CiTO Power CPI-500 Series User manual

USER MANUAL

CiTO Power-INVERTERS Series

CPI-500 / CPI-1000

General Precautions

1. Before using CPI-500 / CPI-1000, read all instructions and cautionary

markings on : (1)CPI-500M / 1000M (2) The batteries (3) This manual

2. CAUTION --To reduce risk of injury, charge only lead-acid type

rechargeable batteries. Other types of batteries may cause damage and

injury.

3. Do not expose Inverter to rain, snow or liquids of any type. Inverter is

designed for indoor.

4. Do not disassemble the Inverter. Take it to a qualified service center when

service or repair is required.

5. WARNING: Provide ventilation to outdoors from the battery compartment.

The battery enclosure should be designed to prevent accumulation and

concentration of hydrogen gas at the top of the compartment.

6. NEVER charge a frozen battery.

7. Input/output AC wiring must be no less than 18 AWG gauge copper wire

and rated for 75oC or higher. Battery cables must be rated for 75oC or

higher and should be no less than 10AWG gauge. The inner diameter of

the copper ring terminal which is used to connect battery cables to

Inverter DC terminals should be no less than 6mm.

8. Be extra cautious when working with metal tools around batteries.

Short-circuiting the batteries could cause an explosion.

9. For battery installation and maintenance: read the battery manufacturer’s

installation and maintenance instructions prior to operating.

10. CiTO Power Inverters can be used with fan, bulb, TV, heater, iron, etc.

Consult local technicians for more advices.

Personnel Precautions

1. Have plenty of fresh water and soap nearby in case battery acid contacts

skin, clothing, or eyes.

2. Avoid touching eyes while working near batteries.

3. NEVER smoke or allow a spark or flame in vicinity of a battery.

4. Remove personal metal items such as rings, bracelets, necklaces, and

watches when working with batteries. Batteries can produce a short-circuit

current high enough to make metal melt, and could cause severe burns.

5. If a remote or automatic generator start system is used, disable the

automatic starting circuit or disconnect the generator to prevent accident

during servicing.

Introduction

CiTO Power Inverters CPI-500 / 1000 is a DC-to-AC inverter with auto

line-to-battery transfer and integrated charging system, serving as an

extended run UPS, a standalone power source or an automotive inverter.

CPI-500 / 1000 supplies power from AC power and DC source. When AC

cable is connected to a wall socket, utility power goes to connected

equipment(s) and/or charges the battery set via charging system. In UPS

mode, Inverter automatically converts battery energy into AC power for

backing up the connected devices.

Features:

