safety

mats

must

be

located

and

connected.

LEVELING

Leveling

adjustments

are

made

using

jackscrews,

which

are

accessible

through

openings

in

the

frame

above

each

of

eight

mounting

pads.

Slotted

shims

are

inserted

between

the

machine

foot

and

the

steel

spacer

block

as

shown

on

the

Foundation

Plan

drawing.

After

shims

are

inserted,

jack

screws

are

to

be

backed-off

or

removed.

On

machines

equipped

with

optional

adjustable

wedge

type

mounts,

adjustments

are

made

using

the

wedge

screw.

Shimming

is

eliminated

and

no

jackscrew

or

spacer

blocks

are

required.

The

procedure

for

leveling

is

described

below:

PRELIMINARY

lEVELING

l.

Cross-leveling

is

checked

by

placing

a

precision

level

on

the

machined

surface

on

the

top

of

the

main

frame

end

plate

nearest

the

laser

head,

and

using

the

jackscrews

and

shims

provided

to

make

adjustments.

2.

Longitudinal

level

is

checked

on

the

top

of

the

X-Axis

guide

way.

Adjust

as

described

above.

FINAl lEVEliNG

1. Use a 15"

precision

spirit

level

with

a

sensitivity

of

.0005"/ft.

2.

Place

the

level

on

the

top

of

the

gantry

and

position

the

gantry

at

X=

0.

3.

The

top

of

the

gantry

is

not

machined.

Therefore,

it

will

be

necessary

to

shim

one

or

both

ends

of

the

level

to

establish

a

reference

reading

and

make

the

level

sit

solidly

in

place.

Paper

shims

can

be

used

for

this

purpose.

4.

Observe

the

position

of

the

bubble

while

slowly

jogging

the

gantry

from

X = 0

to

X =

120.

Maximum

deviation

is

one

division

of

the

level

(.0005/ft.) from

end-to-end.

This

ensures

that

the

frame

is

not

in

a

twist.

Make

adjustments

as

described

above,

using

jackscrews

to

add

or

remove

shims.

5.

When

Step

4

is

complete,

lightly

tighten

anchor

nuts

and

recheck

level

as

specified

in

Step

4.

6.

Tighten

the

anchor

nuts

with

light

hand

pressure

on

the

wrench

so

as

not

to

crush

the

stud

isolation

washer.

Secure

the

anchor

nuts

with

locknuts

provided

as

shown

on

the

Foundation

Plan

drawing.

7.

Repeat

Step

4

as

a final level

check.

INITIAl lUBRICATION

Machines

are

fully

lubricated

before

leaving

the

factory.

Unusual

circumstances,

such

as

storage

for

more

than

one

month

from

shipment

date

will

require

initial

lubrication

per

chart

in

Section

9

of

this

manual.

ElECTRICAL

CONNECTION

Each

Laser

customer

is

supplied

a

complete

set

of

Foundation

Plan

drawings

prior

to

machine

shipment.

The

The

electrical

load

requirements

and

connection

points

are

called

out

on

these

drawings.

Be

certain

that

a

suitably

sized

wire

is

brought

to

the

main

disconnect

and

the

proper

voltage

is

supplied.

The

CL-7

Laser

standard

electrical

input

is

460

volt, 3

phase

and

50/60

hertz.

The

machine

must

be

properly

grounded

in

accordance

with

National

Electric

Code

NFPA

70,

Sections

250-81,

83,84

and

89.

CINCINNATI INCORPORATED

recommends

using

an

individual

electrode

per

Section

250-83

(C)

to

avoid

interference

from

other

equipment.

Do

not

start

the·

machine

until

thoroughly

reading

the

SAFETY

section

of

this

manual

and

a

CINCINNATI INCORPORATED

Service

Represent-

ative

is

present.

SAFETY IS EVERYONE•s

JOB

The

CINCINNATI CNC

Laser

Center

manufactured

by

CINCINNATI INCORPORATED

has

been

designed

to

meet

the

highest

order

of

reliability

and

ease

of

operator

use.

This

system

has

been

certified

under

Federal

Regulations

21 CFR,

subpart

J,

as

a

Class

IV

Laser

product

as

required

by

the

Federal

Radiation

Control

for

Health

and

Safety

Act

of

1968.

This

certification

is

on

file

with

the

Food

and

Drug

Administration

Center

for Devices

and

Radiological

Health

Division,

Laser

Products

Section,

Silver

Springs,

Maryland

20910.

CINCINNATI INCORPORATED

recommends

the

cus-

tomer

read

and

understand

the

requirements

of

the

American

National

Standard

for

safe

use

of

Lasers,

ANSI

Z136.l.

