Cisco MERAKI MS390 Series User manual

MS390 Series Installation Guide

About this Guide

This guide provides instruction on how to install and configure your MS390 series switch. This guide also provides mounting instructions and limited

troubleshooting procedures. For more switch installation guides, refer to the switch installation guides section on our documentation website.

Product Overview

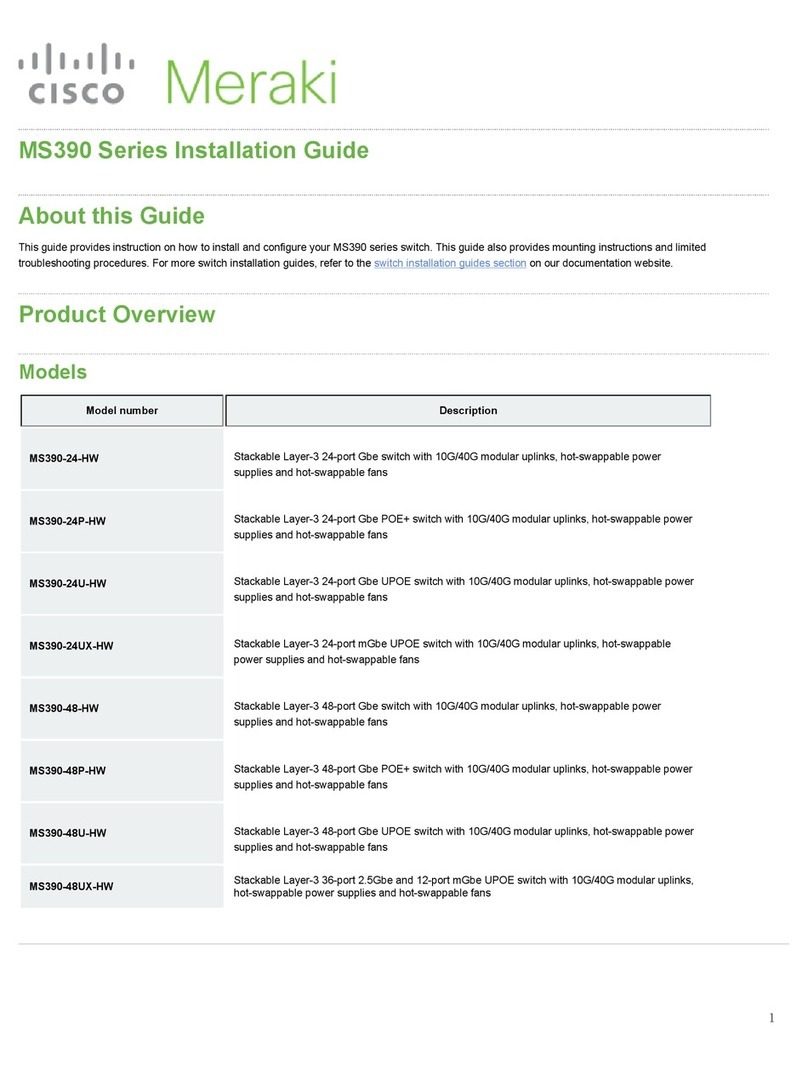

Models

Model number Description

MS390-24-HW Stackable Layer-3 24-port Gbe switch with 10G/40G modular uplinks, hot-swappable power

supplies and hot-swappable fans

MS390-24P-HW Stackable Layer-3 24-port Gbe POE+ switch with 10G/40G modular uplinks, hot-swappable power

supplies and hot-swappable fans

MS390-24U-HW Stackable Layer-3 24-port Gbe UPOE switch with 10G/40G modular uplinks, hot-swappable power

supplies and hot-swappable fans

MS390-24UX-HW Stackable Layer-3 24-port mGbe UPOE switch with 10G/40G modular uplinks, hot-swappable

power supplies and hot-swappable fans

MS390-48-HW Stackable Layer-3 48-port Gbe switch with 10G/40G modular uplinks, hot-swappable power

