Classic Exhibits Perfect 10 User manual

Other Classic Exhibits Monitor manuals

Classic Exhibits

Classic Exhibits Perfect 10 VK-1510 Kira User manual

Classic Exhibits

Classic Exhibits Symphony SYK-1038 User manual

Classic Exhibits

Classic Exhibits visionary DESIGNS VK-1321 User manual

Classic Exhibits

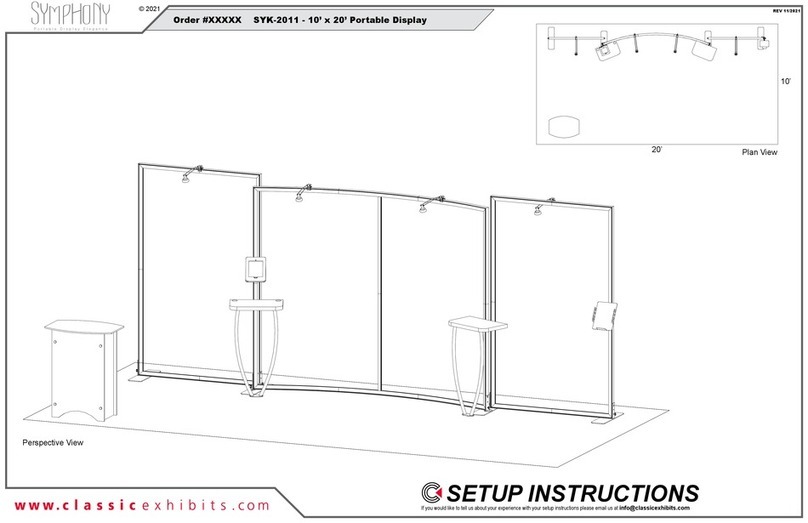

Classic Exhibits Symphony SYK-2011 Manual

Classic Exhibits

Classic Exhibits Symphony SYK-2019 Manual

Classic Exhibits

Classic Exhibits SEGUE DESIGNS VK-1302 Manual

Classic Exhibits

Classic Exhibits Perfect 10 VK-1402 User manual

Classic Exhibits

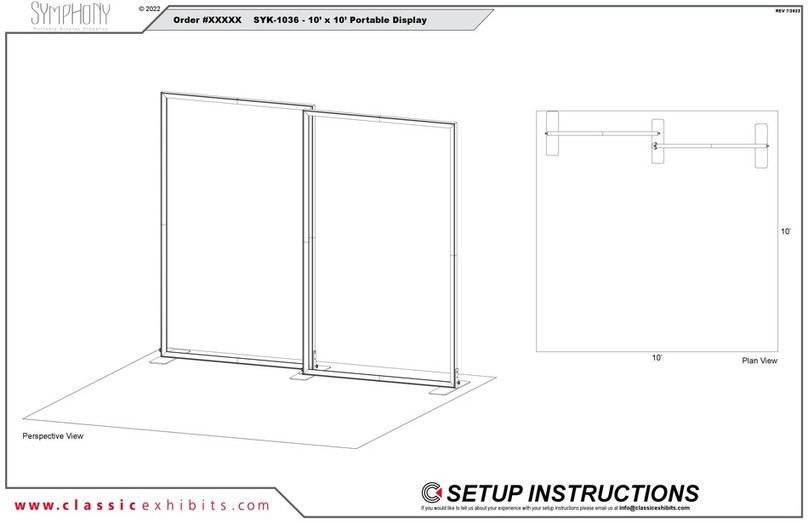

Classic Exhibits Symphony SYK-1036 Manual

Classic Exhibits

Classic Exhibits Symphony SYK-1001 Manual

Classic Exhibits

Classic Exhibits visionary DESIGNS TF-513 Manual