Clean Logix BLX-MR2-CC User manual

USER

MANUAL

English (Original Instrucons)

Updated: 02/11/21

MODEL:

BLX-MR2-CC

MISTER 2 COMPLIANCE COUNTER

BLX-MR2-CC Manual Page 2 of 7 Updated: 02/11/21

USER MANUAL: BLX-MR2-CC

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

!

WARNING:

1. All personnel using this unit must be familiar with the informaon contained

in this manual. Follow all installaon and maintenance instrucons.

2. Ensure solid foong and use both hands when operang the unit.

3. Avoid contact of chemicals with skin and eyes. If contact occurs, see MSDS

sheet for further rst aid measures.

4. Follow safety instrucons of chemical manufacturer (MSDS).

5. Always follow plant and OSHA guidelines about the use of equipment.

6. Disconnect air before servicing equipment.

7. Always follow safety precauons and obey warning labels. Failure to do so

could result in injury or death.

BLX-MR2-CC Manual Page 3 of 7 Updated: 02/11/21

USER MANUAL: BLX-MR2-CC

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

The Compliance Counter add-on allows for automated

tracking and acvaon vericaon for the MR2

footwear sanizer system. The pneumac, 4-digit

counter records the number of successful acvaons

performed by the Mister 2. The system includes a

manual reset buon and window shield to protect

from spray/debris or tampering.

The accessory kit includes all components necessary

to integrate into any exisng unit.

Overview

▪ Construcon: 304 Stainless Steel, polycarbonate,

polypropylene

▪Weight: 2 lbs.

▪ Dimensions: 11.75" x 3.125" x 9.5"

298.45 x 79.375 x 241.3 mm

▪ Connecon Size: 1/4" OD tubing or similar

(5 . included with unit)

Specicaons

▪ Compressed Air: 30 PSI minimum*

▪ Liquid Temperature Range: 40-100°F (4-37°C)

▪ Chemical compability: Chemical products used

with this equipment must be formulated for this

type of applicaon and compable with unit

materials and seals.

Requirements

NOTE: For more informaon on chemical

compability consult the chemical

manufacturer, SDS for your product, or

contact our support department.

*NOTE: Minimum pressure output for

pneumac counter only. Consult User Manual

included with MR2 sanizing system for

system requirements.

Please contact your equipment representave

or manufacturer for further support.

iMore Informaon?

PROTECT THE ENVIRONMENT

Please dispose of packaging materials, old machine

components, and hazardous uids in an environmentally safe

way according to local waste disposal regulaons.

Always remember to recycle.

Specicaons and parts are subject to change without noce.

BLX-MR2-CC Manual Page 4 of 7 Updated: 02/11/21

USER MANUAL: BLX-MR2-CC

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Installaon

CAN BE INSTALLED ON

EITHER SIDE OF UNIT

BLX-MR2-CC Manual Page 5 of 7 Updated: 02/11/21

USER MANUAL: BLX-MR2-CC

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Bracket Installaon

1. Select a handrail/side of the unit to install the

bracket. Consider trac ow direcon and

accessibility.

2. Remove the handrail and install the compliance

counter bracket as shown in [Fig. 5.1]

3. Using a 1/2" socket/wrench, secure the bracket in

place using the (2) included nuts and bolts.

4. Reaach the handrail and secure.

Plumbing Installaon

1. If connected, remove air and soluons lines and

exhaust system of all compressed air.

2. Connect the included 1/4" bulkhead ng to the

open port on the side of the sanizing system

[Fig. 5.2]

3. Remove the plasc base plate and hinge open

each foot plate to expose the plumbing assembly.

4. Disconnect the plumbing assembly from the

soluon and airline bulk-heads and remove.

5. Flip the plumbing assembly over and locate the

1/4" airline leading from the valve to the single-

shot air output inlets.

Installaon (cont.)

Fig. 5.1: Installing Compliance Counter bracket

NOTE: The plumbing system will need to

be removed temporarily to integrate the

compliance counter.

Fig. 5.2: 1/4" bulkhead for Compliance Counter airline

NOTE: Compliance Counter can be mounted

on either side of the unit. It is recommended

to have the air regulator and soluon lter

installed on the opposing side for roung air

and soluon lines.

If necessary, the lter and air regulator can be

removed and installed on the opposing side.

BLX-MR2-CC Manual Page 6 of 7 Updated: 02/11/21

USER MANUAL: BLX-MR2-CC

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

Plumbing Installaon (cont.)

6. Cut the 1/4" airline before the tee ng, as

indicated in [Fig. 6.1] .

7. Using the 1/4" tee ng included with the

compliance counter, tee into the cut airline and

reconnect them.

8. Using the included 1/4" tubing, cut a new airline

long enough to connect from the tee to the 1/4"

bulkhead when the plumbing assembly is in place.

9. Replace plumbing assembly when complete

and reconnect all air and soluon lines to their

appropriate bulkheads.

10. Connect the remaining 1/4" from the Compliance

Counter to the exterior side of the bulkhead to

complete installaon.

11. Replace plasc base plate and reconnect air and

soluon supply to resume normal operaons (see

main user manual for priming instrucons).

Operaon and Use

1. Acvate MR2 to trigger the counter (up to 9,999

acvaons can be recorded before requiring reset)

2. Open the window cover to access reset buon to

restart counter.

Installaon (cont.)

