SE1450 DASH Stroke Generator

Operating and Maintenance Manual Page 9 of 25

Power Connection

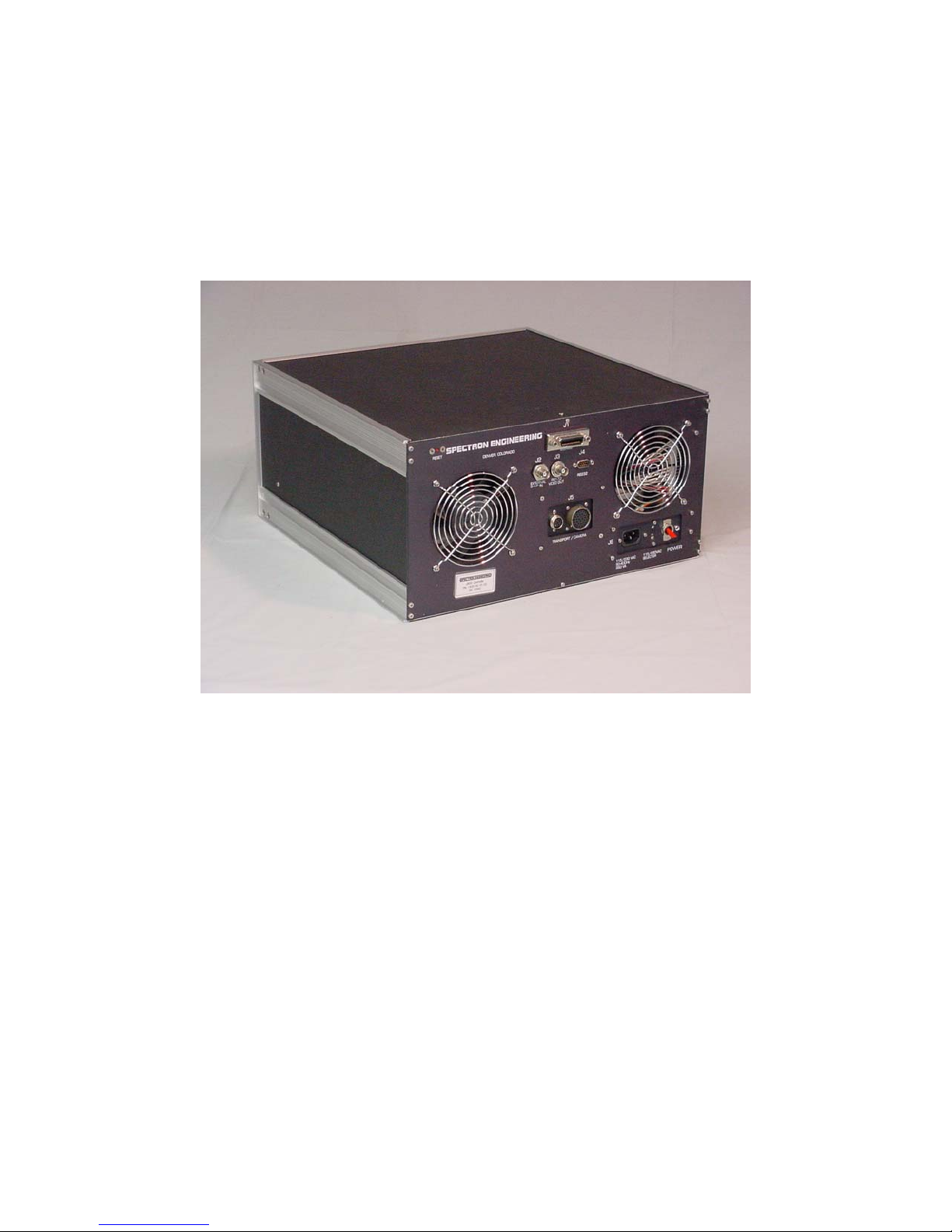

Power Section - SE1450 DASH Stroke Generator Back Panel

1. Determine that the power switch/circuit breaker on the back of the

SE1450 DASH is in the OFF (down) position and that the 115/230 VAC

selector switch is in the correct position for the power source to be used.

2. Connect the 120 VAC Power cord to the back of the SE1450 DASH,

Connector J6, and plug into the power outlet.

3. The system is powered up by turning on the power switch/circuit breaker

on the back of the Controller and operated according to the procedures in

Chapter 3, Operations of this manual.

RS232 Connection and Protocol

User supplied and initiated RS232 Communications with the SE1450 DASH system are

described in Chapter 3, Operations. The following information is supplied as an aid in

initiating proper communications through the RS232 port.

The RS232 connector is a DB9 male connector located on the SE1450 DASH Back Panel

(J4). Only five of the nine pins are used in accordance with the pin out specifications in

table 2-1, below.

Table 2-1

1450 DASH Connection Terminal Connection

Pin 2 RD Receive Data TRANSMIT

Pin 3 TD Transmit Data RECEIVE

Pin 5 GND Ground GROUND

Pin 7 RTS Request to Send CLEAR TO SEND

Pin 8 CTS Clear to Send REQUEST TO SEND

Complete instructions for using the RS232 port are contained in Chapter 3, Operations.

073004