2

tABlE oF contEntS

iMPoRtAnt SAFEtY inFoRMAtion 3

4

gEnERAl inFoRMAtion 5

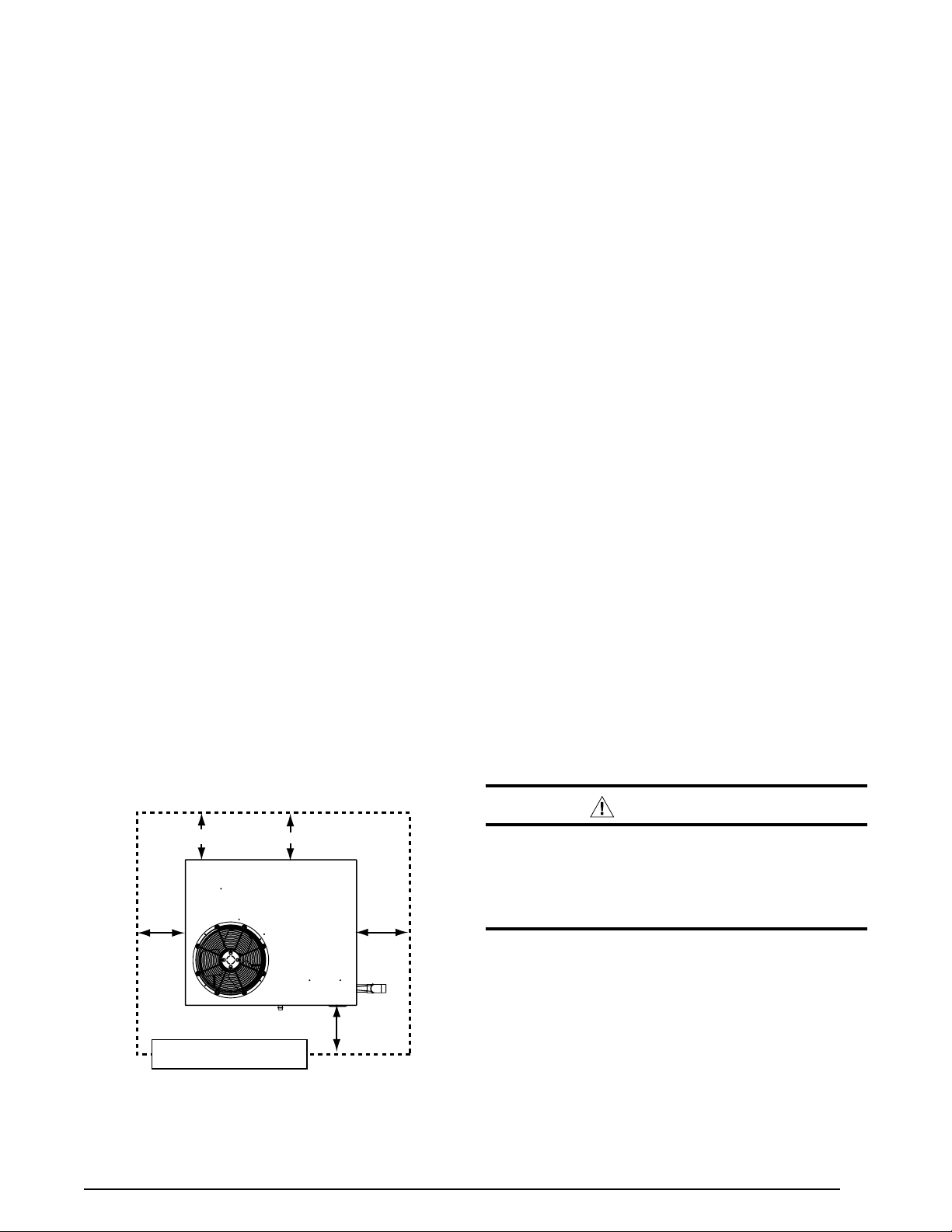

Before you install this unit ........................................................... 5

Locating the Equipment .............................................................. 5

Heating Load ............................................................................... 5

5

Vent Termination.......................................................................... 6

ciRcUlAting AiR SUPPlY 7

Air Ducts...................................................................................... 7

Unconditioned Spaces................................................................ 7

Acoustical Duct Work.................................................................. 7

