Cisco SCE8000 GBE Use and care manual

Other Cisco Computer Hardware manuals

Cisco

Cisco Wide Area Virtualization Engine 594 and 694 User manual

Cisco

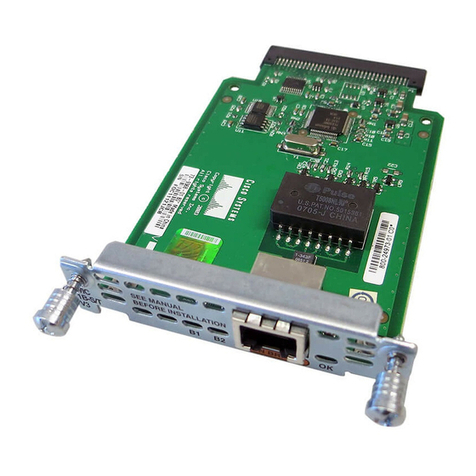

Cisco NPE-G2 - Network Processing Engine G2 Quick guide

Cisco

Cisco WIC36-1B-S Quick start guide

Cisco

Cisco 7541 Manual

Cisco

Cisco HWIC-3G-GSM User manual

Cisco

Cisco RSP1 Operating and maintenance instructions

Cisco

Cisco PRP-2= Operator's manual

Cisco

Cisco CATALYST MEM-C6K-ATA-1-64M( Installation and operation manual

Cisco

Cisco ASA 5512-X User manual

Cisco

Cisco Aironet 350 Series User manual

Cisco

Cisco CX-AIP-TM Operating and maintenance instructions

Cisco

Cisco AS5800 User manual

Cisco

Cisco AVS 3120 Manual

Cisco

Cisco IEC6400 Operator's manual

Cisco

Cisco 8800 Series User manual

Cisco

Cisco ONS 15454 EC1-12 User manual

Cisco

Cisco Prisma II Operating instructions

Cisco

Cisco ciscoBus CSC-C2CTR Quick start guide

Cisco

Cisco Nexus 2000 Series User manual

Cisco

Cisco WS-C1511 Instruction Manual

Popular Computer Hardware manuals by other brands

EMC2

EMC2 VNX Series Hardware Information Guide

Panasonic

Panasonic DV0PM20105 Operation manual

Mitsubishi Electric

Mitsubishi Electric Q81BD-J61BT11 user manual

Gigabyte

Gigabyte B660M DS3H AX DDR4 user manual

Raidon

Raidon iT2300 Quick installation guide

National Instruments

National Instruments PXI-8186 user manual