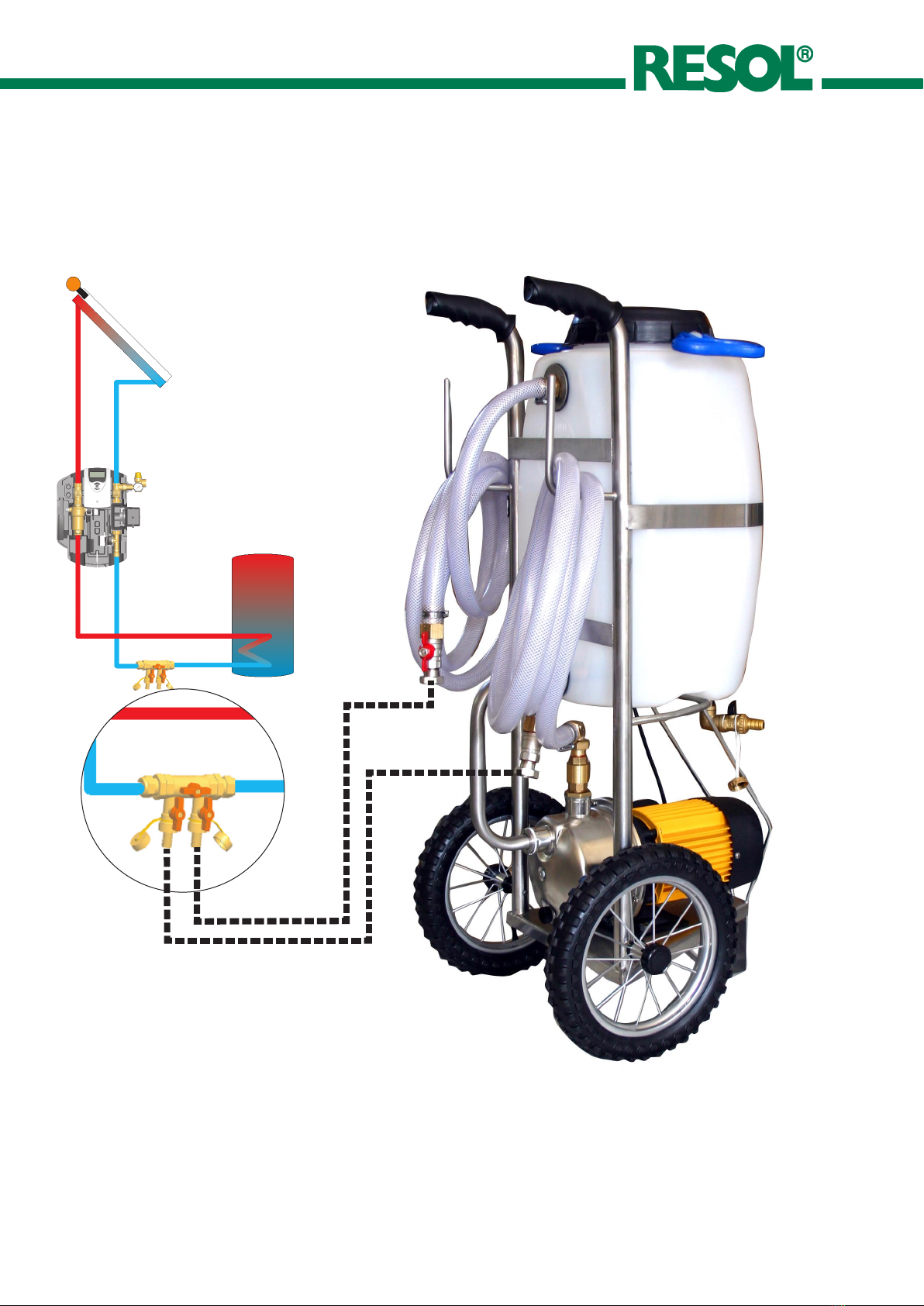

• Disconnecttheexpansionvesselfromthesolar

thermal system.

• ConnectthepressurehoseoftheSBS1000tothell

valve(5)oftheushingandllingunit.

• ConnecttheushinghoseoftheSBS1000tothedrain

valve(3)oftheushingandllingunit.

• Closetheballvalve(4)inthecentreoftheushingand

filling unit

• Turntheballvalvesinow(1)andinreturn(2)withan

open-ended spanner to a 45° position.The non-return

valves in the ball valves are now open.

• Openthellanddrainvalves(3and5).

• OpentheballvalvesoftheSBS1000.

• Flushthesolarthermalsystemusingtheushingand

filling station for at least 15 until the discharged heat

transfer fluid is free of dirt particles and air bubbles.

• Duringushing,bleedthesolarthermalsystemseveral

timesattheAirStopp(6)untilthedischargedheat

transfer fluid is free of air bubbles.

• Closethedrainvalve(3)oftheushingandllingunit

with the filling pump running and increase the system

pressure to approx. 5 bar.The system pressure can be

read from the manometer

• Closethellvalve(5)andswitchoffthepumpofthe

flushing and filling station.

• Checkthemanometertoseewhetherthesystem

pressure reduces and eliminate leaks where necessary.

• Reconnecttheexpansionvesseltotheothercompo-

nents of the solar thermal system.

3

4

5

12

Example: pump station RESOL FlowConC

6

3.2 Flushing and filling the solar thermal

system

• Openthellvalve(5)andswitchonthellingpump.

• Settheoperatingpressureofthesolarthermalsystem

(approx. 0.5 bar higher than the inlet pressure of the

expansion vessel or the indications made by the manu-

facturer).

• Switchoffthellingpump,closethellvalve(5)and

opentheballvalve(4).

• Slowlydischargetheheattransferuidbymeansofthe

drainvalve(3)untiltheoperatingpressure(seeabove)

is set.

• ClosetheballvalvesoftheSBS1000.

• RemovethehosesfromtheSBS1000andscrewthe

caps onto the fill and drain valves

• Empty the contents of the hoses into the tank of

the SBS 1000 by opening the ball valves carefully.

Closetheballvalves.

• Putthenon-returnvalvesinowandreturninopera-

ting position by opening the ball valves with an open-

ended spanner

• Manuallyputthesolarthermalpumpinoperationat

thehighestRPMlevel(seecontrollermanual)andlet

it circulate for at least 15 minutes.

• Duringushing,bleedthesolarthermalsystemseveral

times at the AirStopp,until the discharged heat transfer

fluid is free of air bubbles and increase, if required, the

system pressure to the operating pressure.