Clark-Reliance Levalarm EA100 Series Instruction Manual

InstructionsforInstallingandOperatingClark‐

RelianceEA100SeriesLevalarm®

Thismanualcoversthefollowingmodelnumbers:EA100D,EA100S,EA100SW,EA100DP,EA100SP,

EA100DRPT,andEA100SRPV

Section: R500.532F

Bulletin: 532F

Date: 7/1/2015

Supersedes: 532E

16633 Foltz Parkway, Strongsville, OH 44149 USA

Telephone: (440) 572-1500 Fax: (440) 238-8828

www.clark-reliance.com

STORAGE and HANDLING

All units should be inspected upon receipt to ensure that no damage has been incurred during transit.

If there is a claim due to damage, it should be filed with the carrier immediately. Clark-Reliance Boiler

Trim products should be stored in a dry and sheltered area prior to installation. The equipment

provided may consist of electrical items that are intended for either indoor or outdoor use. As a matter

of good practice, dry storage will prevent the products from exposure to the outdoor elements. This

will eliminate the potential for water damage. The temperature of the storage area should not exceed

150 Deg. F (84 Deg. C) or drop below 32 Deg. F (0 Deg. C).

OPERATION

A stainless steel float swings at the end of a pivot rod. The rod head carries an Alnico V magnet. The

magnet attracts one leg of a U-shaped armature which is attached to a micro switch leaf actuator. A

buoyed float holds the switch open or closed, depending on which terminals are used. As liquid falls

in the chamber, the float drops and directs the magnet to the opposite position. A closed switch

actuates alarms. An open switch achieves fuel cut-out.

INSTALLATION

Caution: Before proceeding, follow any and all plant lock out - tag out procedures required. Verify

that all power is turned off to the Levalarms. If under pressure, the equipment should be isolated, or

the boiler should be shut down before proceeding with the installation. Open drain valve to eliminate

any trapped pressure. All inspection and installation steps should be performed by a qualified

technician and should be executed in accordance with all applicable national and local codes

EA100 Series Levalarm dimensional information.

(Please refer to applicable drawing for component information.)

Standard connections for the EA100 Series Levalarms are 1” FNPT for threaded connections or 1”

FSW for socket weld connections. The Levalarm should be installed with the reference arrow (switch

point) at the level where the alarm or trip is specified. Shut off valves above and below the Levalarm

should be installed for safe inspection or repair of the unit. However, these valves must be locked

open when the boiler is in service.. Also, a drain connection with a shut off valve should be installed

to a point of safe discharge to facilitate blowdowns. Below is a typical arrangement for the installation

of the Levalarm.

After the piping has been installed to the body of the Levelarm, the switch should connected by

following this procedure:

1. Remove the switch cover in order to access the connections on the switch assembly by

loosening the screw ot the bottom of the dome shaped cover.

2. Use the 7/8” Dia. opening in the switch housing assembly for connecting flexible or rigid

conduit when wiring the unit.

