Clarke MIG 160TM Installation and operation manual

Other Clarke Welding System manuals

Clarke

Clarke MIG165TEM Installation and operation manual

Clarke

Clarke MIG 150TE Installation and operation manual

Clarke

Clarke weld MMA/TIG120 Instruction Manual

Clarke

Clarke MIG85ENB Installation and operation manual

Clarke

Clarke AT165 Instruction Manual

Clarke

Clarke EASIARC 110 Instruction Manual

Clarke

Clarke 195TEC Installation and operation manual

Clarke

Clarke Weld MIG 130 TE Turbo Manual

Clarke

Clarke CSW6T Installation and operation manual

Clarke

Clarke EASIARC 200 Manual

Clarke

Clarke Weld 215TE Installation and operation manual

Clarke

Clarke MIG 240 Instruction Manual

Clarke

Clarke IMIG100NG Instruction Manual

Clarke

Clarke PRO-90mig User manual

Clarke

Clarke AT162 Instruction Manual

Clarke

Clarke Weld MIG 130 TE Turbo Manual

Clarke

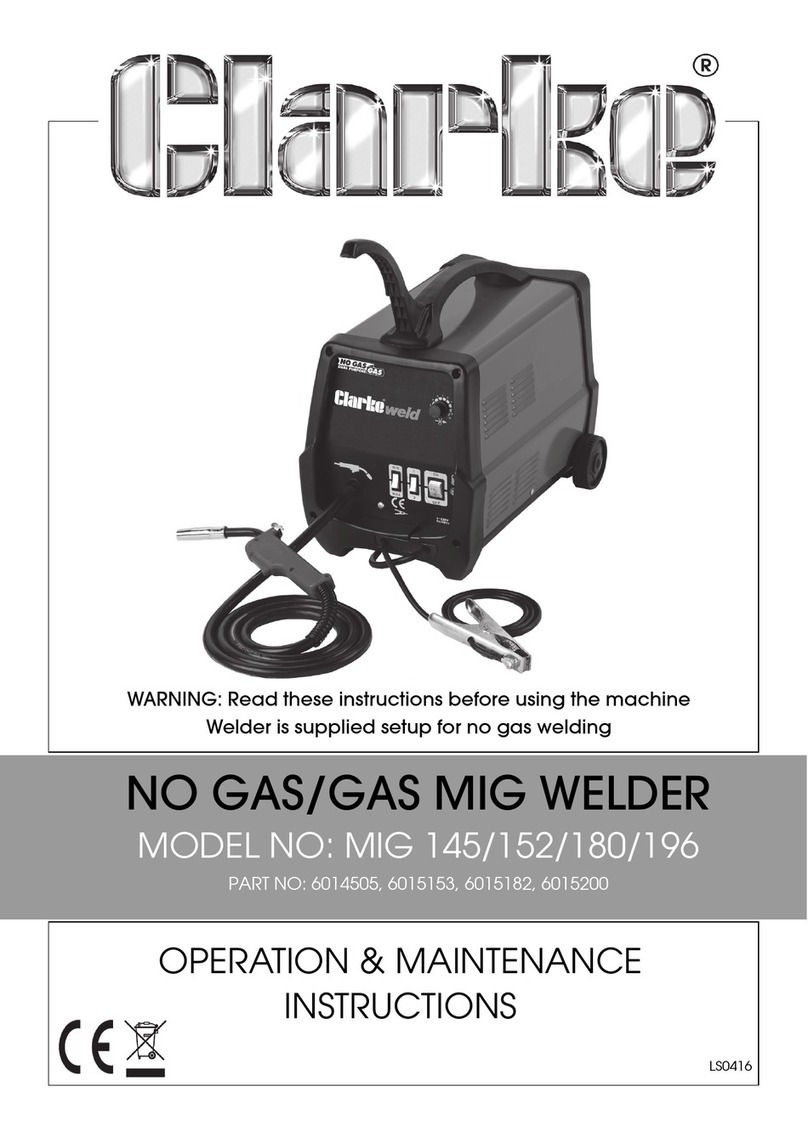

Clarke MIG 152 Instruction Manual

Clarke

Clarke MMA200 Instruction Manual

Clarke

Clarke weld MIG 90EN Installation and operation manual

Clarke

Clarke EASIARC 165 Instruction Manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual