City Theatrical AUTOYOKE User manual

752 EAST 133RD STREET BRONX, NY 10454

718/292/7932 800/230/9497 FAX:718/292/7482

www.citytheatrical.com

ver1.0

email: [email protected]

UserManual

AUTOYOKE

withPARNel

TABLE OF CONTENTS

SECTION 1 SPECIFICATIONS

1-1 Dimensions and Weight

1-2 Compliance

1-3 Electrical

1-4 Protocol

1-5 Motors

SECTION 2 SAFETY

SECTION 3INSTALLATION AND SET-UP

3-1 Unpack and inspect the shipping container

3-2 Balancing the System

3-3 Attaching a Color Scroller

3-4 Replacing the PARNel Lamp Housing Assembly on the Unit

3-5 Hanging the AutoYoke

3-6 Power cable

3-7 Data cable

SECTION 4USER INTERFACE

4-1 Menu system

4-2 Address

4-3 Calibrate

4-3a Calibrate All

4-3b Calibrate a single attribute

4-3c AutoCalibrate

4-4 Invert

4-5 Resolution

4-5a 8 bit or 16 bit

4-5b DMX Smoothing values

4-6 Pan, Tilt, and Focus Limits

4-7 Software release

4-8 LED Display

4-8a Timeout

4-8b Brightness

4-9 Restore factory defaults

4-10 Error messages

p. 1

p. 2

p. 2

p. 2

p. 2

p. 3

p. 4

p. 5 - 6

p. 7 - 9

p. 10

p. 11

p. 11

p. 11

p. 12

p. 13

p. 14

p. 14

p. 15

p. 15

p. 16

p. 17

p. 17

p. 18

p. 19

p. 21

p. 21

p. 21

p. 22

p. 22

p. 23

SECTION 5OPERATION

5-1 DMX channel assignments

5-2 Pan and Tilt

5-3 Default setting

5-4 Personality settings

5-5 Control channel

5-6 Encoders

SECTION 6BEAMSPREAD AND COLOR CONTROL

AutoFocus

Scrollers

SECTION 7MAINTENANCE

Software revisions

Spare parts

Lighting fixture

SECTION 8 WARRANTY

Limited Warranty

Procedure

*** Trouble Shooting Guide and Balancing Guide are located after page 28.

p. 24

p. 24

p. 25

p. 25

p. 26

p. 27

p. 27

p. 27

p. 28

p. 28

p. 28

p. 28

p. 28

1-2COMPLIANCE

Conforms to UL STD 73, Eighth Edition - Motor Operated Appliances.

Certified to CAN/CSA C22.2 NO.: 68.92

ETL# 9801635

CETL# 9801635

CE, GS,

1-3ELECTRICAL

· Working voltage: 100-240 VAC, 50/60 Hz

· Rated current: 1.3A

1-4PROTOCOL

· USITT DMX512

· Start code: (00h)

· Maximum load: 32 fixtures per DMX link (See Section 3-7, Data Cable)

· Maximum length of DMX link: 2000'(See Section 3-7, Data Cable)

· Required control channels: 7 (16-bit) or 5 (8-bit)(See Section 3-7, Data Cable)

· Termination: 120Ω(See Section 3-7, Data Cable)

1-5MOTORS

· High torque stepper motor, half stack

· Rated voltage DC: 8.7

· Step angle (degrees): 1.8

-2-

SECTION 2: SAFETY

· A moving light is a dangerous piece of equipment. It is for professional use only.

· If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly

qualified person in order to avoid a hazard.

· Follow all safety procedures that apply to the lighting fixture, per its manufacturer’s instructions.

1. Refer to the lighting fixture’s user manual for all applicable safety information.

2. Maintain minimum safe distances.

· The AutoYoke with PARNel is designed for use only with the ETCSource Four PARNel. Using a fixture

other than the ETC Source Four PARNel WILL VOID THE AUTOYOKE WARRANTY.

· Always ground (earth) the AutoYoke electrically.

