CIRRUS AIRPLANE MAINTENANCE MANUAL MODELS SR22 AND SR22T

27-31

Page 1

All

EFFECTIVITY:

STALL WARNING SYSTEM

1. DESCRIPTION

A. Stall Warning System - Serials w/o Perspective Avionics

The airplane uses an electro-pneumatic stall warning system. As the angle of attack increases and the

airplane approaches an aerodynamic stall, the stagnation point moves lower on the leading edge

causing low pressure on the upper leading edge to increase. As low pressure passes over the stall

warning port located on the leading edge of the right wing, negative pressure is sensed by a pressure

switch which activates the stall warning horn.

The stall warning horn, located on the top flange of the LH center console rib, is a piezo-ceramic audio

indicator. Serials 22-0002 & subs before SB 2X-27-15: When activated, the horn supplies a continuous

94 dB, 2800 Hz tone. Serials 22-0002 & subs after SB 2X-27-15: When activated, the horn supplies a

continuous 95 dB, 2000 Hz tone.

The pressure switch, located on the mid-console LH side panel, is a normally open, diaphragm-oper-

ated switch. The switch is powered by 28 VDC supplied through the 2-amp STALL WARNING circuit

breaker on the Essential Bus.

B. Stall Warning System - Serials w/ Perspective Avionics and w/o FIKI

The airplane uses an electro-pneumatic stall warning system. As the angle of attack increases and the

airplane approaches an aerodynamic stall, the stagnation point moves lower on the leading edge

causing low pressure on the upper leading edge to increase.

Serials 22-3026 thru 22-3402: As low pressure passes over the stall warning port located on the lead-

ing edge of the right wing, negative pressure is sensed by a pressure switch which activates the stall

warning horn. The stall warning horn, located on the upper surface of the GIA #2 rack, is a piezo-

ceramic audio indicator which, when activated, supplies a continuous 94 dB, 2800 Hz tone.

Serials 22-3403 & subs, 22T-0001 & subs: As low pressure passes over the stall warning port located

on the leading edge of the right wing, negative pressure is sensed by a pressure switch which provides

a signal to the avionics system to activate the aural stall warning and enables the Crew Alerting Sys-

tem (CAS) to display a STALL annunciation on the PFD.

The pressure switch, located on the mid-console LH side panel, is a normally open, diaphragm-oper-

ated switch. The switch is powered by 28 VDC supplied through the 2-amp STALL WARNING circuit

breaker on the Essential Bus.

