CLARIUS EP PLUS IEP-810 User manual

Clarius EP PLUS

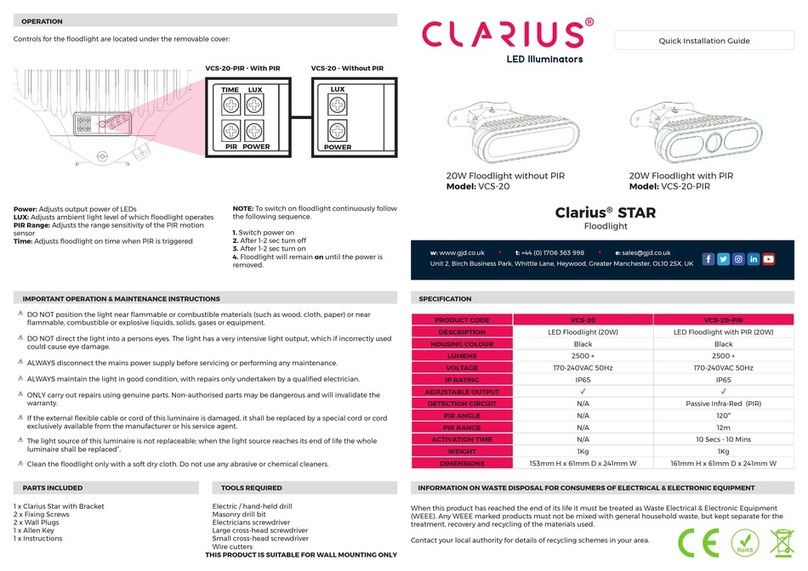

LED FLOODLIGHT

Installation Guide

CERTIFICATION: SIRA09ATEX5159X AND IECEx SIR 09.0064X AND ABS 11-LD801943-PDA

II 2 G D Ex emb IIC T4 Gb Ex t IIIC T103oC Db IP66/67 T4 -20 oC to +50 oC

CONTENT

1. SAFETY INSTRUCTIONS

2. INSTALLATION

3. MAINTENANCE

4. TECHNICAL SPECIFICATION

5. TROUBLE SHOOTING

IMPORTANT INFORMATION

The Clarius EP Plus series of explosion protected oodlights are specialist devices, certied for use in

hazardous gas and dust operating environments.

The units must be installed in accordance with these instructions, must be correctly certied for the

specic operating environment and must be installed by suitably qualied personnel.

If you have any queries about the installation or the certication of the unit – please contact GJD for

immediate assistance and advice.

Unit 2 Birch Business Park, Whittle Lane, Heywood, Lancashire, OL10 2SX

www.gjd.co.uk [email protected] +44 (0) 1706 363 998

Clarius®

1. SAFETY INSTRUCTIONS

1. Read this leaet carefully before commencing to install the Clarius EP Plus unit and retain it for future

use. Installation can only be carried out by suitably qualied personnel.

2. Check the certication nameplate attached to the oodlight to ensure that the mains supply and

the ambient temperature present is suitable for the unit being installed.

3. If the Clarius EP Plus unit is to be installed in areas of high vibration, please consult with GJD.

4. The Clarius EP Plus unit housing is constructed from marine grade aluminium and polycarbonate. The

end user must ensure that these materials are suitable for the atmosphere the Clarius EP Plus unit will

be installed in.

5. The temperature rise on the incoming mains cable is 61oC above the ambient conditions. Select

suitable cable and ATEX/IECEx cable glands. For advice on suitable glands and cables, please con

tact GJD. All unused entries must have a suitable approved stopper plug tted.