· Balance of the lighting fixture as mounted in the AutoYoke is critical to proper operation of the AutoYoke.

Attempting to operate the AutoYoke while the lighting fixture is out of balance presents a significant risk

of inaccuracy, increased motor noise and component failure. See Section 3-4, Balancing the System,

for complete information.

· Never lift the AutoYoke by the lighting fixture. Always lift and carry the AutoYoke by its two

handles, located on the sides of the power supply.

· Always suspend the AutoYoke from approved clamps secured to the designated points on the AutoYoke

power supply. See Section 3-5, Hanging the AutoYoke, for further information.

· Always use an approved safety cable when hanging the AutoYoke.

· Always disconnect the AutoYoke from AC power before service.

· Do not use DMX accessories that are not cited in this manual due to possible electrical incompatibility

with the AutoYoke.

· Do not allow the AutoYoke or its accessories to come into contact with moisture.

· Do not put flammable materials on or near the AutoYoke.

-3-

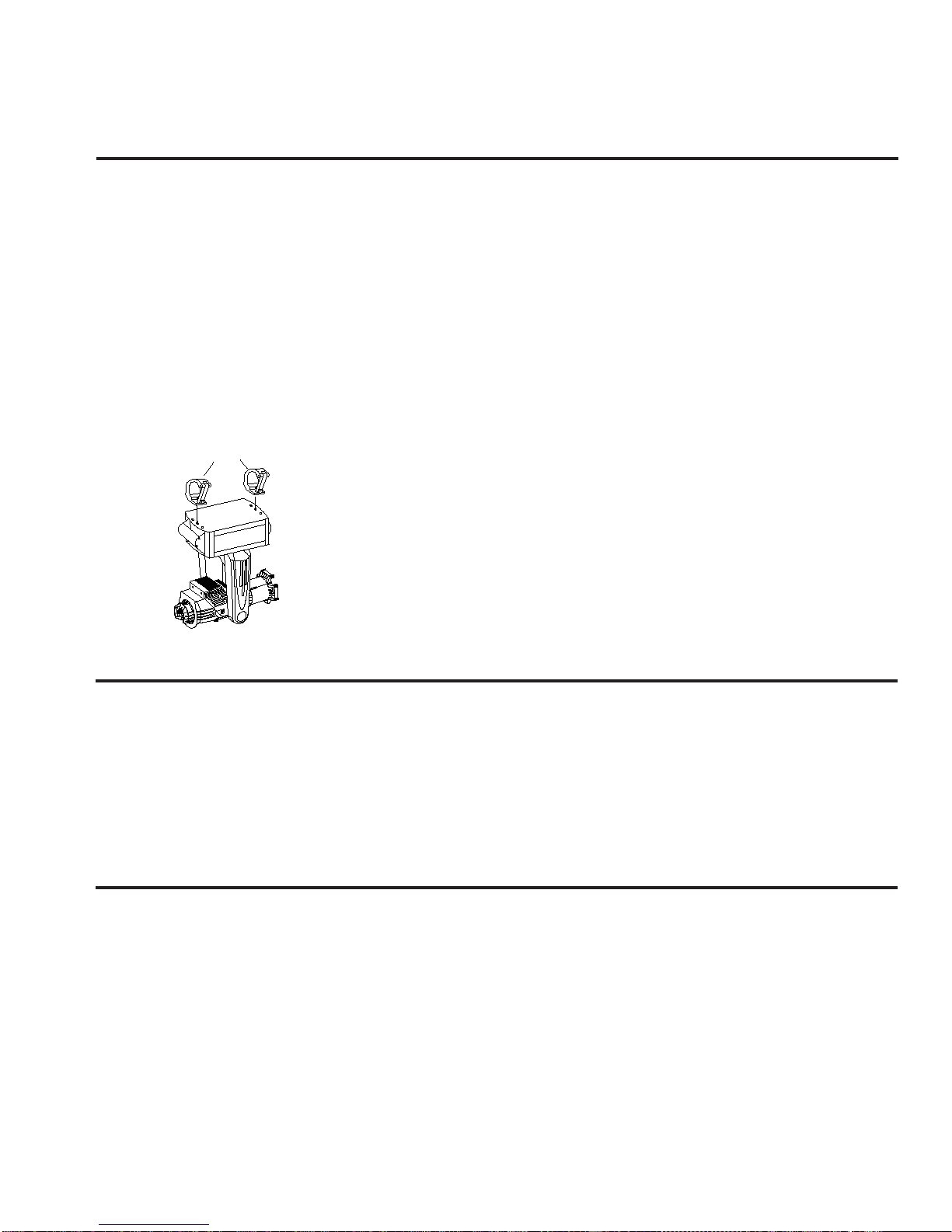

SCROLLER

SCROLLER

control panel

handle

power supply

yoke

side arms

Source Four PARNel

connector box

SECTION 3: INSTALLATION AND SET-UP

WARNING: Using a fixture other than the ETC Source Four PARNel with the AutoYoke

WILL VOID THE AUTOYOKE WARRANTY!

3-1 UNPACK AND INSPECT THE SHIPPING CONTAINER

Addtional hazards include the following:

- Damaging both the AutoYoke and the lighting fixture

- Fixture detaching from the AutoYoke

- Fire hazard

Verify that the AutoYoke has arrived complete and undamaged.The shipping container

should contain the following items:

- (1) AutoYoke with ETC Source Four PARNel

- (1) User's Manual

- 4 -

3-2 BALANCING THE SYSTEM

- 5 -

The AutoYoke with PARNel must be correctly balanced to insure proper operation. Follow the steps described be-

low. There are a total of 6 (six) mounting holes, 3 (three)located on each side arm. They are arranged in a triangle

with the point of the triangle facing backwards. Use 1/4-20 x 1/2 -inch long, pan head screws in all of the mounting