zAutomatic line-to-battery switchover

zSelectable Input voltage ranges

zHigh efficient DC-to-AC conversion, minimizing energy loss

zRack Tower design for flexible placement

zBuilt-in enhanced charger

zIntelligent 2-stage charger control for efficient charging and preventing

overcharge

zProvides overload protection

zAuto restart whileAC recovery

zMulti-function LED indications and buzzer alarms

Operation

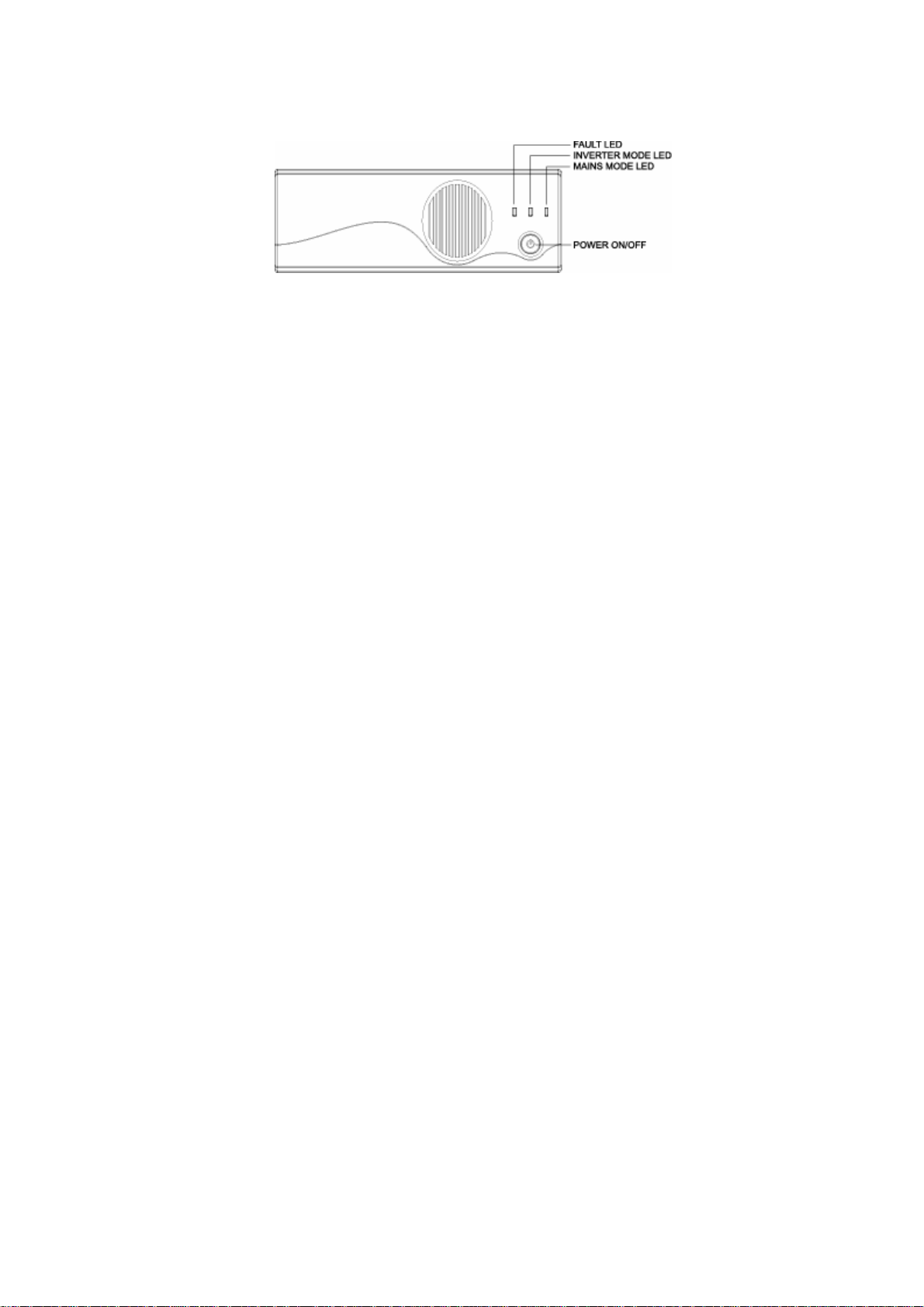

Front Panel Controls and LED Indicators

Shown below are the controls and indicator lights on the front of CPI-500 /

1000

Figure 1 Front Panel of CPI-500 / 1000

Power

On/Off

Power on/off button is shown as above. Once Inverter has been properly

installed and batteries are connected, press this button and Inverter will turn

on automatically, and works in mains mode or inverter mode according to

input AC source’s status. When press this button again, Inverter will turn off

automatically.

Mains Mode LED

The green LED will blink or light steadily when power mains is normal.

Note: The green LED blinks every 2 seconds to indicate that battery capacity

is not full enough and battery is being charged by high rate.

Inverter Mode LED

The Yellow LED will light when power mains is abnormal. And unit will work

in inverter mode.

Fault LED

The red LED will light when fault occurs.

Back Panel Description

Shown below are the components on the back of CPI-500 / 1000.

Figure 2 Back Panel

1. DC Input Connector (Battery Terminal)

2. Input Breaker

3. AC Input Connector (Three-station Terminal Block)

4. Output Receptacle(s)

5. Input Voltage Range Selector : (Input voltage range is defined in

specification chapter, and output voltage is the same as input voltage in

mains mode)

A. Select ‘Narrow’ setting for general electrical appliances,

B. To save energy, ‘Wide’ setting could be selected only when using

some special load, such as daylight lamp, fan etc.

Battery Connection

Step 1- Pinch the bottom of DC input cover and Open it. See Figure 4.

