cleanAIR CAP18 Instruction Manual

8605 Wyoming Avenue N. • Minneapolis, MN 55445

763-425-9122 • 800-423-9728 • Fax: 763-425-2004

E-Mail: sales@cleanairproducts.com

www.cleanairproducts.com

Engineering Solutions with Value and Integrity

OPERATION & MAINTINENCE INSTRUCTIONS FOR

CAP18

Pass Thru Air Lock Cleanroom Entry System

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

2

Table of Contents

Safety Warnings 3

Installation 3

Wall Mounted Pass Thru Installation 4

Floor Mounted Pass Thru Installation 5

Fire Rated Pass Thru Installation 7

Operation & Maintenance 8

Interlock Operation 8

HEPA Filter Operation 8

Maintenance 9

Troubleshooting 9

Warranty Information 10

Read and Save These Instructions

Please observe the following information related to your product

Read this guide before installing and/or operating the unit.

Keep this guide as a reference to the safety and operating instructions.

Observe warnings associated with handling, installing, using, and maintaining the

CAP18.

Follow all instructions for set-up, operation, and use.

Operate ONLY from the type of power source indicated. If you are unsure of the type

of power available to you, contact your dealer or power company.

This unit may be equipped with a polarized alternating current (AC) plug with one

blade wider than the other. This plug will only fit into the power outlet one way for

safety reasons. If the plug does not fit, call an electrician to replace the outlet. DO

NOT REMOVE THE ROUND GROUNDING TERMINAL. THIS UNIT MUST BE GROUNDED

FOR SAFETY REASONS AND FOR PROPER OPERATION.

Do not place any power cords where they will have things placed on or against them,

be walked on, or be pinched, especially near the outlet, the plug, or where the power

cord exits the unit.

Overloading outlets and/or extension cords can result in fire and/or electrical shock.

ONLY use parts supplied by the manufacturer. Substitutions may result in fire,

electrical shock, or other safety hazards.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

3

Safety Warnings

Never expose the assembly to moisture or rain.

If the unit gets wet, disconnect the power at the source and have an authorized

service inspection before using it again.

Do not pull on power cords to unplug the unit, and never handle the cord with wet

hands.

Do not clean the unit with flammable chemicals.

Do not expose to explosive or hazardous vapors or materials.

Make sure the unit is well supported to prevent falling.

Do not block airflow to the unit.

Disconnect the power before servicing.

Do not operate below 0 degrees Fahrenheit or above 110 degrees Fahrenheit.

This unit is designed to operate in a non-hazardous (non-explosive) environment

with non-condensing air.

NEVER put objects into the blower.

Do not operate blower without metal blower guard.

Review application with your safety commissioner for proper use

Installation

Notes

Pass thrus must be installed in a flat and level wall capable of supporting the weight

of the pass thru. Weight depends on size, model, and options package.

The pass thru should be well supported on all sides and securely mounted so that it

will not shift when weight is inserted. If the pass thru is not securely mounted it may

loosen over time.

Pass thrus need to be installed so that they are square and level. This is critical to

ensure proper alignment of the latch and interlock components.

The recommended wall cutout is ½” larger than the exterior of the pass thru in each

direction.

Sloped top mounting frames should be attached to the pass thru before installing in

wall. If there is a sloped top on both sides, one side is screwed into the pass thru

and the wall, the opposite side is only screwed into the wall.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

4

Standard Wall Mounted Pass Thru Installation

Before installation locate all mounting frames and mounting frame hardware. The “notched”

frame pieces attach to the vertical sides of the pass thru. Wall mounted pass thrus featuring

universal mounting frames can be installed in a variety of configurations as outlined below.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

5

Floor Mounted Pass Thru Installation

Before installation locate all mounting frames, mounting frame hardware, and shipping

braces. The “notched” frame pieces attach to the top of the pass thru. Floor mounted pass

thrus featuring universal mounting frames can be installed in a variety of configurations as

outlined below.