holes. Failure to do so may result in poor performance of the of the AutoYoke. There are extra holes that are not

marked in the Balancing Guide to allow for balancing of the unit in the future for other accessories that were either

not available or not used when the Balancing Guide was published.

a) Refer to Balancing Guide table and figure at the last page of this manual.

b) Locate along the top of the table which color scroller will be used.

c) Locate along the side of the table which accessory will be used, if any.

*Note: Not all accessories are usable with all color scrollers. The combinations that are not valid are

marked with an "N A" (not applicable) in the table.

d) The intersection of the color scroller column and the accessory row will determine which set of holes

to use in the side arms for the proper balancing of the system.

e) Mount the PARNel-cradle assembly to the side arms usingthe set of holes determined from the previous

step. Make sure that the cradle is square with respect to the side arms.

f) Mount and secure the color scroller (if any) to the PARNel fixture and connect scroller to the connector box

of the AutoYoke. Please refer to Section 3-3, Attaching a Color Scroller/ Accessory, for instructions.

g) Mount and secure the accessory (if any). Refer to Section 3-3, Attaching a Color Scroller/ Accessory, for

instructions.

h) Tighten all hardware.

i) The lighting fixture is balanced when it free drifts to a near horizontal position (perpendicular to the Auto-

Yoke) or slightly front heavy.Operating an imbalanced AutoYoke will result in inaccuracy.

mounting screws

side arm

- 6 -

Some examples are as follows:

EXAMPLE 1

You will use the system without a color scroller and with or wothout a color frame. Look in the table for No

Scroller and No Accessory or Color Frame. The table will show that the PARNel-Cradle assembly shouldbe mounted

to the side arms using the #1 set of holes. This is the default configuration when the unit is shipped from the factory

(unless special instructions have been provided to have the unit in another configuration prior to shipment). This

allows the user to run the AutoYoke straight from the box.

