Clarus Technologies PCS-15 User manual

Rev 8/2012

Operators Manual

PCS/WCS 15/25

Parts/Weapons Cleaning Stations

RPW-15/25

Recycling Parts Washer

RWC-15/25

Recycling Weapons Cleaner

Clarus Technologies, LLC

2015 Alpine Way, Suite C

Bellingham, WA 98226

(360) 715-1356

www.clarustechnologies.com

info@clarustechnologies.com

To order parts:

cari.willia[email protected]

or call: (360) 715-1356

2

Table of Contents

I. INTRODUCTION ............................................................................................................................ 4

II. STANDARD AND ADD-ON FEATURES (SPECIFICATIONS) ................................................ 5

III. WARRANTY INFORMATION...................................................................................................... 6

IV. SAFETY ............................................................................................................................................ 6

A. SAFETY WARNINGS........................................................................................................................... 6

B. SAFETY EQUIPMENT.......................................................................................................................... 7

V. QUICK START GUIDE................................................................................................................... 7

A. UNCRATE UNIT................................................................................................................................. 7

B. INSTALL LIGHT/LID BAR ASSEMBLY................................................................................................. 7

C. ESTABLISH WORK AREA................................................................................................................... 8

D. FILL UNIT WITH SOLVENT ................................................................................................................. 8

E. OPTIONAL EQUIPMENT INSTALLATION –PRE-CLEAN SHELF............................................................. 8

VI. PARTS DESCRIPTION & OPERATION ...................................................................................... 9

A. SOLVENT FLOW SWITCH ................................................................................................................... 9

B. LIGHT SWITCH .................................................................................................................................. 9

C. CLEANING BRUSH............................................................................................................................. 9

D. OPTIONAL ADD-ON FEATURES.......................................................................................................... 9

E. FLUID NOZZLE –SHUTOFF............................................................................................................... 10

F. FILTER DIFFERENTIAL PRESSURE GAUGE........................................................................................ 10

G. FUSIBLE LINK.................................................................................................................................. 10

J. LEVELING BOLTS ............................................................................................................................ 10

VII. CARE AND MAINTENANCE...................................................................................................... 11

A. SUMP MAINTENANCE...................................................................................................................... 11

B. CANISTER LID O-RING MAINTENANCE............................................................................................ 11

C. CHANGING FILTERS......................................................................................................................... 11

VIII. DISPOSAL OF WASTE OIL AND BY-PRODUCTS................................................................. 13

A. SOLVENT AND SLUDGE................................................................................................................... 13

B. FILTER DISPOSAL............................................................................................................................ 13

IX. TROUBLE-SHOOTING................................................................................................................ 13

A. LIGHT DOESN’T WORK..................................................................................................................... 13

B. FUSIBLE LINK DOESN’T LINE-UP WITH TAB ON LID........................................................................... 13

C. AIR GUN HAS LOW PRESSURE OR DOESN’T WORK............................................................................ 13

D. SOAK TANK PUMP DOESN’T WORK.................................................................................................. 14

E. WAND/BRUSH LEAKING OR DRIPS ................................................................................................... 14

F. CANISTER LIDS DIFFICULT TO REMOVE AND INSTALL ...................................................................... 14

G. SIGHT GLASS DIRTY OR CLOGGED ................................................................................................... 14

H. MAIN PUMP NOT RUNNING.............................................................................................................. 14

I. PUMP RUNNING BUT NOT PUMPING FLUID........................................................................................ 14

J. MAIN PUMP LEAKING...................................................................................................................... 14

K. SLUDGE PUMP LEAKING.................................................................................................................. 14

L. PLUMBING LEAKING........................................................................................................................ 14

M. NO POWER MAIN PUMP,LIGHT,SOAK TANK PUMP DO NOT WORK................................................. 14

X. SOLVENT, FILTERS AND REPLACEMENT PARTS.............................................................. 15

3

FOREWORD

1. This manual describes the procedures required to operate the Clarus PARTS

WASHING/WEAPONS CLEANING SERIES. Every effort has been made by

Clarus Technologies, LLC to assure the accuracy and reliability of the information

contained in this document. Clarus Technologies, LLC, however, makes no

representation, warranty, or guarantee in connection with this manual and hereby

expressly disclaims any liability or responsibility for loss or damage resulting from

its use or for the violation of any federal, state, provincial or municipal regulation

with which this publication may conflict.