Unit inStAllAtion 7

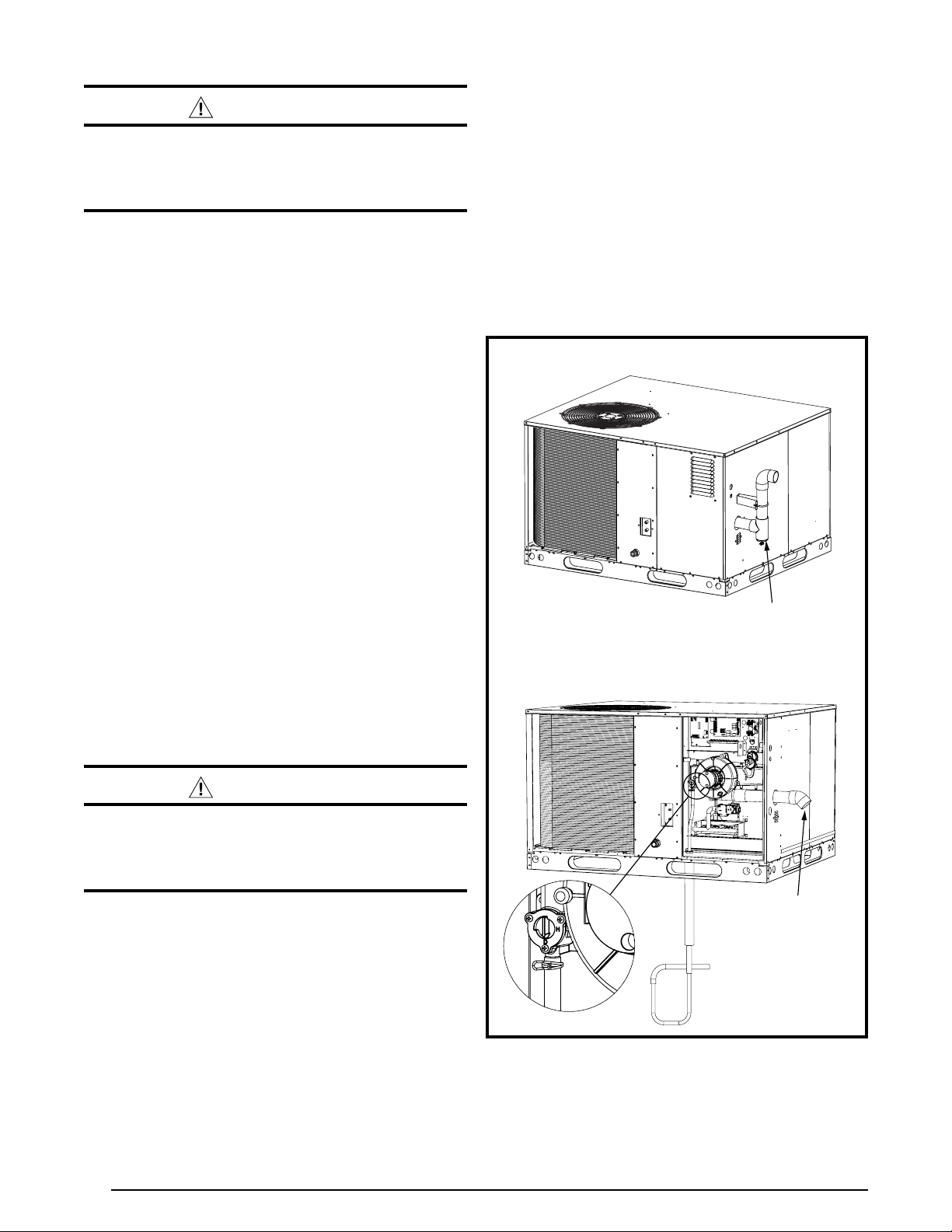

Packaging Removal..................................................................... 7

Rigging & Hoisting....................................................................... 7

Clearances to Combustible Materials......................................... 8

Ground Level ............................................................................... 8

Rooftop ........................................................................................ 8

Horizontal to Downflow Conversion............................................ 9

Condensate Drain (Air Conditioning).......................................... 9

Air Filter Requirements................................................................ 9

Removal of Internal Filter Rack................................................... 9

Installing Filters in the Internal Filter Rack.................................. 9

1” to 2” Filter Conversion ......................................................... 9

Removing Filters from Internal Filter Rack.................................. 10

ElEctRicAl WiRing 11

Pre-Electrical Checklist............................................................... 11

Grounding.................................................................................... 11