EXAMPLE 2

You will use the system with a Top Hat but the system is configured/balanced for No Accessory. Begin by

removing the screw at the point of the "V" on one side arm, and loosen the other two screws. Remove all the screws

from the #1 set of holes in the other side arm and loosely reinstall them in the #2 set of holes in accordance to the

Balancing Guide table. Remove the two screws from the #1 set of holes in the first side arm and tightly reinstall them

along with the third screw in the #2 set of holes, while making sure that the cradle is square with respect to the side

arms. Tighten the screws in the other side arm, again making sure the cradle is square. Mount and safety the Top Hat.

*Note: The method cited in Example 2 is only useful when moving from an adjacent set of holes. By leaving

some of the screws in loosely, it allows you to move the PARnel-cradle assembly to the other hole location easily.

If the new set of holes is further than the adjacent set of holes, all of the screws must be removed and reinstalled to

the new location.

EXAMPLE 3

You will use the system with a "Wybron" CXI color scrollerbut the unit is configured/balanced for No Acces-

sory. Look in the table for the CXI color scroller then the top hat. The table will show that the PARNel-cradle assembly

should be mounted to the side arms using the #6 set of holes. Follow steps e through h of the instructions on the

previous page.

CXI Color Scroller- #6 set of holes

- 7 -

3-3 ATTACHING A COLOR SCROLLER

A color scroller is an optional accessory, and is not supplied by City Theatrical, Inc. See Section 6 for

further information.

THE AUTOYOKE SUPPORTS THE WYBRON FORERUNNER, WYBRON CXI (See cable note below),

WYBRON COLORAM II (See cable note below), RAINBOW PRO SERIES, AND CHROMA Q M-1 COLOR

SCROLLERS. THE AUTOYOKE SUPPLIES POWER TO THE SCROLLER; OTHER MANUFACTURER’S

SCROLLERS ARE NOT ELECTRICALLY COMPATIBLE. ATTEMPTING TO USEA SCROLLER OTHER THAN

THOSE LISTED ABOVE WILL POTENTIALLY DESTROY THE SCROLLER.

All AutoYoke-compatible scrollers that are not Wybron CXInor Wybron Coloram II are referred to in this

manual as direct DMX scrollers.

See Section 4-2 for addressing.

1. Insert the scroller into the lighting fixture gel frame holder.

2. Secure color scroller to the fixture as tight as possible by use of plastic cable ties. This ensures that

the scroller will not move no matter what position it is in. Any extra movement on the scroller while

the unit is moving may cause inaccuracy due sudden weight shifts.

Loop the cables thru the adaptor plates then thru the tabs near the rim of the fixture. Use four attach-

ments points if possible. See pictures below on various attachment styles depending on the choice of

scroller.

CXI, Coloram II

tab

cable tie

adaptor plate

- 8 -

Chroma Q - M1*

* Note that the Chroma-Q M1 is inserted to the fixture upside down due to the location of its data in/out connectors

and due to this, secure the scroller cable to make sure that it does not interfere in any way to the AutoYoke's range

of motion.

PARNel tabs

Rainbow scroller tabs

Rainbow Pro Series 8"*

* For the Rainbow scroller, use the two tabs at the top ofthe scroller as attachment points to the tabs of the PARNel

fixture.

- 9 -

3. Plug an 18" 4-pin XLR cable to the scroller and to the connector box of the AutoYoke.

(Refer to drawing below for view of the connector box)

***Note: City Theatrical does not recommend using a cable that is longer than 18”. Using a scroller cable

that is longer than 18” runs the significant risk of interfering with the AutoYoke’s range of motion.

***Note: When using a Wybron CXI or a Coloram II, the scroller cable must be wired in the following

way:

Male pin 1 to Female pin 4

Male pin 2 to Female pin 2

Male pin 3 to Female pin 3

Male pin 4 to Female pin 1

Using a cable that is not wired this way will destroy the scroller. Always consult the color scroller

manufacturer’s signal cable requirements before connecting a scroller to the AutoYoke.

connector box

4-pin XLR female connector

(scroller out)

USING A TOP HAT OR OTHER ACCESSORIES

Use only the accessories listed in the Balancing Guide (located at the end of the Manual) and secure tightly

to the fixture or to the scroller by means of cable ties whenever possible.

scroller with top hat

3-4 REPLACING THE PARNEL FIXTURE LAMP HOUSING ASSEMBLY ON THE UNIT

- 10 -

The AutoYoke with PARNel is supplied with the lampwire already terminated to the AutoYoke connector

box. However, the lamp housing assembly might need replacing at some point. The cap-wire assembly

may be replaced as follows but be sure that AutoYoke power and the lamp power cables are unplugged.