supplies and hot-swappable fans

MS390-48P-HW Stackable Layer-3 48-port Gbe POE+ switch with 10G/40G modular uplinks, hot-swappable power

supplies and hot-swappable fans

MS390-48U-HW Stackable Layer-3 48-port Gbe UPOE switch with 10G/40G modular uplinks, hot-swappable power

supplies and hot-swappable fans

MS390-48UX-HW Stackable Layer-3 36-port 2.5Gbe and 12-port mGbe UPOE switch with 10G/40G modular uplinks,

hot-swappable power supplies and hot-swappable fans

1

MS390-48UX2-HW Stackable Layer-3 48-port 5Gbe UPOE switch with 10G/40G modular uplinks, hot-swappable

power supplies and hot-swappable fans

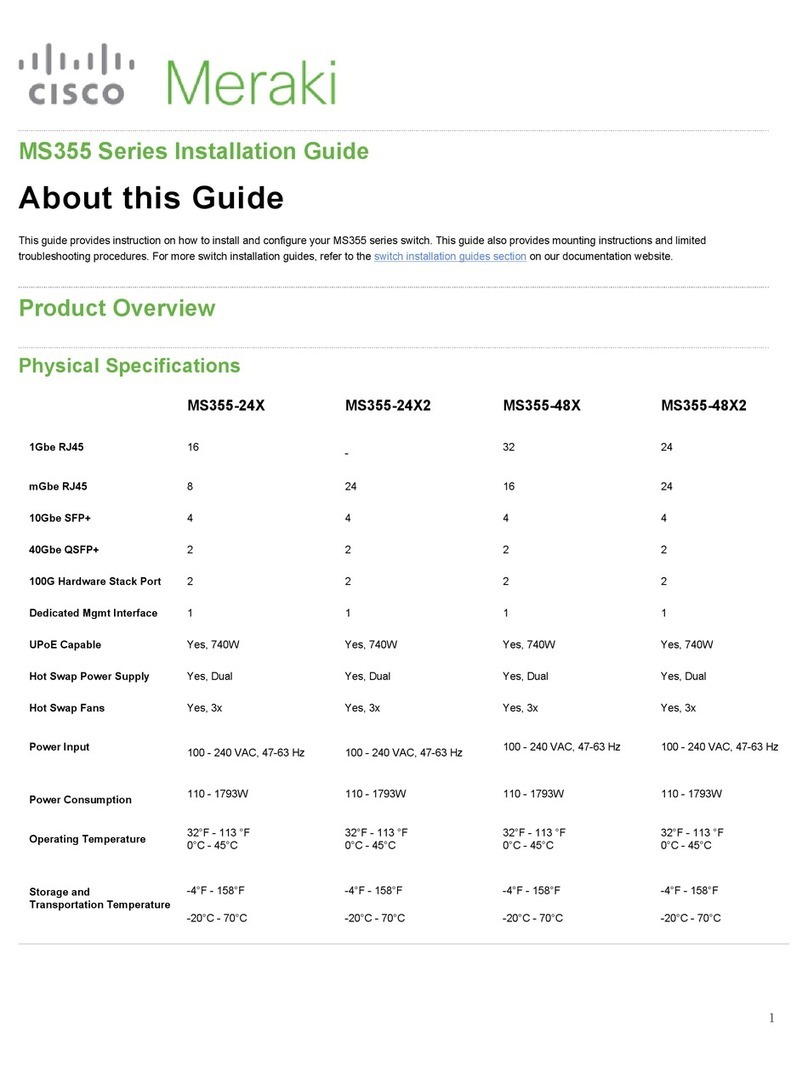

Technical Specifications

•Each model has 1 dedicated management interface

•Each model has two 120G stack ports

•Each of the model has modular uplinks where you can choose from 3 different options of 10G and 40G SFP+ and QSFP+ uplink modules

