2

CONTENTS

Contents................................................................................................................................................ 2

Copyright Notice .................................................................................................................................. 3

Product Approvals............................................................................................................................... 4

Warranty & Service .............................................................................................................................. 5

1. Overview ........................................................................................................................................... 6

2. Purpose............................................................................................................................................. 6

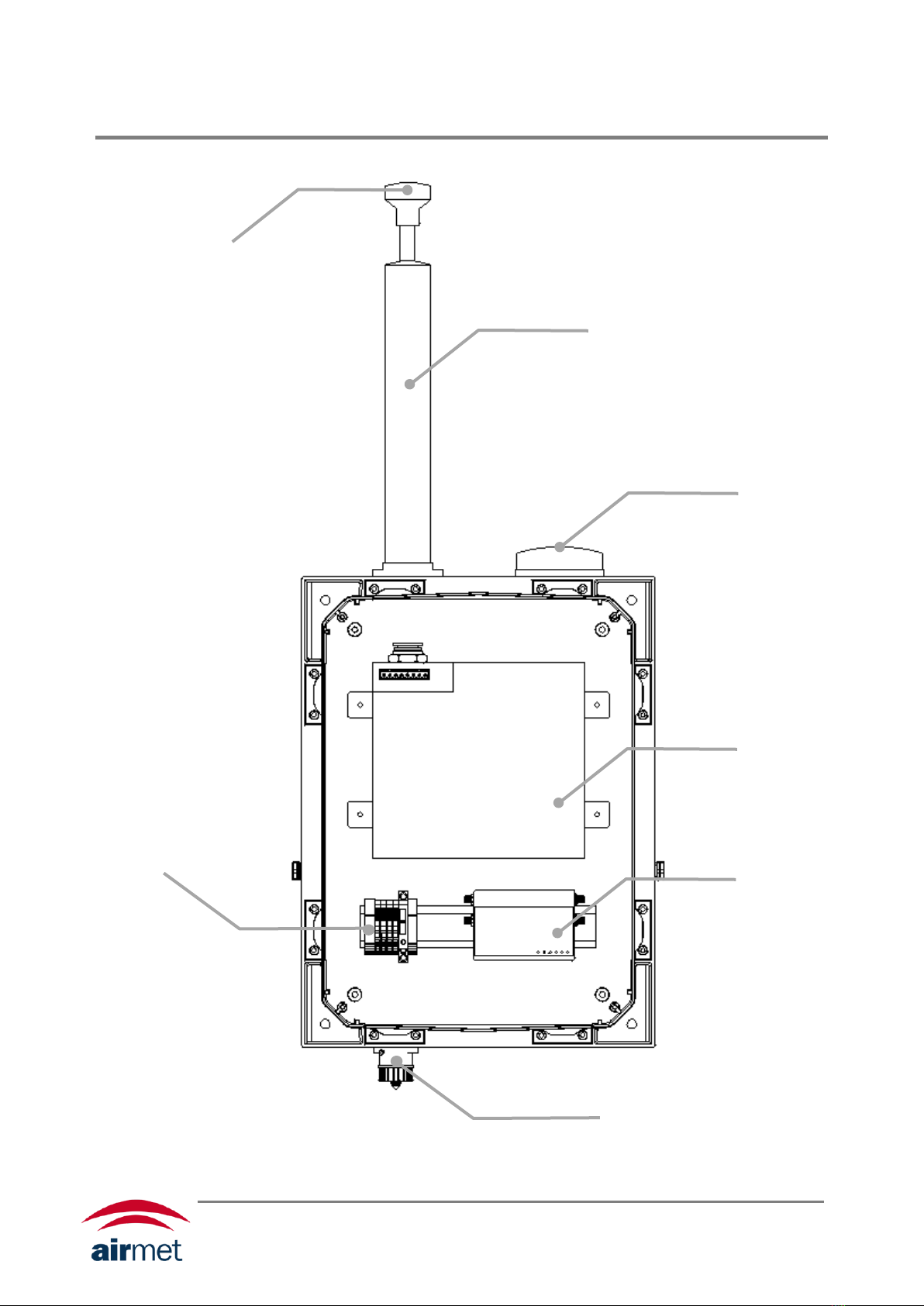

3. Monitor Assembly............................................................................................................................ 7

4. Detector Labeling............................................................................................................................. 8

5. Installation ........................................................................................................................................ 9

Conditions of Use ............................................................................................................................ 9

Location and Mounting of Monitor............................................................................................... 10

Connection...................................................................................................................................... 11

6. Air-Met Scientific Data Portal........................................................................................................ 11

7. Maintenance ................................................................................................................................... 12

Maintenance Frequency ................................................................................................................ 12

Annual Calibration ......................................................................................................................... 12

8. Field K Factor Adjustment ............................................................................................................ 13

9. Performance ................................................................................................................................... 14

10. Spare parts & accessories.......................................................................................................... 15

11. Specifications............................................................................................................................... 16

Contact information........................................................................................................................... 17