1. Remove the connector box cover by using a philip's head screwdriver to remove the four

6-32 x 1/4 inch screws, two on each side, and locate the terminal block.

2. Using a 1/8-inch wide slotted screwdriver, loosen thetwo screws from the cells that holds the

two white wires coming from the lamp housing assembly, andpull the two wires out.

3. Using a 5/16-inch socket driver, remove the 6-32 nutthat secures the ring terminal of the ground

wire coming from the lamp housing.

4. Locate the black strain relief and loosen the nut at the outside of the connector box to free up the

wires.

5. Pull out the wire harness from the strain relief.

6. Loosen the knurled knob of the cap and remove the lamp housing assembly from the PARNel fixture.

7. Cut the lamp harness of the new lamp housing assembly to about 13 inches from the cap.

8. Screw the new cap to the PARNel fixture (you may putin the HPL lamp at this point).

9. Slip the nut removed from the strain relief over the new lamp harness and insert the harness into

the strain relief from the outside of the connector box.

10. Strip about 1/4 inch of insulation from the three wires and crimp a ring terminal to the ground

(green) wire. Ring terminal should be for gauge #22-18 and with a #6 hole.

11. Place the new ground wire (with ring terminal) over the stud bolt where the first ground wire was

removed and secure with the 6-32 nut.

12. Insert the two white wires to the terminal block and tighten the screws.

13. With the wires terminated inside the box, tighten the nut of the strain relief from the outside of the

box to secure the lamp harness.

14. Reinstall the connector box cover.

- 11 -

3-5 HANGING THE AUTOYOKE

The AutoYoke must be securely attached to the hanging position with hanging clamps. The Power Supply

must be placed either directly above or directly below the lighting fixture for proper operation (see note

below). A secondary means of suspension, a safety cable - must be used to prevent the AutoYoke from

falling in the event of hanging clamp failure.

***NOTE: The AutoYoke MUST NOT be hung at any angle to avoidimbalance and malfunction of the

unit.

Pan direction is CLOCKWISE from 0% to 100% when the AutoYoke is hanging Power Supply up, facing the

Front Panel, looking at the AutoYoke hanging from below. Keep this in mind when choosing hanging

orientation for optimal travel.

1. Attach the hanging clamps to the specified holes on the top of the

Power Supply.

2. Hang the AutoYoke on a minimum of 2’3” centers and with a clearance

of 3’ from the top of the Power Supply to the fixture and color scroller

(clearance will be greater ifa top hat is used).

3. Fasten a safety cable through one of the handles of the AutoYoke, and

secure it to the hanging position.

3-6 POWER CABLE

AutoYoke: The cable with the three pin Edison connector supplies power to the AutoYoke. Plug to a

NON DIM power supply that is configured for a switchable PSU or a hot circuit that does

not pass through a dimmer rack.

Lamp: The cable with the three pin stage or twist lock connector (or without connector) supplies

power to the lighting fixture. This may be plugged into a dimmer.

3-7 DATA CABLE

Plug a DMX cable to the male 5-pin XLR on the AutoYoke Power Supply.

· Cable must be twisted pair, 120W, shielded EIA485 cable (Belden 9829, 9842 or equivalent),

minimum 22 AWG.

· Recommended maximum cable length is 1640’ (500m). [Recommended Practice for DMX512,

Adam Bennette 1994] Maximum cable length is 2000’ (610m).

· A maximum of 32 DMX receiving devices can be present on a single DMX line.