2. The electrical components of the Clarus Parts/Weapons Cleaning Series have been

designed and assembled with UL-approved equipment where required.

WARNING! The operational techniques used with this equipment are more

important than the design of the equipment for the safety of the worker.

Therefore, each technician involved in the operation of the Clarus

Parts/Weapons Cleaning Series must have the proper hazardous materials

training.

DANGER! This system can only be used with solvent that has a minimum

flashpoint of 140Fahrenheit. Use of solvents with flashpoints lower than 140

Fahrenheit are likely to cause a fire, injuries or death. If you are not sure of a

solvents flashpoint refer to the appropriate material safety data sheet

(“MSDS”) sheet.

3. Clarus is not undertaking to meet the duties of employers to warn and properly train

and equip their employees, and others exposed, concerning health and safety risks

and precautions, nor undertaking their obligations under local, state, provincial or

federal laws.

4. Information concerning safety and health risks and proper precautions with respect to

particular materials and conditions should be obtained from the employer, the

manufacturer or supplier of that material, or MSDS.

4

CLARUS PARTS/WEAPONS CLEANING SERIES

OPERATOR’S MANUAL

I. INTRODUCTION

Congratulations on your purchase of the Clarus Parts/Weapons Cleaning Series (models

PCS-15/25; WCS-15/25; RPW-15/25; RWC-15/25)! This equipment series is the

product of Clarus engineering and manufacturing. They are made of the finest materials

under a rigid quality control system. With proper care they will give you long and

satisfactory service.

To obtain the best use of your equipment, please read this manual carefully. It will help

you become familiar with the operation of the equipment and contains many helpful

hints about parts/weapons cleaner maintenance.

The instructions and specifications contained in this manual were in effect as of August

2012. Due to the policy of Clarus Technologies, LLC to continually improve its

products, however, modifications in these specifications may be made at any time.

This Operators Manual was compiled for your benefit. By reading and following the

safety, setup, operation, and trouble-shooting instructions described in the manual, you

should receive many years of trouble-free operation. Familiarize yourself with the

names of the parts/weapons cleaner components, which appear as capitalized terms

throughout this manual. Read this entire manual before attempting to start and

operate the Clarus Parts/Weapons Cleaner.

5

II. STANDARD AND ADD-ON FEATURES (SPECIFICATIONS)

STANDARD FEATURES ON ALL PARTS/WEAPONS CLEANING EQUIPMENT

Large format tank that uses 27.5 (17.5 for the 15 series) gallons of solvent

PCS/WCS/RPW-25 Height/width/depth (inches) - 44/51/31 (Height to top of light 73”)

PCS/WCS/RPW-15 Height/width/depth (inches) –40/40/27 (height to top of light 73”)

Single phase, 110V, 60 Hz, 5A

High capacity, ultra-fine 0.5-micron particulate filtration

Constant flow system regardless of how clogged the filters are

Filter canisters inside tank provide spill containment during filter change-outs

Oven-baked polyester powder coat finish

High quality steel construction with stainless steel work surface

Two brushes on weapons cleaners. Brush and flexible gooseneck nozzle on parts cleaners

Bright stainless steel work surface for better visibility and no darkening from corrosion

Leveling feet

Warnings and instructions describing all operational procedures are provided on clearly

marked decals, including a QR code for watching how-to maintenance videos while at the unit

UL-approved fusible link for fire protection

Consistently clean solvent not reliant on service intervals

System can be moved with forklift or pallet jack even while full

Limited Lifetime Warranty

ADD-ON FEATURES FOR ALL PARTS CLEANING MODELS

Optional pre-clean shelf

Optional tank with agitation pump for soaking parts

ADD-ON FEATURES FOR ALL WEAPONS CLEANING MODELS

Optional air gun for blowing parts clean and dry which can be connected to shop air

or an on-board air compressor.

