Danfoss APP 11-13 User manual

Other Danfoss Industrial Equipment manuals

Danfoss

Danfoss MCD 200 Series User manual

Danfoss

Danfoss ET6200 User manual

Danfoss

Danfoss VACON NX User guide

Danfoss

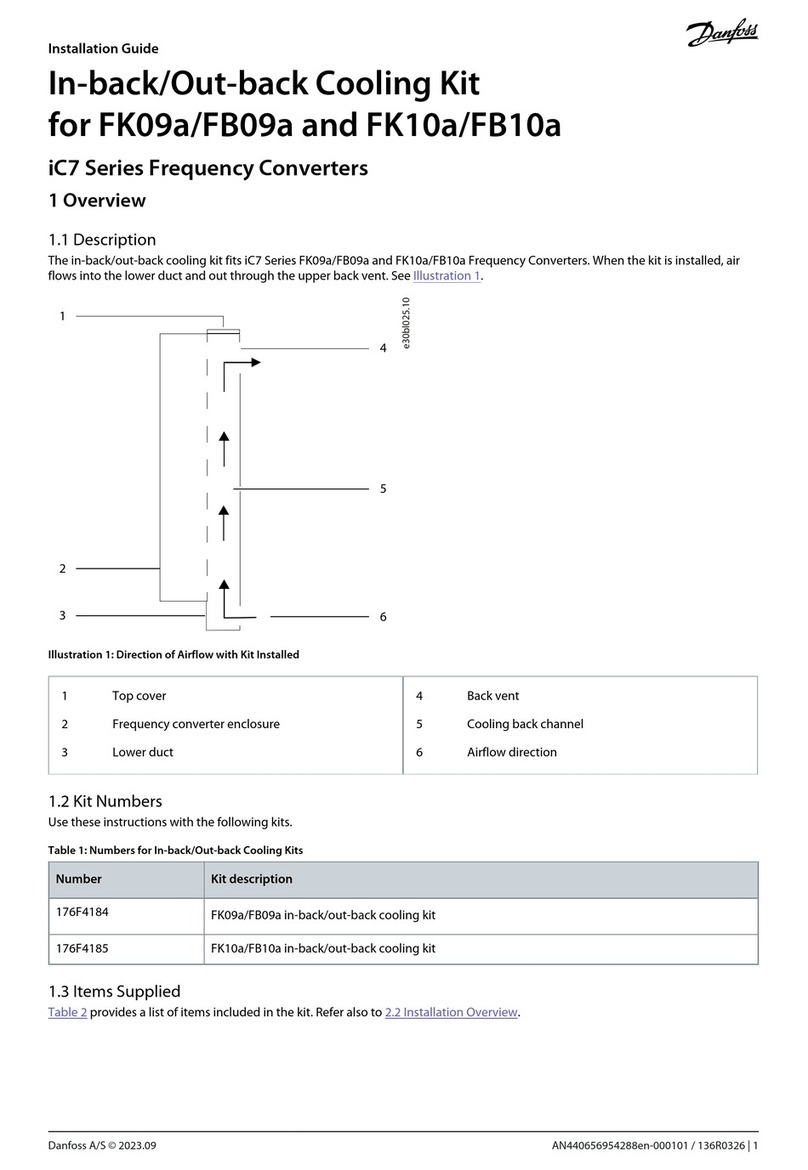

Danfoss 176F4184 User manual

Danfoss

Danfoss T-420 User manual

Danfoss

Danfoss VXe SLS User manual

Danfoss