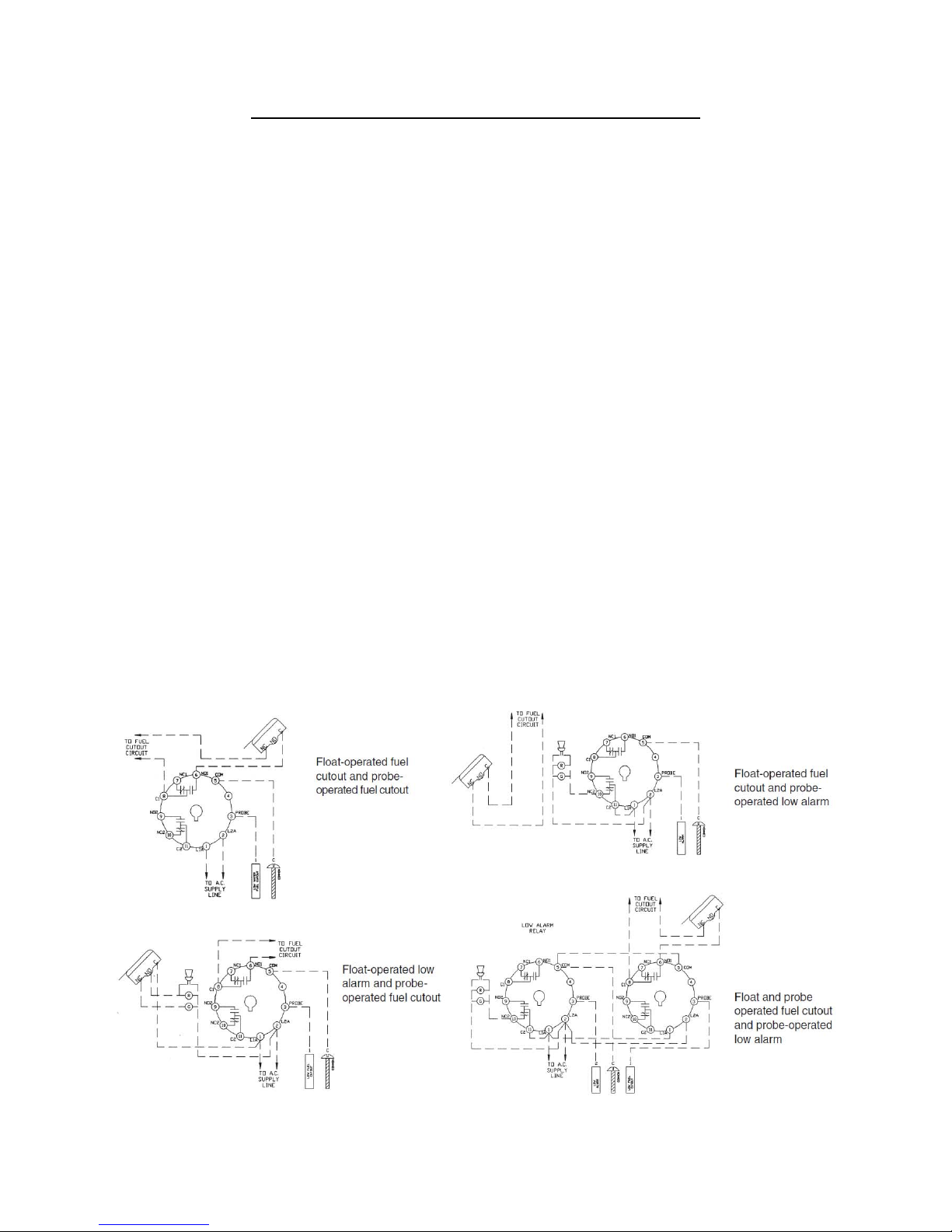

3. Example wiring diagrams for connectiong the low water cutout, alarms (such as lights or and

audible signal), etc, are illustrated below.

4. After checking that all connections are tight and correct, replace the switch cover, as the unit is

now ready do be put in operation.

LowWaterCutoutLevel

Note:Somejurisdictionsdonotpermitthe

installationofisolationvalvesasshown.

ConsultapplicableCodesbeforeinstallation.

CAUTION: Make sure that all wire leads to the switch do not interfer with the operation of the switch

actuator before replacing the switch cover!

NOTE: It is recommended that periodic inspection and routine maintenance be conducted to ensure

that the Levalarm continues to work properly. This can be conducted by following the procedure:

1) Isolate the Levalarm by closing the steam and water isolation valves.

2) Open the drain valve to drain the unit and relieve any internal pressure.

3) Remove the switch cover, disconnect the wiring and the conduit.

4) Using a ¾” wrench or socket for the bolt and a 7/8” wrench or socket for the nut, remove the

nuts on the flanged cover (4 nuts on the EA100D and 6 nuts on the EA100S/EA100SW).

Discard old gasket.

5) Removing the flange provides complete access to the float and switch assembly.

6) Inspect the float to make sure that water has not leaked directly into the float.

7) Check to make sure the float and pivot rod assembly freely moves up and down and does not

stick or bind.

8) Inspect the magnet tube to make sure there is no contamination in the tube or attached to the

magnet itself.

9) After the inspection is complete, re-assemble the flanged switch assembly to the body using a

new part number C1-3 gasket. The gasket may be held in place by applying a silicone based

pipe joint compound onto the flange gasket surface. Make sure the flange unit is oriented

properly.