Step 2- Following battery polarity guide located near battery terminal. Place

the battery cable ring terminal over Inverter’s battery terminal.

Tighten the M5 nut. Do not place anything between the flat part of

battery terminal and the battery cable ring terminal, or overheating

may occur.

Figure 4 Battery Cable Connections to CPI-500 / 1000

Caution! DO NOT place

anything between battery cable

ring terminals and battery

terminals. The terminal stud is

not designed to carry current.

Apply Anti-oxidant paste to

terminals after terminals have

been securely connected.

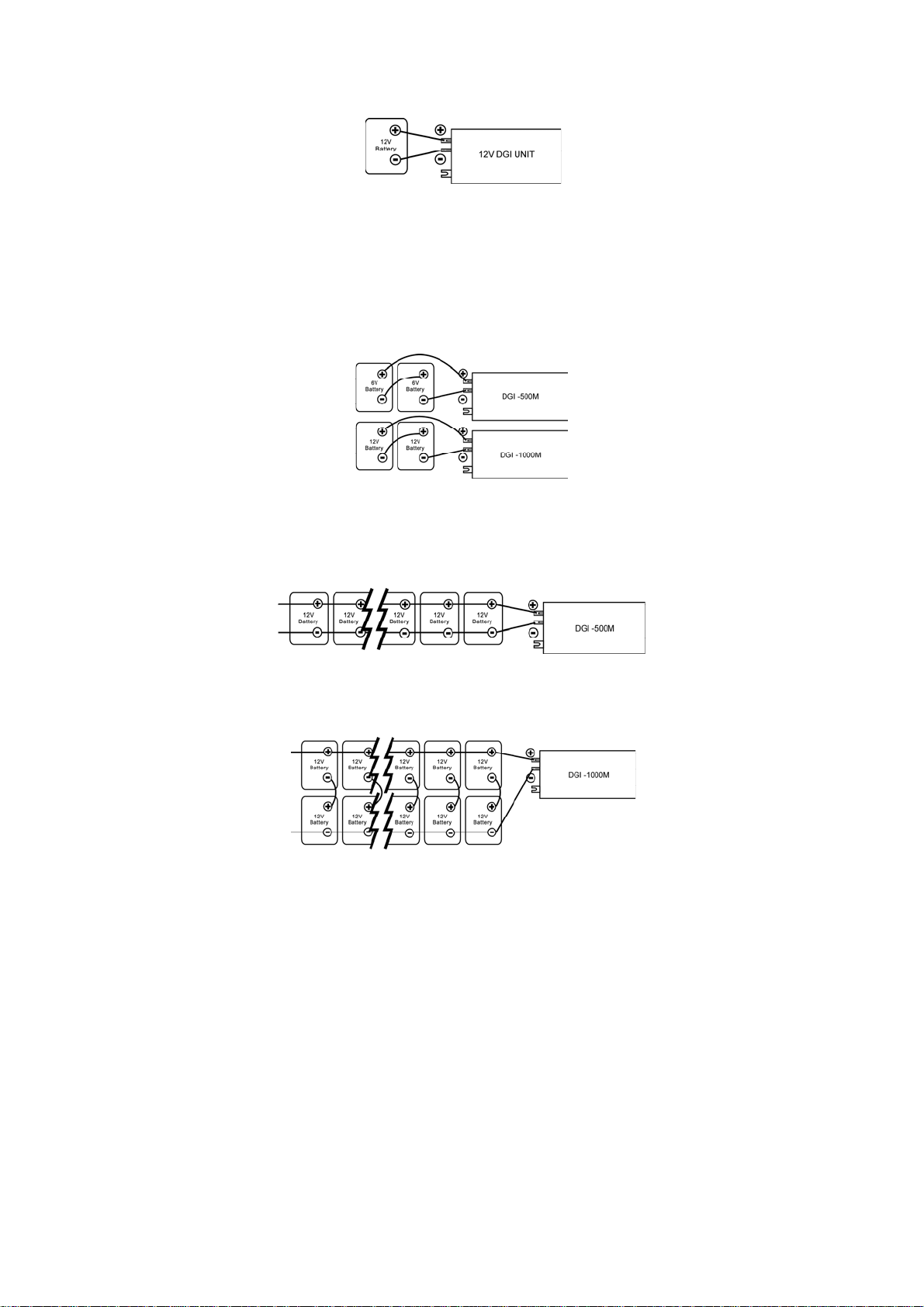

Step 3- Connect battery cables to your batteries

The battery must be wired to match the units DC input voltage specifications

(CPI-500 for 12Vdc, CPI-1000 for 24Vdc).

