Cinders Barbecues CLASSIC TG160 User manual

®

OPERATING INSTRUCTIONS

Model: CLASSIC

THIS IS YOUR INSTRUCTION BOOKLET

DO NOT THROW IT AWAY

THIS BOOKLET MUST BE READ THOROUGHLY

BEFORE THE BARBECUE IS OPERATED

For use in GREAT BRITAIN and IRELAND

ISSUE 12

January 2022

CINDERS BARBECUES LIMITED

High Bentham, Lancaster LA2 7NB

Tel: 01524 262900

www.cindersbarbecues.co.uk

UKLPG Code of Practice 24:Part 3-2017

2.2 Build-ups, Gazebos, Marquees, Tents, Stalls or other

Temporary Structures

‘These shall be erected or built in accordance with manufacturer's or supplier’s

instructions and located in accordance with this Code.

Where a single appliance supplied by a single cylinder without a Flame Supervision

Device is in use, ventilation shall be equal in area to that of the longest wall (from

eaves to ground level).

Also, additional ventilation shall be provided by a 150mm high gap at ground level

on each of the other walls.’

3.2 Storage of LPG cylinders for use Outdoors

‘The number of cylinders kept at the unit shall be no more than the number needed

to meet the maximum offtake requirements of the appliance, plus an equivalent

number in reserve.’

6.5.5 Barbecues

‘Barbecues and other single appliances supplied by a single cylinder should have a

hose not exceeding 1.5 metres and shall be sited and used in accordance with

manufacturer’s instructions.’

A full edition of the UKLPG Code relating to Use of LPG for

Commercial Catering Events, Street Food and Mobile

Catering can be ordered from www.liquidgasuk.org

WARNINGS

USE OUTDOORS ONLY

(BS EN 498:2012)

ACCESSIBLE PARTS MAY BE VERY HOT. KEEP YOUNG

CHILDREN AND VULNERABLE ADULTS AWAY.

TAKE CARE NOT TO TOUCH THE TOP OR SIDES OF

THE BARBECUE AS THESE AREAS GET EXTREMELY

HOT AND WILL RESULT IN BURNS.

PROTECTIVE GLOVES MUST BE WORN WHEN USING

THIS BARBECUE.

DO NOT MOVE THE APPLIANCE WHILST IT IS ALIGHT

OR IN THE HOT CONDITION.

ANY MODIFICATION OF THE APPLIANCE MAY BE

DANGEROUS.

TURN OFF THE GAS SUPPLY AT THE CYLINDER AFTER

USE.

THIS APPLIANCE SHALL BE KEPT AWAY FROM

FLAMMABLE MATERIALS.

Information: DO NOT FIT A DOMESTIC LOW PRESSURE

(37mbar) REGULATOR. This commercial appliance

operates at 1bar (1000mbar) input pressure.

SPECIFICATIONS

DIMENSIONS:

Height: 790mm. Length: 1700mm. Depth: 660mm. Weight: 44.5Kg.

GAS:

PROPANE only (G31) at input pressure 1.0 bar (1000 mbar).

SUPPLY CYLINDER:

This barbecue is for use with propane cylinders of 19Kg (12hrs run time) with L/H female screw

thread connections. eg. CALOR GAS RED CYLINDERS.

REGULATOR:

BS EN 16129:2013 with L/H male screw thread and brass ‘bullnose’ connection. Output pressure

1.0bar (1000mbar).

HOSE:

BS EN 3212 type 2 or ISO 3821

Maximum service life 5 Years.

Approved length 1.5m (1500mm).

HEAT INPUT

Heat input = 20.0kw (1450g/hr propane).

INJECTOR SIZE

60cc (ori ice 0.7mm)

APPLIANCE CATEGORY.

13P (1000mbar)

Page 1 Issue 12

ASSEMBLY INSTRUCTIONS.

Hold the barbecue on its side and release the folded legs from their retaining clips at either end

of the barbecue. Swing the legs out completely, and rotate the inner struts so they can be pushed

rmly into the same retaining clips. Stand the barbecue upright on a rm and level surface.

When required, use an empty ring-pull

drinks can as a fat drain container. A

stainless steel clip emerges from each

drain hole, which can be found within

the area of the chromed hoop at either

end of the barbecue. Thread the clip

through the hole in the can.

