Conduct Length Measurement

You can conduct length measurement by using reflective sensor (default

etting) for I-Mark media roll or transmissive sensor for gap label roll.s

Please refer to the VersaJet Programming Reference for changing the sensor

from reflective to transmissve, if the gap label roll is used.

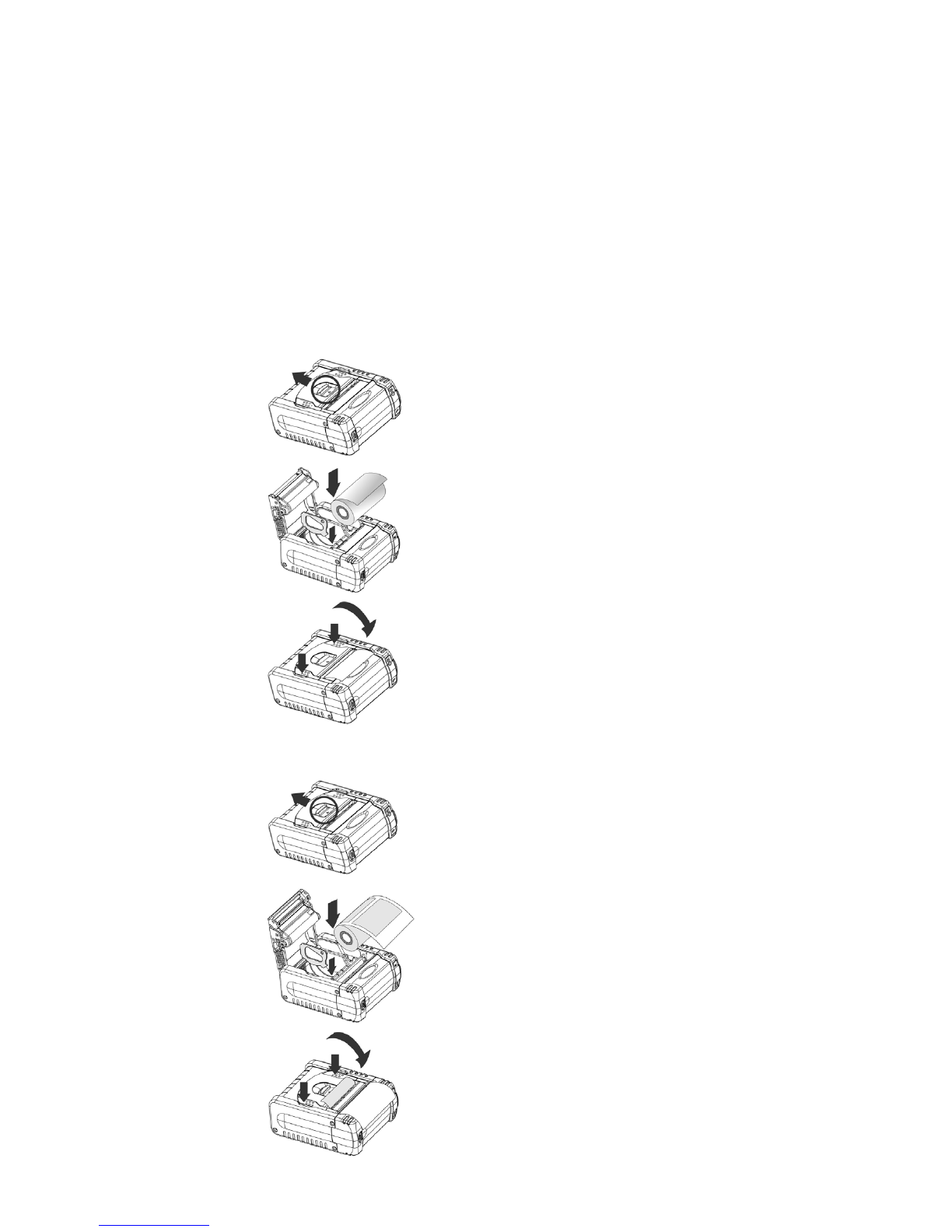

1. Open the media compartment cover, the LED1 will light up orange, and

LED2, LED3 will light up green respectively, and then start flashing after 10

seconds.

2

. Load the media roll.

3

. Press the FEED button and release it.

4. Close the media compartment cover, the LED3 flashes green 3 times. The

Micro2 will feed several labels to execute length measurement. After the

length measurement is completed, the Micro2 will be ready in the next

printing position and the LED1 will flash green at 2 seconds intervals.

If the length measurement is failed or executed without setting the correct

media roll, the Micro2 will issue a paper jam error. Please conduct length

measurement once again. On condition that the length measurement is done

successfully, the value will be stored into the flash memory. When you load

the same media roll next time, the Micro2 will perform top-of-form by feeding

one label or one measured length of the receipt paper right after you close the

edia compartment cover in power-on state.m

The Micro2 will also feed one label or one measured length of the receipt

paper while pressing the FEED button. However, if you load a different media

roll, you will have to re-conduct length measurement.

Revert to Standard Mode

The printing mode will be switched to page mode after the length

measurement is completed. If you would like to revert it to standard mode,

please follow the steps indicated below:

1. Open the media compartment cover, the LED1 will light up orange, and

LED2, LED3 will light up green respectively, and then start flashing after 10

seconds.

2. Load the receipt roll (without I-Mark), then press the FEED button and

release it.

3. Close the media compartment cover, the LED3 flashes green 3 times. The

Micro2 will feed about 16 cm receipt paper and remain ready for the next

printing position. The Micro2 will give two beeps, the LED1 and LED2 will

light up orange and green respectively.

4. Press “FEED” button, the LED1 of Micro2 will flash green at 2 seconds

intervals.

5. The Micro2 is now ready for standard mode operation.

4