•Operating temperature for each of the model: -5°C to 45°C

•Storage and Transportation Temperature: -20°C - 70°C

•Humidity: 5 to 90%

Model Interfaces PoE/ UPoE

Capabilities

Power Load (idle/max) Available PoE Hot Swap Power Supply

MS390-24-HW 24 x 1GbE R 45 n/a 79.2 / 99 W - Yes, Dual

MS390-24P-HW 24 x 1GbE R 45 PoE 84.1 / 554.4 W 445W Yes, Dual

MS390-24U-HW 24 x 1GbE R 45 UPoE 85.4 / 990.3 W 830W Yes, Dual

MS390-24UX-HW 24 x mGbE R 45 UPoE 162.7 / 809.9 W 560W Yes, Dual

MS390-48-HW 48 x 1GbE R 45 n/a 83.9 / 109.9 W - Yes, Dual

MS390-48P-HW 48 x 1GbE R 45 PoE 92.6 / 555 W 437W Yes, Dual

MS390-48U-HW 48 x 1GbE R 45 UPoE 145 / 844.9 W 822W Yes, Dual

MS390-48UX-HW 36 x 100M/1G/2.5G +

12 x 100M/1G/2.5G/5G/10G

UPoE 218.5 / 785.5 W 490W Yes, Dual

MS390-48UX2-HW 48 x 100M/1G/2.5G/5G UPoE 157.9 / 843.8 W 645W Yes, Dual

Product View and Physical Features

2

Front Panel Components

Item Component LED Status Description

1 Restore N/A Restore button to clear switch IP and local configuration settings

2 Power LED Solid amber Switch is unable to connect to the Meraki cloud or it is in the inital stage of boot-up process

Cycling through different colors Management plane is initializing and the switch initiates communication to Meraki cloud

Solid white Switch is fully operational and connected to the Meraki cloud

Flashing white Firmware upgrade in process

Off Switch does not have power

3Switch Ports Off No client connected

Solid amber 10/100 Mbps (1 Gbps on SFP+)

Solid green 1/2.5/5/10 Gbps (10 Gbps on SFP+)

3

Back Panel Components

Item Component LED Status Description

1 Management Interface Green Connected, used for easy access to the local status page

2 Stack Ports N/A Stack Cables are connected here

3 Redundant Fans Green Active and operational

4 StackPower Ports N/A StackPower cables are connected here

5 Power Supplies Green Active and functional power supplies

MS390 Series Front and Back Panel

MS390-24 Series front panel

MS390-24P Series front panel

4

In addition to the MS switch, the following are provided:

• 2 x (19 inch) Mounting brackets and screw kit that includes:

◦ 8 x Flat-head screws

◦ 4 x number-12 pan-head screws

◦ 4 x number-10 pan-head screws

◦ 1 x (4 x 20 mm) pan-head screw

◦ 1 x Ground lug screw and ring terminal

◦ 4 x Rubber mounting feet

• 1 x Default Power Supply Unit

• 3 Pre-installed Fans

• Cable guide

• Installation instruction pamphlet

• Regulatory Compliance and Safety Information handbook

Safety and Warnings

These operations are to be taken with respect to all local laws. Please take the following into consideration for safe operation:

• Power off the unit before you begin. Read the installation instructions before connecting the system to the power

source.

• Before you work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents.

• Read the mounting instructions carefully before beginning installation. Failure to use the correct hardware or to

follow the correct procedures could result in a hazardous situation to people and damage to the system.

• This product relies on the building’s installation for short-circuit (overcurrent) protection. Ensure that the protective

device is rated not greater than: 15 A, 125 Vac, or 10A, 240 Vac.

• Please only power the device with the provided power cables to ensure regulatory compliance.

MS390 Deployment Best Practices

Before powering on devices or connecting an uplink port to the LAN, ensure to follow the steps outlined below or watch this short video.

Configure your Dashboard Network

To add devices to your Meraki dashboard network please refer to the Creating a Dashboard Account and Organization document.