This

is

available

from

the

American

National

Standards

Institute,

1430

Broadway, New

York,

NewYork

10018.

For

additional

safety

information

we

recommend:

•

Securing

applicable

safety

data

from

the

National

Safety

Council,

425

North

Michigan

Avenue,

Chicago,

Illinois

60611

and

Laser

Institute

of

America,

5151

Monroe

Street,

Toledo,

Ohio

42623.

•

Determining

your

responsibilities

under

your

state

and

local

safety

codes.

"

Requesting

assistance

from

the

loss

prevention

department

of

your

workmen's

compensation

carrier.

Personnel

responsible

for

your

Laser

Center

opera-

tor

training

program,

maintenance,

and

manufac-

turing

operations

must

read

and

understand

this

safety

section

and

operator's

manual.

No

one

should

set-up,

operate

or

maintain

this

Laser

Center

until

they

thoroughly

understand

it

and

know

how

to

do

their

job

safely.

INTRODUCTION

TO

LASER SAFETY

The

laser

is

an

intense,

highly

directional

beam

of

light

that,

if

directed,

reflected

or

focused

upon

an

object,

will

be

partially

absorbed.

This

raises

the

temperature

of

the

surface

and/

or

the

interior

of

the

object,

which

can

potentially

cause

an

alteration

or

deformation

of

the

material.

These

properties,

which

have

been

applied

to

laser

material

process-

ing,

can

also

cause

adverse

biological

effects

in

human

tissue.

The

CINCINNATI CNC

Laser

Center

operates

in

the

far-infrared

region,

which

:i.s

invisible

and

has

high

heat

energy.

The

beam

emitted

has

a

wavelength

of

10.6

~m (micrometers).

A BRIEF DiSCUSSION

ON

RADIATION

Radiation

is

defmed

in

Webster's

as

"energy

radiated

in

the

form

of

waves

or

particles".

Radiation

is

a

form

of

energy

emitted

from

a

wide

range

of

sources,

some

man-made

and

some

natural.

The

electromagnetic

spectrum

covers

those

forms

of

energy

with

wavelengths

of

approximately

10-11

meters

to

107

meters.

That

corresponds

to

frequen-

cies

of

approximately

1022

hertz

to

approximately

1000

hertz.

All

forms

of

electromagnetic

radiation

travel

at

the

speed

of

light,

but

at

differing

frequencies.

The

wavelength

of

such

a

wave

is

inversely

proportional

to

the

frequency,

and

often

a

particular

type

of

radi-

ation

is·

described

in

terms

of

its

wavelength

rather

than

its

frequency.

The

energy

transmitted

by

such

radiation

is

also

related

to

its

frequency

-

the

higher

the

frequency,

the

greater

the

energy.

The

energy

of.radiation

tends

to

interfere

with

the

internal

energy

that

holds

atoms

together

as

molecules.

If

the

energy

of

a

ray

of

radiation

is

great

enough,

it

will

attract

electrons

away

from

an

atom

or

add

additional

elec-

trons

to

it.

Radiation

that

lacks

the

energy

to

deform

atoms,

(non-ionizing)

radiation,

can

still

cause

bodily

harm

by

raising

the

temperature

of

the

body

tissue

the

radiation

contacts

with

the

energy

it

imparts.

If

this

tissue

is

the

hardened,

dead-cell

tissue

of

the

outer

skin,

it

does

little

harm.

It

may

produce

reddening

of

the

tissue

and

mild

soreness.

However,

if

that

same

radiation

energy

gets

inside

the

body

to

less

well-protected

tisSIUe,

the

tissue

may

not

only

be

heated,

but

may

become

damaged

as

well.

The

eyes

are

also

very

susceptible

to

radiation

energy.

The

cells

of

the

cornea

and

the

retina

are

easily

destroyed

and

must

always

be

protected

from

radi-

ated

energy.

Ordinary

industrial

type

safety

glasses

will

provide

this

protection.

Figure

3-1

is

a

chart

of

that

portion

of

the

electro-

magnetic

spectrum

pertinent

to

our

discussion.

The

area

the

CINCINNATI

CL-7

LASER

operates

in

is

located

between

3x10-5

and

3x10-6

meter

wave-

length.

This

brief

introduction

has

been

prepared

to

alleviate

any

unwarranted

worries

regarding

laser

radiation

safety.

SAFETY STANDARDS

Research

studies,

along

with

an

understanding

of

the

hazards

of

sunlight

and

conventional,

man-

made

light

sources

have

also

permitted

scientists

to

establish

safe

exposure

limits

for

nearly

all

types

of

laser

radiation.