Line Voltage................................................................................. 11

Unbalanced 3-Phase Supply Voltage......................................... 12

Thermostat / Low Voltage Connections...................................... 12

2-Stage Heat / 1-Stage Cool Thermostat ................................ 12

Single Stage Heat / Single Stage Cool Thermostat................. 12

Heat Anticipator........................................................................... 13

Cooling Configurations................................................................ 13

Heating Configurations................................................................ 13

Blower Speed .............................................................................. 13

Configuring the Fixed Speed Blower ....................................... 13

Selecting Cooling Airflow......................................................... 13

Selecting Heating Airflow......................................................... 13

Dehumidification Options............................................................ 14

Optional Furnace Control Board Connections............................ 14

Electronic Air Cleaner.............................................................. 14

Humidifier ................................................................................ 14

15

Leak Check.................................................................................. 15

High Altitude Conversion - Natural Gas...................................... 16

LP / Propane Gas Conversion..................................................... 16

18

Pre-Start Check List.................................................................... 18

Start-Up Procedure ..................................................................... 18

Air Circulation .......................................................................... 18

Lighting the Appliance............................................................. 18

Verifying System Heating ........................................................ 19

Verifying & Adjusting Temperature Rise .................................. 19

Gas Supply Pressure Verification & Adjustment...................... 19

Verifying the Firing Rate of the Appliance ............................... 19

Measuring the Manifold Pressure............................................ 20

Adjusting the Manifold Pressure.............................................. 20

Removing the Manometer/Pressure Gauge............................ 20

Verifying Over-Temperature Limit Control Operation............... 20

Verifying Burner Operation...................................................... 21

Verifying System Cooling......................................................... 21

oPERAting SEQUEncE 21

Heating Mode .............................................................................. 21

Thaw Cycle Start Up / Shutdown ................................................ 22

Blocked Vent / Condensate Disposal Shut Down....................... 23

Cooling Mode - Single Stage Operation ..................................... 23

De-Humidification Control........................................................... 23

Fan Mode..................................................................................... 23

coMPonEnt FUnctionS 23

EQUiPMEnt MAintEnAncE 24

Heat Exchanger & Burner Maintenance ..................................... 24

Cleaning of Burners..................................................................... 25

REPlAcEMEnt PARtS 25

tRoUBlESHooting 25

Cooling Mode .............................................................................. 25

Heating Mode .............................................................................. 25

26

Figure 8. Unit Dimensions ....................................................... 26

Table 7. Center of Gravity & Shipping Weights........................ 27

28

Table 8. Cooling Airflow Settings ............................................. 28

Table 9. Heating Airflow Settings............................................. 28

Table 10. Blower Performance - 2 & 2.5 Ton............................ 29

Table 11. Blower Performance - 3 Ton ..................................... 30

Table 12. Blower Performance - 3.5 Ton .................................. 31

Table 13. Blower Performance - 4 & 5 Ton............................... 32

33

Table 14. Gas Pipe Capacities................................................. 33

Table 15. Gas Flow Rates........................................................ 33

Figure 9. Gas Valve Label........................................................ 34

35

Table 16. Electrical Data.......................................................... 35

Table 17. Copper Wire Size ..................................................... 35

Table 18. Thermostat Wire Gauge........................................... 35

36

Figure 10. Two Stage Heating / Single Stage Cooling

Configuration........................................................... 36

Figure 11. Fixed Speed Motor Control Board .......................... 36

Figure 12. Ignition Control Board - 624817 ............................. 36

37

Figure 13. Single Phase, 2-5 Ton, 208/230V .......................... 37

Figure 14. Three Phase, 3-5 Ton, 208/230V............................ 38

Figure 15. Three Phase, 3-5 Ton, 460V................................... 39

40

Figure 16. Charging Chart for 2 Ton Units ............................... 40

Figure 17. Charging Chart for 2.5 Ton Units ............................ 40

Figure 18. Charging Chart for 3 Ton Units ............................... 41

Figure 19. Charging Chart for 3.5 Ton Units ............................ 41

Figure 20. Charging Chart for 4 Ton Units ............................... 42

Figure 21. Charging Chart for 5 Ton Units ............................... 42

43

Figure 22. Filter Comversion ................................................... 43