Fig. 6.1: Airline cut locaon for tee

cut herecut here

NOTE: Ensure the new airline is long enough

to reach the bulkhead without kinking, but is

not excessively long where it interferes with

removing/replacing the catch pan.

NOTE: It is recommended to route the airline

around the handrail to prevent unintended

interacon (tripping, snags, etc.)

Fig. 6.2: Compliance Counter bulk-head connecon

BLX-MR2-CC Manual Page 7 of 7 Updated: 02/11/21

USER MANUAL: BLX-MR2-CC

READ ALL INSTRUCTIONS BEFORE OPERATING EQUIPMENT

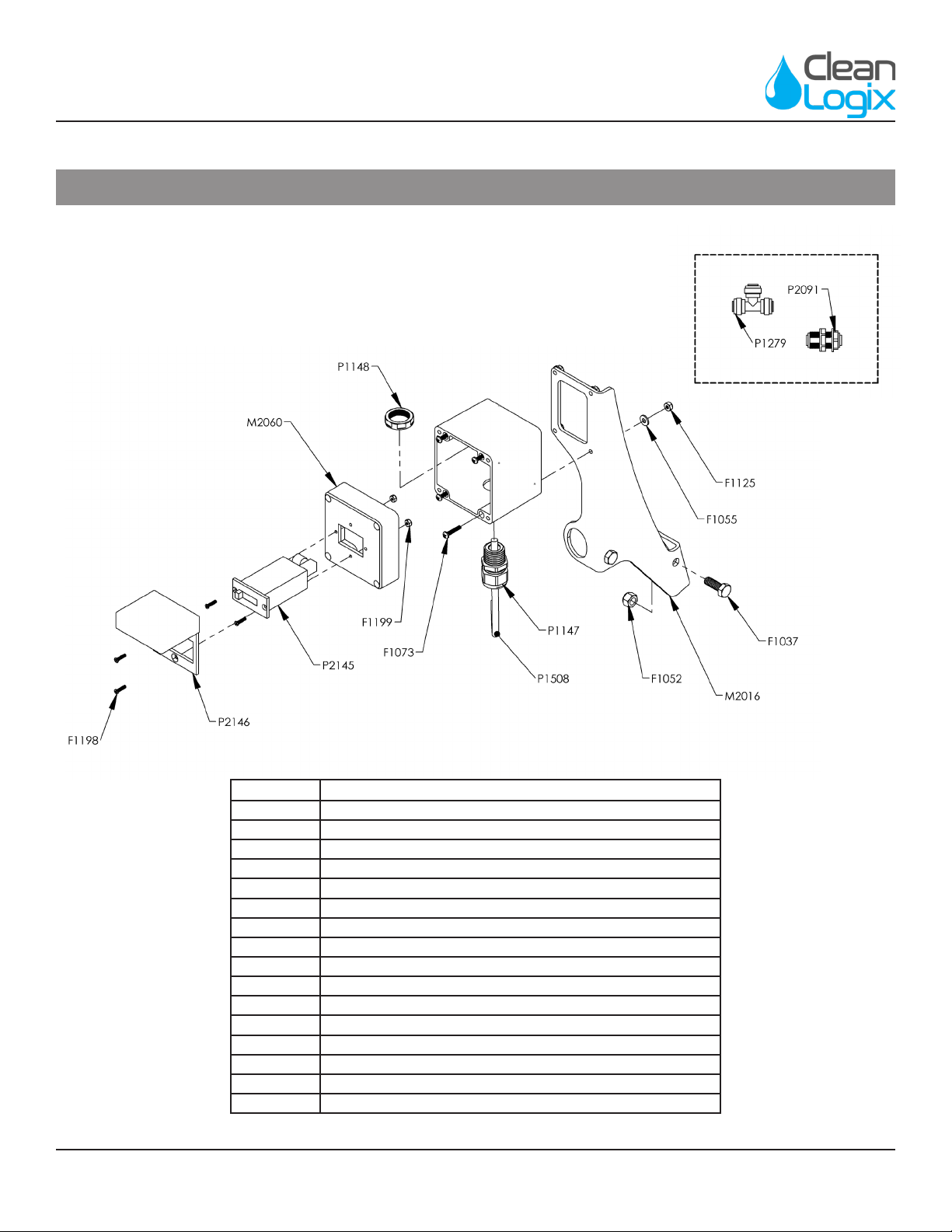

Appendix A - Parts Callout

Part No. Descripon

F1037 BOLT HHC 5/16-18 x 7/8 SS

F1052 NUT NYLOCK 5/16-18 SS

F1055 WASHER #8 SS TYPE A

F1073 SCREW MACHINE 6-32 x 3/4 SS PHILLIPS PAN HD

F1125 NUT NYLOCK 6-32 SS

F1198 SCREW MACHINE 4-40 X 1/2 FLAT HEAD PHILLIPS 316SS

F1199 NUT NYLOCK 4-40 ZN

M2016 BLX-MR2 COUNTER BRACKET

M2060 ENCLOSURE PC 8X8X10 - CUSTOM MACHINED

P1147 CORD GRIP 1/2 NPT X .170-.450 BLK

P1148 CORD GRIP NUT 1/2" NPT BLACK

P1279 QUICK FIT TEE 1/4"

P1508 1/4" OD POLYETHYLENE TUBING (sold by the foot)

P2091 QUICK FIT BULKHEAD 1/4"

P2145 TOTALIZER PNEUMATIC 4-DIGIT

P2146 TOTALIZER WINDOW COVER

Table of contents