cleanAIR CAP577 Installation and operating instructions

INSTALLATION GUIDE

GETTING READY CAP577

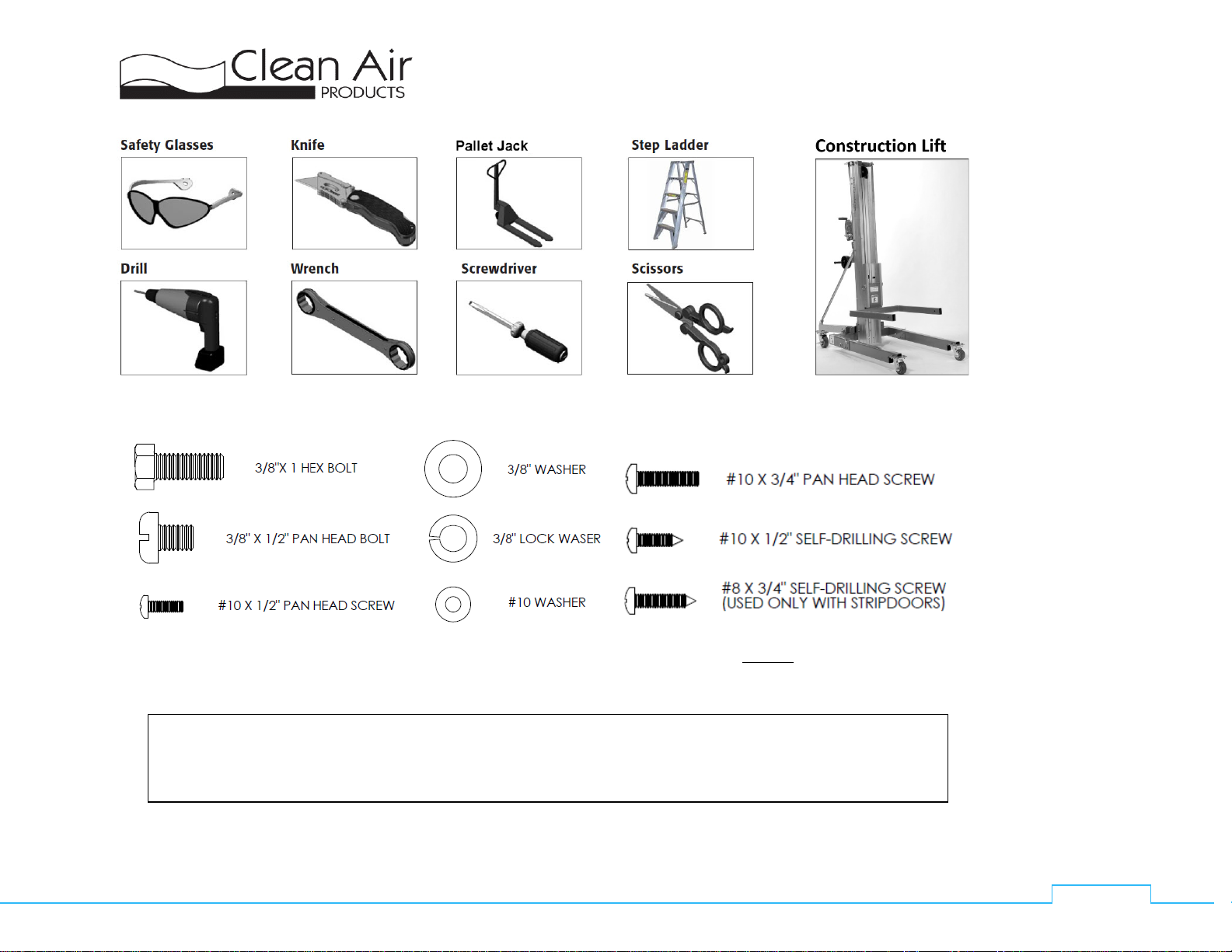

TOOLS AND EQUIPMENT REQUIRED FOR ASSEMB Vertical Flow

8605 Wyoming Avenue N. • Minneapolis, MN 55445

763-425-9122 • 800-423-9728 • Fax: 763-425-2004

E-Mail: [email protected]

www.cleanairproducts.com

200706

Engineering Solutions with Value and Integrity

INSTALLATION & MAINTENANCE INSTRUCTIONS FOR

CAP577

Vertical Flow Softwall Modular Cleanroom

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

2

SUPPLIED HARDWARE

•One or more A-frame style ladders that allow workers safe access above the cleanroom ceiling.

•**A sheet good lift can be useful to help position the filters in the ceiling.

**Review the details of the clean rooms design and become familiar with the layout and

optional items that have been included. Many of these options affect the build process.