44

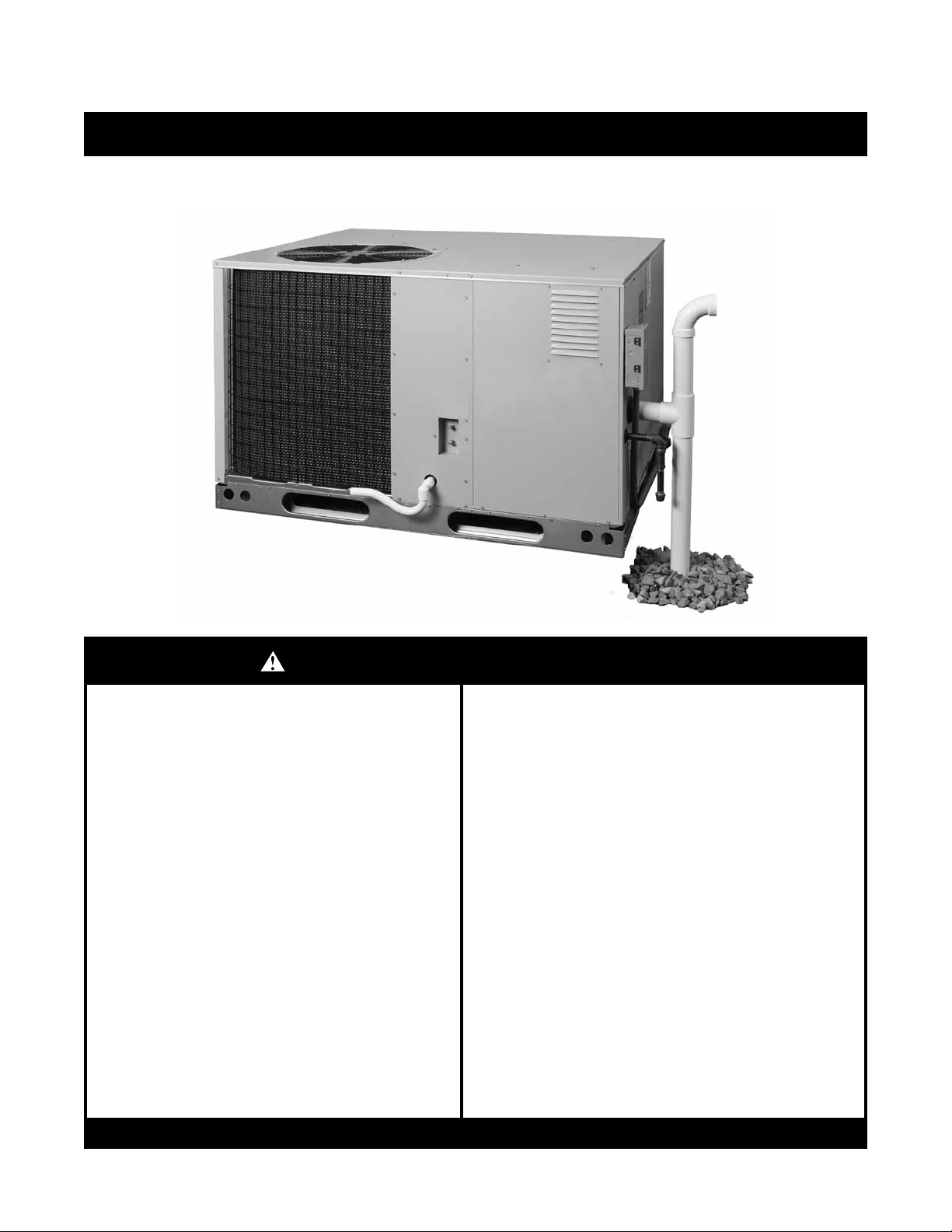

About the Kit................................................................................ 44

Vent Pipe & Drain Hose Assembly.............................................. 44

Vertical Drain Pit Method ............................................................ 44

Preparing the pit...................................................................... 45

Percolation Test (Optional) ...................................................... 45

Vertical Drain Pipe Installation................................................. 45

Horizontal Drain Trench Method ................................................. 45

Preparing the Trench ............................................................... 46

Horizontal Drain Pipe Installation ............................................ 46

Completing the Vent Installation ................................................. 46

48

About the Kit................................................................................ 48

Before Setting unit on the Curb................................................... 48

Setting the Unit............................................................................ 49

Completing the Heat Exchanger Condensate Drain Installation 49

Completing the Vent Pipe Installation and Assembly................. 49

inStAllAtion / PERFoRMAncE cHEck liSt 52