· The last DMX device on the line must be terminated with a resistor with a value of 120W.

hanging clamps

SECTION 4: USER INTERFACE

4-1MENU SYSTEM

Several of the routines (marked with a * below) that are performed at the front panel are also

accessible from the control channel (See Section 5-4, Control Channel, for further details).

The menu on the front panel of the AutoYoke allows you to do the following:

· Set DMX address

· Calibrate*

· Invert Pan, Tilt, and Focus travel direction

· Select 8- or 16-bit operation

· Select DMX smoothing value

· Set Pan, Tilt, Iris and Focus Limits*

· Display software version

· Invert display

· Change LED display properties

· Restore Factory Defaults (except for DMX512 address and display settings)

· Display Error messages

Throughout this manual, the following conventions will be used to explain menu navigation:

· Menu:The Menubutton allows you to enter the menu item or return to the

upper level menu items.

· Enter: The Enterbutton allows you to select a function.

· st: The arrow keys allow you to navigate into and out of the

menu system.

· AddrAddr:Menu items that appears on the LED display on the front

panel will be presented in this format.

-12-

SECTION 5: OPERATION

5-1DMX CHANNEL ASSIGNMENTS

16-BIT OPERATION ***Refer to the Scroller note below for Scroller

1 - Pan Coarse DMX Channel information

2 - Pan Fine

3 - Tilt Coarse

4 - Tilt Fine

5 - Unused but occupied

6 - Focus

7 - Control

8-BIT OPERATION:

1 - Pan

2 - Tilt

3 - Unused but occupied

4 - Focus

5 - Control

***Scroller Note:

The scroller requires an address other than those addresses occupied by the AutoYoke. When using a

Wybron CXI scroller, the scroller must be addressed at 001001, and it will occupy 3 control channels - the

8th, 9th, and 10th in the sequence when operating in 16-bit and the 6th,7th, and 8th when operating in

8-bit. When using a Coloram II scroller, the address at the head is inconsequential, but the scroller will

always occupy the 8th channel in the sequence (in 16-bit) and the 6th channel in the sequence (in 8-

bit). All other specified scrollers can be set at a user selected DMX address as long as it is not occupied

by an AutoYoke attribute.

5-2PAN AND TILT

· Pan360° - can travel the full range in 4 seconds (maximum)

· Tilt270° - can travel the full range in 3 seconds (maximum)

· To optimize smooth Pan and Tilt travel, select the DMX smoothing setting applicable to your controller.

See section 4-5b, DMX Smoothing, for further information.

· The Pan and Tilt travel directions can be inverted for programming convenience. See Section 4-4,

Invert, for further information.

· Pan and Tilt range can be limited to optimize smooth travel. See Section 4-6, Limits, for further

information.

-24-

5-3DEFAULT SETTINGS

The AutoYoke is shipped from City Theatrical with the following default settings and configuration:

· Configured/ balanced as a unit without scroller or accessory (#1 set of holes)

· DMX address is 1

· DMX resolution is 16 bit

· Smooth Setting 1 (Strand and ETC consoles)

· AutoCalibrate all attributes at power up.

· Pan direction is CLOCKWISE from 0% to 100% when the AutoYoke is hanging

Power Supply up and when the operator below is facing the Front Panel.

· Tilt is at 0% (Pan is at 0%) when the gel frame holder side (front) of the lighting fixture is

tilted towards the rear of the power supply [the rear of the power supply is the long side

without the label, the front of the power supply is the long side with the label] and con-

nector box is up; Tilt is at 100% when the front of the lighting fixture is tilted towards the

front of the power supply, connector box is down.

· Focus direction: Spot - 0% Flood - 100%

· Pan, Tilt, and Focus have a full range of travel.

· LED timeout system is engaged.

· LED brightness is at 68.

Refer to Section 4-9, Restoring Factory Defaults, for further instructions.

5-4PERSONALITY SETTINGS AND MAINTENANCE LIGHT CUES

The AutoYoke will be controlled differently on different consoles. Refer to the console manufacturer for

instructions on writing a personality.