10)Lubricate the threads on the bolts with a high temperature nickel based lubricant. Torque the

bolting in the proper sequence (see below) to 70 ft-lbs in 1/3rd increments.

11)Re-install the conduit and the wiring.

Bolt Torqueing Pattern:

MODELS WITH PROBES - EA100DP AND EA100SP

For Levalarms with optional probes, follow this procedure after piping has been connected to body of

the unit:

1. Install relay control unit at any convenient location, as the connecting wires may be of any

reasonable length up to 1000 ft. Verify that the control unit is rated for the correct supply line

voltage and frequency (cycles).

2. Install optional light indicator, or horn, or both at a convenient location for the operator.

3. Remove the probe fitting housing. This will give you access to the terminals on the probe

assemblies for wiring. Verify with a calibrated torque wrench that the probe fittings are torqued

to 40 Ft-Lb. The conduit bracket has an 7/8” Dia. opening for the conduit.

4. Wire per wiring diagram. See below.

5. Replace probe fitting housing.

The probe assemblies have a 5/8"-24 UNEF thread and are furnished with a copper or monel gasket.

Stainless steel rods are connected to the probes with a coupling nut to make a complete assembly.

Probe installation and maintenance instructions can be found in IOM #R500.E189-A-3. The probe(s)

can be removed for inspection and cleaning by merely removing them from the Levalarm body with a

7/8” deep well socket. When replacing the probes, be sure to lubricate the threads and use a new

gasket. Probes can usually be cleaned by wiping with a damp cloth. Future cleaning frequency will

depend upon conditions of boiler water. Routine blowdowns help keep probes clean. Refer to IOM

#R500.E156C.

RELAY CONTROL UNIT

Please refer to actual relay control unit drawing provided with your system for details. ECID Series

Relay specifications can be found in IOM #R500.E137E

Instructions for Model EA100DRPT and EA100SRPV

RetroPak™ Probe Cap Assemblies

Identification:

- Model EA100DRPT is designed to fit Model EA100 or Model EA100D Levalarms, which have

a 4 bolt flange design.

- Model EA100SRPV is designed to fit Model EA100S Levalarms, which have a 6 bolt flange

design.

Installation Procedure:

This procedure must be performed with the boiler down to prevent any false alarms or wiring

hazard. Verify the power at the existing switch is off, before installing the upgrade.

1. Be certain there is no internal pressure on the Levalarm assembly.

2. Remove switch cover

3. Remove the existing wiring from switch.

4. Remove flange bolts (4 on EA100D models and 6 on EA100S models) and nuts.

5. Discard flange cover assembly with float mechanism.

6. Remove old flange gasket.

7. Install new flange gasket (Part No. C1-3).

8. Attach new flange cover.

9. Install bolts and nuts. Torque in an “X” pattern in 1/3 increments up to 70 Ft-Lbs.

10.Mount relay control unit at convenient location.

11.Attach high temperature wires (furnished) from probe and cap assembly (common wire) and

wire to relay socket terminals (See actual relay for wiring schematic diagram label).

12.Attach original switch wires from EA100 to the new relay location on the desired switch

contact terminals.

13.The relay will require a 120 VAC or 230 VAC power source depending upon the Part Number

(Use Relay Part No. ECID-23R for 120 VAC or Part No. ECID-56R for 230 VAC).

14.Recheck all wiring before returning to service.

15.Installation is complete.

Note: The relay can be installed in user supplied enclosure with a surface mount relay socket

(Part No. ECID-49) or the relay can be ordered already mounted in an Indoor or Outdoor

enclosure. Refer to bulletin D3.2C and D3.3C for additional information on relay control

options.

BLOWDOWNS

The importance of proper cleaning and maintenance of the Levalarm cannot be stressed enough. The

Levalarm must he kept clean to ensure the water level in the gage glass accurately represents the

water level in the boiler. Note that the frequency and method of blow-down may affect service life and

performance of the Levalarm.

The connection lines to the Levalarm can become clogged with sediment and indicate a normal water

levels when water may be low. After performing the blow-down procedure, if the water level does not

appear to return to normal promptly, the connecting piping may be partially clogged and have to be

cleaned.