Danfoss VACON 1000 User manual

Danfoss

Danfoss EC-LTS1200-410 User manual

Danfoss

Danfoss iSave 21 User manual

Danfoss

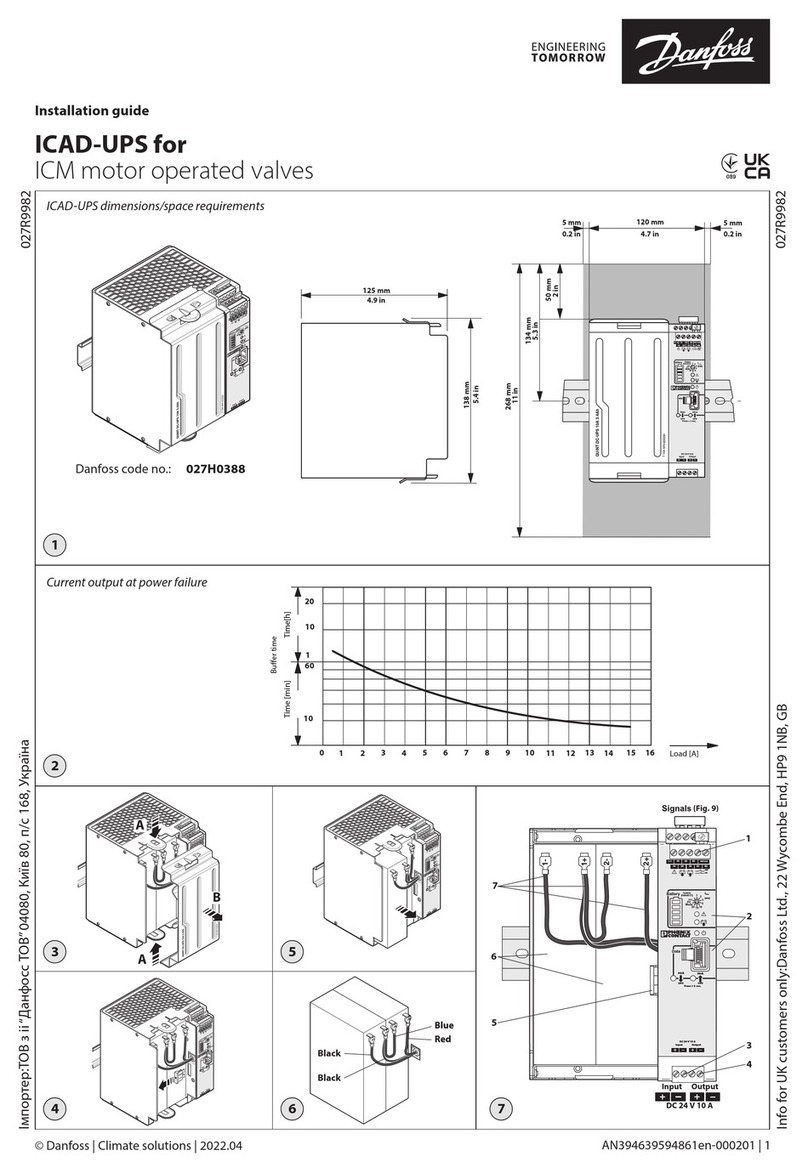

Danfoss ICAD-UPS User manual

Danfoss

Danfoss IPS 8 User guide

Danfoss

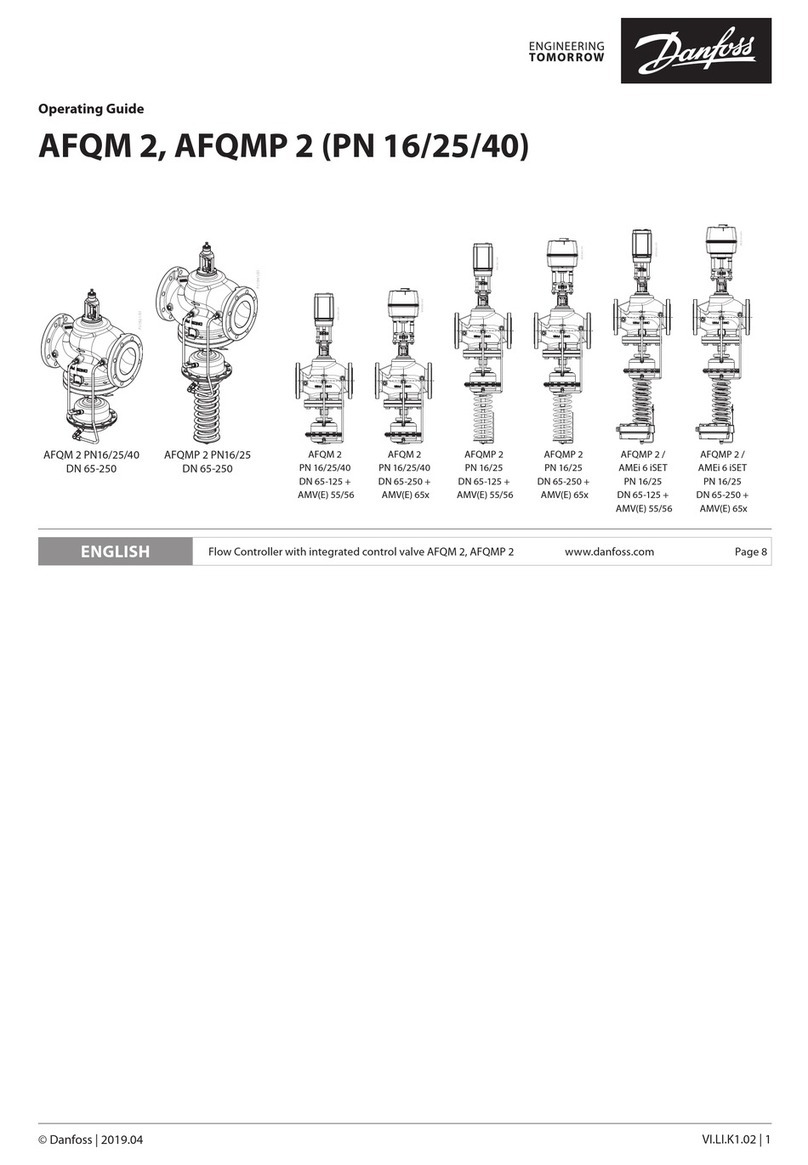

Danfoss AFQM 2 PN16 User manual

Danfoss

Danfoss DHP-AQ Quick start guide

Danfoss