These

limits

are

generally

referred

to

FREQUENCY WAVELENGTH

(hertz) (meters)

-

1022

3x1

0"

14

-

-

1021

3x1

0"

13

-

~Gamma

-

1020

3x1

0"

12

-rays

-

1019

3x1o-

11

-<

X-rays

-

1018

3x1

0"

10

-Ultraviolet

-

1017

3x1o·9 -rays

-

1016

3x1o·8 -

Visible light ·(380-780 {

nanometers wavelength) · _

1015

3x1o·7

-"""

I

-

1014

3x1o·6 -

~INCINNAll

Lasers

-

~Infrared

CNCLASER

--.·J

-

1013

3x1o·5 -rays

-

1012

3x1o·4 -

-

1011

3x1o·3

_.,;

-

1010

3x1o·2 -

~Microwave

-109

3x1

o·

1 -

FM

broadcast band

-(

-108 3 -

~,

Radio -frequency

-107 30 -(RF) waves

AM broadcast band

-{

(535-1605 kilohertz) -106 3x102 -

-105 3x103 -

Telephone

{

~

104 3x104 -

103 3x105

f-

Commercial electric

--=

100 3x106

1-

power (60 hertz) -10 3x107

.__

Figure

3-1

-Electromagnetic spectrum

3-2

as

Maximum

Permissible

Exposures

(MPE's)

by

laser

safety

specialists.

In

many

cases,

it

is

unnec-

essary

to

make

use

of

MPE's

directly.

The

past

experience

gained

in

millions

of

hours

of

laser

use

in

the

laboratory

and

in

industry

has

permitted

the

development

of

a

system

of

laser

hazard

categories.

Each

laser

is

placed

into

one

of

at

least

four

sepa-

rate

classes,

or

risk

categories.

The

safety

measures

to

reduce

or

eliminate

accidents

depend

u_pon

which

class

of

laser

is

being

used.

There

are

a

variety

of

laser

safety

standards.

These

include

regulations

of

the

Federal

Govemment,

and

of

several

state

and

local

govemments.

Additionally

there

are

non-regulatory

standards,

such

as

the

ones

of

the

American

National

Standards

Institute

(ANSI)

and

of

the

American

Conference

of

Governmental

Industrial

Hygienists

(ACGIH).

On

the

international

scene,

the

World

Health

Organization

(WHO)

has

laser

safety guidelines,

and

the

International

Electrotechnical

Commission

(IEC)

has

been

developing

laser

safety

standards.

Of

the

standards

that

apply

to

users,

the

ANSI

standard

Zl36.1

is

probably

the

most

important

and

most

often

quoted.

It

provides

information

on

how

to

classify

lasers

for

safety,

laser

safety

calculations

and

measurements,

and

laser

hazard

control

mea-

sures.

LASER HAZARD CLASSIFICATION

As

previously

indicated,

laser

systems

can

be

grouped

into

at

least

four

primary

categories

to

indicate

relative

potential

risk:

Class

I - A

class

I

laser

is

considered

safe

based

upon

current

medical

knowledge.

This

class

includes

all

lasers

or

laser

systems

which

can-

not

emit

levels

of

optical

radiation

above

the

exposure

limits

for

the

eye

under

any

exposure

conditions

inherent

in

the

design

of

the

laser

product.

There

may

be

a

more

hazardous

laser

embedded

in

the

enclosure

of

the

Class

I

prod-

uct,

but

no

harmful

laser

radiation

can

escape

the

enclosure.

Class

II

- A

class

II

laser

or

laser

system

must

emit

a

visible

laser

beam,

which

by

its

very

bright

nature

will

be

too

dazzling

to

stare

into.

Momentary

viewing

is

not

considered

hazardous

since

the

upper

radiant

power limit

on

this

type

of

device

is

1 mW

which

corresponds

to

the

total

beam

power

entering

the

eye for a

momentary

exposure

of

0.25

second

that

is

just

safe

(i.e.,

the

MPE for a

0.25

second

exposure).

Class

III - A

class

III

laser

or

laser

system

can

emit

any

wavelength,

but

it

cannot

produce

a

haz-

ardous

diffuse

reflection

unless

focused

or

viewed for

extended

periods

at

close

range.

It

is

also

not

considered

a fire

hazard

or

a

serious

skin

hazard.

Any

CW

(continuous

wave)

laser

3-3

that

is

not

class

I

or

class

II

is

a

class

III

device

if

its

output

power

is

0.5

W

or

less.

Since

the

output

beam

of

such

a

laser

is

definitely

haz-

ardous

for

intrabeam

viewing,

control

measures

center

on

eliminating

this

possibility.

