6

OPERATION

RAISING A LOAD

1. Before use, check for any damage or worn parts. Do not use the jack

unless it is perfectly serviceable.

2. Ensure the load is chocked and stable, and on firm level ground, before

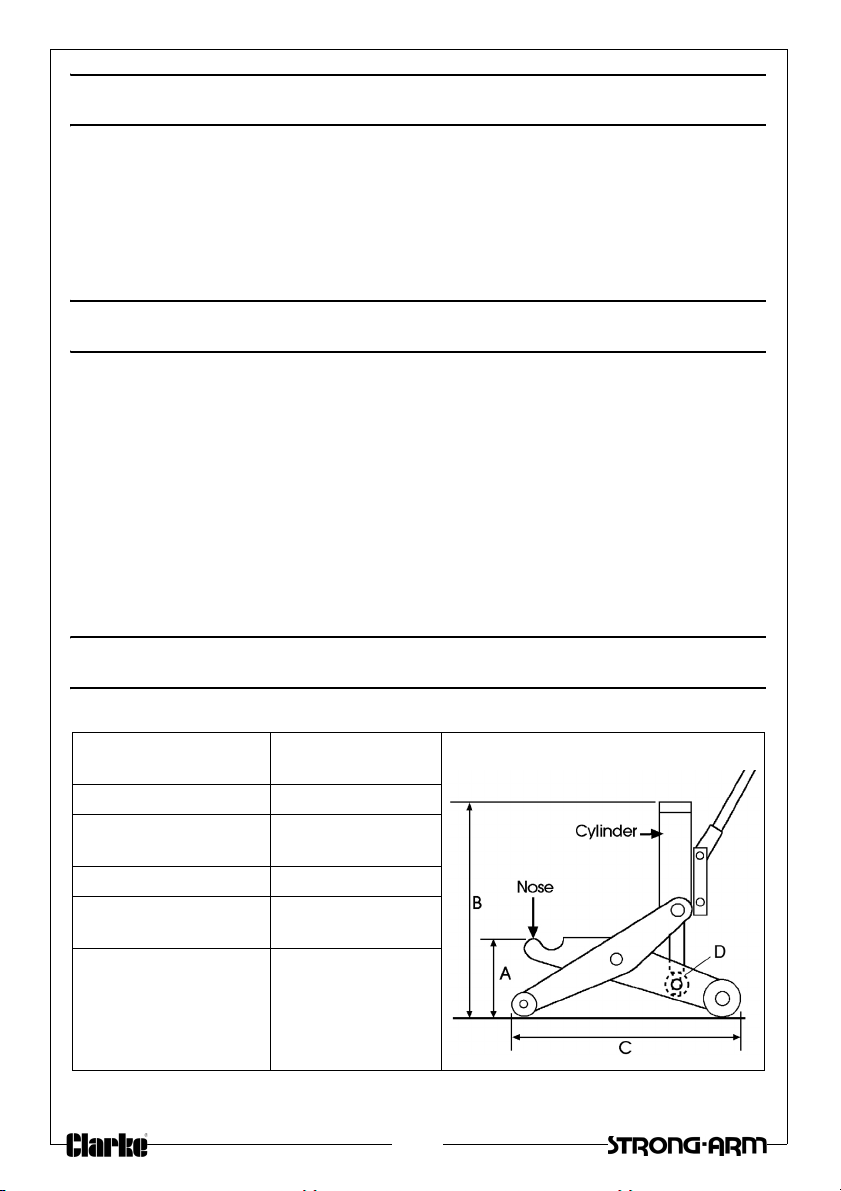

manoeuvring the jack so that the grooves in the nose or the top of the

cylinder, (whichever is to be used), is directly beneath the lifting point of the

load.

3. Twist the handle clockwise to close the release valve.

4. Put the nose directly below the lifting point of the vehicle (see the

manufacturers handbook for the best locations).

• Make sure that there is no obstruction that will prevent a clear lift

and that all personnel are in a safe position before you lift the

vehicle.

5. Pump the handle to raise the jack until contact is made with the lifting

point.

6. Make one final check to ensure that there are no obstructions to lifting and

that all personnel are well clear before continuing to pump the handle and

lift the load.

7. NEVER allow any individual to get beneath the load until it is firmly chocked

or supported on axle stands or similar supports.

LOWERING THE LOAD

1. With the axle stands/supports removed, check to ensure that there are no

personnel in the immediate vicinity before VERY SLOWLY twisting the lifting

handle anticlockwise and allowing the jack to lower the load.

NOTE: This operation must be done very slowly and in full control. DO

NOT let the load lower suddenly, this could damage internal

components.

WARNING: BEFORE LIFTING, ENSURE THE SAFETY PRECAUTIONS ARE

STRICTLY FOLLOWED. NO RESPONSIBILITY CAN BE ACCEPTED FOR

INCORRECT USE OF THE JACK.

WARNING: PLEASE NOTE THAT THE SCISSOR ACTION OF THE JACK WILL

CAUSE THE JACK TO MOVE SLIGHTLY AS IT IS RAISED AND LOWERED. IT IS

MOST IMPORTANT THAT THIS MOVEMENT IS NOT RESTRICTED IN ANY WAY.

ENSURE THE GROUND IN THE IMMEDIATE VICINITY OF THE JACK IS FREE

FROM DEBRIS.