Relevant documents can be found on the following pages. **

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

3

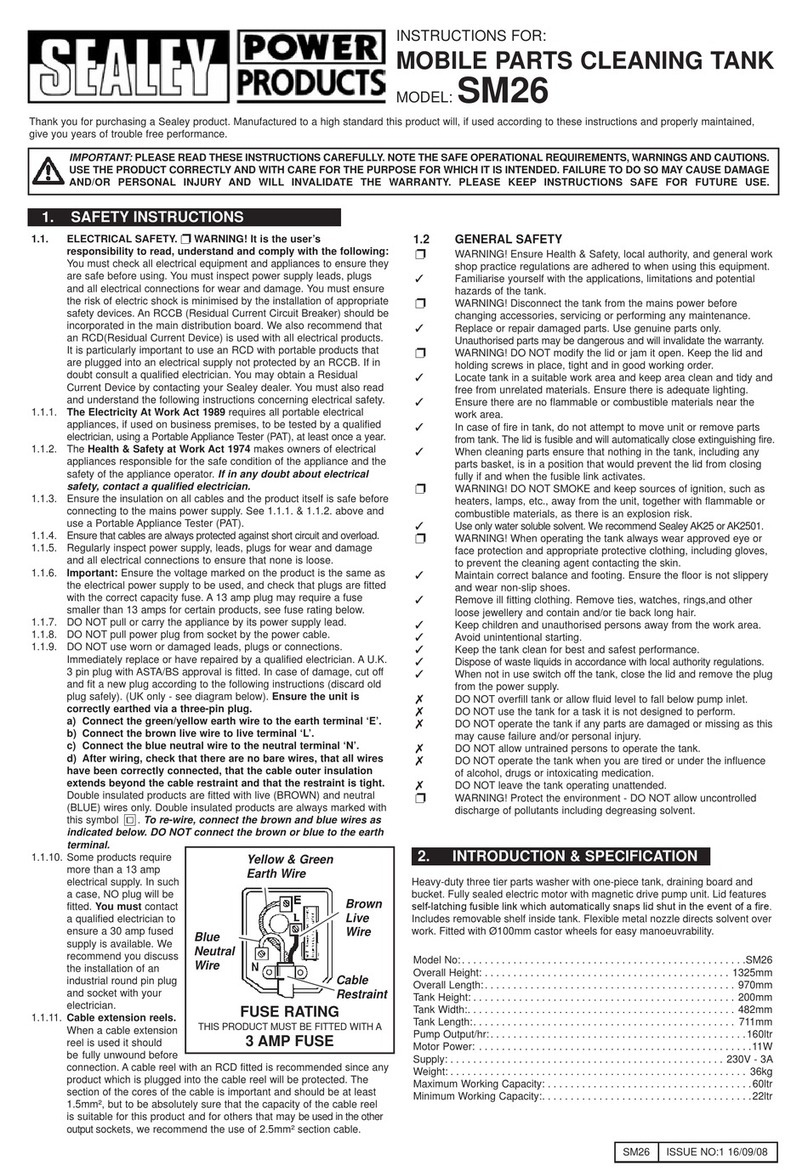

Please observe the following information related to the

product:

1) Read this guide before installing and/or operating

the unit and retain for future reference.

2) Observe warnings associated with handling,

installing, using, and maintaining the CAP577.

3) Follow all instructions for set-up, operation, and

use.

4) Operate ONLY from the type of power source

indicated. If you are unsure of the type of power

available to you, contact your dealer or power

company.

5) This unit may be equipped with a polarized

alternating current (AC) plug with one blade wider

than the other. This plug will only fit into the power

outlet in one way for safety reasons. If the plug does

not fit, call an electrician to replace the outlet. DO NOT

REMOVE THE ROUND GROUNDING TERMINAL. THIS

UNIT MUST BE GROUNDED FOR SAFETY REASONS

AND FOR PROPER OPERATION.

6) Do not place power cords (optional) where they will

be damaged, especially near the outlet, the plug, or

where the power cord exits the unit.

7) Overloading outlets and/or extension cords can

result in fire and/or electrical shock.

8) ONLY use parts supplied or authorized by the

manufacturer. Substitutions may result in fire,

electrical shock, or other safety hazards.

Safety Warnings

1) NEVER expose the assembly to moisture or rain.

2) If the unit gets wet, disconnect the power at the

source and have an authorized service inspection

before using it again.

3) Do not pull on the optional power cord to unplug

the unit, and never handle the cord with wet hands.

4) Do not clean the unit with flammable chemicals.

5) Do not expose to explosive or hazardous vapors or

materials.

6) Make sure the unit is well supported to prevent

falling.

7) Do not block airflow to the unit.

8) Disconnect the power before servicing.

9) Do not operate below 0 degrees Fahrenheit or

above 110 degrees Fahrenheit.

10) This unit is designed to operate in a non-

hazardous (non-explosive) environment with non-

condensing air.

11) NEVER put objects into the blower.

12) Do not operate without metal blower guard.

