11

CHEMICAL CLEANING AGENTS

To improve cleaning qualities, it is possible to introduce chemical cleaning

agents (detergents) using the foam lance. This is particularly useful for

washing cars, greasy engine parts, removing oil spots on concrete etc.

Use ONLY those detergents recommended for use with power washers,

such as CLARKE Traffic Film Remover which is a powerful low foaming agent

for car cleaning, patio cleaning etc., or CLARKE Wash & Wax, both

available from your CLARKE dealer.

To prepare for detergent application, ensure the trigger safety latch is set

to prevent the trigger from being pulled accidentally and the machine is

switched OFF. It is not necessary to pull

the trigger to release the pressure.

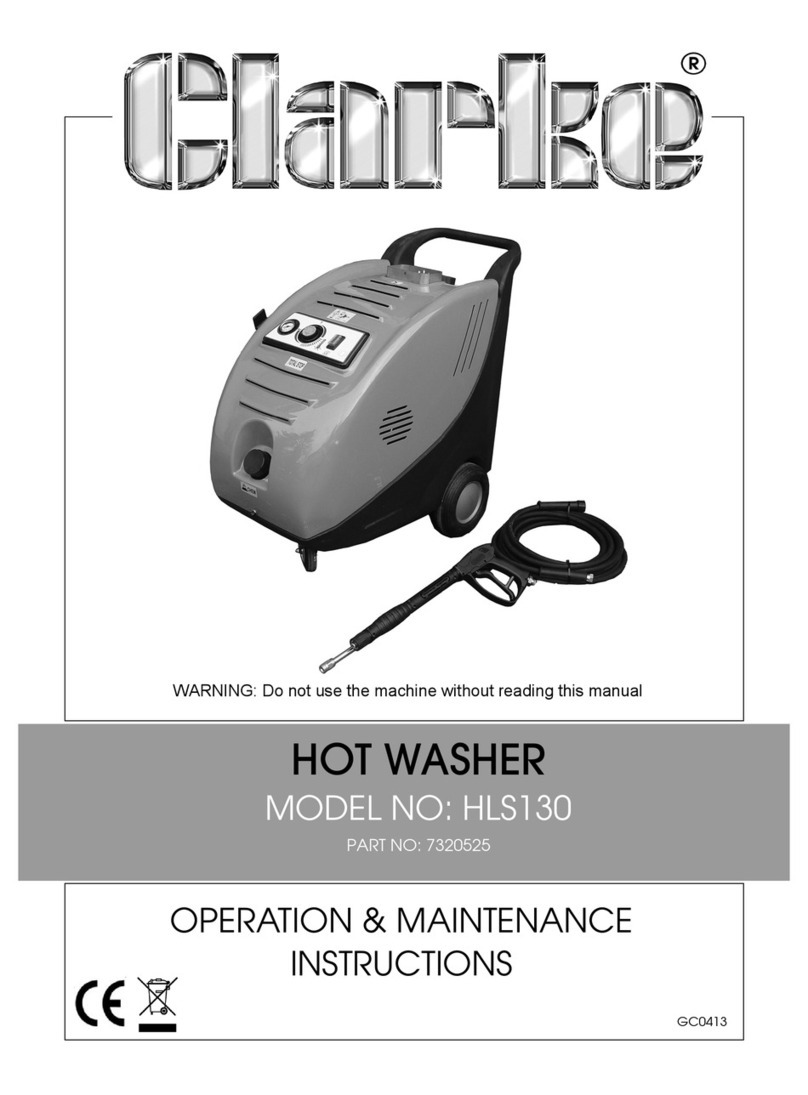

Remove the lance from the trigger/

handle assembly by twisting it clockwise

looking down from the handle end, and

pulling it free. Insert the detergent lance,

push in firmly and twist anticlockwise to

lock in position.

NOTE: It may be necessary to lubricate

the lance spigot when new to assist when

attaching to the handle.

With the container filled with detergent, screw it on to the detergent lance

ensuring the plastic pickup tube is in place.

IMPORTANT:

ALWAYS read and comply with the manufacturers instructions

issued with the chemical detergent.

Spray the detergent on to the vehicle, patio etc., and allow it to work

itself into the grime.

To rinse and clean, set the safety latch, replace the detergent lance with

the main lance, release the safety latch and blast off the dirt.

After using the detergent lance, rinse it thoroughly, together with the

container, with clean water. (See Maintenance)

Fig.8

THERMAL OVERLOAD

The machine is protected against damage which could result should the

machine overheat. If the thermal overload cuts in, allow at least 5 minutes,

to allow the machine to cool, before attempting to restart.

ELECTRICAL CONNECTIONS

WARNING: THIS MACHINE MUST BE EARTHED.

This product is provided with a standard 13 amp, 230 volt (50Hz). BS 1363 plug, for

connection to a standard, domestic electrical supply. Should the plug need

changing at any time, ensure that a plug of identical specification is used.

IMPORTANT: The wires in the mains lead should be wired up in accordance with

the following colour code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

As the colours of the wires in the mains lead may not correspond with the coloured

markings identifying the terminals in your plug, proceed as follows:

• Connect the GREEN & YELLOW cord to terminal marked with a letter “E” or

Earth symbol “ ”

• Connect BROWN cord to plug terminal marked letter “L”

• Connect BLUE cord to plug terminal marked letter “N”

We recommend that this machine is connected to the mains supply through a

Residual Current Device (RCD).

FUSE RATING

The fuse in the plug for this appliance must be rated at 13 amps

IMPORTANT:

If this appliance is fitted with a plug which is moulded onto the electric cable (i.e

non-rewirable):

1. The plug must be thrown away if it is cut from the electric cable. There is a

danger of electric shock if it is subsequently inserted into a socket outlet.

2. Never use the plug without the fuse cover fitted.

3. Should you wish to replace a detachable fuse carrier, ensure that the correct

replacement is used (as indicated by marking or colour code).

4. Replacement fuse covers can be obtained from your local dealer or most

electrical stockists.

EXTENSION CABLES

If an extension cable is used always ensure that it is fully unwound. The maximum

extension length is 25M, and the wire size in the cables must be at least 1.5mm in

diameter. As a general rule the extension cable must be thicker than the cable

supplied with the Washer. If longer extensions are required please seek advice

from a qualified electrician.

IF IN DOUBT CONSULT A QUALIFIED ELECTRICIAN.

DO NOT ATTEMPT ANY ELECTRICAL REPAIRS YOURSELF.

6