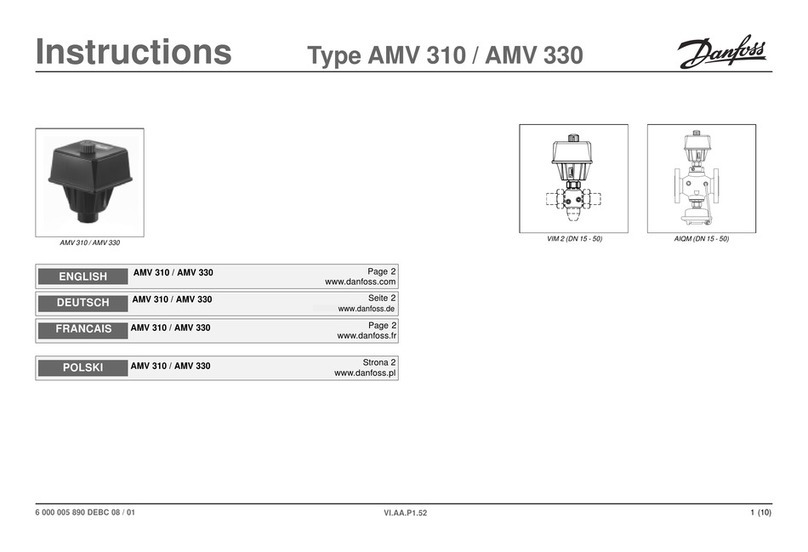

Danfoss AMV 310 User manual

Danfoss

Danfoss BOCK FK40 User manual

Danfoss

Danfoss Termix VVX-IV 7 Series User manual

Danfoss

Danfoss IPS 8 User manual

Danfoss

Danfoss VLT AQUA Drive D-Frame User manual

Danfoss

Danfoss DTW 300 SP Manual

Danfoss

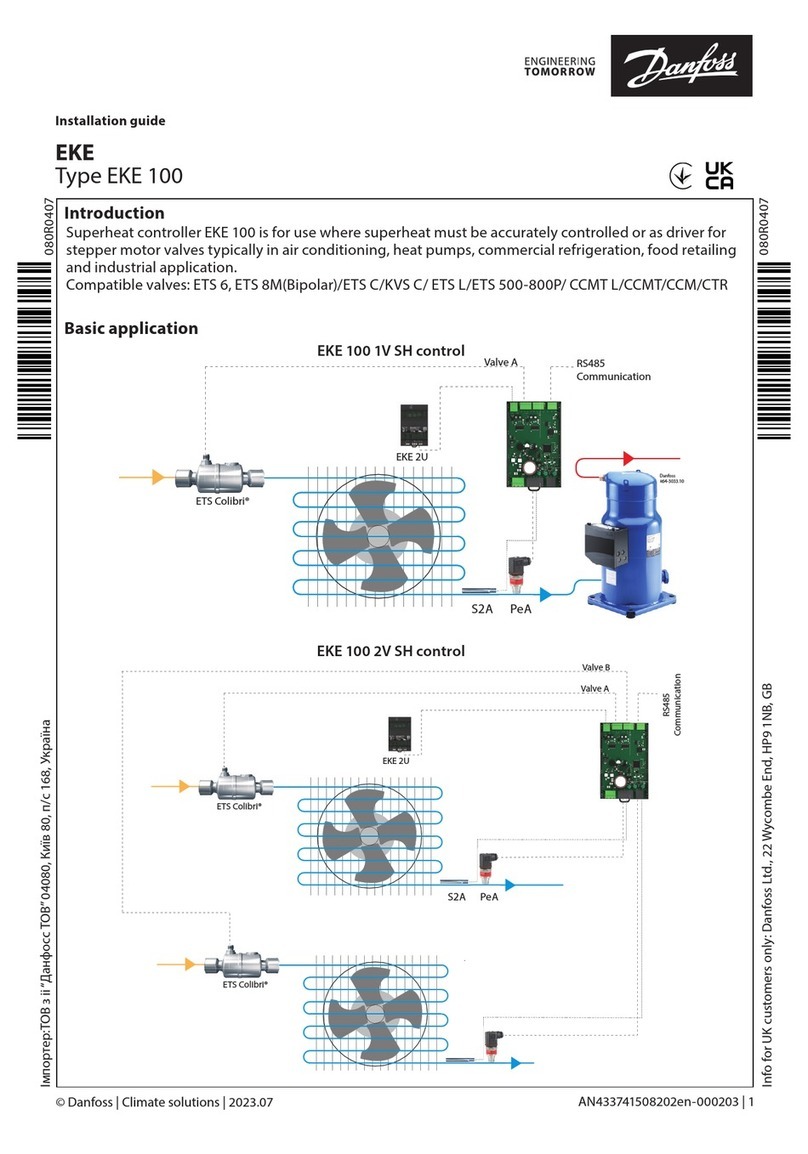

Danfoss EKE User manual