Optional pre-clean shelf

STANDARD FEATURES ON PARTS/WEAPONS CLEANING EQUIPMENT MODELS

PCS-25/WCS-25 /15 (OPTIONAL ADD-ON FEATURES ON THE RPW/

RWC-25/15)

150-watt halogen light

Dual canister high capacity filtration (15 Series has single canister filtration)

On-board pump for easy removal of sludge and to minimize service requirements

Fluid level gauge with indicator for “Add 5 gallons” of make-up fluid

Pressure gauge shows status of filter and when filter change out is needed

6

III. WARRANTY INFORMATION

Clarus Technologies, LLC, will for the life of the unit, repair or replace without charge,

parts which our examination proves to be defective in material or workmanship. This

warranty is valid only if the unit has not been tampered with by unauthorized persons,

misused, abused, or improperly installed and has been used in accordance with the

instructions and/or ratings supplied. The foregoing is in lieu of any other warranty or

guarantee expressed or implied, and we are not responsible for any expense (including

installation and removal), inconvenience, or consequential damage, including injury to

any person, caused by items or our manufacture or sale. Some states do not allow

certain exclusion or limitations found in this warranty so that they may not apply to you.

In any event, Clarus Technologies, LLC total liability, under all circumstances, shall not

exceed the full replacement cost of this unit.

This Limited Lifetime Parts Warranty is limited to the following components:

Main chassis

Tank lid

Light bar assembly (excluding light fixture and light bulb)

Stainless steel work surface

Stainless steel baffle system

Soak Tank

Clarus Technologies, LLC, will for the period of 1 year from the date of purchase, repair

or replace without charge, the items listed below which our examination proves to be

defective in material or workmanship. This warranty is valid only if the unit has not been

tampered with by unauthorized persons, misused, abused, or improperly installed and

has been used in accordance with the instructions and/or ratings supplied.

This 1 year Mechanical/Electrical Component Warranty covers the following

components:

Electrical control systems

Main pump

Agitation pump

Hand pump

NOTE: Consumable items such as light bulbs, solvent brushes, O-Rings and

filters are excluded from any such warranty.

IV. SAFETY

To safely operate the Clarus Cleaner, it is essential to know the proper safety procedures

and equipment.

A. Safety Warnings.

The definitions for the safety warnings used throughout this manual are as follows:

7

Warning Means that if the safety information is not followed, personnel,

equipment or the environment may be damaged or hurt.

Material Safety Data Sheets (MSDS)

The MSDS provides technical information regarding use, hazards, precautions and

emergency procedures related to specific fluids. The MSDS also contain toll-free phone

numbers that may be called to provide further safety and emergency treatment

information.

Operators of the Clarus Cleaner must have on hand an MSDS for each type of

solvent that they will be using. The MSDS are available from the solvent supplier. In

some localities it is required by law that appropriate MSDS are on hand whenever

hazardous or flammable material is being processed.

B. Safety Equipment.

1. Safety Glasses. Operators should wear safety glasses during the operation of the

Cleaner. The major hazard is the possibility of splashing petroleum-based fluids

into the eye. If petroleum-based fluid is splashed into the eye, severe damage

may occur. First Aid treatment should be initiated immediately. Refer to MSDS.

2. Protective Gloves. Appropriate protective gloves should be worn whenever there

is a possibility that the fluids being used may come into contact with the hands.

Different types of gloves may be required for differently types of fluids. The

local safety supply source can recommend the appropriate protective gloves.

Flammable. For the safety of owners and operators NO SMOKING around or near this

equipment.

V. QUICK START GUIDE

Please read entire Quick Start Guide before beginning, this will avoid possible start up

problems.

A. Uncrate Unit

1. Remove outer wrap.

2. Unbolt legs from pallet.

3. Remove Light Bar Assembly from packaging.

4. Remove all loose packing.

B. Install Light/Lid Bar Assembly

The PCS/WCS models are equipped with a light bar assembly. A standard RPW/RWC

model contains a lid bar. The light bar assembly is optional on the RPW/RWC models.

Both of the bars are required to hold the lid up when using the equipment.

To install the light/lid bar assembly, unscrew the provided hardware and attach it to the

Light/Lid Bar Bracket located on the center/backside of the Cleaner. Before tightening

the bolts, open the tank lid and secure it to the light/lid bar assembly fusible link. Do not

8

bend the fusible link. Tighten all bolts. Once the light/lid bar assembly is secured,

connect the male plug of the light bar to the female plug labeled “light bar” out of the

electrical box.