13) Review application with your safety commissioner

for proper use

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

8

GETTING READY: UNPACK BEAMS

Locate the area that the clean room is going to be assembled and mark out on the ground the final dimensions of

the room with tape or suitable substitute. This is helpful in a later step to ensure the room is “true” and square.

** ONLY USE IPA AS CLEANER ON PAINTED METAL SURFICES TO AVOID RESIDUES THAT MAY CAUSE

ISSUES WITH THE DUAL LOCK ADHESIVE **

Open the beam boxes on the ground and leave the beams on the boxes. Remove and dispose of the shipping blocks

and shipping hardware.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

9

FRAME PREPARATION

Reference your Curtain drawing at the beginning of the manual for the beam layout. On the ground, arrange and

bolt together one section of side beams and their corresponding center beam(s) as seen in the diagram below.

Ensure that the 11/64” holes running along the beams are oriented UP. Keep the beams protected by keeping them

on their shipping boxes. Note the installation order of the washer, lock washer and bolt in the diagram below.

EXAMPLE CURTAIN DRAWING BEAM ASSEMBLY EXAMPLE

ROOM NOTES:

*Larger rooms with more than 4 legs will start by building one “Four Leg Section” of the frame and then add

additional beam sections to the standing structure as described in the FRAME ASSEMBLY section.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

10

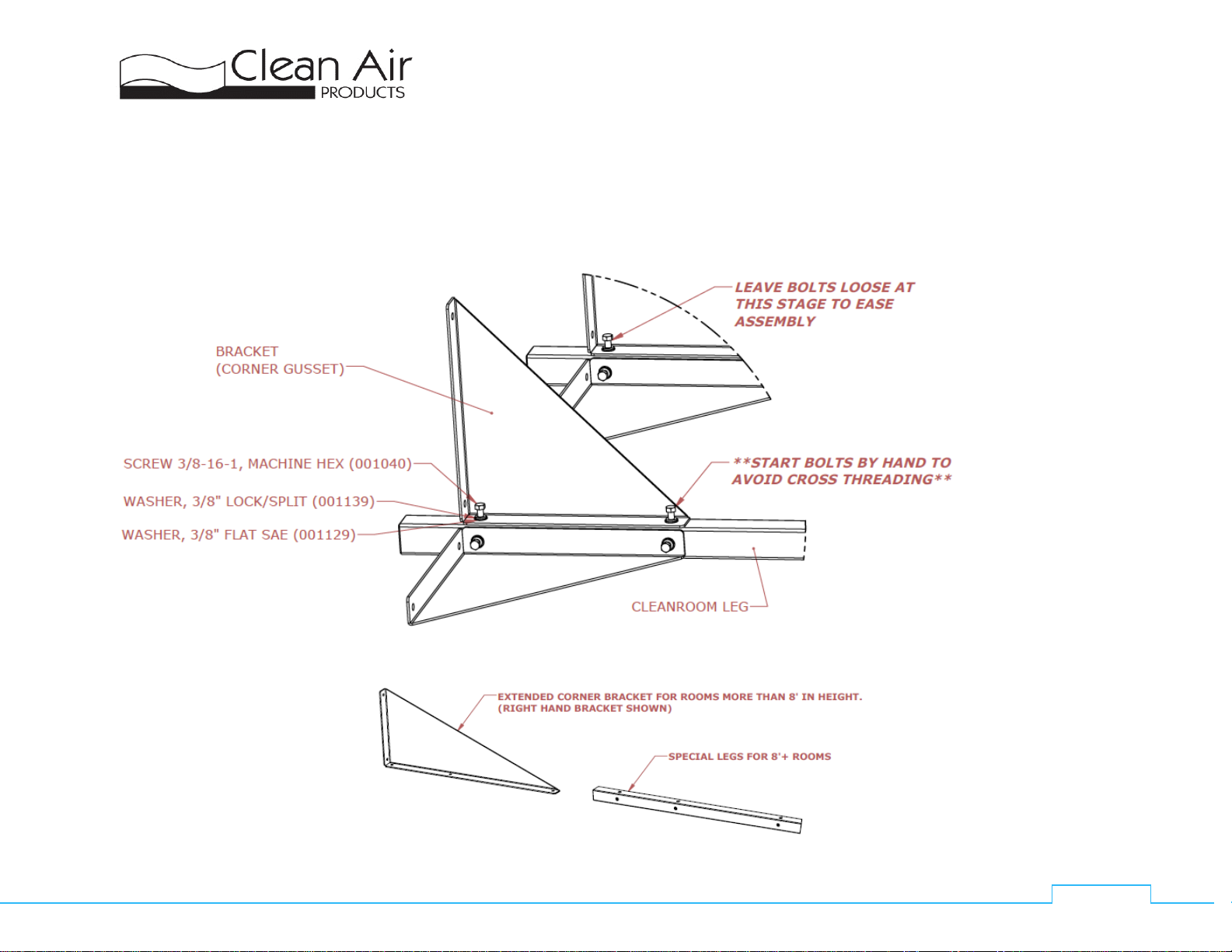

LEG PREPARATION

Note the installation order of the washer, lock washer and bolt. Attach the corner brackets (577 Corner Gusset) to

the legs by manually turning the bolt three full threads by hand. This reduces the chances of cross threading when

using a power driver. Assemble the brackets with the open sides towards each other as seen below. Leave the bolts

loose until the legs are attached to the frame.