Unpackaging

If the pass thru is fully welded, skip to mounting frame installation. Non-fully welded floor

mounted pass thrus are attached to a plywood base for shipping. To remove the plywood

base, remove any screws attaching it to the pallet. Then slide the pass thru off the edge of

the pallet and remove the (4) bolts attaching the plywood base located near each corner.

These bolts thread into a nut plate within the pass through walls.

Installation

Remove both of the interior side panels and all shipping braces from within the cabinet. At

this point the interior nut plate can also be removed.

Next reinstall the galvanized shipping braces

along with one shim on each end. These braces

will help retain the correct pass thru width.

Some very large pass thrus also include

diagonal shipping braces to maintain

squareness, these should be installed as well if

applicable. At this point the mounting frames

can be installed.

It is critical that the pass thru is square when

mounting frames are installed. If the pass thru

is not square the latch and interlock

components can become misaligned.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

6

Floor Mounted Pass Thru Installation (Continued)

Anchoring to Floor (Optional)

To anchor a non-fully welded pass thru to the floor, drill though the 7/16” holes within the

pass thru wall cavity into the floor for anchor bolts.

Clean Air Products does not provide

anchoring hardware.

The shipping braces and shims should still be installed during this step.

Final Assembly

Once the pass thru is fully secured and functioning within the wall remove the shipping

braces and reinstall the interior side panels. Adjust floor sweeps if needed by loosening all

screws attaching the sweep and moving it along the slots. Replace any exposed zinc

hardware with the provided stainless steel hardware.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

7

Fire Rated Pass Thru Installation

Most fire rated pass thrus come with pre-installed universal anchoring brackets welded into

the frame throat as shown. These can be anchored to a variety of wall types. Below are the

most common installation methods.

The pass thru must be installed plumb and square to ensure proper door alignment.

Shimming may be necessary to square the cabinet.

Installation Notes

It is recommended that floor

mounted fire rated units be

anchored to the floor in addition to

the wall.

Maintain clearance between frame

return flanges and stud for inserting

drywall.

Do not install drywall until you are

certain the frame and pass thru are

plumb and square.

Drywall must extend at least ½” into

the frame.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

8

Operation & Maintenance

After installation the pass thru should be checked for proper function. Door latches and

interlock components should be aligned and operate smoothly.

Interlock Operation

Pass thru interlocks prevent both doors from being open at the same time. When one door

opens the opposite side is locked. The most common interlock styles are listed below.

90° Rotation T-Handles

The T-handles are connected so when one side is

unlocked (T-handle vertical) the opposite side will be

locked (T-handle horizontal). The T-handles can only be

turned when both doors are closed; when one door is

open the internal guide pin is decompressed and will

prevent the T-handles from turning.

Fire Rated / Bio-Design Interlocks

Fire rated and Bio-Design interlocks do not have stainless steel T-handles. They both have

interlock mechanisms which will lock the opposite side automatically as soon as a door is

opened.

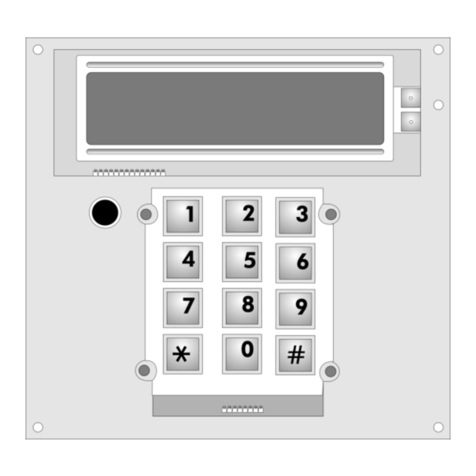

Magnetic Interlocks

If your pass thru is equipped with magnetic style interlocks the doors are normally locked.

The doors are unlocked by an illuminated capacitive touch button. When both of the doors

are closed the buttons are green the doors can be unlocked. If a door is open the buttons

are red and the opposite door cannot be unlocked.