When writing the AutoYoke personality, take into consideration the desired default levels for each attribute.

Each attribute will go to its default level when the console is cleared. City Theatrical suggests writing the

Pan / Tilt default levels at 50/50 (50/50 is the middle of the travel). The AutoYoke goes to a 50/50

position following calibration unless it is receiving a DMX value.

In addition, it is recommended that the AutoYoke be moved to a position prior to power down that

prevents an out of balance fixture from slamming the end stop on the tilt axis.

-25-

5-5CONTROL CHANNEL

The Control Channel allows the operator to Calibrate and set Limits and configure the scroller from the

console. The Control Channel must remain stable at the appropriate level for 2 seconds to engage function.

CONTROL CHANNEL VALUES

WHEN USING DIRECT DMX SCROLLERSWHEN USING WYBRON COLORAM IIWHEN USING WYBRON CXI

0%Operation0%Operation0%Operation

5%unused5%Calibrate scroller***5%Calibrate scroller***

10%Calibrate All Attributes 10%Calibrate All Attributes10%Calibrate All Attributes

15%unused15%Motor slow15%unused

20%Calibrate Pan20%Calibrate Pan20%Calibrate Pan

25%unused25%Motor normal25%unused

30%Calibrate Tilt30%Calibrate Tilt30%Calibrate Tilt

35%unused35%Fan slow35%Fan slow

40%Calibrate Iris40%Calibrate Iris40%Calibrate Iris

45%unused45%Fan normal45%Fan normal

50%Calibrate Focus50%Calibrate Focus50%Calibrate Focus

55%Cut Power to scroller***55%Fan off55%Fan off

60%Set Pan Low Limit60%Set Pan Low Limit60%Set Pan Low Limit

65%Set Pan High Limit65%Set Pan High Limit65%Set Pan High Limit

70%Set Tilt Low Limit70%Set Tilt Low Limit70%Set Tilt Low Limit

75%Set Tilt High Limit75%Set Tilt High Limit75%Set Tilt High Limit

80%unused80%unused80%unused

85%unused85%unused85%unused

90%Set Focus Low Limit90%Set Focus Low Limit90%Set Focus Low Limit

95%Set Focus High Limit95%Set Focus High Limit95%Set Focus High Limit

100%unused100%unused100%unused

***NOTE: 55% (when using direct DMX scrollers) and 5% (when using Wybron Coloram II and CXI) allow

the operator to remotely recalibrate the scroller. Direct DMX scrollers (using control channel 55%)

will recalibrate once the control channel reverts to operation mode; Wybron Coloram II and CXI will

not and does not need to calibrate if their power is not cut off from the time of their initial power up.

SETTING LIMITS WITH THE CONTROL CHANNEL

1. Bring the Control Channel to the appropriate level.

2. Bring the channel that operates the attribute to the desired level.

***NOTE: The attribute channel level must change once before the desired level can be selected. If the

attribute channel is already at the desired level move it off of the desired level and then back to the

desired level -This is to prevent inadvertent limit selection during programming.

3. Bring the Control Channel to 0.

4. Bring the attribute channel to 0 to complete the setting of limits.

-26-

5-6ENCODERS

The AutoYoke is designed to return to its recorded position if it has been knocked or obstructed. If it has

been knocked, the motors will lose power to prevent damage to the AutoYoke or the obstruction. The

AutoYoke will then attempt to return to its recorded position after approximately 2 seconds. In the event

that the obstruction is not removed before the AutoYoke attempts to return to its recorded position and the

AutoYoke again hits the obstruction, the AutoYoke will again lose power to the motors and double the

waiting period before again attempting to return to its recorded position. The AutoYoke will make 7

attempts before the motor shuts down. Recalibration is required for the motor to work again after

obstruction has been cleared.

SECTION 6: BEAMSPREAD AND COLOR CONTROL

Beamspread, and color are controlled with the following features of the AutoYoke.

AutoFocus:The AutoFocus rotates the outer lens of the PARNel fixture. It changes the beamspread

from spot to flood.

