5

MANUAL - WALL MOUNT WATERBORNE GUN CLEANERS - UM80 SERIES REVISED 2015-5-30

• Clean the Cap by rubbing it on the Flat Brush mounted on the inside of the tank.

• Exterior Cleaning - Clean the exterior of the gun with the Flow-through brush. Activate the flow of liq-

uid through the Brush by turning the long arm of the Selector Knob to the left to the Brush position.

When finished, turn it to the closed position.

UM80S

The S model does not have a whip line. Follow the procedure above starting with Interior Cleaning

UM80W / WF / A

• Dry Spray Gun: Use the Air Blow Gun to dry the outside of the spray gun. To dry the paint channel,

squeeze the trigger of the spray gun.

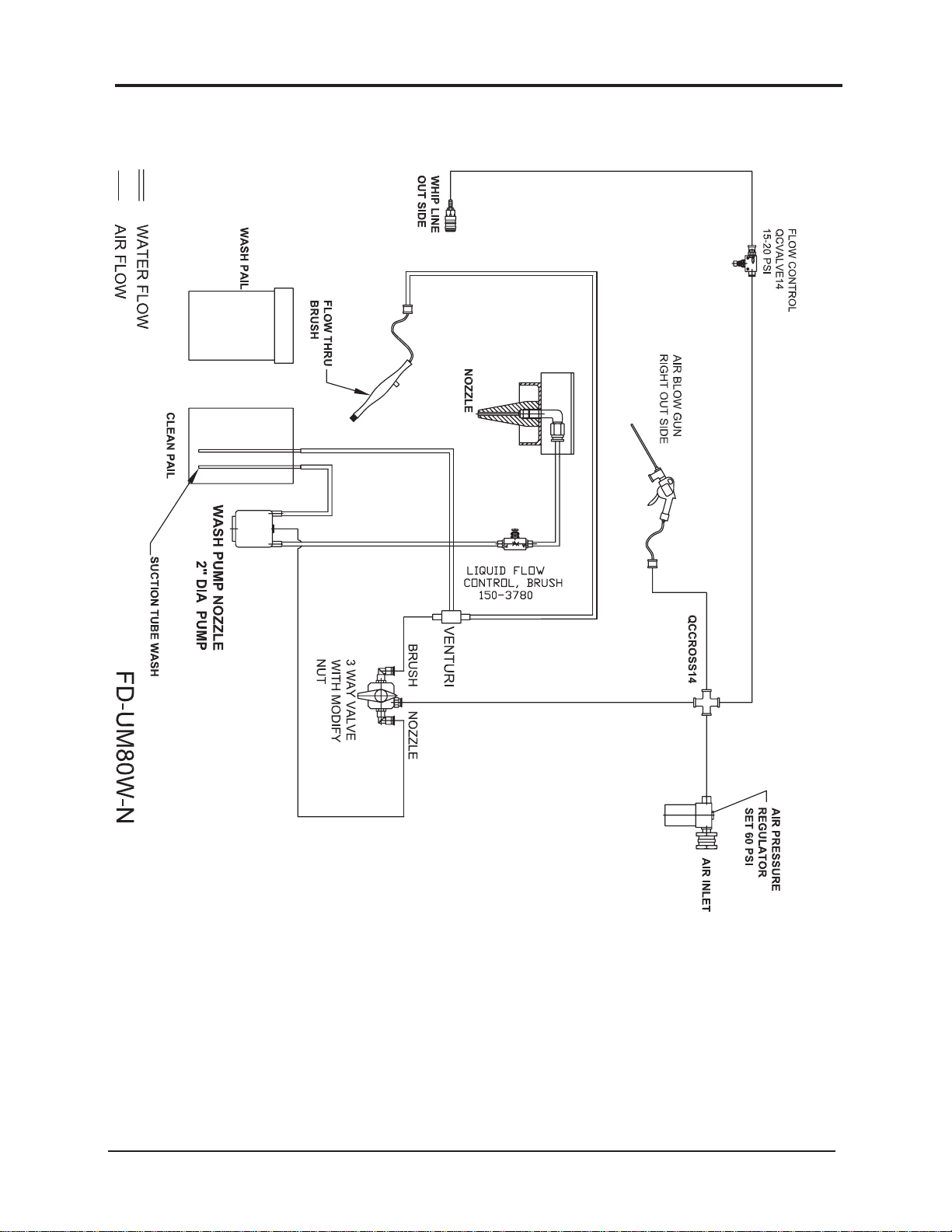

• Flow Control: To adjust the flow of water through the Nozzle, use the control on the right side. The

controls are pre-set at the factory - change only if necessary. To increase the flow, loosen the nut,

then turn the knob to the left. To reduce the flow loosen the nut, turn the knob to the right.

UM80S

• Dry Spray Gun: Use the Air Blow Gun to dry the paint channel and the outside of the spray gun.

• Flow Control: The "S" model has a flow control for the Nozzle and Brush on the right side of the unit.

The controls are pre-set at the factory - change only if necessary. To increase the flow, loosen the

nut, then turn the knob to the left. To reduce the flow loosen the nut, turn the knob to the right.

CAUTION: MAKE SURE THE GUNS ARE COMPLETELY DRY AFTER USE

FLOCCULATION (WF Model Only)

The dirty water from cleaning accumulates in the flocculation reservoir during use. When the Wash Pail is

empty follow these steps to treat the water for re-use:

• Remove the Screen at the bottom of the work area and sprinkle 1 full scoop of the flocculant,

COAG-KLEEN, evenly over the dirty water. Replace the screen and turn the Flocculation Timer

fully to the 5 minute position. When the Timer is finished wait one minute and then turn the timer a

second time to the one minute mark. Note: As the flocculation proceeds, the water should become

clear. The debris consisting of paint absorbed into the flocculant will collect in the filters during the

next step.

• To allow the water-flocculant mixture to flow into filters, open the Flocculation Drain valve.

• Clean the tank with the Brush.

• Close the Flocculation Drain valve (horizontal position).

• Ensure that the Air Agitator in the bottom of the tank lies flat.

• Leave the two filters containing the debris in place until the next day to allow for them to dry

throughly. When the debris is dry, it should have an "oatmeal like" consistency. The debris can now

be disposed of according to local environmental regulations.

• If the filtered water is not clean, see the Troubleshooting section.

• The treated water can be reused until it becomes "silky" to the touch and then it should be dis-

posed of according to local environmental regulations. When adding fresh water, refill until the

water reaches the bottom of the filter holder.