NOTES: *Rooms over 8’ in height have special Right and Left handed extended Brackets and matching legs

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

11

*Rooms with six or more legs will require assembling legs with 3 or 4 brackets. Reference the curtain drawing at the

beginning of this manual for quantity and locations.

*Rooms with casters will require the installation of the casters into the legs. The casters are shipped separately in

the hardware box. Slide the top of the caster insert into the bottom of the leg. If necessary, carefully drive the

insert in with a mallet and dowel.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

12

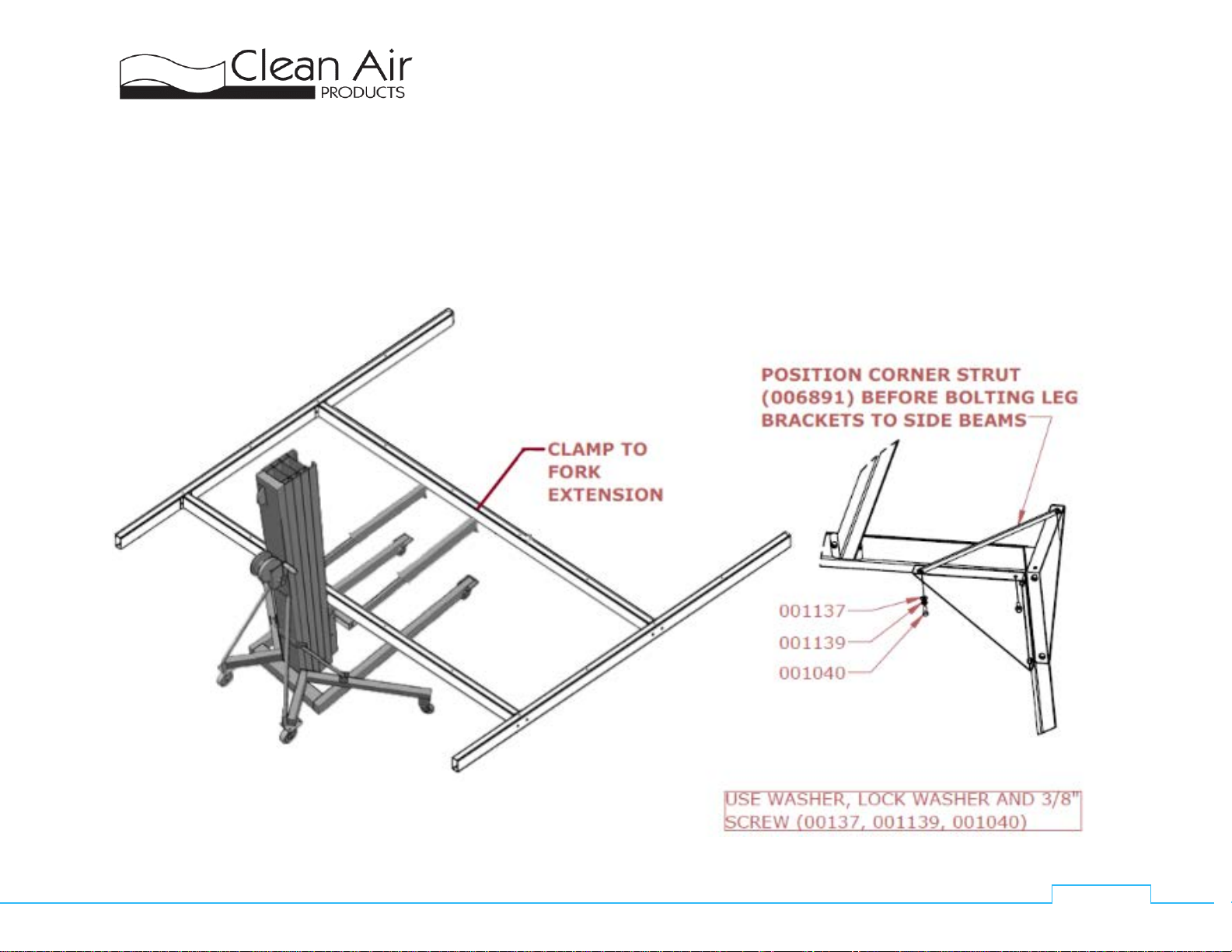

FRAME ASSEMBLY

Using a cardboard box under the beams, position the Lift so that the fork extensions span under a center beam(s).