C. Establish Work Area

1. Create a properly sized area where the Cleaner will be located. This area should

be a level, solid working area with sufficient overhead room for the light/lid bar

assembly. A 110 volt 15 amp circuit should be within 6 feet of this area.

2. Place the Cleaner in working area with a forklift or pallet jack with front of unit

facing out.

3. Use front leveling feet to reduce any rocking from an uneven floor. The leveling

feet should not be used to raise the unit off the floor. Use a Bubble level to level

Front/Back and Left/Right.

D. Fill Unit with Solvent

1. Once the unit is set into place, leveled and power plugged in, you can fill it with

solvent. The 15 Series requires 17.5 gallons of solvent. The 25 Series requires

27.5 gallons of solvent.

2. NOTE: If your unit is equipped with a fluid level gauge, fill with solvent until

fluid level gauge (located on front left corner) reads full. If there is no fluid level

gauge, the fill line is located underneath the filter access cover on the tank wall.

Do not fill the solvent past the FILL LINE indicated by the decal.

3. Make sure both the cleaning brush and fluid nozzle are inside the tank before

turning the system on. Turn system on with the switch labeled “Solvent Flow”

(NOTE: Models built prior to June 2012 were equipped with a 4-minute timer

and a green push button.)

4. Turn the unit off and check fluid level and fill to solvent line if needed.

E. Optional Equipment Installation –Pre-Clean Shelf

1. Confirm all pieces and necessary parts

a. (3) sets of: Bolts with washers, lock washers & nuts.

b. (1) Green pre-clean shelf with cut out

c. (1) Black support bracket/brace

d. (1) Black plastic shelf liner/insert

e. (1) Grey plastic bin

NOTE: Do not tighten all the bolts until each one has been installed and hand

tightened.

2. From the left side of the unit:

a. Remove inner leg attachment bolts from both Top & Bottom.

b. Install green pre-clean shelf into top holes.

9

3. Take the three (3) bolt sets and install the black bracket to the open side of the

pre-clean shelf

4. Attach the bottom of the bracket to the main body of the unit.

5. Insert grey plastic bin into brackets underneath shelf.

6. Lay black plastic insert/shelf liner onto pre-clean shelf (prevents scratches)

Congratulations –your unit is ready!

VI. PARTS DESCRIPTION & OPERATION

A. Solvent Flow Switch

1. To start the solvent flow from the brush and wand nozzle, simply turn the

switch to “ON”. To stop the flow of the solvent, turn the switch to “OFF”.

(NOTE: Models built prior to June 2012 were equipped with a 4-minute timer

and a green push button. The green push button turns the system on for a 4-minute cycle.

When the cycle is over the system will shut off automatically. If continued operation is

needed, simply depress the green “ON” button again.

B. Light Switch

(Standard on PCS/WCS; Optional on RPW/RWC models). The light switch on the

control panel operates the overhead 150-watt halogen light. The light does not

automatically switch off, so the operator must manually turn the light off.

C. Cleaning Brush

This ergonomically designed Parts Cleaning brush self cleans during use.

D. Optional Add-on Features

The Cleaner can be customized with additional features to make your shop’s parts and/or

weapons cleaning even more efficient. The following describes the operation of these

options; however, not all units are equipped with the same option packages.

Air Tool with Air Pump

If the optional Air Tool with Air Pump was purchased for your Cleaner, you will have an

air nozzle/handle hanging on the inside of the Cleaner lid. The air flow is controlled by

the Solvent Flow switch.

To activate the air tool, first turn the Solvent Flow Switch to “ON”, starting the

compressor. Next, take hold of the Air Tool, point it down and away from your body

and depress the trigger on the handle to release the pressurized air.

Regulated Shop Air Operated Air Tool

If the optional regulated “Shop Air” model was purchased, hook up the Shop Air Hose

to the air regulator located on the backside of the lower shelf. Manually adjust the

amount of air needed by pulling up the knob on the regulator and turning it to the

10

appropriate setting. When the proper amount of air is achieved, push knob down to lock

your setting. With this set-up, air will always be available at the nozzle.

