CleanCraft GPI 5548 User manual

garden pump

GPI 5548

operating manual

GPI 5548

WATERPUMP

Machine Translated by Google

imprint contents

12 Disposal, recycling of old devices...17

1. Introduction ................................................ ...............3

1.1 Copyright................................ ....................... 3 1.2

Customer Service........................ ............................ 3

1.3 Limitation of liability................. .................... 3

6 Transport, packaging, storage........................8 6.1

Delivery................ .......................................... 8 6.2

Transportation ..... .................................................. .....

8 6.3 Packaging........................................ ............... 8

6.4 Storage................................ ....................... 8 7

Description of the device .................. .............................9

7.1 Accessories .................. .......................................

10 7.2 Functional description..... ................................ 10

10 Operation ..................................... ..................14 10.1

Operating the water pump ........................ 14 11 Care ,

maintenance and repairs ..16 11.1 Care through

cleaning .................................. 16 11.2 Maintenance

and maintenance/repair......... 16 11.3 Inspection of

the pump................................. ..... 17

16 EU Declaration of Conformity ........................22 17

Notes .......... .................................................. .....23

8 Installation ................................................ .............11

4 Nameplate ..................................................... .............8

5 Specifications................................. ...................8th

9 Commissioning................................................ ......13

15 Spare parts ..................................................... ............20

15.1 Ordering spare parts................................... ......

20 15.2 Spare parts drawing........................................ 21

13 Malfunctions, possible causes and measures ..17

14 Error codes .................................. ...................19

item number

Internet:

0049 (0) 951 96555 - 55

www.cleancraft.de

GPI 5548

Edition: 19.11.2019 Version:

1.02 Language: German

product identification

garden pump

E-mail:

8.1 Notes on installation................................. 11 8.2 Assembling

the pump ...... .................................... 11 8.3 Connection of the

suction line .......... ..................... 12 8.4 Electrical

connection........................ ............. 13

Fax:

12.2 Disposal of electrical devices......... 17 12.3 Disposal of

lubricants......................... 17 12.4 Disposal at municipal

collection points . 17

GPI series | Version 1.02

Stuermer Maschinen GmbH Dr.-

Robert-Pfleger-Str. 26 D-96103

Hallstadt

12.1 Decommissioning........................................ 17

Manufacturer

2

Technical changes and errors reserved.

Original operating instructions

copyright

Passing on and duplicating this document, using and

communicating its contents are prohibited unless expressly

permitted. Violations oblige to compensation.

Information on the operating instructions

2 Security ..................................................... .................3 2.1

Explanation of symbols...................... ................... 3 2.2

Responsibility of the operator ........................ .. 4 2.3 Personnel

qualifications ................................ 5 2.4 Personal protective

equipment ........ .................... 5 2.5 General safety

instructions ........................ 5 2.6 Safety labeling on the water

pump .. 7 3 Intended use ........................7 3.1

Misuse............ ........................................ 7 3.2 Residual

risks....... .................................................. 7

Copyright © 2019 Stürmer Maschinen GmbH, Hallstadt, Germany.

The contents of these operating instructions are the sole

property of Stürmer Maschinen GmbH.

7521400

Author: FL

Machine Translated by Google

1. Introduction

2 security

water pump.

Illustrations in these operating instructions are for

basic understanding and may deviate from the

actual design.

E-mail:

Safety instructions are identified by symbols in

these operating instructions. The safety instructions

are introduced by signal words that

- Improper use,

The obligations agreed in the delivery contract, the

general terms and conditions and the

0049 (0) 951 96555-111

service@stuermer-maschinen.de

All information and instructions in the operating

instructions have been compiled taking into account

the applicable standards and regulations, the state of

the art and our many years of knowledge and

experience.

- Use of unapproved spare parts.

They will be happy to help you with expert advice and

information.

You have made a good choice with the purchase of

the CLEANCRAFT garden pump.

- unauthorized conversions,

regulations.

Spare parts order:

will result in death or serious injury if not avoided.

Fax:

The manufacturer accepts no liability for damage in

the following cases:

It must always be kept at the place where the water

pump is used. In addition, the local accident prevention

regulations and general safety regulations for the area

of application of the water pump apply.

The contents of these instructions are protected

by copyright. Their use is permitted within the

scope of using the water pump. Any other use is

not permitted without the written consent of the

manufacturer.

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

We are always interested in information and

experiences that result from the application and can

be valuable for improving our products.

- non-observance of the operating instructions,

3

Internet:

The actual scope of delivery may deviate from the

explanations and illustrations described here in the

case of special versions, when using additional order

options or due to the latest technical changes.

for safe and trouble-free operation. Additional task-

related safety instructions are included in the individual

chapters.

safety instructions

Express the level of risk.