Clamp the Frame to the fork extension to aid stability. Position a worker on a ladder at a corner to help carefully lift

the structure to the room height. Position a leg in the corner and bolt the leg bracket and corner strut to the side

beam as shown. Leave the lift in place and repeat this process at each corner.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

13

With all four legs attached use one person on each end to lift the additional side beams into place. Bolt them to the

leg brackets while securing the second side of the corner struts. Check the frames dimensions and the spacing of

the legs at the floor to ensure the room is square while tightening all bolts. It is now safe to remove the lift. Use the

leg levelers to plumb the room.

ROOMS W/ MULTIPLE SECTIONS:

Larger rooms with multiple sections are built by adding

additional sections to the first by following the same

procedure.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

14

FRAME ASSEMBLY

Locate all unused 3/8” holes in the frame and legs and insert

the 3/8” white nylon slotted screws (056586). Gasket the

tops of the beams with the 50’ roll(s) of 1/4” x 1/2” foam

gasket (012231). Apply one strip around the inside perimeter

of the room and two strips down the center beams as shown.

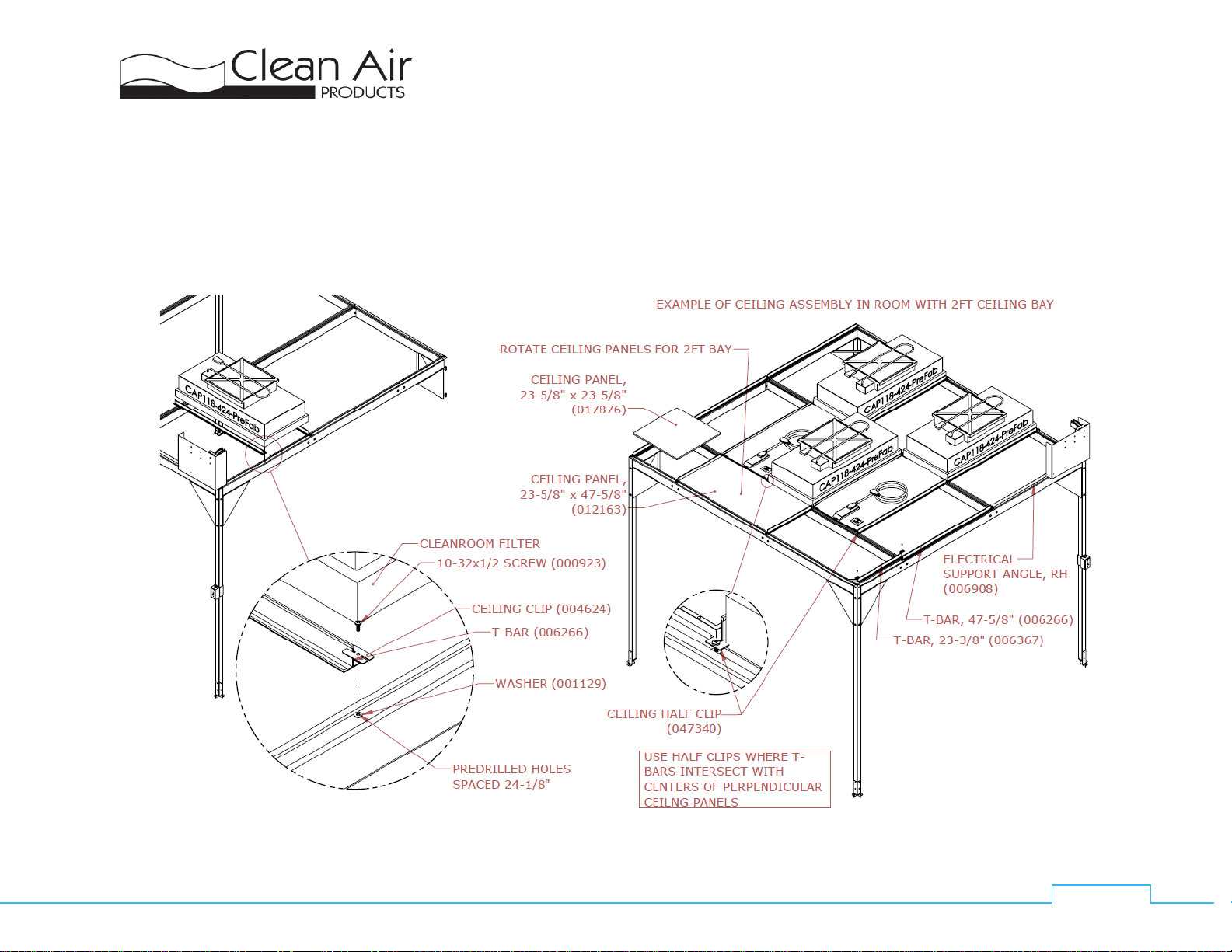