Agitation Tank/Pump Assembly

The PCS/RPW-25 and PCS/RPW-15 can be equipped with an optional stainless steel

soak tank (“Soak Tank”) and a UL-approved submersible agitation pump. The

“ON/OFF” switch for the Soak Tank is located on the left side of the lid. The switch may

be located on the right side of RPW models not equipped with an optional halogen light.

Prior to turning the agitation on:

1) Place the stainless steel tank along the left hand side wall of the working surface,

2) Turn on the Solvent Flow Switch. As the solvent begins to flow, use the

cleaning brush and/or nozzle to fill the stainless steel soak tank until it covers the

pump.

3) Once the soak tank is full you can turn on the pump. The agitation pump will

stay on until it is manually turned off.

E. Fluid Nozzle –shutoff

(PCS/RPW parts cleaning models only) The fluid nozzle flow can be adjusted or turned

off by turning the yellow valve handle at the nozzle’s base.

F. Filter Differential Pressure Gauge

(Standard on PCS/WCS; Optional on RPW/RWC models). The PCS/WCS models use a

pressure gauge to indicate when the filters need replacing. This is an optional feature in

the RPW/RWC models. Replace filters when the gauge reads 40 PSI. Operating system

beyond 40 PSI will not damage the unit; however, the quality of the solvent will degrade

beyond 40 PSI.

G. Fusible Link

The OSHA Regulated Fusible Link that holds the lid open will release the lid if the

ambient temperature reaches 165F. Never bend the Fusible Link, as this will weaken

it.

WARNING! Do not coat or paint fusible link as this may prevent proper

operation. Inspect fusible link annually and replace if corrosion and/or stress is

evident.

J. Leveling Bolts

The front two legs contain bolts, which are used to minimize any rocking from uneven

floors, and will aid in leveling the unit. The unit must be level to work properly.

11

VII. CARE AND MAINTENANCE

A. Sump Maintenance

(Standard on PCS/WCS; Optional on RPW/RWC Models). The PCS/WCS models are

equipped with a sump pump to remove the accumulated sludge from the bottom of the

tank. This is an optional feature in the RPW/RWC models. The pump interval depends

on usage. For motor pools this interval is 3-6 months. For weapons cleaning this

interval is 6 months to 1 year.

Watch a video on how to pump out sludge at http://www.clarustechnologies.com/whats-

new/#howtovideo

To dump the sump, first remove the hose on the front right side of the unit, remove the

cap and put it either in a bucket or barrel and turn the hose end valve on. Second, open

the yellow valve handle on the main shelf. Third, move the handle back and forth on the

sump pump located on the shelf. Pump the sump out till the solvent changes color. This

usually takes 2-5 gallons. Turn off hose end valve, yellow handle valve, replace cap and

return it to its hangar. Dispose of waste properly.

B. Canister Lid O-Ring Maintenance

Every time the filters are changed, smear a small amount of petroleum jelly around the

o-ring to keep it lubricated.

WARNING! ALWAYS WEAR GLOVES AND EYE PROTECTION WHEN

HANDLING SOLVENT OR FILTERS.

WARNING! When changing filters, make sure to have something underneath the

used filter as you move it, such as a bucket or oilsorb, to capture any incidental

drips.

C. Changing Filters.

Watch a how-to video on changing filters online at www.clarustechnologies.com/whats-

new/#howtovideo

The Cleaner comes equipped with one or two 5” X 18” filter canisters. Inside these

canisters are 4.5” X 17” filter cartridges. These filters need to be changed when

indicated by the filter status lights (older models) or by a 40 PSI reading on the pressure

gauge mounted on the filter canisters (standard feature for PCS/WCS models; Optional

for RPW/RWC models). If your unit has neither feature, the recommended change

interval for motor pools is 3-6 months. For weapons cleaning the filter change interval

is 6 months to 1 year. If the Cleaner receives heavy usage, the change interval may need

to be adjusted accordingly as the quality of the solvent will be degraded.

When the gauge or lights indicate a filter change or the recommended time interval has

been reached, follow these steps to change the filters:

1. Turn all power to the system off.

12

2. Unplug the unit from wall receptacle.

3. Remove any soak tanks or supplies located on the working surface.

4. To create access to the filter canister lids for the Cleaner, lift and remove filter access

cover cutout located on left side of work surface. (Older models require a filter wrench

to twist the filter canister lid). Screw off filter canister lid.