CAUTION: Use an oven glove when removing the can, which may be very hot. Dispose of

any hot fat with due caution.

POSITIONING THE BARBECUE.

Propane is heavier than air, and enclosures must meet ventilation required by the UKLPG

Code of Practice 24, Pt2:2017. Three open sides and a continuous back wall is also sufficient

to clear away smoke from cooking, along with any accidentally spilt gas.

Ensure the barbecue is placed on a level steady surface with clearances as below, and not in

an excessively windy environment. Do not place near or under combustible materials.

Page 2 Issue 12

POSITIONING THE GAS CYLINDER.

Ensure that the gas cylinder is not placed in contact or underneath the barbecue. The hose should

be routed away from the barbecue without touching any hot surfaces.

Ensure the cylinder is placed on a rm and level surface and that the hose is neither stretched nor

twisted when connected. The cylinder must also be located to give good access to connect and

disconnect the regulator, or to turn off in an emergency.

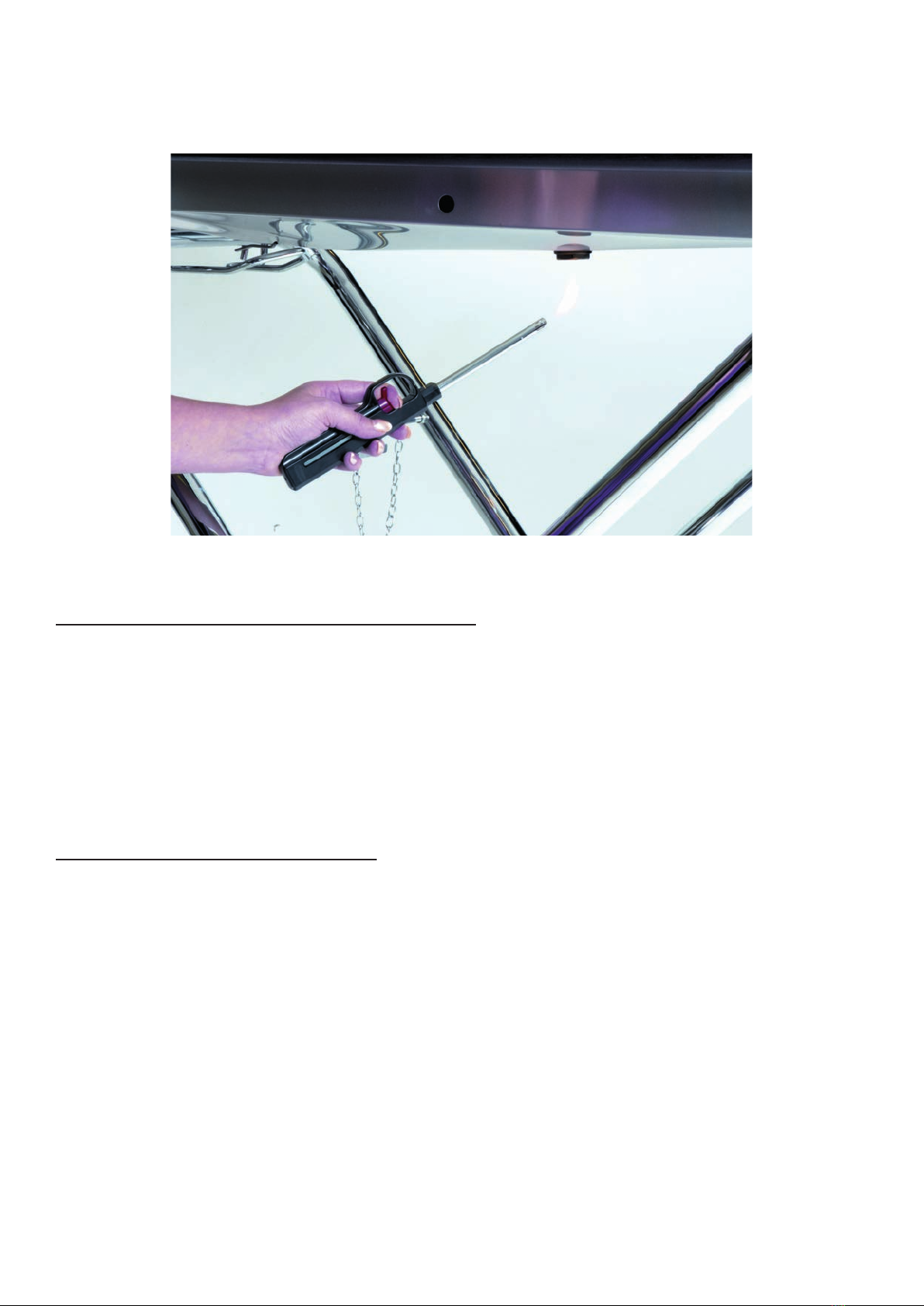

CONNECTING THE REGULATOR TO THE CYLINDER

Check that the hose is completely over the nozzle on the regulator and the nozzle on the barbecue

and that it is secured rmly. The hose may be secured by a continuous circular hose clip or by

the metal swaging process we use at our factory. ‘Jubilee’ clips must NOT be used as they don’t

impart a perfectly circular pressure and can even push a section of hose away from contact with

the nozzle.

Examine the exible hose regularly and get your dealer to t a new hose if perished, worn

or damaged in any way. L.P.G. ATTACKS NATURAL RUBBER – ONLY USE HOSE TO BS: 3212

TYPE 2 OR ISO 3821 SUPPLIED BY YOUR DEALER.

Remove the protective plastic plug from the cylinder outlet and save for replacement into the

cylinder when empty.

Use the spanner provided to tighten the regulator to the propane cylinder in an ANTI-CLOCKWISE

direction when viewed from the hose connection.

LIGHTING THE BARBECUE.

a) Turn BOTH control valves on the barbecue OFF, by turning them clockwise to a firm ‘stop’.

b) Turn the supply from the cylinder ON by turning the cylinder valve anticlockwise.

c) A LEAKAGE CHECK SHOULD BE CARRIED OUT NOW, IN THE ABSENCE OF ANY NAKED

FLAME. Use a soapy water solution around all gas connections and along the hose. Turn