In addition, the batteries can be wired to provide additional runtime. The

various wiring configuration are as follows:

zSeries Connection: Wiring batteries in “series” increases the total output

voltage. This voltage MUST match the DC voltage requirements of the

CiTO unit, or damage may occur to both the CiTO unit and/or the

batteries.

zParallel Connection: Wiring batteries in “parallel” increases the total run

time the batteries can operate theAC loads. The more batteries

connected in parallel the longer the loads can be powered from the CiTO

unit.

zSeries-Parallel Connection: “Series-parallel” configurations increase

both the battery voltage (to match the DC requirements of CiTO unit) and

run-time for operating theAC loads.

AC Connection

Before having AC connection, match the power requirements of connected

devices with the power output of Inverter to avoid overload. Consult a

qualified electrician, and follow local code for the proper wire sizes,

connectors and conduit requirements.

Step 1- A three-station terminal block is provided to make AC input

connections. Remove the cover plate.

Caution!! Be sure that AC source is disconnected before attempting to

connect AC power cables and load to Inverter.

Step 2- Connect the hot wire (black/brown)

of AC input cable to the HOT IN terminal.

Step 3- Connect the neutral wire (white/blue)

of AC input cable to the NEU IN terminal

Step 4- Connect the ground wire

(green) of AC input cable

to the GND IN terminal

Step 5- Tighten screws to affix wires

in terminal block.

Step 6- Cover up theAC Input by the

plastic cover.

Step 7- Simply plug your equipment(s)

into the output receptacle(s).

Step 8- Turn on Inverter when you are

using connected equipment(s).