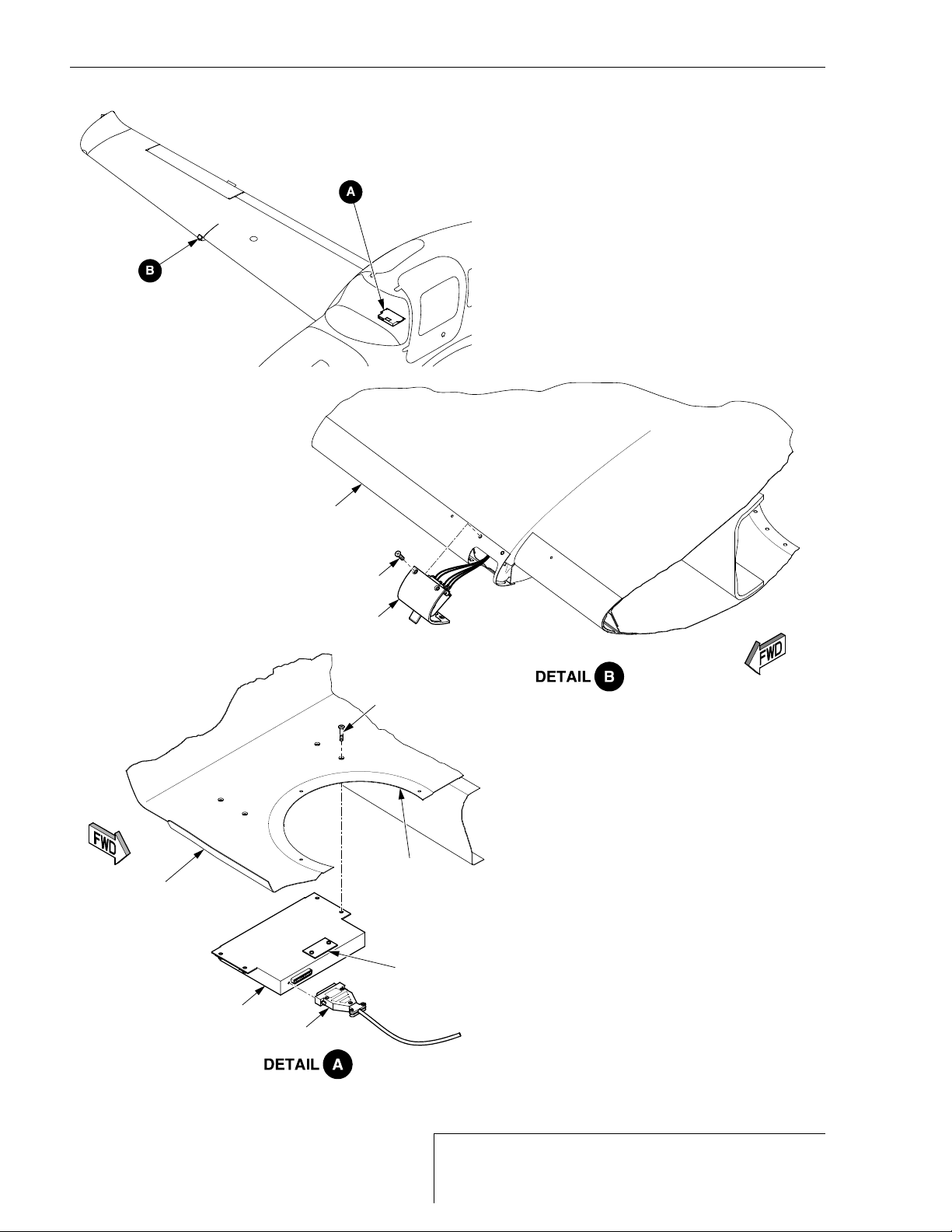

C. Stall Warning System - Serials w/ FIKI

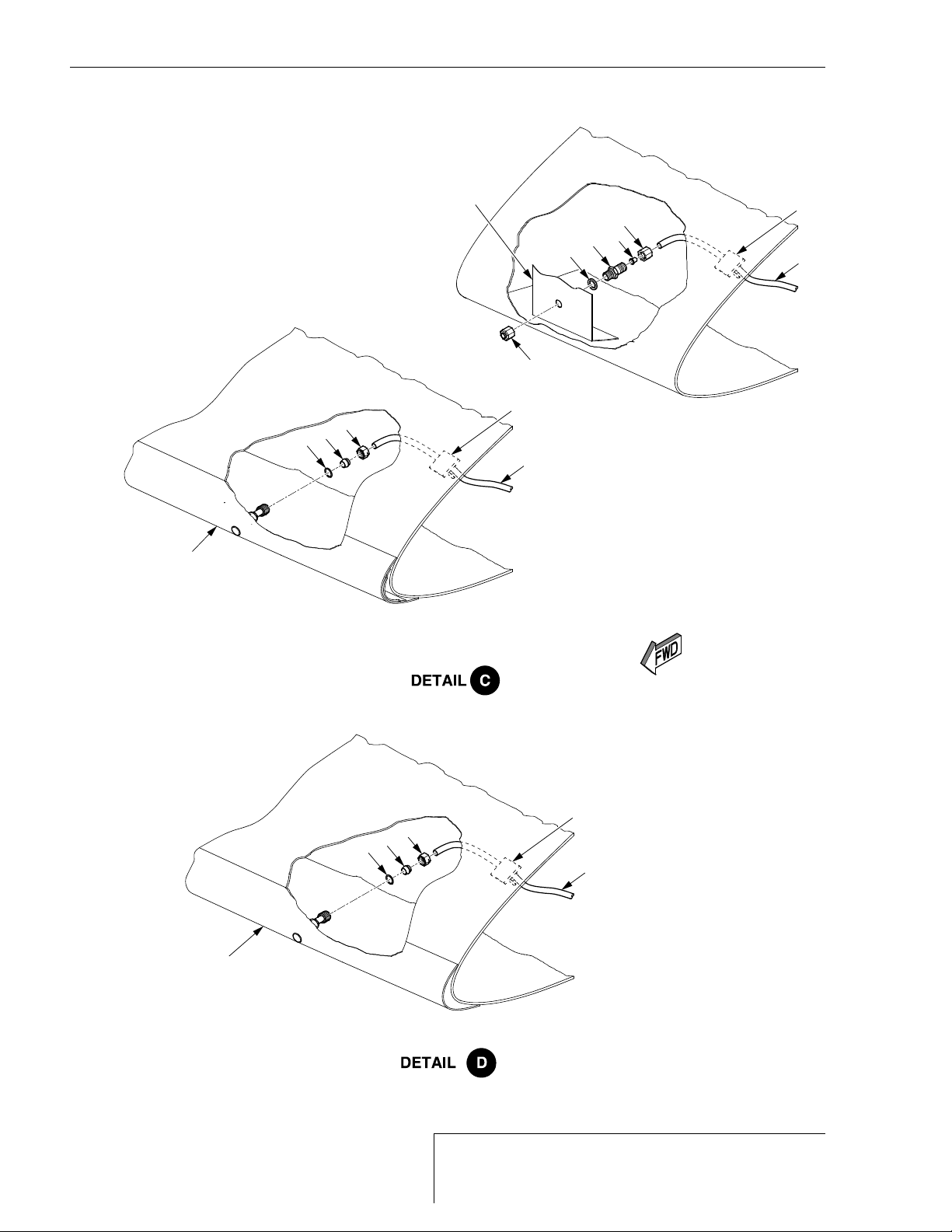

The airplane uses an electro-mechanical lift transducer, mounted on the leading edge of the right wing.

As the angle of attack increases, the stagnation point moves below the transducer, increasing the

upward pressure on the spring loaded vane. The movement of the vane produces an electrical output

that is sent to a stall warning computer located under cabin access panel CF3R. The stall warning

computer provides a signal to the avionics system to activate the aural stall warning and enables the

Crew Alerting System (CAS) to display a STALL annunciation on the PFD. The transducer is powered

by exciter voltage supplied by the stall warning computer. The stall warning computer is powered by 28

VDC supplied through the 5-amp STALL WARNING circuit breaker on the Essential Bus.

15 Jun 2010