Class

N -A

class

N

laser

or

laser

system

is

any

that

exceeds

the

output

limits

(Accessible

Emission

Limits, AEL's)

of

a

class

III

device.

As

would

be

expected,

these

lasers

inay

be

either

a

fire

and

skin

hazard/

or

a diffuse reflection

haz-

ard.

Very

stringent

control

measures

are

required

for a

class

IV

laser

or

laser

system.

CONTROL MEASURES

The

CINCINNATI

CNC

Laser

Center

has

been

designed

and

manufactured

using

the

highest

engi-

neering

control

measures

practical,

however,

even

these

high

standards

have

limitations.

Laser

safety

requirements

call for

administrative

and

procedural

controls

to

be

incorporated

in

the

use

of

lasers

in

order

tQ

minimize

or

eliminate

the

potential

of

per-

sonal

inju:ry

during

laser

operation.

The

position

of

Laser

Safety

O.tficer

(LSO)

must

be

established

within

the

management

organization

of

a

company

using

a

laser

cutting

machine.

This

per-

son

has

the

responsibility

and

authority

to

monitor

and

enforce

the

control

of

laser

hazards.

He

or

she

should

have

the

knowledge

to

effectively

evaluate

and

control

hazards

involved

in

laser

cutting.

The

LSO

is

responsible

for

requiring

written

standard

operating,

maintenance

and

service

procedures

for

the

laser

center.

These

procedures

should

be

kept

at

the

laser

center

for reference

by

operating

main-

tenance

and

service

personnel.

Continued

education

and

training

for

operating

maintenance

and

service

personnel

is

mandatory

for

an

adequate

laser

safety

program

to

exist.

The

Laser

Safety

Officer

should

see

to

it

that

personnel

involved

in

various

aspects

of

laser

operation

have

been

trained

to

a level

commensurate

with

the

level

of

potential

hazards

to

which

they

may

be

exposed.

OPERATING

PER~NNEL

These

people

are

responsible

for

the

productive

use

of

the

laser

cutting

center

over

the

full

range

of

its

intended

function.

These

persons

should

be

thor-

oughly

familiar

with

all

operating

controls,

adjust-

ments

and

hazards

associated

with

their

function.

MAINTENANCE PERSONNEL

These

individuals

are

responsible

and

should

be

thoroughly

trained

in

the

performance

of

adjust-

ments

or

procedures

specified

in

the

User

Information

manuals

provided

by

the

manufacturer

of

the

laser

center.

The

functions

performed

are

to

insure

the

intended

performance

of

the

laser

center

is

realized.

SERVICE PERSONNEL

These

individuals

are

responsible

for

the

perfor-

mance

of

procedures

and

adjustments

described

in

the

manufacturer's

service

manual.

The

duties

of

a

service

person

requires

a

higher

level

of

training

and

education

than

that

of

the

maintenance

func-

tion, however, a service individual

does

not

neces-

sarily

include

the

duties

or

responsibilities

of

a

maintenance

person.

A

strong

commitment

from

management

must

exist

in

order

for

an

effective

safety

program

to

be

estab-

lished

with

personnel

involved

in

the

use

of

the

CINCINNATI

CNC

Laser

Center. Additional

informa-

tion

concerning

this

topic

can

be

located

in

the

American

National

Standard

Z136.1-1986.

Refer

to

Appendix

D

of

this

standard

for a

guide

for organiz-

ing

and

implementing

a

laser

safety

and

training

program.

EXPLANATION

OF

LASER RADIATION

Light

is

a form

of

energy

that

is

released

from indi-

vidual

atoms

or

molecules

in

a

substance.

To

understand

how

a

laser

works,

it

is

necessary

to

know

something

about

the

nature

of

atoms

and

how

they

interact

with

light

and

other

forms

of

energy.

Every

atom

is

a

storehouse

of

energy.

The

amount

of

energy

in

an

atom

depends

in

part

on

the

motion

of

the

electrons

that

orbit

the

atom's

nucleus.

When

an

atom

absorbs

energy,

the

energy

levels

of

the

electrons

increase,

and

the

atom

is

said

to

be

excit-

ed.

The

atoms

of a

substance

become excited

when

they

absorb

heat,

light,

or

other

forms

of

energy

that

pass

through

the

substance.

An

excited

atom

can

return

to

its

normal

energy

level

by

releasing

its

excess

energy

in

the

form

of

light.

This

release

of

light

is called

spontaneous

emission.

In

spontaneous

emission,

excited

atoms

release

light

irregularly.

As

a

result,

the

light

has

different

frequencies, different

phases,

and

travels

in

differ-

ent

directions.

Light

released

in

this

way

is

called

incoherent

light.