The manufacturer's terms of delivery and the

statutory provisions valid at the time the contract was concluded

- Use of untrained personnel,

If you have any questions about your water pump or

require technical information, please contact your specialist dealer.

www.cleancraft.de

This combination of symbol and signal word

indicates an immediately dangerous situation

Germany:

- technical changes,

Fax: 0049 (0) 951 96555-119

Email: ersatzteile@stuermer-maschinen.de

GPI series | Version 1.02

Read the operating instructions carefully before

starting up.

Repair service:

The operating instructions are part of the water pump.

This provides information about proper commissioning,

intended use and safe and efficient operation and

maintenance of the Was

We register trademark, patent and design rights

to protect our products, provided this is possible in

individual cases. We strongly oppose any

infringement of our intellectual property.

This section gives an overview of all important security

packages for the protection of people as well as

DANGER!

introduction

1.1 Copyright

1.2 Customer Service

2.1 Explanation of symbols

1.3 Limitation of Liability

Machine Translated by Google

WARNING!

security

ATTENTION!

ATTENTION!

A NOTICE!

tips and recommendations

2.2 Responsibility of the operator

Obligations of the operator:

This combination of symbol and signal word indicates a

potentially dangerous situation that can lead to damage to

property and the environment if not avoided.

and to avoid dangerous situations, the safety instructions

given in these operating instructions must be observed. Furthermore, the operator is responsible for ensuring that the

machine is always in perfect technical condition.

This combination of symbol and signal word indicates a

possibly dangerous situation that can lead to minor or light

injuries if not avoided.

tips and recommendations

Therefore the following applies:

- The operator must ensure that the maintenance intervals

described in these instructions are observed.

If the machine is used in the commercial sector, the operator of

the device is subject to the statutory occupational safety

obligations. For this reason, the safety instructions in these

operating instructions as well as the safety, accident prevention

and environmental protection regulations applicable to the area

in which the machine is used must be observed. The following

applies in particular:

- The operator must clearly regulate and define the

responsibilities for installation, operation, troubleshooting,

maintenance and cleaning.

- The operator must have all safety devices checked

regularly for functionality and completeness.

4GPI series | Version 1.02

This combination of symbol and signal word indicates a

potentially dangerous situation that can lead to damage to

property and the environment if not avoided.

- The operator must ensure that all persons handling the

device have read and understood these instructions. In

addition, he must train the staff at regular intervals and

inform them about the dangers.

- The operator must be aware of the applicable Art

This symbol highlights useful tips and recommendations as

well as information for efficient and trouble-free operation.

This combination of symbol and signal word indicates a

potentially dangerous situation which, if not avoided, will

result in death or serious injury.

The operator is the person who operates the machine himself for

commercial or economic purposes or lets a third party use it and

bears the legal product responsibility for the protection of the

user, the staff or third parties during operation.

Inform yourself about occupational health and safety

regulations and, in a risk assessment, identify additional

hazards that result from the special working conditions at

the place of use of the device. He must implement these in

the form of operating instructions for operating the machine.

To reduce the risk of personal injury and property damage

- During the entire period of use of the machine, the

operator must check whether the operating instructions

he has drawn up correspond to the current status of the

regulations and, if necessary, adapt them.

Machine Translated by Google

protective gloves

security

Danger if people are not sufficiently

qualified!

safety goggles

safety shoes

protective clothing

WARNING! 2.4 Personal Protective Equipment

2.3 Personnel Qualifications

2.5 General safety instructions

Only persons who can be expected to carry out this

work reliably are permitted to carry out any work.

People whose ability to react e.g. B.

The following should be noted:

The operator has been instructed by the operator

about the tasks assigned to him and the possible

dangers of improper behavior. The operator may only

carry out tasks that go beyond normal operation if

this is specified in these operating instructions and

the operator has expressly entrusted him with them.

always clean. Provide adequate lighting and

ventilation.

Manufacturer foreseen operations are used.

keep away from the work area.

The protective gloves protect the hands from

sharp-edged components, as well as from

friction, abrasions or deeper injuries.

relevant standards and regulations, able to carry out

work on electrical systems and independently

recognize and avoid possible dangers.

Protective work clothing is close-fitting clothing

that is not very tear-resistant.

listed qualifications of the persons for the various

tasks named:

- Use the guards and fasten them securely. Never

work without protective devices and keep them

functional.

have it carried out.

The various ones described in this guide

The safety goggles are used to protect the

eyes from flying parts.