Check and Set Network Firmware

7

Ensure that the switch network is set to the correct firmware version. As of September 9th, 2020 MS 12.28 is the recommended version. Recommended

versions are subject to change.

You can refer to Managing Firmware Upgrades for steps to set network firmware to the desired version.

Check and Configure Upstream Firewall Settings

If a firewall is in place, it must allow outgoing connections on particular ports to particular IP addresses. The most current list of outbound ports and IP addresses

for your particular organization can be found under Help → Firewall info. The help button is located on the top right corner of any dashboard page. For more

information refer to Upstream Firewall Rules for Cloud Connectivity.

Stacking

For stacking please refer to this section Stack Cabling Installation

Assigning an IP Address

All switches must be assigned routable IP addresses. These IP addresses can be dynamically assigned via DHCP or statically assigned. MS390 switches can

support a total count of 1000 VLANs per stand-alone switch or switch stack. VLAN ID 1-1000 are configured by default, however, the active VLANs can be

changed via the local status page or dashboard. When installing an MS390, it is important to ensure that any DHCP services or IP address assignments used for

management fall within the active VLAN range.

Dynamic Assignment

When using DHCP, the DHCP server should be configured to assign a static IP address for each MAC address belonging to a Meraki switch. Other features of

the network, such as 802.1X authentication, may rely on the property that the switches have static IP addresses.

Please make sure that the DHCP server used for providing a management IP address to the switch has an available address pool that falls within the active

VLAN range.

Static Assignment

Static IPs can be assigned using the local status page on each switch. For more information on how to configure static IP from the local status page refer to this

documentation.

Static IP via DHCP Reservations

Instead of associating each Meraki switch individually to configure static IP addresses, an administrator can assign static IP addresses on the upstream DHCP

server. Through “DHCP reservations,” IP addresses are “reserved” for the MAC addresses of the Meraki switches. Please consult the documentation for the

DHCP server to configure DHCP reservations.

8

Check upstream VLAN configuration

Ensure the upstream switch/router port is configured properly and there is no VLAN mismatch.

Check STP configuration

MS390 series switches run a single instance of MST out of the box. Please refer to this document for interoperability.

Device reboot/ reset precaution

After powering on the unit or a device reboot, the power LED goes through the following cycle -

1. Solid amber

2. Cycle through different colors

3. Solid white if dashboard connectivity is successful or, remain solid amber if dashboard connectivity is unsuccessful. Different power LED colors and their

interpretation are listed under this section. It may take some time for a device to boot up so refer to the power LED indicators to understand what the switch is

doing during boot up. Be patient and let the switch complete the whole boot-up process and connect to the Meraki cloud.

Do not power down or reset the device during a firmware upgrade. A device which has its power LED blinking white is indicating that it is going through a

firmware upgrade.

Once the devices are upgraded to the latest version continue configuring other switch features/settings. For details refer to the MS documentation

Installation Instructions

1. Attach the rack mount bracket to both sides of the switch as shown below:

Note: Each switch comes with a graphical instruction pamphlet within the box. This pamphlet contains detailed

step by step guides and images to assist in the physical install of the switch.

9

3. Secure and screw in the rack mount bracket on to the rack.

11

Stack Cabling Installation

• Connect the cable to the stack port on the switch back panel (as shown in the back panel diagram). Align the

connector and connect the stack cable to the stack port on the switch back panel and finger-tighten the screws

(clockwise direction). Make sure the Cisco logo is on the top side of the connector.

• Connect the other end of the cable to the port on the other switch and finger-tighten the screws. Avoid over tightening

the screws.

Please refer to these instructions here before stacking MS390 out of the box.

13

StackPower Cabling Installation

• StackPower on MS390 supports a ring topology of upto 4 switches.

• Connect the end of the cable with a green band to either StackPower port on the first switch (see back panel diagram

to locate the StackPower ports). Align the connector correctly, and insert it into a StackPower port on the switch rear

panel.