Clark-Reliance suggests the following blow-down procedure:

1. Close both the steam and water valves between the boiler drum and the Levalarm unit.

2. Open the drain valve fully on the bottom of the Levalarm piping.

3. Crack open the steam valve and allow a gentle rush of steam to pass through the device. The

steam should not pass through for longer than 20 seconds.

4. Close the steam valve.

5. Close the blow-down valve and simultaneously open the steam and water valves, slowly bringing

the equipment back to a normal operating level.

6. Water should enter the Levalarm quickly when the blow-down valve is closed. This will indicate that

the lines are free of sludge, sediment, or scale buildup.

Note:

1. Any trip or alarm circuits that are actuated by the equipment being blown-down should be

bypassed to prevent false alarms during the blow-down process. A Clark-Reliance model HS-0 can

be used to by-pass the Low Water Cutout to prevent a false trip during the blow-down procedure.

2. Blow-down should be conducted on a weekly basis, or as necessary, based on water quality.

SPECIFICATIONS

Connection sizes: EA100D/EA100DP: 1” FNPT

EA100S/EA100SP: 1” FNPT

EA100SW: 1” FSW

Pressure Rating: EA100D/EA100DP: 350 PSI @ 432° F.

EA100S/EA100SP: 800 PSI @ 520° F.

EA100SW: 800 PSI @ 520° F

Float Switch Rating: UL listed and CSA approved SPDT

5A-125 VAC, 5A-250 VAC

1/2A-125 VAC, 1/4A-250 VAC

Switch Max. Temperature: 400° F.

Environment: Indoor or outdoor

TROUBLESHOOTING THE EA100 SERIES LEVALARM

Caution: Before proceeding, follow any and all plant lock out - tag out procedures required. All

installation steps should be performed by a qualified technician and should be executed in

accordance with all applicable national and local codes.

Symptom Probable Cause

1) Float is stuck in the “up” position” a) Contamination on magnet

b) Magnet too strong

c) Pivot Rod wear or contamination

Possible remedies:

1. Conduct a blow down, to ensure there is no water trapped in the unit.

2. Inspect the internal portion of the Levalarm Chamber

a. Isolate the Levalarm and make sure there is no pressure in the unit.

b. Remove the flange head assembly

c. Remove the stainless steel cotter pin(s) that hold the axle pin for the float rod in

place. Inspect the pivot point where the pivot rod is inserted. Make sure that the

hole in the magnet tube is not elongated. This can cause the float assembly to

hang up.

d. Remove, inspect, and clean the magnet, if needed.

e. Examine inside the opening of the magnet tube with a light to make sure there is

no debris trapped inside the tube.

3. Reassemble the unit. Be sure to use stainless steel cotter pins (if not reusing the

original ones) on the float rod axle pin. Reinstall the Switch head assembly onto the

body with a new C1-3 gasket and apply a Teflon based sealant to both sides of the

gasket. Lubricate the bolts with a Nickel based high temperature lubricant and torque

the 4 or 6 bolts to 70 FT-LB, in 1/3 increments.

4. Test the unit for proper functioning

a. To test the switch assembly, set the unit in a vise and make sure that the switch

housing is on the same 45 degree angle as if it were mounted on the boiler

piping.

b. Attach an ohm meter to the common and normally open switch contact and

manually move the float up and down and verify the switch operates on both

directions. The meter should indicate continuity only when the switch is operated

in the closed position.

c. Then, move the ohm meter terminal from the normally open terminal to the

normally closed terminal and repeat the test. The meter should indicate an open

circuit only when the switch is in the open position.

5. If the unit fails to test properly, contact Clark-Reliance for further instructions to adjust

the switch mechanism or to obtain authorization to return the unit for factory inspection.

If the switch tests OK, return unit to service.