2. INSTALLATION

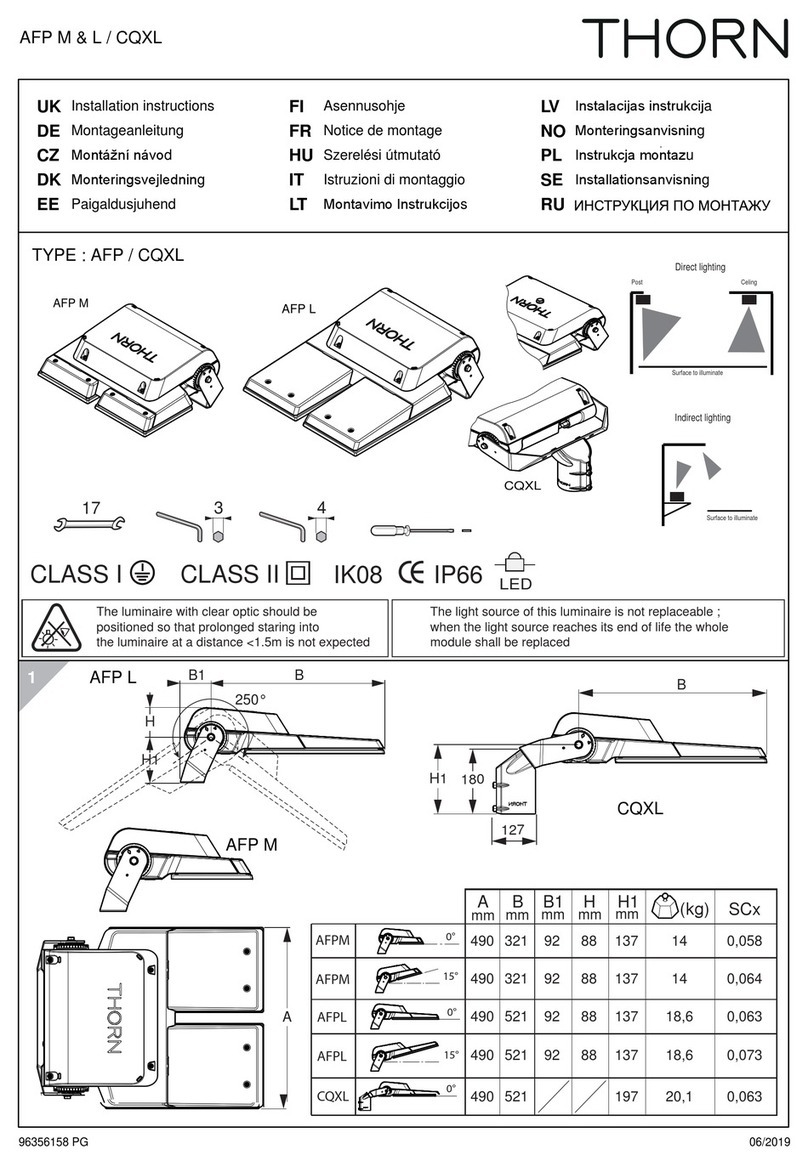

MOUNTING Clarius EP Plus UNIT

1. To meet the requirements of certication a MINIMUM of two xing points must be used. The xing

points must be suitable for the conditions of use. The drawing below shows horizontal mount, single

unit. For multiple mounting brackets and other mounting options please contact GJD.

www.gjd.co.uk

Tel: +44 (0) 1706 363 998

2. The unit may have been ordered and supplied with an integrated photocell. Care should be taken

when positioning the unit to ensure the sensor is not shielded, is not pointing directly at another light

source and is monitoring the general, prevailing light conditions.

3. The mounting bracket for the Clarius EP Plus oodlight is packed separately in the carton. The bolts in

the side of the housing shall be removed and used to secure the bracket to the Clarius EP Plus

housing. It is very important that the red bre washers are tted between the Clarius EP Plus housing

and the mounting bracket. The unit must be aligned rst before securing the bracket. The unit can

be mounted horizontally or vertically allowing the unit to point up/down or left/right, 2 additional

holes allow the bracket/fasteners to be moved to suit mounting application. An external eye bolt is

supplied to allow safety chains/suspension cords to be tted if required.

POWER CONNECTIONS

4. Wire the Mains cable into the terminal block. Provision has been made for this and identied as the

E (Earth), L (Live) and N (Neutral) terminals. There are two pairs of contacts for each of these to

facilitate a mains cable that can be looped in and out of the unit.