the gas OFF at the propane cylinder if the solution bubbles to indicate a leak and call an

LPgas engineer. A list of qualified engineers can be found on our website www.cindersbar-

becues.co.uk

d) If no leaks are indicated, insert a lighted taper or gas match into one of the brass lighting holes

(located centrally under each firebox), then turn ON the control valve at that end of the barbecue

by turning anti-clockwise. The burner should light immediately and can be checked by looking

through the 10mm diameter sighting hole in the side of the firebox.

Page 3 Issue 12

Use a 1bar (1000mbar)

regulator ONLY

e) If the burner doesn’t light immediately, turn OFF the control valve at the barbecue by turning

clockwise to a rm ‘stop’ and try again after 5 minutes. If still unsuccessful, call an LPgas

engineer or contact us for information or advice.

TURNING OFF THE BARBECUE

First turn OFF the gas supply at the cylinder valve in a clockwise direction to a firm ‘stop’. Next,

turn the control valves at BOTH ends of the barbecue to the OFF position by turning them also

to clockwise to a firm ‘stop’.

Detach the regulator from the gas cylinder if cooking has finished by unscrewing CLOCKWISE,

when viewed from the hose connection and replace the protective plastic plug into the cylinder

outlet.

Wait for the barbecue to cool before moving.

CHANGING CYLINDERS

CHANGING CYLINDERS MUST BE DONE WITH NO NAKED FLAME IN THE VICINITY.

You MUST begin the procedure by first turning OFF the gas supply at the cylinder valve, then

turning OFF both control valvesat the barbecue BEFORE disconnecting the regulator from the

gas cylinder.

EMPTY CYLINDERS MUST BE SITED WELL AWAY FROM THE BARBECUE AND IN A

SECURED AND FLAME-FREE ENVIRONMENT, WITH THEIR PROTECTIVE PLASTIC PLUGS

FIRMLY SCREWED IN POSITION.

Page 4 Issue 12

CLEANING THE BARBECUE

This barbecue internally self-cleans. Do NOT remove the stainless steel cooking

surface at any time.

Allow the barbecue to burn away fatty debris inside the body of the barbecue, until no more smoke

exits through the cooking surface. No further internal cleaning is required.

The cooking surface is easily cleaned by turning the barbecue on full power and laying the at

griddle accessory on top, which super-heats the surface by reection. This will convert the carbon

to white uffy powder in a very few minutes. Alternatively, a stiff wire brush and nylon scouring pad

can be used.