If prefabricated wiring was purchased determine the

location and orientation of the optional prefabricated

wiring panel. Inspect the approval drawings and

determine the orientation of the 4’ sides of the ceiling

panels. This is the side that will have T-bars. The

electrical mounting angle will be orientated in the

same direction as the T-Bars and be installed in place

of one. Mount the angle and then position and mount

the electrical box with (3) 10x1/2 Self Drilling

screws(000960). Do not add clips to the conduit or

mount the light switch until after the curtains are

installed.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

15

CEILING ASSEMBLY

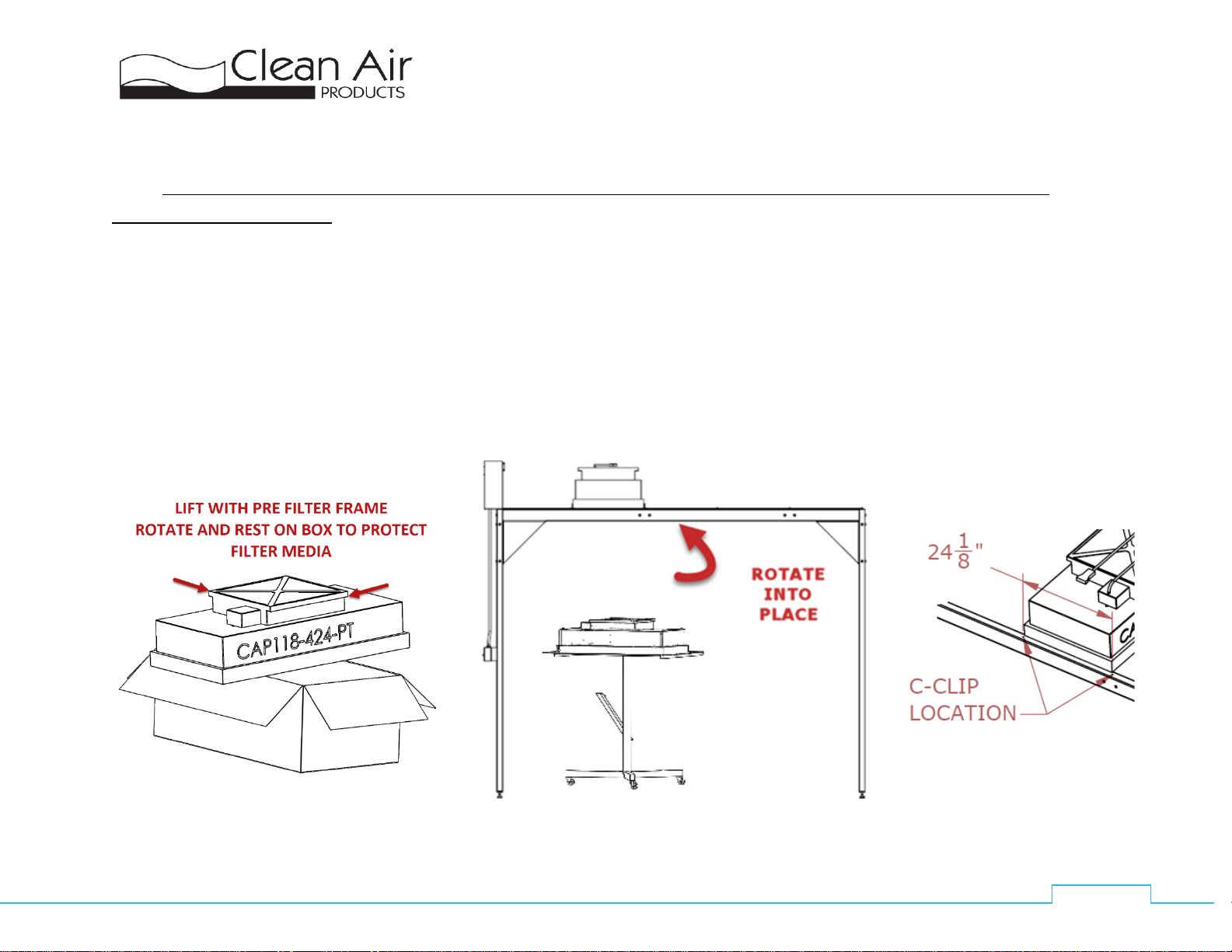

**CAUTION: While working with the filter units do not touch the filter screen. Filter

damage may result. **

Choose the layout of the filter units in the ceiling grid or refer to the reference drawings. Install them one by one

starting nearest to the wiring location so that they can be wired as they are installed. Daisy chain the filters

together using the prefabricated connecters if ordered. Do not connect more than (6) to a circuit.

It is easiest to remove the filter with a helper. Hold the box steady and grasp the prefilter frame. Carefully pull the

filter out and rest it perpendicularly on the box to prevent damage to the filter media.