Certain work may only be carried out by the

manufacturer's specialist staff. Other personnel are

not authorized to carry out this work. Our customer

service to carry out the necessary work

injuries.

Electrician:

to carry out the work assigned to him and to

independently recognize possible dangers and hazards

Personal protective equipment is used to protect

people from impairments to safety and health at work.

During the various works on and with the water pump,

the personnel must wear personal protective

equipment, which is referred to separately in the

individual sections of these instructions.

influenced by drugs, alcohol or medication are not

permitted.

Specialists:

GPI series | Version 1.02

Personal protective equipment is explained in the

following section:

Operator:

- Keep the water pump and its working environment

- The design of the water pump must not be modified

or used for purposes other than those specified in

Tasks place different demands on the qualifications

of the people who are entrusted with these tasks.

- Insufficiently qualified people and children out

- All work only by qualified persons

In these operating instructions, the following

The electrician is due to their professional training,

knowledge and experience as well as knowledge of

to avoid.

to contact.

Manufacturer:

Insufficiently qualified persons cannot assess the

risks involved in working with the machine and

expose themselves and others to greater danger

The safety shoes protect the feet from bruises,

falling parts and slipping on slippery surfaces.

Due to their technical training, knowledge and

experience as well as their knowledge of the relevant

standards and regulations, the specialist staff is able to

5

Machine Translated by Google

ATTENTION!

ATTENTION!

ATTENTION!

ATTENTION!

ATTENTION!

ATTENTION!

ATTENTION!

security

ATTENTION!

ATTENTION!

ATTENTION!

.

to be pulled out of the socket. Protect the cable

from heat, oil and sharp edges.

Do not pump salt water with the pump!

- Do not use the pump in hazardous areas or near

flammable liquids and gases.

- Never work under the influence of illnesses that

affect concentration, overtiredness, drugs, alcohol

or medication.

GPI series | Version 1.02

When the ambient temperature is lower than 4°C

or the pump is not used for a long time,

Damaged parts must be replaced immediately to

avoid sources of danger.

- Keep children and do not use the water pump

set up again before switching off.

- Before each use, make sure that no

- Do not touch the pump until it has been switched

off and cooled down for at least 5 minutes.

- Seal all screw connections with a thread

- Do not pull the power cord to unplug the plug

The pump is not suitable for pumping salt water,

faeces, flammable, caustic, explosive or other

hazardous liquids. The pumped liquid must not

exceed or fall below the maximum or minimum

temperature stated in the technical data.

- Do not touch the power plug with wet hands

- Only use original spare parts and accessories to

avoid possible dangers and accident risks.

- Eliminate faults that impair safety immediately.

6

- Do not run the pump dry.

Operate and store the device taking into

account its weight, ie on a solid, level surface

and only in a closed room without moisture.

In the event of a tipping over, it is recommended that the device

The water pump must not be used to supply

drinking water or to pump food.

Check that the supply voltage of the pump

corresponds to the type plate of the water pump.

Failure to follow these rules can result in fire and

injury, including death, to the user.

drain the piping system to avoid ice formation

in the pump chamber.

- Only disassemble the pump body when the pump

is switched off and the pump chamber is empty.

- The pump must be supplied via a residual current

circuit breaker (RCD) with a maximum rated

residual current of 30 mA.

Parts of the water pump are damaged.

When pumping dirty liquids, install a suction

strainer to protect the pump from dirt.

- Do not start the water pump until the pump

chamber has filled with water.

- Do not overload the water pump! You work better

and safer in the specified performance range.

familiar people away from their work environment.

the.

If no water is delivered after the pump has been

in operation for 5 minutes, switch off the pump,

top up with water and check the lines for leaks.

sealing tape to avoid water leakage.

The pumped liquid can be hot and under high

pressure. Before moving or dismantling, drain

the fluids in the pump and piping to avoid

scalding.

Machine Translated by Google

ATTENTION!

WARNING!

ATTENTION!

Danger in case of misuse!