Such

light

is

produced

by

the

sun

and

by

ordinary

electric

light

bulbs;

Excited

atoms

also

may

release

light systematically.

This

kind

of

release, called

stimulated

emission,

is

the

main

process

that

takes

place

in

a

laser.

Stimulated

emission

occurs

when

the

energy

released

from

one

atom

interacts

with

another

atom

that

is

still excited.

The

interaction

stimulates

the

excited

atom

into

releasing

its

own

energy

as

light.

Most

of

the

light

produced

by

stimulated

emission

has

the

same

frequency

and

same

phase

as

the

stimulating

light.

It

also

travels

in

the

saine.

direc-

tion,

and

so

it

combines

with

and

amplifies

the

trig-

gering

light.

Such

light

is

called

coherent

radiation.

3-4

LASER TYPES.

There

are

three

major

kinds

of

lasers

based

on

their

lasing

medium:

solid

lasers,

gas

lasers,

and

liquid

lasers.

The

CINCINNATI

CNC

Laser

Center

model CL-7

is

a

gas

type laser.

Gas

lasers

use

a

gas

or

a

mixture

of

gases

as

their

light-amplifying·

substance.

In

most

cases,

the

gas

is

contained

in

a

glass

or

quartz

tube

from

one

to

three

feet (30

to

91

centimeters)

long.

Such

gas

lasers

have

been

built

in

glass

tubes

mea-

suring

up

to

30

feet

(9

meters)

in

length.

Gas

lasers

have

several

power

sources,

including

chemical

reactions,

electric

current,

electron

beams,

and

ultraviolet

rays.

Most

gas

lasers,

produce

a

continu-

ous

beam

of

light.

They

also

can

produce

beams

of

higher

average

power

than

solid

lasers

can.

They

can

do

so

because

they

are

cooled

by

the

gas

as

it

flows

through

the

tube.

The

light

from a

gas

laser

has

a

narrower

frequency

range

than

the

light

from

a solid laser.

As

an

option, a

second

laser

can

be

added

to

the

CL-7 CNC

Laser

Center.

This

is

the

HeNe

laser,

which

is

a

gas

laser

using

helium-neon

gases

to

produce

a

visible

red

beam.

Due

to

the

visible

nature

of

this

beam

and

its

power

level,

it

is

desig-

nated

as

a

Class

II

laser

product.

Class

II

levels

of

laser

radiation

are

considered

a

chronic

viewing

hazard

and

thus

the

warning

not

to

stare

into

the

red

beam

as

given

on

our

warning

sign.

HAZARDS

EVE HAZARDS

The

eye

hazards

represent

a

potential

for

injury

to

several different

parts

of

the

eye, generally

depend-

ing

upon

which

eye

part

absorbs

the

most

radiant

energy.

Laser

radiation

in

the

far-infrared

region

with

wave

lengths

of

3J.Im

to

1 millimeter will

be

absorbed

in

the

front

surface

of

the

eye.

Thus,

if

the

eye

is

not

protected,

it

may

receive

damage

to

the

cornea

and

lens

from

direct

or

reflected

laser

beam

exposure.

Therefore, eye

protection

must

be

worn

by

all

oper-

ation,

maintenance

and

service

personnel

while

working

at

the

CINCINNATI CNC

Laser

Center.

The

type

and

style

of

eye

protection

to

use

should

be

worked

out

with

the

supplier

of

your

shop

eye

pro-

tection

program.

In

general,

the

normal

safety

glasses

with

side

shields

used

in

metal

working

shops

will

provide all

the

protection

necessary.

It

is

the

user's

responsibility

to

establish

and

enforce

an

eye

protection

program.

SKIN HAZARDS

Laser

radiation

striking

the

skin

is

reflected,

absorbed,

and

transmitted;

the

percentage

of

each

depends

upon

the

characteristics

of

the

skin

at

the

II

wavelengths

of

concern.

Effects

on

the

skin

from

absorbed

radiation

may

vary

from mild

redness

to

blistering

and/

or

charring,

depending

upon

the

total

energy

absorbed

and

the

rate

at

which

it

is

absorbed.

Unnecessary

exposure

of

the

skin

to

laser

radiation

should

be

avoided regardless

of

the

level

of

radiant

energy.

The

CINCINNATI

CNC Laser

Center

has

beeri

tested

and

found

to

have

no

detectable

x-ray

emissions

and

related

hazards.

In

general,

the

hazards

pre-

sented

by

the

CINCINNATI

CNC

Laser

Center,

which

operates

in

the

far-infrared.(invisible light) region,

will

be

severe

burns,

lacerations

and

possible

amputation

if

members

of

the

body

come

in

contact

with

the

direct

beam

or

close to reflected

beams

of

high

energy.