Caustic cleaners will reduce the life of the heat exchanger, which sits below the cooking surface.

The rest of the appliance can be cleaned with hot soapy water. TAKE CARE NOT TO BLOCK

ANY PORTION OF THE BURNER AERATION PORT.The aeration port is an 11.75mm diameter

hole in the short horizontal metal pipe that the control valve screws into, and will be checked by a

qualied gas engineer during servicing.

STORING THE BARBECUE AND ITS PROPANE SUPPLY

CYLINDERS .

It is important that the barbecue is stored in dirt free, damp free, hygienic conditions indoors when

not in use for any period of time. The barbecue should always be disconnected from the cylinder

during storage.

PROPANE CYLINDERS MUST ALWAYS BE STORED OUTDOORS.

Consult your propane supplier for the best way to store cylinders, in your particular circumstances.

MAINTENANCE.

Servicing is recommended at least once per season, according to usage.

SERVICING AND MAINTENANCE OF THIS APPLIANCE MUST NOT BE CARRIED OUT BY THE

OWNER. ALWAYS USE A REGISTERED GAS-SAFE ENGINEER, OR CONTACT ‘CINDERS’

FOR ADVICE.

A current list of qualied engineers can be found on the CINDERS website,

www.cindersbarbecues.co.uk

SPARES and ACCESSORIES

Images for easy identication and ordering of Spares and Accessories are also available on our

website, www.cindersbarbecues.co.uk

Page 5 Issue 12

TROUBLE SHOOTING

CHECK FIRST IF THE PROBLEM IS COMMON TO BOTH SIDES,

OR UNIQUE TO ONLY ONE SIDE.

BOTH SIDES:

-The most common reason for very low power is that a domestic low pressure (37mbar) regulator

has been retro-fitted. This barbecue was supplied with an adjustable 0.5bar (500mbar) to 1bar

(1000mbar) regulator and a replacement hose and regulator is available from our website.

-The adjustable regulator is set on half heat. Unscrewing control knobs on propane regulators

actually reduces pressure, -see yellow tag on the neck of the regulator for instruction.

-The gas level in the cylinder is low. Empty cylinders are heavy and the level is not easy to gauge

when running out of gas.

ONE SIDE:

-The most common reason is that the injector is blocked. Cleaning the injector is part of the

routine annual maintenance which should be undertaken by a qualified gas engineer. A list of

engineers is on our website.

-A very loud roaring noise, sometimes with flames exiting the end of the barbecue means either a

severely blocked burner through years of zero maintenance, or you are lighting at the air intake.

The air intake is located next to the control knob. See pages 3 and 4 for correct lighting.

FLARE-UPS:

Rarely, these can be due to a very high-pressure regulator being retro-fitted. 2bar (2000mbar)

regulators are common and cannot be accurately regulated to the maximum 1bar pressure

required by this barbecue.

More common is that there is simply too much fat in the food. Sadly, ‘100% burgers' can mean

100% animal, including ground up fat and offal. Good quality thin burgers bulked with rusk with a

shorter cooking time are easier for high volume catering.

As a benchmark, try thinly sliced and tenderised steak which is great with onions and steadily

move onto cheaper options to find a balance. Never cook from frozen as the fat will render out

from the outside as it cooks first, before the inside is up to safe temperature.

A solid griddle accessory is available from our website, which is also useful for eggs, bacon and

mounds of onions.

‘Getting the best from your barbecue’ is on our website and remember, barbecuing doesn’t make

poor quality food better.

Page 6 Issue 12

®

www.cindersbarbecues.co.uk

CINDERS BARBECUES LIMITED

High Bentham, Lancaster LA2 7NB

Tel: 01524 262900

www.cindersbarbecues.co.uk

Table of contents

Other Cinders Barbecues Grill manuals

Popular Grill manuals by other brands

Smoke hollow

Smoke hollow PT300B Assembly, care & use manual warning & safety information

Tepro Garten

Tepro Garten 3198 Assembly instructions

Nexgrill

Nexgrill 730-0896B Assembly & instruction manual

Gold Uniflame

Gold Uniflame GBC1069WB-C owner's manual

Taylor

Taylor QS11 Original operating instructions

Backyard

Backyard CBT1310W-C owner's manual