4. With the lid off, carefully pull the used filter out of the canister. Rest the used filter

on the working tray to allow it to fully drain.

5. Place a new (Clarus Stock# WP680SR) filter in the canister.

6. Inspect the lid o-ring for wear, replace if needed. Apply a generous amount of

petroleum jelly or grease to the lid o-ring.

7. Replace lid, screwing the lid on hand tight, then one more quarter turn. Do not

overtighten.

8. If lid wrench as used, return it to its proper location. Replace the filter access cover

cutouts.

13

VIII. DISPOSAL OF WASTE OIL AND BY-PRODUCTS

A. Solvent and Sludge.

Through normal operation, the Cleaner sump assembly will collect small quantities of

waste solvent and sludge. These small quantities of solvent and sludge should be stored

in waste tank/drums and must by disposed of properly.

The disposal of waste solvent and water can most easily be done by contacting a waste

oil hauling company in your area or the environmental specialist at your place of

operation.

It is the responsibility of Cleaner owner to contact all local, county, state provincial and

federal agencies to inquire about guidelines for proper disposal of solvent and sludge and

other fluids generated through the use of these Cleaners. Obtain these guidelines in

writing and keep them in your files. It is critical to follow these guidelines and stay

tuned to any changes in the laws that might affect your practices.

Disposal of all waste solvent and sludge must be tracked and documentation of proper

disposal kept on file.

B. Filter Disposal.

As the filters of the Cleaner plug over time, they will need to be changed out and

disposed of properly

The owner of the Cleaner is responsible for contacting all local, county, state, provincial

and federal agencies regarding handling and disposal of used filters and oilsorbs. Obtain

these rules in writing and keep them on hand for reference.

To document compliance, owners must follow these guidelines and track all disposal

times and charges with receipts.

IX. TROUBLE-SHOOTING

A. Light doesn’t work

1. Check power cord, is it plugged into electrical box plug labeled “Light”?

2. Replace light bulb, 150-watt halogen.

3. Confirm cleaner is plugged into wall outlet.

B. Fusible Link doesn’t line-up with tab on lid

1. Adjust bolt on fusible link.

2. Switch fusible link to other side of mount on light bar.

3. Loosen and realign light/lid bar assembly and retighten in correct position.

4. Never bend Fusible Link, this will weaken it!

C. Air Gun has low pressure or doesn’t work

1. Check air source.

2. Check adjustment of regulator.

14

3. Check air hose for kinks or damage.

4. Confirm air pump is plugged into the electrical box.

D. Soak Tank Pump doesn’t work

1. Check for defective power cord; plug in pump with extension cord.

2. Inspect pump base screen and impeller for damage or obstruction.

E. Wand/Brush leaking or drips

1. Tighten fittings.

2. Remove fittings and remove Teflon tape, then re-tape and re-assemble.

3. Tighten hose clamps.

4. Check for damage and wear, replace as necessary.

F. Canister Lids difficult to remove and install

1. Lubricate lid o-ring and threads with petroleum jelly (note: always apply

petroleum jelly to o-ring with every filter change). Do not overtighten lids.

G. Sight Glass dirty or clogged

1. Blow clean with air gun or fluid nozzle (opening is inside tank just above pan

opposite sight glass).

2. Replace with new clear hose (Tygon 3/8” ID).

H. Main Pump not running

1. Check power cord, is it plugged in to electric box on lower shelf?

2. Plug pump into extension cord to verify power.

I. Pump running but not pumping fluid

1. Remove fluid from tank, remove intake and discharge hose from pump. Use

compressed air to clear hoses.

2. Remove front cap on pump and check for debris or wear. Replace if necessary.

J. Main Pump leaking

1. Inspect for damage.

2. Remove front head assembly and inspect for proper assembly, blow clean with

air gun and reassemble.

K. Sludge Pump leaking

1. Inspect for cracks, damage or wear

L. Plumbing leaking

1. Tighten hose clamps.

2. Check all hose connections and hoses for wear or damage and replace if

necessary.

3. Remove plumbing fitting and re-tape with Teflon tape. Re-install and tighten.

M. No Power Main Pump, Light, Soak Tank Pump do not work

1. Confirm power to wall outlet.

2. Check fuse (10Amp) in electrical box.

15

X. SOLVENT, FILTERS AND REPLACEMENT PARTS

Item No.

