Mounting Instructions

ProfiDAT®compact

Data Transmission System

MAL0515-0001i-EN

www.conductix.com Translated from MAL0515-0001k-DE Page 3 of 169

3Technical Data ....................................................................................................................................................................... 24

3.1 General information................................................................................................................................................ 24

3.2 Interfaces................................................................................................................................................................ 24

3.2.1 Electrical / Electronic .............................................................................................................................................. 24

3.2.2 Control signal cycle times....................................................................................................................................... 26

3.2.3 Data transfer limitations.......................................................................................................................................... 26

3.2.4 Network integration................................................................................................................................................. 26

3.2.5 Mechanical ............................................................................................................................................................. 27

3.3 Transceiver technical data...................................................................................................................................... 27

3.4 Transceiver housing technical data........................................................................................................................ 29

3.5 Passive HF components technical data ................................................................................................................. 31

3.5.1 HF cables ............................................................................................................................................................... 31

3.5.2 Further passive HF components ............................................................................................................................ 34

3.6 Operating conditions............................................................................................................................................... 35

3.7 Type plate............................................................................................................................................................... 36

4Product Description and Functional Principle ........................................................................................................................ 37

4.1 Overview................................................................................................................................................................. 37

4.2 Brief description...................................................................................................................................................... 38

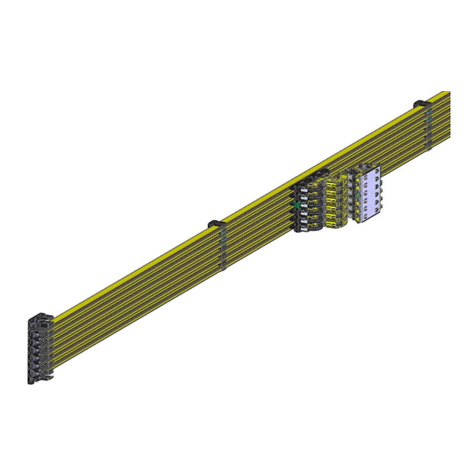

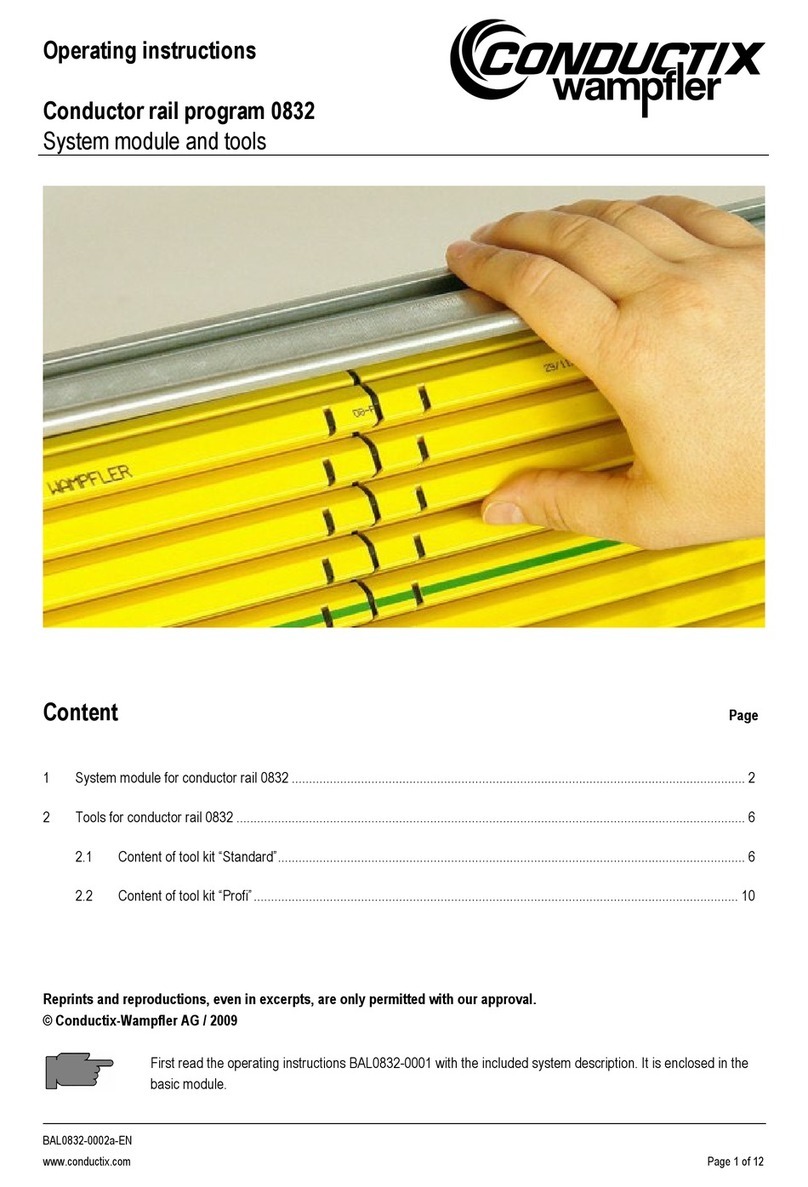

4.3 ProfiDAT®compact rail components ....................................................................................................................... 39

4.4 ProfiDAT®compact electrical components (example layout) .................................................................................. 42

4.5 Modes of operation................................................................................................................................................. 44

4.5.1 Normal operation.................................................................................................................................................... 44

5Transport, Packaging and Storage ........................................................................................................................................ 45

5.1 Transport ................................................................................................................................................................ 45

5.1.1 Safety instructions for transport.............................................................................................................................. 45

5.1.2 Transporting packaged parts.................................................................................................................................. 45

5.1.3 Transport inspection............................................................................................................................................... 46

5.2 Packaging............................................................................................................................................................... 46

5.3 Storage of packaged parts ..................................................................................................................................... 47

6Installation and Commissioning ............................................................................................................................................. 48