Symptom Probable Cause

2) Float is stuck in the “down” position” a) Pivot Rod wear or contamination

b) Failed float

Possible remedies:

1. Inspect the internal portion of the Levalarm Chamber

a. Isolate the Levalarm and make sure there is no pressure in the unit.

b. Remove the flange head assembly

c. Remove the stainless steel cotter pin(s) that hold the axle pin for the float rod in

place. Inspect the pivot point where the pivot rod is inserted. Make sure that the

hole in the magnet tube is not elongated. This can cause the float assembly to

hang up.

d. Remove, inspect the float assembly.

e. If the float contains water or shows signs of obvious damage, such as collapse or

a crack near the spud where the float rod attaches, replace the float (Ref: Part #

F3S) and use Loctite or equal on the threads of the float and float rod. Tighten

the new float securely onto the float rod

2. Reassemble the unit. Be sure to use stainless steel cotter pins (if not reusing the

original ones) on the float rod axle pin. Reinstall the Switch head assembly onto the

body with a new C1-3 gasket and apply a Teflon based sealant to both sides of the

gasket. Lubricate the bolts with a Nickel based high temperature lubricant and torque

the 4 or 6 bolts to 70 FT-LB, in 1/3 increments.

3. Test the unit for proper functioning

a. To test the switch assembly, set the unit in a vise and make sure that the switch

housing is on the same 45 degree angle as if it were mounted on the boiler

piping.

b. Attach an ohm meter to the common and normally open switch contact and

manually move the float up and down and verify the switch operates on both

directions. The meter should indicate continuity only when the switch is operated

in the closed position.

c. Then, move the ohm meter terminal from the normally open terminal to the

normally closed terminal and repeat the test. The meter should indicate an open

circuit only when the switch is in the open position.

4. If the unit fails to test properly, contact Clark-Reliance for further instructions to adjust

the switch mechanism or to obtain authorization to return the unit for factory inspection.

If the switch tests OK, return unit to service.

Symptom Probable Cause

3) Float arm operates properly, but the

switch does not change state. a) The EA100-14X switch is out of

adjustment

b) The EA100-14X switch has failed

1. Test the EA100-14X Microswitch

a. Isolate the Levalarm and make sure there is no pressure in the unit.

b. Remove the flange head assembly

c. Remove the Switch cover

2. Test the unit for proper functioning

a. To test the switch assembly, set the head assembly in a vise and make sure that

the switch housing is on the same 45 degree angle as if it were mounted on the

boiler piping.

b. Attach an ohm meter to the common and normally open switch contact and

manually move the float up and down and verify the switch operates on both

directions. The meter should indicate continuity only when the switch is operated

in the closed position.

c. Then, move the ohm meter terminal from the normally open terminal to the

normally closed terminal and repeat the test. The meter should indicate an open

circuit only when the switch is in the open position.

3. If the unit fails to test properly, contact Clark-Reliance for further instructions to adjust

the switch mechanism or to obtain authorization to return the unit for factory inspection.

If the switch tests OK, return unit to service.

4. Reassemble the unit. Reinstall the Switch head assembly onto the body with a new C1-

3 gasket and apply a Teflon based sealant to both sides of the gasket. Lubricate the

bolts with a Nickel based high temperature lubricant and torque the 4 or 6 bolts to 70

FT-LB, in 1/3 increments.

SPARE PARTS

PART NUMBER DESCRIPTION

EA100-14X SWITCH ASSEMBLY

F3S FLOAT

C1-3 GASKET

X172372 CAP BOLT

X171501 NUT

T***RK ‘T’ probe for models with probes (up to 250 PSI)

V***RK ‘V’ probe for models with probes (251 to 800 PSI)

*** = Probe Length measured from gasket surface of Probe fitting body. First (2) digits indicate length in whole inches, 3rd digit indicates

additional one-eighths of an inch.

Warning: If this equipment is used in a manner not specified by Clark-Reliance, the protection

provided by the equipment may be impaired. Only replacement parts manufactured by Clark-Reliance

should be used to ensure safety and reliable operation.

The use of non-Clark-Reliance parts will void the factory warranty and any agency approvals.

Order genuine Clark-Reliance replacement parts at: http://parts.clark-reliance.com or contact your

local Clark-Reliance Representative.

Any additional questions should be directed to your local Clark-Reliance Representative, or to the

Factory: Phone: (440) 572-1500 Fax: (440) 238-8828

This manual suits for next models

7

Table of contents

Other Clark-Reliance Industrial Equipment manuals