To install a filter unit place cardboard on the lift supports to protect the filter. Carefully rest a filter unit on the

cardboard and lift the filter to the height of the beam grid. Carefully, avoiding contact with the filter screen, tilt the

filter through the frame to rest on the tops of the beams between two holes (11/64”) .

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

16

Slide a T-bar (006266) under one edge of the filter housing and attach it to the frame with a Washer (001129),

Ceiling clip (004624) and 10-32 screw (000923) in the predrilled hole. Repeat the process of adding a T-bar to the

other side of the filter. Continue to repeat this process to install the rest of the Filter units and Lights. When wiring

is complete install the remaining T-Bars and ceiling clips to complete the grid before lifting the Gypsum ceiling

panels into place.

**MAXIMUM 6 Filter Units per 20A Circuit **16 Lights per connector/ MAXIMUM 32 lights per 20A Circuit

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

17

CURTAIN INSTALLATION

Attach the 1 inch wide “fine” Dual Lock to the outside TOP EDGE of the rooms frame. Refer to the included Curtain

Drawing for suggested positioning and orientation of the cleanroom curtains.

If strip doors were ordered locate their positions and install them onto the Dual Lock. Use (3) #8 self-drilling Pan

head screws (000919) to secure the door frames to the Beams.

Next place your Filler Curtain(s). Filler curtains have Dual Lock on the full width of both sides of the curtain to allow

for the end curtain to overlap as needed. The filler curtain(s) will be located next to a strip door or at a room corner

as seen on your

rooms curtain

drawing. Be sure to

attach the coarse

side of the Dual

Lock inwards to the

already hung “Fine”

style Dual Lock.

Start hanging

curtains on the

other side of the

strip door and work

around the room

until the last curtain

overlaps the Filler

Curtain. Each

curtain will overlap

the last by 6” by

attaching to the

“Fine” Dual Lock

mounted to the

outside of the last curtain.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

