7

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

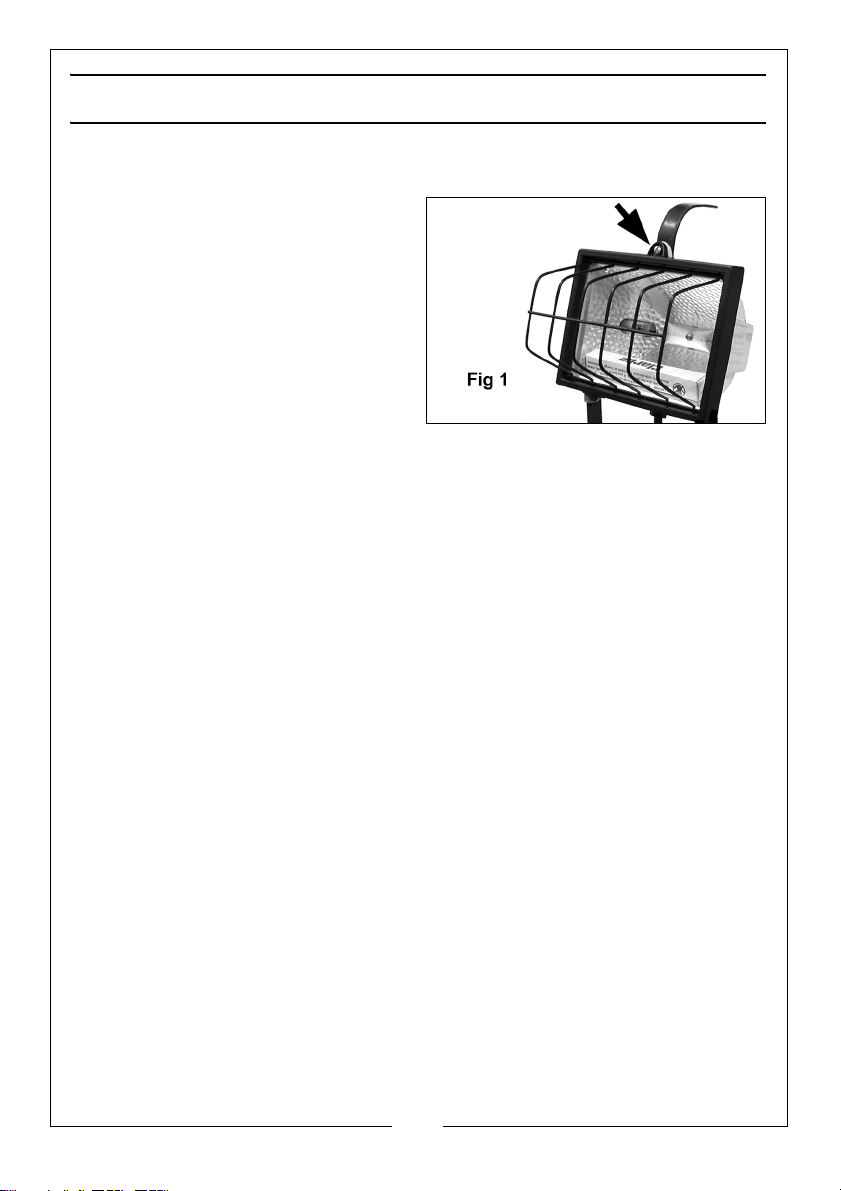

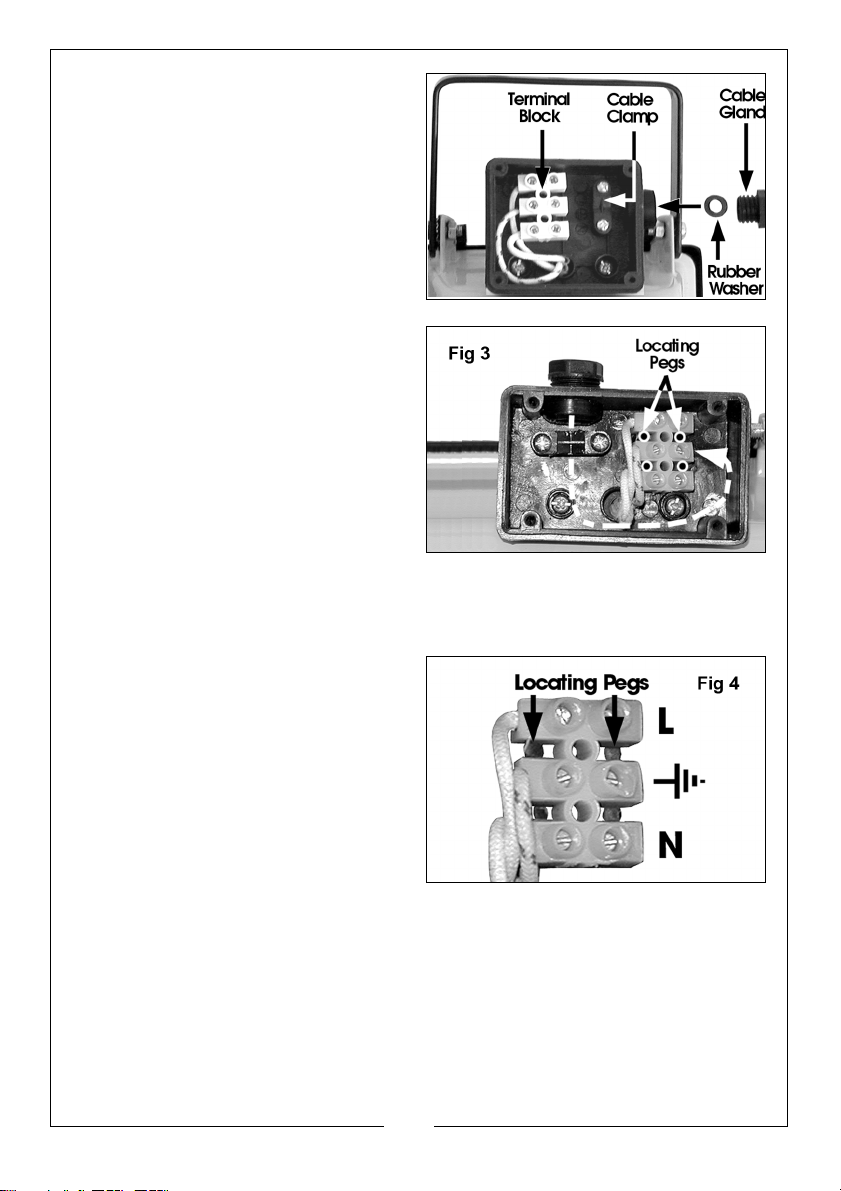

Wiring up these models should be

carried out as follows:

1. Remove the cable gland and

rubber washer from the cable

inlet and retain. Fig. 2 shows the

gland and washer removed from

model 150D.

2. Remove the Terminal Box cover

by unscrewing the four securing

screws.

3. Remove the screws securing the

cable clamp.

4. Thread the cable gland, followed

by the rubber washer over the

cable, then thread the cable

through the cable inlet.

5. Carefully strip the outer insulation

from the conductors for a

distance of approx. 30mm taking

care not to damage the

conductor insulation.

6. Strip the conductor insulation, for a distance of approx. 8mm and twist the

strands together, on each conductor.