Scrollers:THE AUTOYOKE SUPPORTS WYBRON FORERUNNER, CXI, COLORAM II,

RAINBOW PRO SERIES, AND CHROMA Q M1COLOR SCROLLERS ONLY. Other

Manufacturers’ scrollers are NOT electrically compatible. Always consult the color scroller

manufacturer’s signal cable requirements before connecting a scroller to the AutoYoke.

When using a Wybron CXI or a Coloram II, the scroller cable must be wired in the following

way: Male pin 1 to Female pin 4

Male pin 2 to Female pin 2

Male pin 3 to Female pin 3

Male pin 4 to Female pin 1.

The scroller requires anaddress other than those addresses occupied by the AutoYoke.

When using a Wybron CXI scroller, the head must be addressed at 001001, and it will occupy

3 control channels - the 8th, 9th, and 10th in the sequence when operating in 16-bit and

the 6th, 7th, and 8th when operating in 8-bit. When using a Coloram scroller, the address

at the head is inconsequential, but the scroller will always occupy the 8th channel in the

sequence (in 16-bit) and the 6th channel (in 8-bit). All other specified scrollers can be

set at a user selected DMX address as long as it is not occupied by an AutoYoke attribute.

It is only necessary to select the first DMX address for the AutoYoke. Refer to Sections 3-4

and 4-2 for further instructions.

-27-

SECTION 7: MAINTENANCE

Software Revisions:To find the current software release, either visit the City Theatrical, Inc. website

www.citytheatrical.comor contact City Theatrical, Inc. directly. To find out

which release of software your AutoYoke is operating on, go to the Release

submenu on the control panel. See Section 4-7, Software Release, for further

instructions.

Spare Parts:Contact City Theatrical or your dealer for AutoYoke spare parts information.

Lighting Fixture:Refer to lighting fixture user manual for all information regarding lighting fixture

maintenance.

SECTION 8: WARRANTY

Limited Warranty:The AutoYoke is covered by a one year parts and labor limited warranty from the

date of purchase by the original owner. It is the original owner’s responsibility to

provide documentation of the purchase date and dealer. In the event that this

documentation can not be provided, City Theatrical Inc. will begin the warranty

period on the manufacturing date. During the warranty period, AutoYokes will be

repaired or replaced at the discretion of City Theatrical, Inc.

Any lighting fixtures or devices that are connected with the AutoYoke other than

those clearly authorized by City Theatrical Inc. will void the AutoYoke warranty.

City Theatrical Inc. will not be responsible for any authorized lighting fixtures or

devices that are incorrectly connected to the AutoYoke.

Procedure: Contact City Theatrical Inc. to obtain a Return to Manufacturer Authorization

number prior to shipping. All products that are returned to City Theatrical, Inc.

must be clearly marked with the Return to Manufacturer Authorization (RMA)

number on the exterior of the shipping container. City Theatrical Inc. will refuse

any product/s that are returned without a Return to Manufacturer Authorization

number. A detailed explanation of the alleged failure or malfunction must be

included inside the shipping container.

The purchaser of the product will pay all shipping expenses. City Theatrical Inc.

will pay for return shipping of products under warranty in the continental United

States, excluding overnight, rush or expedited shipping. All products returned to

City Theatrical Inc. must be packaged in a shipping container that adequately

protects the contents. City Theatrical Inc. will not be responsible for any damage

incurred during shipping.

-28-

Other manuals for AUTOYOKE

2

Table of contents

Other City Theatrical Lighting Equipment manuals

City Theatrical

City Theatrical QolorPoint User manual

City Theatrical

City Theatrical 1504 User manual

City Theatrical

City Theatrical QolorPoint User manual

City Theatrical

City Theatrical QolorFLEX User manual

City Theatrical

City Theatrical QolorFLEX 4x5A DINrail Dimmer User manual

City Theatrical

City Theatrical Follow Spot Yoke User manual

City Theatrical

City Theatrical QolorFLEX 5917 User manual