HEPA filtered units equipped with the optional air shower style controls may also be locked

while the filter is running. Wiring schemtics are included with the manual inside unit.

HEPA Filtered Pass Thru Operation

HEPA filter blowers are set to a velocity of 90ft/min from the factory and feature a speed

control for adjustment in the field. HEPA filters will remove 99.99% of airborne particles at

0.3 µm. Test sheets and a wiring schematic are included in each pass thru with the manual.

Do not touch the filter media; if the media becomes damaged the filter will need to be

replaced.

Air Flow

Standard CAP18WHF HEPA filtered pass thrus continuously recirculate the air within the

walls through perforations in the inner side panels. Fully welded HEPA filtered pass thrus

purge air through the dirty side door. Air flow diagrams can be found on our website.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

9

Maintenance

At least once a day wipe down interior surfaces and knobs. Contaminate can get into

the pass thru while the dirty side door is open. Particles can float into the pass thru

and settle on the interior. If left uncleaned this contamination can then be

transferred into the cleanroom.

If the pass thru doors feature polycarbonate or acrylic windows wipe them down

lightly with soft cleanroom wipes to avoid scratching. Verify that any cleaning

chemicals used are compatible the with window material before cleaning.

Once a year check that the pass thru is securely mounted. All hardware, including

perimeter mounting screws should be securely fastened.

Verify that any cleaning chemicals used are compatible with cabinet materials.

Troubleshooting

Mechanical Interlock T-handles will not turn

Check that the interlock strikes aren’t bent; they should be at a 90° angle to the door.

Mechanical Interlock T-handles turn even when the door is open

Look inside the rectangular slot on the front of the cabinet to check that the guide pin is

functioning properly.

8605 Wyoming Ave. N.

•

Minneapolis, MN 55445

•

763

-

425

-

9122

• 800

-

423

-

9728 • Fax 763

-

425

-

2004

200625

OPERATION & MAINTINENCE INSTRUCTIONS

CAP18

Pass Thru Air Lock Cleanroom Entry System

www.cleanairproducts.com

10

Warranty Information

Clean Air Products Corporation warrants that it will repair FOB its factory or furnish without

charge FOB its factory a similar part to replace any material in its equipment within one

year after the date of sale if proved to the satisfaction of the company to have been

defective at the time it was sold provided that all parts claimed defective shall be returned,

properly identified to the company at its factory, freight charges prepaid. Factory installed

equipment of accessories is warranted only to the extent guaranteed by the original

equipment manufacturer, and this warranty shall not apply to any portion of the equipment

modified by the user. Claims under this warranty should be directed to Clean Air Products,

8605 Wyoming Avenue North, Brooklyn Park, MN 55445, setting forth in detail the nature of

the defect, the date of the initial installation, and the serial number and model number of

the equipment.

HEPA filters are warranted to have their given efficiency at the time of shipping

Parts shipped to replace warranty items shall be invoiced out with 60 day terms. Credit shall

be issued when defective parts are returned to Clean Air Products’ factory. (Contaminated

materials shall be credited after receipt of proper disposal is sent to Clean Air Products.)

When special shipping containers are used to ship out new product, defective parts are to

be returned in the same container. This shall be so stated on the Bill of Lading sent with the

replacement parts.

Contaminated Parts and Equipment

Clean Air Products must be notified if defective parts, or other materials supplied to the

purchaser are contaminated with hazardous chemicals or carcinogenic materials that are

considered hazardous or carcinogenic by the EPA or other regulatory agencies. These parts

are not to be shipped back to Clean Air Products’ factory. The purchaser shall be responsible

for proper disposal and all costs associated with the disposal and/or storage of the defective

contaminated equipment. Prior to their disposal, Clean Air Products may require inspection

of said defective materials.

The user and purchaser shall each be responsible and be back charged for cleanup and

disposal of all contaminated materials shipped back to Clean Air Products’ factory.

Table of contents