5. The installer should earth the unit separately.

6. Connect wires to mains supply; Blue=neutral: Brown=Live: Green/Yellow=Earth

7. Isolate the unit before opening.

www.gjd.co.uk

ADDITIONAL IMPORTANT INFORMATION

Note: Torque = Newton Meter (Nm)

8. All Clarius EP Plus units have terminal blocks suitable for 4mm2 live, neutral and earth.

9. To maintain an IP rating of 66/67 All M6 socket head cap bolts xing the

polycarbonate lid to the enclosure shall be tightened down to 2.5 Nm.

10. When installing the unit the special conditions for safe use should be adhered to –

i. Except for internal wiring, not more than one single or multiple strand lead shall be

connected into either side of any terminal unless multiple conductors have been joined in

a suitable manner, e.g. two conductors into a single insulated crimped boot lace ferrule.

ii. Leads connected to the terminals shall be insulated for the appropriate voltage and this

insulation shall extend to within 1 mm of the metal of the terminal throat.

iii. When terminals in accordance with certicate Sira 01ATEX3247U are used, all terminal

screws, used and unused, shall be tightened down to between 0.5 Nm and 0.7 Nm.

iv. When terminals in accordance with certicate Sira 01ATEX3249U are used, all terminal

screws, used and unused, shall be tightened down to between 1.2 Nm and 2 Nm.

v. When terminals in accordance with certicates Sira 01ATEX3247U and Sira 01ATEX3249U

are used, they shall only be installed and wired with cable within a temperature range of

-10°C to +80°C.

vi. When cross-connecting combs are used on terminals to certicates Sira 01ATEX3247U and

Sira 01ATEX3249U, the relevant conditions certication associated with those certicates

shall be applied.

vii. Cable entry holes shall be tted with either an appropriately certied cable gland or

appropriately certied blanking element. These shall provide and maintain a minimum

enclosure ingress protection of IP66 or IP67 as appropriate.

viii. If more than 8 individual LED’s are not illuminated the LED assembly must be replaced.

ix. When the optional fuse is not tted, the supply circuit must be protected by a fuse capable

of withstanding a prospective short circuit current of 1500A

Tel: +44 (0) 1706 363 998

3. MAINTENANCE

1. Isolate the Clarius EP Plus unit from the mains supply and allow it to cool before carrying out

any maintenance work.

2. In the unlikely event of the failure of a string of LED’s (6 or 8), the assembly must be re

placed. Contact GJD for immediate assistance and advice.

3. It is essential that all Clarius EP Plus units are maintained in accordance with the

requirements of the EN60079-17 standard: Electrical apparatus for explosive gas

atmospheres – other than mines.

4. IMPORTANT! No modications are permitted to the unit. All spare parts must be purchased

from the manufacturer or authorized distributor. Any unauthorized modications or spare

parts may make the apparatus dangerous and invalidate certication.

5. ELECTROSTATIC CHARGING HAZARD - Plastic components may be cleaned with water

containing a small amount of detergent, followed by a clean water wash. Surplus water

can be wiped off plastic components, but they should not be wiped or polished with a dry

cloth to avoid a build-up of static electricity. Strong cleaning solvents could cause damage

to plastic components.

6. Disposal of packaging, Clarius EP Plus units and old LED assemblies should be carried out in

accordance with national regulations.

