3Product description

3.1Configuration

The scope of delivery encompasses:

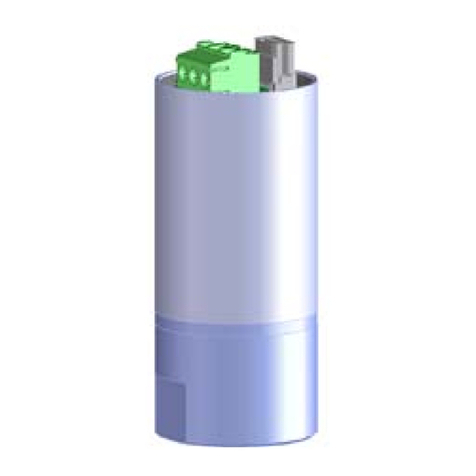

l19"module card VEGALOG 571 AT

lDocumentation

-this operating instructions manual

3.2Principle of operation

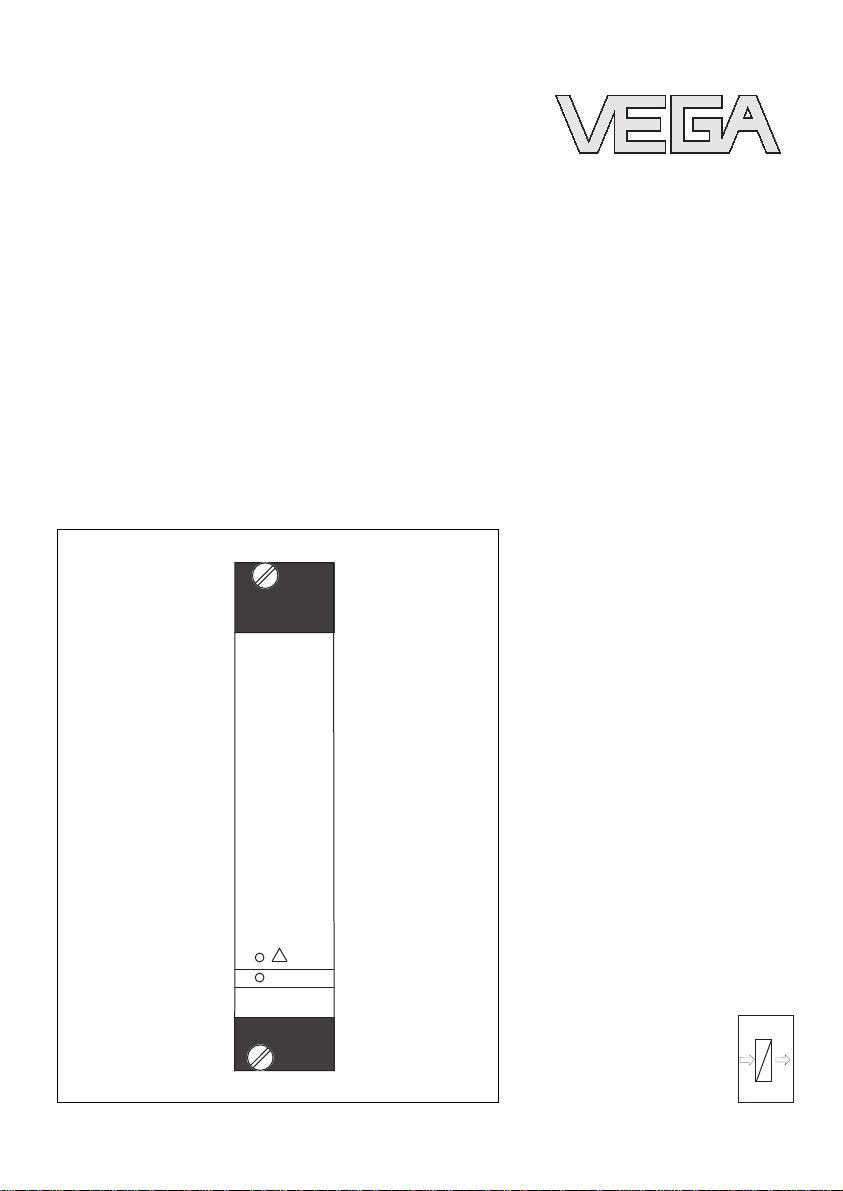

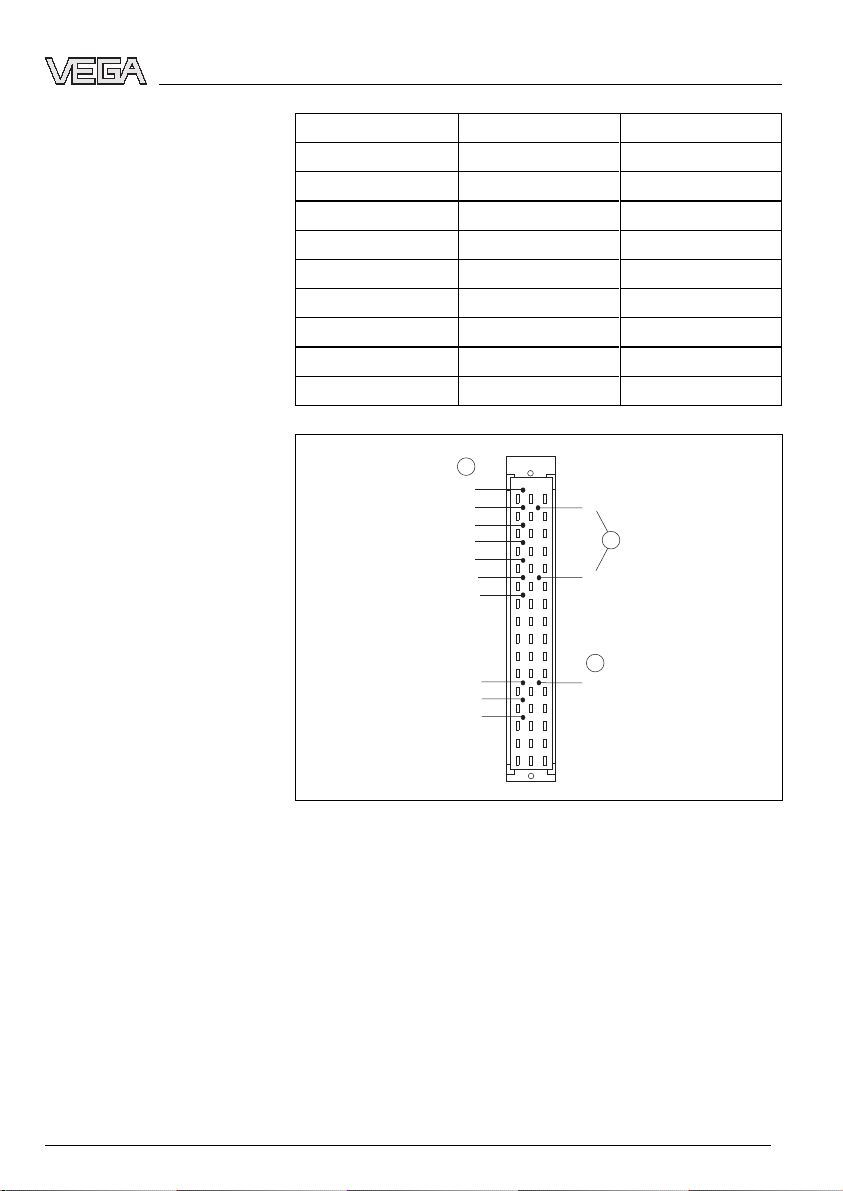

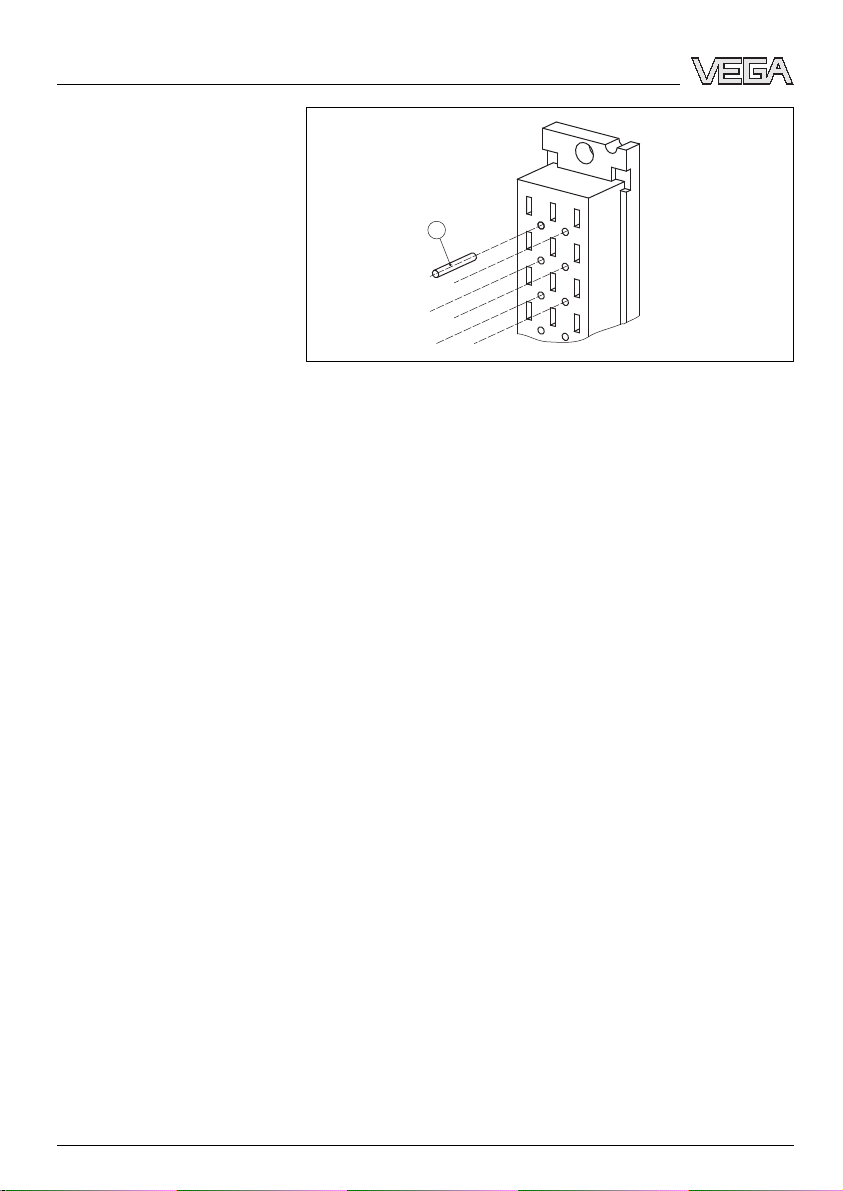

The AT card (output transistor)provides together with the

VEGALOG 571 processing system ten floating outputs via

NPN transistors.

These can be used for transmission of the measuring results,

e.g.to binary input cards of a PLC.

The VEGALOG 571 AT card makes the processing results

available on up to ten outputs.It is suitable for outputting level,

single or sum fault messages.The switching condition of each

output is displayed via a two-coloured LED in the front plate.

Depending on the parameter adjustment,this LED lights

yellow as switching output,or if so configured,red as fault

output.

The voltage supply of the module card is provide via the

common power supply unit of the VEGALOG system.

You can find detailed information on the power supply in the

"Technical data"in the "Supplement".

3.3Operation

The operation of VEGALOG 571 is carried out via a PC which

can be connected via the RS232 interface of the CPU.Asan

alternative,connection via Ethernet and VEGACOM 558 is

possible.

The adjustment software PACTware™with the corresponding

DTMs is installed under Windows™and ensures easy

configuration of measuring systems as well as parameter

adjustment of connected VEGA sensors.For this purpose,

PACTware™provides a clear adjustment interface with menu

structure,window technology and graphic support.In addition,

online help is available which describes the available functions

Scope of delivery

Area of application

Physical principle

Power supply

6VEGALOG 571 AT -Output card transistor

Product description

31951-EN-060720