The

design

of

the

Laser

Center

pro-

vides engineered protection from

these

hazards

for

personnel

while properly

using

this

equipment. This

basic

design

should

not

be

altered

or

modified

in

any

manner.

ASSOCIATED HAZARDS

ELECTRICAL

Because

of

the

high

electrical energies

used

to gen-

erate

the

laser

beam

in

the

CINCINNATI

CNC

Laser

Center,

electrocution

hazards

are

possibly

a

far

greater

danger

to

personnel

than

those

of

the

laser

beam

itself.

This

is

why

no

access

to

high

electrical

energy

is

possible

without

going

through

a

safety

interlocked door

or

pqnel. Before

any

maintenance

or

service

is

undertaken,

you

should

ensure

that

the

laser

component

has

been

isolated

from

the

electrical service

and

all

other

precautions

taken

as

prescribed

in

this

manual

and

the

other

component

manuals

provided.

CAUTION

HIGH VOLTAGE OF UP TO 30,000 VOLTS

IS

PRE·

SENT

IN

THE LASER HEAD AND POWER SUPPLY

CABINET. CONTACT WITH VOLTAGE CARRYING

CONDUCTORS IS NOT NECESSARY, AS ENERGY

AT THIS POTENTIAL CAN JUMP TO A CLOSE

BODY

AT

GROUND POTENTIAL, SUCH

AS

YOUR·

SELF, CAUSING IMMEDIATE DEATH. DO NOT

ENTER ANY HIGH VOLTAGE

AREA

WITHOUT

FIRST

DISCONNECTING POWER. REFER TO

LASER MANUFACTURER'S SERVICE MANUAL

BEFORE ENTERING THIS CABINET.

FIRE

Fire

hazard

is

present

in

the

processing

area

through

interaction

with

the

laser

beam

and

materi-

als

present

in

the

work

area. Additional fire

hazards

exist

in

the

electrical controls enclosed

in

the

Laser

Center

cabinets. Appropriate fire

equipment

should

3-5

be

available

and

the

purpose

of

such

equipment

should

be

understood

by

operating

per~onnel.

This

equipment

should

be

provided to

extinguish

or

con-

trol

small fires only. Follow

basic

fire fighting proce-

dures.

FUME AND DUST

WARNING

-POISONOUS

FUMEs

MAY

BE

FORMED

BY

LASER CUTIING. DO NOT BREATHE FUMES.

Use

only

with

adequate

ventilation

or

respirators.

The

ventilation

requirements

should

be

determined

by

a professional qualified

to

assess

ventilation con-

trol

requirements.

The

CL-7 Laser

is

equipped

with

an

exhaust

system

that

draw$

air

down from

the

cutting

surface.

The

optimal

exhaust

rate

for

your

specific

application

of

the

CL-7 Laser

should

be

determined

by

a profes-

sional

qualified

to

assess

ventilation

systems.

The

OSHA-required Material Safety

Data

Sheet

for

the

material

being

processed

should

be

reviewed to

aid

in

determining

the

nature

and

composition

of

the

fumes being released.

The

need

and

subsequent

design

of

a device

to

eliminate

poisonous

emissions

from

the

ventilation

exhaust

should

be

made

by

a

professional

qualified

to

evaluate

control

devices.

Finally,

the

presence

of

personnel

exposures

to

fumes

should

be

determined

by

a professional qual-

ified to

evaluate

workplace

exposures

to

chemical

and

physical

hazards.

Operation

of

the

CL-7

Laser

and

ventilation

sys-

tem/control

device

may

subject

you

to

local

state

and

federal environmental

and

occupational protec-

tion

laws

and

regulations. A professional qualified

to

assess

environmental

and

occupational

protec-

tion

laws

and

regulations

must

be

consulted

before

the

CL-7 Laser

is

installed

and

operated.

'GAS STORAGE

Various

gases

are

used

in

the

laser

cutting

process

to

assist

in

the

actual

cutting

or

to

perform

auxil-

iary

functions.

The

gases

most

commonly

used

are

oxygen, nitrogen,

carbon

dioxide,

helium,

and

com-

pressed

air.

These

gases

are

commonly·available

in

compressed

gas

cylinders.

Oxygen,

nitrogen,

and

helium

are

also

available

as

cryogenic

liquid.

Carbon

dioxide, while

not

classified

as

a

c:ry"Ogenic,

is

also widely available

in

liquid form.

The

discus-

sion

below

will

address

safety

consideration

when

storing

and

handling

compressed

gas

cylinders.

Later

in

this

section

will

be

a

discussion

on

safety

precautions

concerning

cryogenic liquids.