• Connect the end of the cable with the yellow band to another switch. Hand-tighten the captive screws to secure the

StackPower cable connectors in place.

• StackPower feature doesn't need any dashboard configuration but is automatically enabled when the cables are

installed.

Basic Troubleshooting

The following steps can be used for troubleshooting basic connectivity issues with your switch.

• Factory reset the switch by holding the factory reset button for 10-15 seconds

• Try switching cables, or testing your cable on another device

Reference https://documentation.meraki.com/MS for additional information and troubleshooting tips.

If you are still experiencing hardware issues, please contact Cisco Meraki support by logging in to dashboard and using the Help option near the top of the page,

then opening and email case or calling using the contact information on that page.

Warranty

MS Warranty coverage periods are as follows:

14

Time

Period Comments

MS390

Series Lifetime -

MS

Accessories 1 Year The following are considered accessories: SFP Modules, twinax/SFP+ cables, stacking cables, all mounting kits and stands,

interface modules, additional power cords, PoE injectors

Note: The above table is a general guideline for warranty terms and is not final. Warranty terms are subject to printed warranty information on the online Meraki

Returns and Policy section.

If your Cisco Meraki device fails and the problem cannot be resolved by troubleshooting, contact support to address the issue. Once support determines that the

device is in a failed state, they can process an RMA and send out a replacement device free of charge. In most circumstances, the RMA will include a pre-paid

shipping label so the faulty equipment can be returned.

Additional warranty information can be found on: https://meraki.cisco.com/support#process:warranty

Support and Additional Information

If issues are encountered with device installation or additional help is required, contact Meraki Support by logging in to dashboard.meraki.com and opening a

case by visiting the Get Help section.

• The equipment is intended for industrial or other commercial activities.

• The equipment is used in areas without exposure to harmful and dangerous production factors, unless otherwise

specified in the operational documentation and/or on the equipment labeling.

• The equipment is not for domestic use. The equipment is intended for operation without the constant presence of

maintenance personnel.

• The equipment is subject to installation and maintenance by specialists with the appropriate qualifications, sufficient

specialized knowledge, and skills.

• Rules and conditions for the sale of equipment are determined by the terms of contracts concluded by Cisco or

authorized Cisco partners with equipment buyers.

• Disposal of a technical device at the end of its service life should be carried out in accordance with the requirements

of all state regulations and laws.

• Do not throw in the device with household waste. The technical equipment is subject to storage and disposal in

accordance with the organization's disposal procedure.

• The equipment should be stored in its original packaging in a room protected from atmospheric precipitation. The

In order to initiate a hardware replacement for non-functioning hardware that is under warranty, you must have access to the original packaging

the hardware was shipped in. The original hardware packaging includes device serial number and order information, and may be required for return

shipping.

Meraki MS390 devices have been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC rules. A digital

device that is marketed for use in a residential environment notwithstanding use in commercial, business and industrial environments.

15

permissible temperature and humidity ranges during storage are specified in the Operation (Installation) Manual.

• Transportation of equipment should be carried out in the original packaging in covered vehicles by any means of

transport. The temperature and humidity during transportation must comply with the permissible established ranges

of temperature and humidity during storage (in the off state) specified in the Operation Manual (Installation).

For additional information on Meraki hardware and for other installation guides, please refer to documentation.meraki.com.

16

This manual suits for next models

9

Table of contents

Other Cisco MERAKI Switch manuals

Popular Switch manuals by other brands

Hendrickson

Hendrickson HXL5 Maintenance procedures

OT Systems

OT Systems IES24242MPp9-S-8 Quick installation guide

Panasonic

Panasonic AVHS400AN - MULTI-FORMAT LIVE SWITCHER operating instructions

Growatt

Growatt Battery HUB user manual

Tesla

Tesla TSL-SWI-SCENEZG4 quick start guide

Cabletron Systems

Cabletron Systems MMAC-Plus 9E312-12 user guide