Item

Description

1156-5

Solvent - 5 gallon Type II-A

MIL-PRF-680 Type II specification solvent in a 5-gallon pail.

1156-5

Solvent - 15 gallon Type II-A

MIL-PRF-680 Type II specification solvent in a 15-gallon pail.

1156-55

Solvent - 55 gallon Type II-A

MIL-PRF-680 Type II specification solvent in a 55-gallon drum.

250-SS-5

Solvent - 5 gallon Type V

MIL-PRF-680 Type IV specification solvent in a 5-gallon pail.

250-55

Solvent - 55 gallon Type V

MIL-PRF-680 Type IV specification solvent in a 55-gallon drum.

1157-5

Solvent - 5 gallon Type II-B

Solvent conforms to MIL-PRF-680 Type II. 5-gallon pail.

1157-55

Solvent - 55 gallon Type II-B

Solvent conforms to MIL-PRF-680 Type II. 55-gallon drum.

WP680SR

Solvent Tank Filters (case)

0.5 micron filters in a case of four.

WP680SR-01

Solvent Tank Filter (each)

0.5 micron filters individually.

113253 (PCS-0031

Filter gauge

A gauge telling you when to change the filters

113252

Fluid level indicator

Indicator for solvent levels

PCS-0005

Soak Tank Pump

A pump for agitating parts in the soak tank.

PCS-0029

Control Box for Soak Tank

The electrical control box for the soak tank. Contains switch

and cord.

PCS-0036

Grey Plastic Bin for Pre-Clean

Pre-cleaning bin to collect debris.

PCS-0037

Pre-Clean Shelf Tray Liner

Lines the pre-clean shelf.

PCS-0058

Air gun hose

Replacement hose for the air gun.

AGOAPP

Onboard Air Pump Option

The optional pump and regulator for use with the air gun.

PCS-0057

Air Gun replacement

Includes only the air gun.

PCS-0001

Light Bar Assembly

Halogen light fixture with attaching bar, fusible link and

halogen bulb.

PCS-0002

Wand Nozzle

PCS-0003

Wand Valve

Valve to turn on/off nozzle

PCS-0004

Main Solvent Pump

The pump that circulates the solvent through filtration.

PCS-0006

Misc. 1/2" Hose per foot

The red solvent hose, 1/2"

PCS-0007

Misc. 3/8" Hose per foot

The red solvent hose, 3/8"

PCS-0008

Plug

Plastic plugs (specify size)

PCS-0010

Hose Clamp Large

Waste Hose Clamp

PCS-0011

Fusible Link

The fusible link

PCS-0012

Switch (for light/soak pump)

The switch for the light and soak tank (option)

PCS-0013

Main Switch (gr push button)

The green, ON push button.

PCS-0015-36

Molded Cord - 36"

Power cord, 36" long

PCS-0015-96

Molded Cord - 96"

Power cord, 96" long

PCS-0016

Fuse Holders (rectangular

grey)

Fuse holder for current models. Rectangular grey plastic holder,

located inside electrical box.

PCS-0017

Clamp, Solvent Brush

Clamps solvent hose to brush.

OC-1294

Fuse Holder (round black)

Fuse holder for older machines. Round black holder, located on

outside of electrical box.

PCS-0019

Drain Screen

Metal screen for the drain.

PCS-0022

Guzzler/Sump Pump

The hand pump for draining the sludge.

PCS-0023

Light Bulb

Halogen light bulb

PCS-0024

Replacement Solvent Brush

Replacement Solvent Brush

PCS-0025

Brush Hose (yellow) 4'

Yellow brush hose, 4' long

PCS-0026

Fuses

10-amp fuse

PCS-0027

Lid O-Ring Viton - Filter

Canister

Filter canister lid o-ring

PCS-0028

Switch contact block

Contact block for the two-position switch.

PCS-0030

Lid Clips

The clip that holds the lid open.

PCS-0031

Pressure Gauges

The filter pressure gauge

16

Item No.

Item

Description

PCS-0032

Relief Valve

Relief valve

PCS-0033

Soak Tank Pump Screen

Small white screen for the soak tank pump.