COMPRESSED

GAS

CYLINDERS

HANDLING

Serious

accidents

may

result

from

the

misuse,

abuse,

or

mishandling

of

compressed

gas

cylinders.

Workers

assigned

to

the

handling

of

cylinders

under

pressure

should

be

properly

~rained

and

should

work

only

under

competent

supervision.

Observing

a few

basic

rules

will

help

control

hazards

in.

the

handling

of

compressed

gas

cylinders.

.,

Because

of

their

shape,

smooth

surface,

and

weight,

cylinders

are

difficult

to

carry

by

hand.

Cylinders

may

be

rolled

on

their

bottom

edge

but

never

dragged.

Cylinders

weighing

more

than

40

pounds

(18.2 kg) (total)

shall

be

transported

on

a

hand

or

motorized

truck,

suitably

secured

to

keep

them

from falling.

..

Do

not

lift

compressed

gas

cylinders

with

an

electromagnet.

Where

cylinders

must·

be

handled

by

a

crane

or

derrick,

carry

them

in

a

cradle

or

suitable

platform

and

take

extreme

care

that

they

are

not

dropped

or

bumped.

Do

not

use

slings.

"

Do

not

drop

cylinders

or

let

them

strike

each

other

violently.

"'

Do

not

use

cylinders

for rollers,

supports,

or

any

purpose

other

than

to

contain

gas.

..

Do

not

tamper

with

safety

devices

in

valves

or

on

cylinders.

"

When

empty,

cylinders

are

to

be

returned

to

the

vendor,

mark

them

EMPTY

or

MT

with

chalk.

Close

the

valves

and

replace

the

valve

protection

caps,

if

the

cylinder

is

designed

to

accept

a

cap.

.,

Always

consider

cylinders

as

being

full

and

han-

dle

them

with

corresponding

care.

Accidents

have

resulted

when

containers

under

partial

pressure

were

thought

to

be

empty.

STORING

Cylinders

should

be

stored

in

an

upright

position

in

a

safe,

dry,

well-ventilated

place

prepared

and

reserved

for

the

purpose.

Flammable

substances,

such

as

oil

and

volatile liquids,

should

not

be

stored

in

the

same

area.

Cylinders

should

not

be

stored

near

elevators,

gangways,

stairwells,

or

other

places

where

they

can

be

knocked

down

or

damaged.

.,

Oxygen

cylinders

should

not

be

stored

within

20

ft.

(6

m)

of

cylinders

containing

flammable

gases

or

near

the

location

of

other

highly

combustible

materials.

o

Cylinders

are

not

designed

for

temperatures

in

excess

of

130°F

(54°C). Accordingly,

they

should

not

be

stored

near

sources

of

heat,

such

as

radi-

ators

or

furnaces,

or

near

highly

flammable

sub-

stances

like gasoline.

e

Cylinder

storage

should

be

planned

so

that cylin-

ders

will

be

used

in

the

order

in

which

they

are

received

from

the

supplier.

Empty

and

full cylin-

ders

should

be

stored

separately,

with

empty

cylinders

being

plainly

identified

as

such

to

avoid

confusion.

Group

together

empty

cylinders

which

have

held

the

same

contents.

USING

Safe

procedures

for

the

use

of

compressed

gas

cylinders

include:

<l

Use

cylinders

in

an

upright

position

and

secure

them

against

accidentally

being

knocked

over.

@

Unless

the

cylinder

valve

is

protected

by

a

recess

in

the

head,

keep

the

metal

cap

in

place

to

pro-

tect

the

valve

when

the

cylinder

is

not

connected

for

use.

A

blow

on

an

unprotected

valve

might

cause

gas

under

high

pressure

to

escape

.

"'

Make

sure

the

threads

on

a

regulator

or

union

correspond

to

those

on

the

cylinder

valve

outlet.

Do

not

force

connections

that

do

not

fit.

"'

Open

cylinder

valves slowly. A

cylinder

not

pro-

vided

with

a

handwheel

valve

should

be

opened

with

a

spindle

key

or

a

special

vvrench

or

other

tool

provided

or

approved

by

the

gas

supplier.

"'

Do

not

use

a

cylinder

of

compressed

gas

without

a

pressure

reducing

regulator

attached

to

the

cylinder

valve,

except

where

cylinders

are

attached

to

a manifold,

in

which

case

the

regula-

tor

will

be

attached

to

the

manifold

header.

"'

Before

making

connection

to

a

cylinder

valve

out-

let, "crack"

the

valve for

an

instant

to

dear

the

opening

of

particles

of

dust

or

dirt.