18

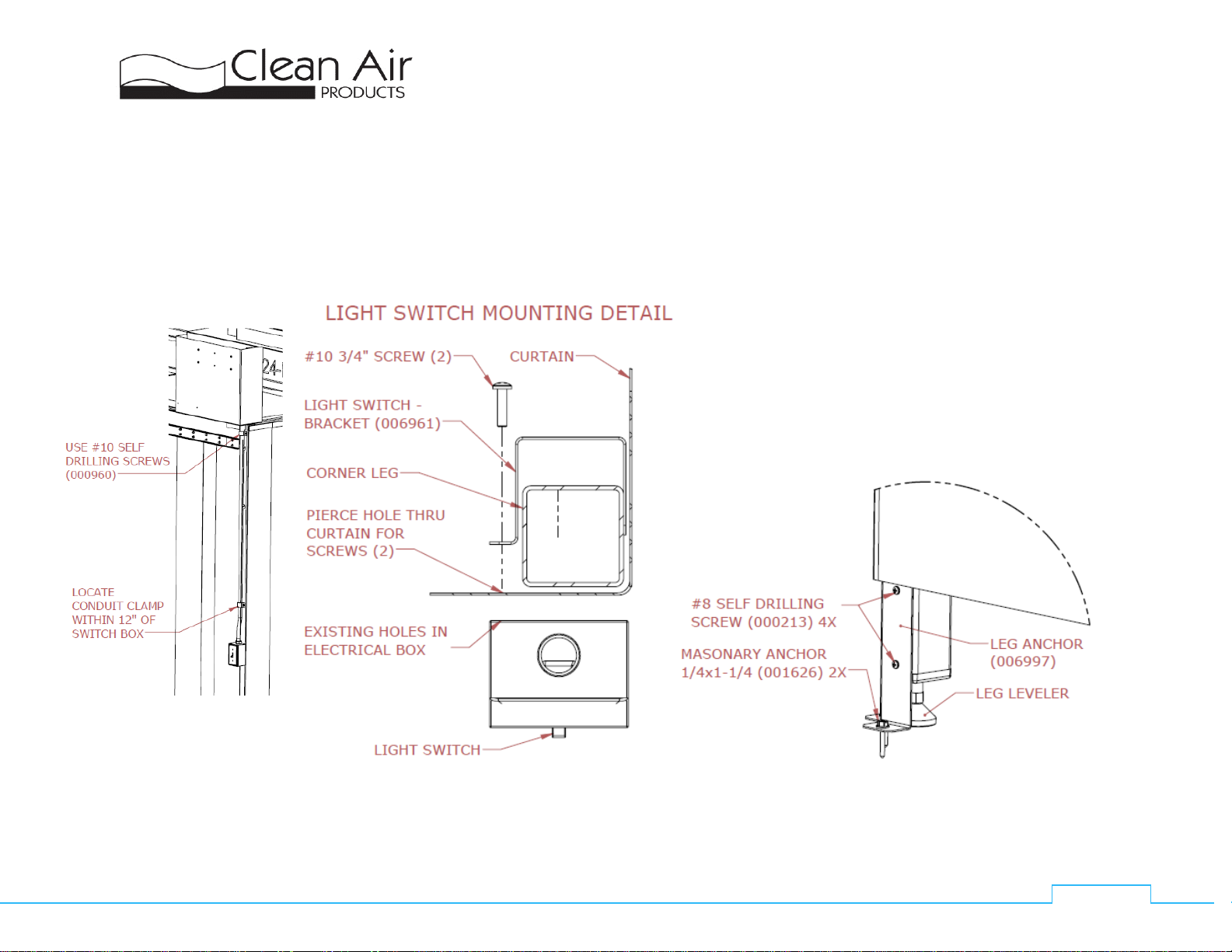

FINISHING THE ROOM

After all curtains have been hung mount the light switch with the included bracket and complete the installation of

the electrical box. Secure the conduit with the two supplied ¾” clamps (029622) and #10 self drilling screws

(000960).

Anchor the room to the floor with the included Leg Anchors (006997) and ¼” x 1-1/4” masonry anchors (001626).

Use (4) #8 -1/2 self Drilling screws (000213) to attach the Leg Anchors to the Legs.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

19

Maintenance of the CAP 577

PREFILTERS

It is recommended that the prefilters be visually checked on a regular basis. If the filter appears dirty, it is time to

replace it. Typically, one would change the prefilters once a month. However, some environments may require

different replacement intervals.

HEPA/ULPA Filters

It is recommended that clean rooms be certified by a third party on an annual basis. Certification will verify the

expected class of the room. As the HEPA/ULPAs are new, the rooms have a certain number of air changes per hour

based upon the class of the room. As the HEPA/ULPAs get dirty, the air changes per hour goes down. If the prefab

wiring kit was purchased, the speed control should then be turned up so the velocity out of the filters reaches 90

feet/min. average face velocity. This will provide the proper air changes per hour. When the velocity falls to 70

feet/min. and the speed control is at its highest setting, the filters need to be changed. If this situation occurs, it

does not mean that the room is not functioning, it just means the conditions are not ideal and the filters need to be

replaced.

If you do not have access to a velocity meter or cannot get certification, a general rule of thumb is that the filters

should last 3 to 5 years and can last as long as 10 years depending on the cleanliness of the environment.

MOTORS

The motors do not need maintenance. They are permanently lubricated.

GENERAL CARE

Periodically check cleanroom components to be sure they are in good working order.

Clean the interior of the cleanroom and floors on a regular basis.

Check the filter velocity on a regular basis.

Annually check filters for leaks.

8605 Wyoming Ave. N. •Minneapolis, MN 55445 • 763-425-9122 • 800-423-9728 • Fax 763-425-2004

210226

INSTALLATION & MAINTENANCE GUIDE

CAP577

Vertical Flow Softwall Modular Cleanroom

www.cleanairproducts.com

20

Warranty Information

Clean Air Products Corporation warrants that it will repair FOB its factory or furnish without charge FOB its factory a similar part

to replace any material in its equipment within one year after the date of sale if proved to the satisfaction of the company to

have been defective at the time it was sold provided that all parts claimed defective shall be returned, properly identified to the

company at its factory, freight charges prepaid. Factory installed equipment of accessories is warranted only to the extent

guaranteed by the original equipment manufacturer, and this warranty shall not apply to any portion of the equipment modified

by the user. Claims under this warranty should be directed to Clean Air Products, 8605 Wyoming Avenue North, Brooklyn Park,

MN 55445, setting forth in detail the nature of the defect, the date of the initial installation, and the serial number and model

number of the equipment.

HEPA filters are warranted to have their given efficiency at the time of shipping

Parts shipped to replace warranty items shall be invoiced out with 60 day terms. Credit shall be issued when defective parts are

returned to Clean Air Products’ factory. (Contaminated materials shall be credited after receipt of proper disposal is sent to

Clean Air Products.)

When special shipping containers are used to ship out new product, defective parts are to be returned in the same container.

This shall be so stated on the Bill of Lading sent with the replacement parts.

Contaminated Parts and Equipment

Clean Air Products must be notified if defective parts, or other materials supplied to the purchaser are contaminated with

hazardous chemicals or carcinogenic materials that are considered hazardous or carcinogenic by the EPA or other regulatory

agencies. These parts are not to be shipped back to Clean Air Products’ factory. The purchaser shall be responsible for proper

disposal and all costs associated with the disposal and/or storage of the defective contaminated equipment. Prior to their

disposal, Clean Air Products may require inspection of said defective materials.

The user and purchaser shall each be responsible and be back charged for cleanup and disposal of all contaminated materials

shipped back to Clean Air Products’ factory.

Table of contents