Figure 5 AC Input Connections

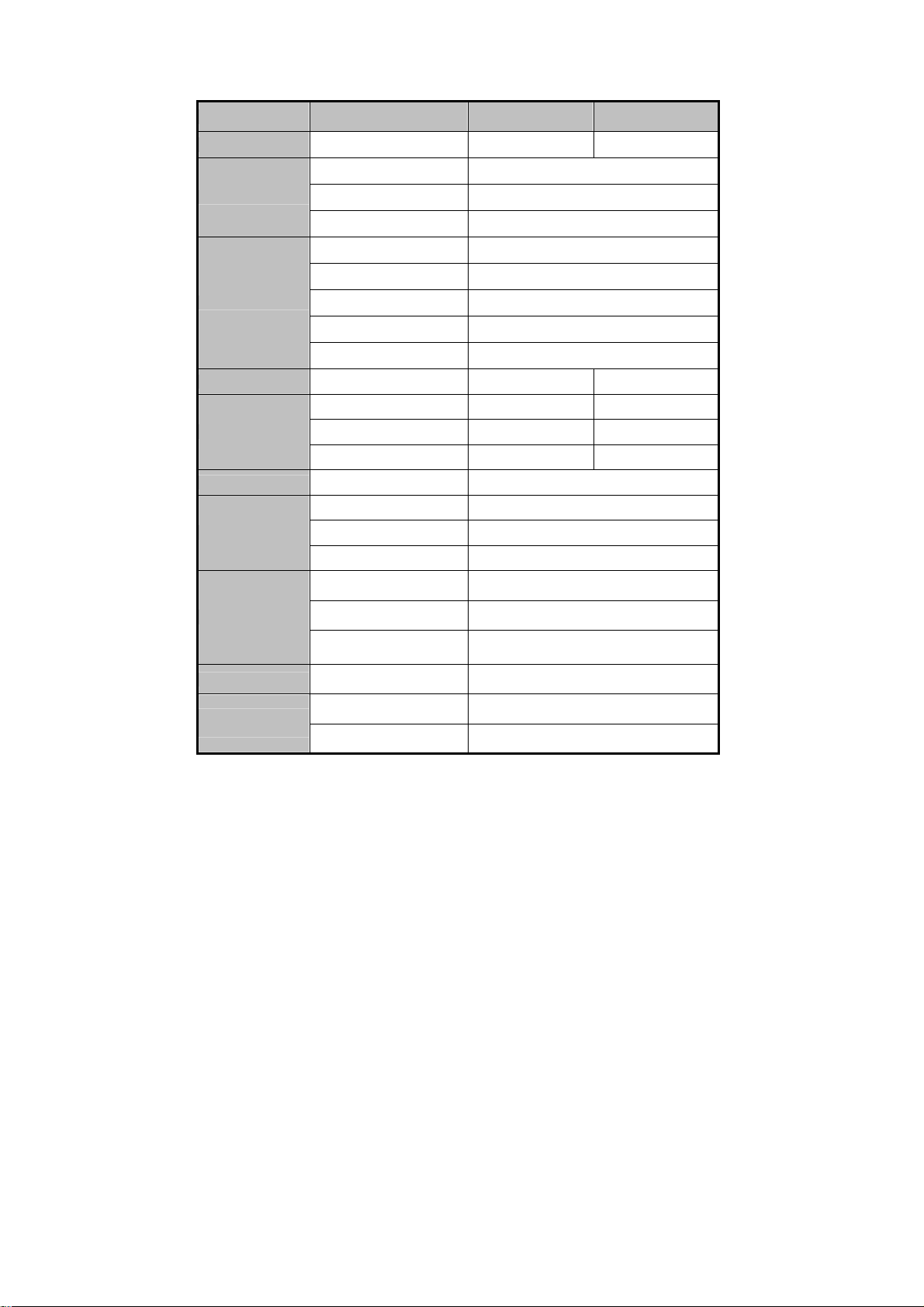

SPECIFICATION

MODEL CPI-500 CPI-1000

CAPACITY VA/W 500VA/300W 1000VA/600W

Nominal Voltage 220~240VAC

Input Voltage Range 90~280VAC

AC INPUT

Nominal Frequency 50Hz or 60Hz (Auto Detection)

Voltage ±15%

Frequency 50/60Hz ±0.1Hz

Waveform Modified Sine-wave

Efficiency (AC toAC) > 95%

OUTPUT

Efficiency (DC toAC) > 80%

BATTERY Nominal Voltage 12Vdc 24Vdc

Charging Voltage 13.7V 27.4V

Charging Current 8A max. 6A max.

CHARGER

Overcharging Protection 14.5V 29V

TRANSFER Transfer Time 8ms typical

Line mode Green LED blinks or lights steadily

Battery mode Yellow LED lights

INDICATOR

Overload/fault Red LED blinks or lights steadily

Low Battery Voltage in

battery mode Buzzing every 2 seconds

Overload Buzzing every 0.5 second.

AUDIBLE ALARM

Fault Buzzing continuously

ENVIRONMENT Temperature 0 ~ 40°C

Dimension (mm) DXWXH 224x255x80

PHYSICAL Net Weight (Kg) 1.7

Troubleshooting

Problem Possible Cause Remedy

Battery discharged

C

harge battery for 8

h

ours or more.

Battery defect Battery replacement.

No LED display

Power switch is not

pressed Press and hold power

switch.

AC Input is missing

C

heck AC input

c

onnection.

Mains normal but

works in inverter

mode Input protector is

effective Reset the input

protector.

Alarm buzzer beeps

continuously Overload

V

erify that the load

m

atches the capability

s

pecified in the specs.

Overload

Remove some

n

on-critical load.

Back up time is

shorten Battery voltage is too low.

C

harge battery for 8

h

ours or more.

If any abnormal situations occur that are not listed above, please call service

technician immediately.

This manual suits for next models

1

Table of contents

Popular Inverter manuals by other brands

Fimer

Fimer UNO-DM-6.0-TL-PLUS-US-Q Quick installation guide

CPS

CPS SCA Series Installation and operation manual

Generac Power Systems

Generac Power Systems G007144 Installation guidelines

Omron

Omron SYSDRIVE 3G3IV Installation instructions manual

Spectron

Spectron SE1450 Operating and maintenance manual

Hoymiles

Hoymiles HMS-300-1T user manual