Always

point

the

valve

and

opening

away

from

the

body

and

not

toward

anyone

else.

<~>

Use

regulators

and

pressure

gages

only

with

gases

for

which

they

are

designed

and

intended.

Do

not

attempt

to

repair

or

alter

cylinders,

valves,

or

attachments.

This

work

should

be

done

only

by

the

manufacturer.

@

Unless

the

cylinder

valve

has

first

been

closed

tightly,

do

not

attempt

to

stop

a

leak

between

cylinder

and

regulator

by

tightening

union

nut.

..

Do

not

permit

sparks,

molten

metal,

electric

cur-

rents,

excessive

heat,

or

flames

to

come

in

con-

tact

with

the

cylinder

or

attachments

.

.,

Never

use

oil

or

grease

as

a

lubricant

on

valves

or

attachments

of

oxygen

cylinders.

Keep

oxygen

cylinders

and

fittings

away

from

oil

and

grease,

and

do

not

handle

such

cylinders

or

apparatus

with

oily

hands,

gloves,

or

clothing.

..

Never

use

oxygen

as

a

substitute

for

compressed

air.

Use

it

only

for

the

purpose

for

which

it

is

intended.

<~~

Before

a

regulator

is

removed

from

a

cylinder

valve, close

the

cylinder

valve

and

release

the

gas

from

the

regulator.

.,

Cylinder

valves

shall

be

closed

when

work

is

fin-

ished.

Table of contents

Other Cincinnati Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT609755 Operation manual

NPK

NPK DG-4 instruction manual

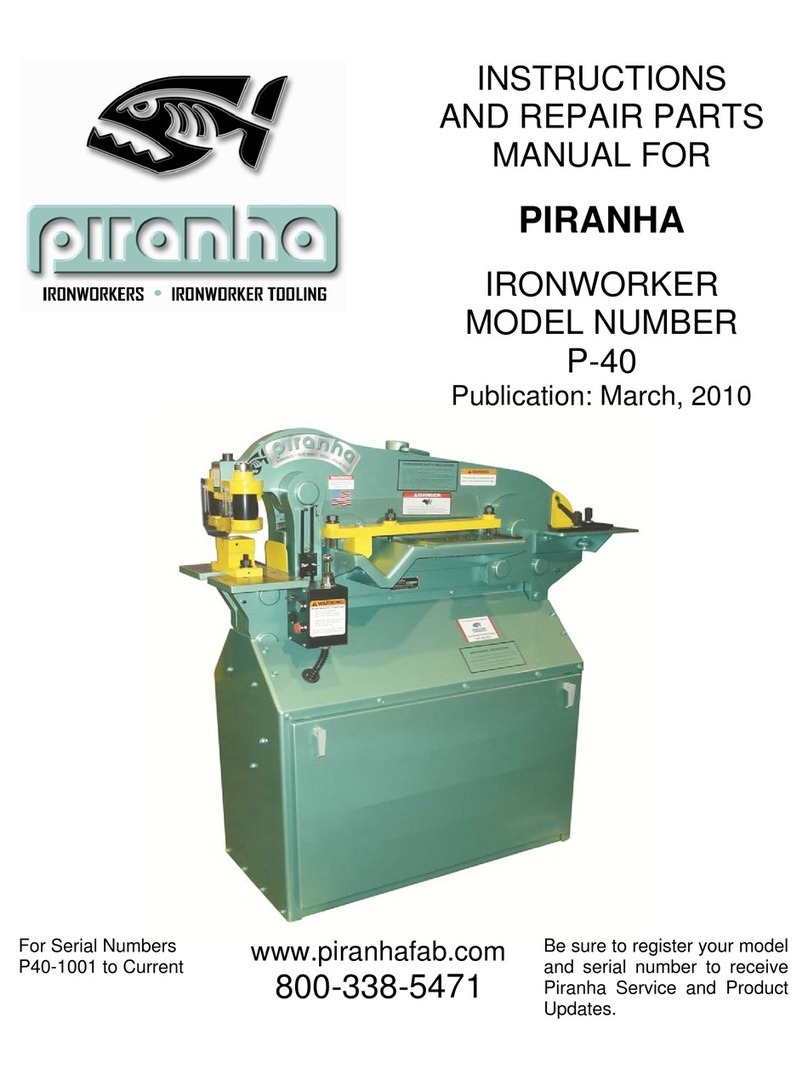

Piranha

Piranha P-40 instructions

Endress+Hauser

Endress+Hauser Hart Proline Promag P 500 Special Documentation

KTR-Group

KTR-Group KTR-STOP S-A-F B Series Operating & assembly instructions

TGW

TGW NBS 90 SP Installation, operation & maintenance manual