4. TECHNICAL SPECIFICATION

CERTIFICATION

II 2 G D Ex emb IIC T4 Gb SIRA09ATEX5159X

Ex t IIIC T103°C Db IP66/67 IECEx SIR09.0064X

Ta = -20°C to +50°C ABS 11-LD801943-PDA

Clarius EP Plus SPECIFICATION

Input Voltage 24V AC/DC or 100-240V AC

Consumption 60W max

Power Factor >0.95 or better

Mains Frequency 50/60Hz

IP Rating 66/67

Single Unit Weight 6Kg per module

Dimensions 250 135 x 315mm

ATEX and IECEx Rating Zone 1 gas and dust hazardous environments

Unit 2 Birch Business Park, Whittle Lane, Heywood, Lancashire, OL10 2SX

www.gjd.co.uk [email protected] +44 (0) 1706 363 998

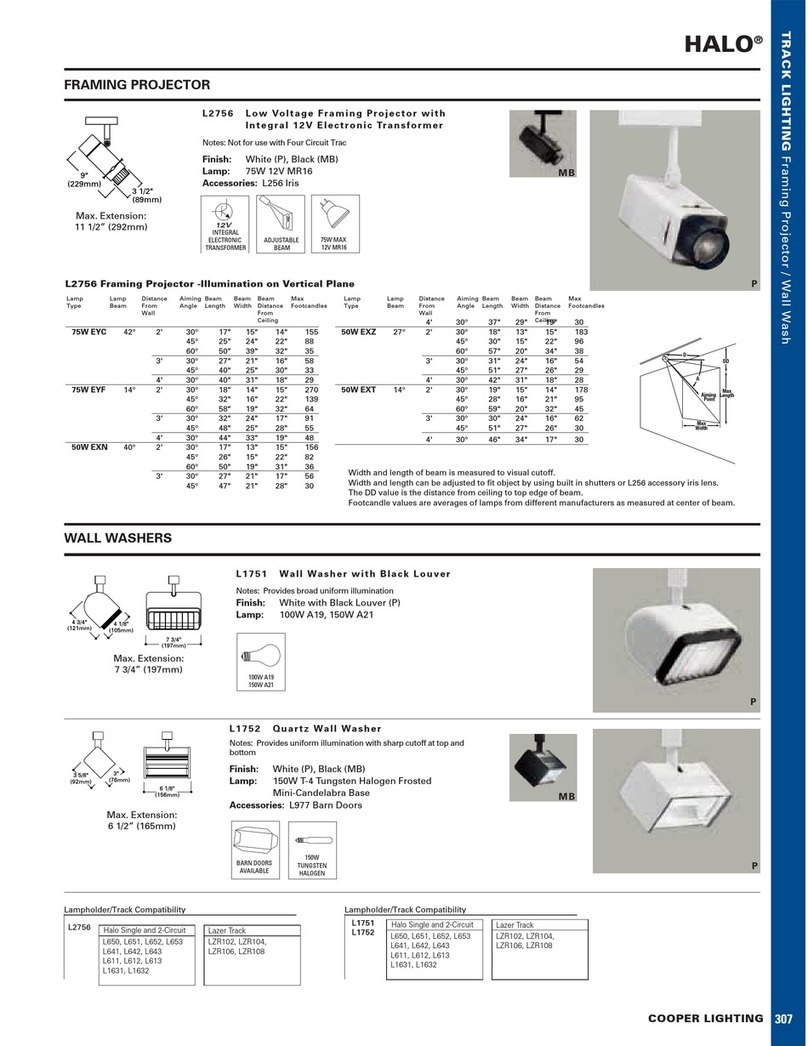

Ordering codes Clarius EP Plus Floodlight

MODEL NUMBER WAVELENGTH ANGLE DISTANCE FOV

IEP-810 850nm 10 150m 492ft 26m 85ft

IEP-830 850nm 30 80m 262ft 42m 137ft

IEP-860 850nm 60 56m 184ft 64m 210ft

IEP-810-PC 850nm 10 150m 492ft 26m 85ft

IEP-830-PC 850nm 30 80m 262ft 42m 137ft

IEP-860-PC 850nm 60 56m 184ft 64m 210ft

MODEL NUMBER ANGLE DISTANCE FOV

VEP-CW10 10 120m 394ft 21m 69ft

VEP-CW30 30 65m 262ft 34m 111ft

VEP-CW60 60 45m 184ft 52m 170ft

VEP-CW10-PC 10 120m 394ft 21m 69ft

VEP-CW30-PC 30 65m 262ft 34m 111f

VEP-CW60-PC 60 45m 184ft 52m 170ft

Infra Red

White Light

Please contact GJD for alternative mounting options, voltages, colour of LEDs etc.

Multiple units are also available.

5. TROUBLE SHOOTING

1. Ensure the two LED boards are correctly wired to terminal block.

Red to Red: Black to Black

2. Ensure Mains input is correctly connected.

Earth to Yellow/Green: Live to Brown: Neutral to Blue

3. Ensure Mains Input is turned on at the source.

This manual suits for next models

11

Table of contents

Other CLARIUS Floodlight manuals