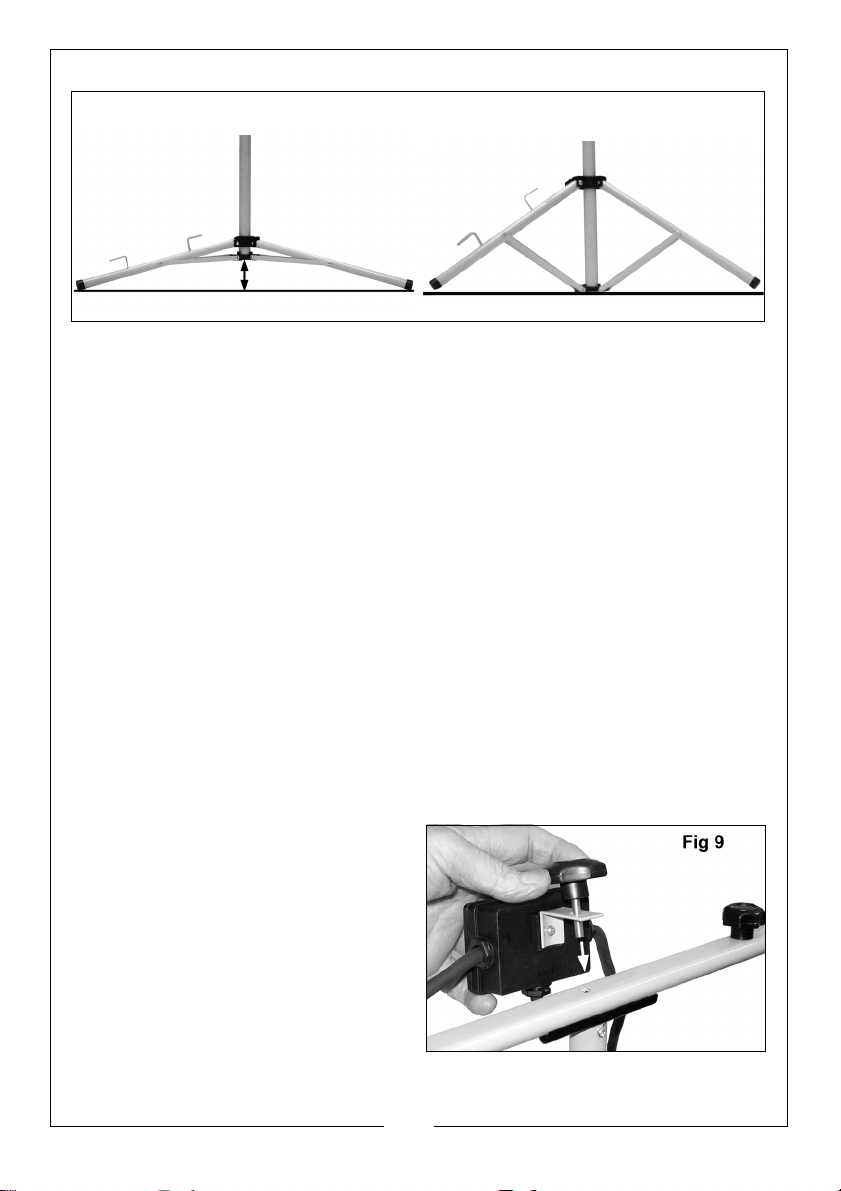

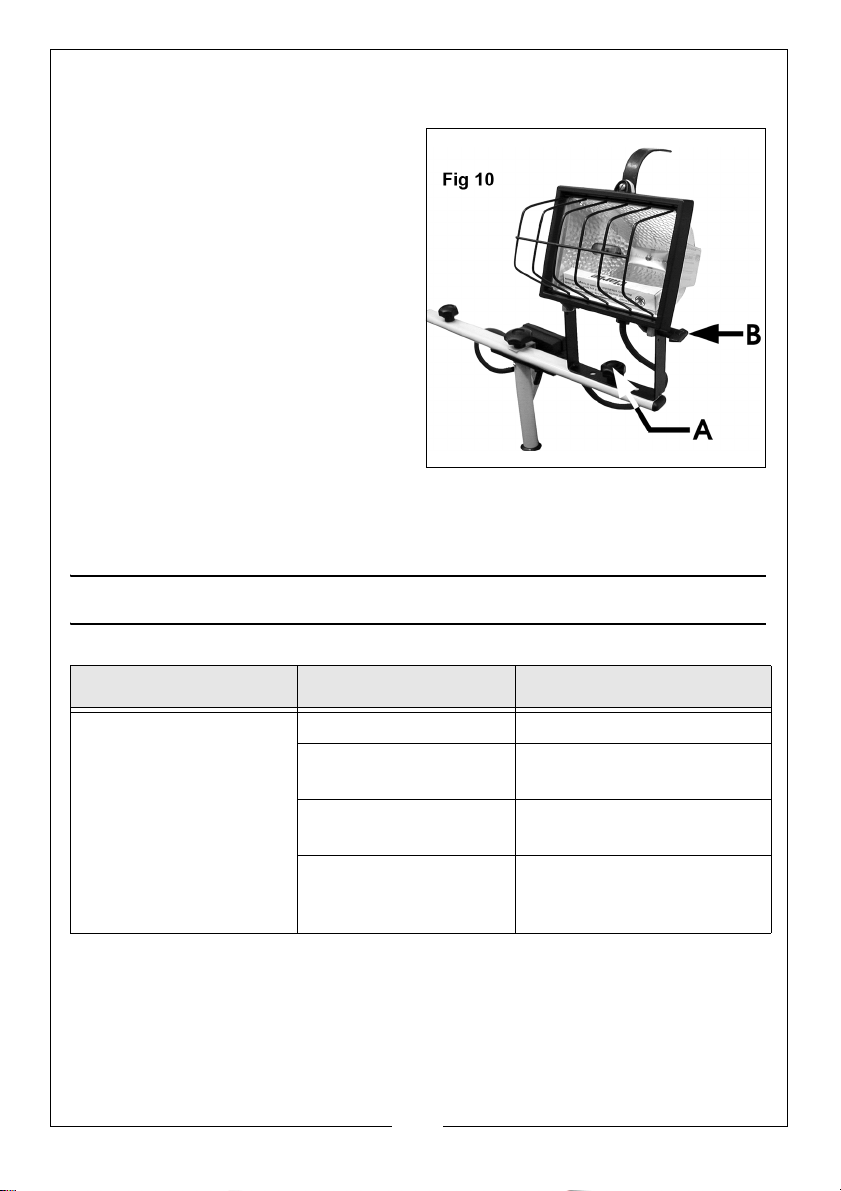

7. Identify the terminals by observing

the embossed symbols on the

base of the junction box, and

indicated in Fig.4.

These are L - Live, N - Neutral and

earth.

Connect the conductors

accordingly.

NOTE: The cable path for the 500SD

is shown by the dotted line in

Fig. 3.

8. Replace the cable clamp ensuring it firmly clamps the OUTER insulation, or

sheathing, and NOT the conductors.

9. Push the rubber washer into the cable inlet and screw in the cable gland

firmly. Do not overtighten as this could strip the plastic threads.

10. Before replacing the cover, ensure the terminal black is located snugly on

the locating pegs, illustrated in Figs. 3 and 4.