PCS-0035

Light Assembly, 150 watt

The halogen light fixture without the bar.

PCS-0038

Filter Access Hole Cover

The metal plate that covers the filter access.

PCS-0039

Plastic Electrical Control Box

The grey box that houses the electrical components.

PCS-0041

Filter Housing with Fittings

Red filter housing with fittings included.

PCS-0042

Filter Housing and Lid

Red filter housing lid. Includes O-ring.

PCS-0044

Fluid Indicator (6" clear hose)

6" clear hose

PCS-0050

Completed Electrical Control

Box Assembly

The main electrical control box with push buttons and cord.

PCS-0051

Timer

The 4-minute timer.

PCS-0053

Banjo Valve

Valve for sump pump

PCS-0056

Electrical Modification to

220v/50Hz

Plug-in step-up/down transformer for power conversion.

$100 minimum order. MasterCard and VISA accepted.

This manual suits for next models

7

Table of contents

Popular Other manuals by other brands

K&K Sound

K&K Sound PURE 12-STRING product manual

SentrySafe

SentrySafe Fire-Safe owner's manual

Cleanmaxx

Cleanmaxx 05991 instruction manual

Painless Performance Products

Painless Performance Products 20110 installation instructions

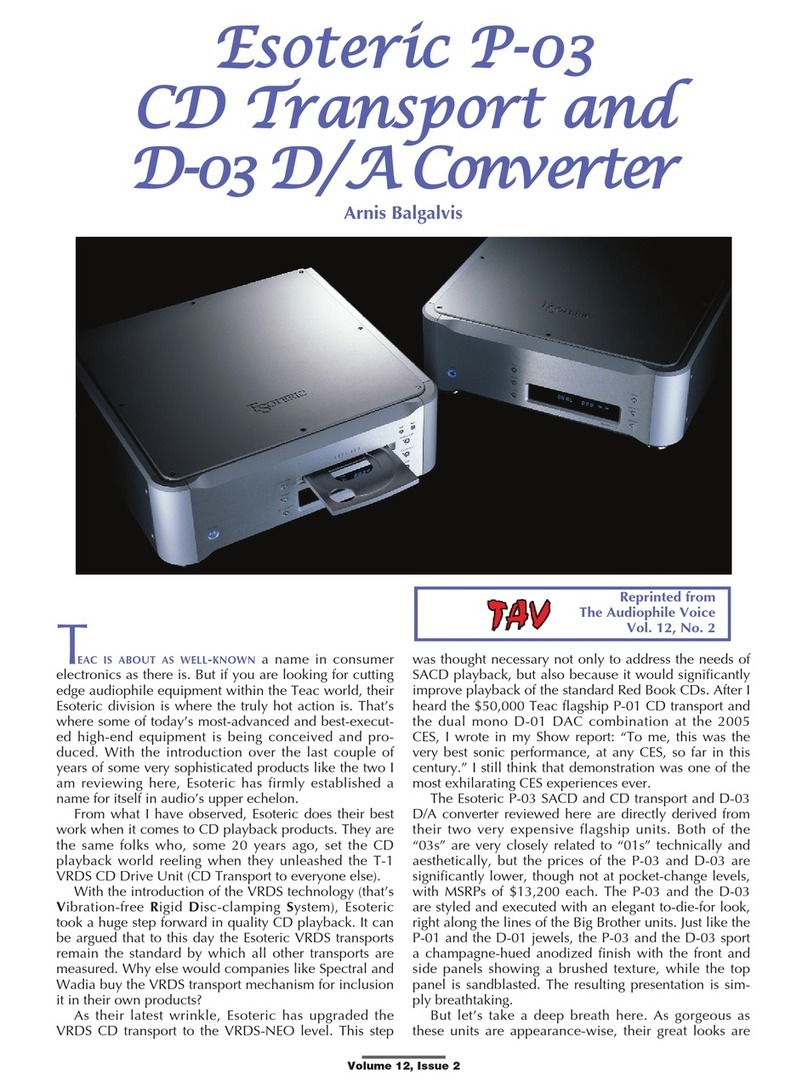

Teac

Teac Esoteric D-03 supplementary guide

ZKTeco

ZKTeco PB3000 Series user manual