Intended Use

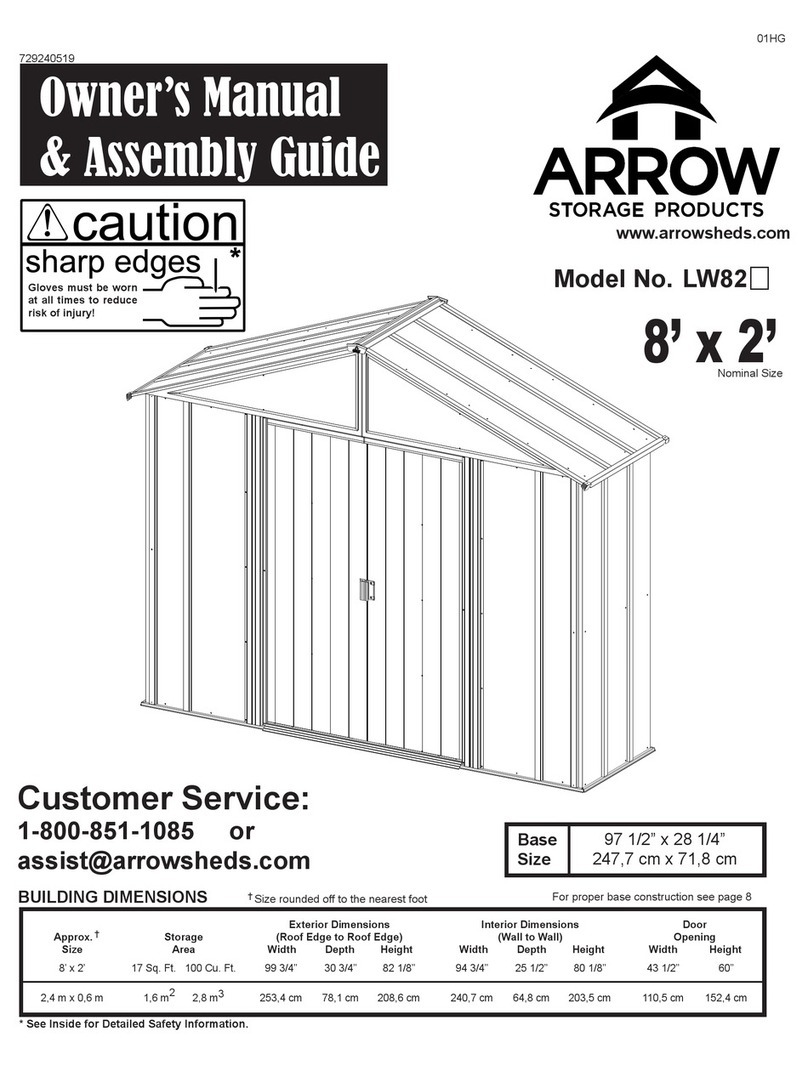

Fig. 1: Safety markings

water pump

3.1 Misuse

3.2 Residual Risks

2.6 Safety markings on the Was

The manufacturer assumes no liability for damage

- Do not vacuum up any materials that could

damage the filter elements (e.g. glass splinters, metal, etc.).

which cause damage to property or persons as a

result of failure to follow these instructions or

misuse of the device.

3 Intended use

- Never bypass the safety devices

and the water pump is used properly, there are still residual

risks, which are listed below:

GPI series | Version 1.02

- The water pump only in technically perfect condition

The water pump must not be in explosive

- Heat development on components can lead to burns and

other injuries.

Intended use also includes compliance with all information in

this manual.

Water pump can lead to incorrect actions with personal

injury and damage to property. The safety symbols attached

to the machine must not be removed

senior

- Do not vacuum up aggressive cleaning agents, because

Safety markings and instructions are attached to the water

pump (Fig. 1), which must be observed and followed.

- Operate the water pump only in the performance range

that is listed in the technical data.

The water pump is used exclusively for water supply, for

pressurizing pipes, for central air conditioning and for heating

circulation systems. The water pump may only be used to

pump non-eroding liquids. It must not be used to pump

flammable, explosive and easily vaporized liquids, and the

liquid must not contain any solid particles or fibers.

Stürmer Maschinen GmbH assumes no liability for the water

pump.

Even if all safety regulations are observed

with sucking up wrong liquids.

- There is a risk of injury to the upper limbs (eg hands, fingers).

or override.

7

and high voltage (direct contact) or with parts that are under

high voltage due to a defect in the device (indirect contact).

operate state.

Damaged or missing safety symbols on the

environments and the max. permissible temperature of the

pumped medium must not exceed 40°C.

Claims of any kind for damage due to improper use are

excluded

In the case of design and technical changes to the

- Risk of fire and explosion related

will. Damaged safety symbols must be replaced

immediately. From the point at which the signs are not

immediately recognizable and understandable at first glance,

the machine must be taken out of service until the new signs

can be attached.

Any modification of the device is prohibited. The

modification may result in fire and injury, including

death, to the user, in addition to voiding the warranty.

- Electrical hazard from touching parts

Misuse of the water pump can lead to dangerous situations.

The pump is not suitable for pumping salt water, faeces,

flammable, caustic, explosive or other hazardous liquids.

The pumped liquid must not exceed or fall below the

maximum or minimum temperature stated in the technical

data.

they could damage the device.

Machine Translated by Google

ATTENTION!

type label

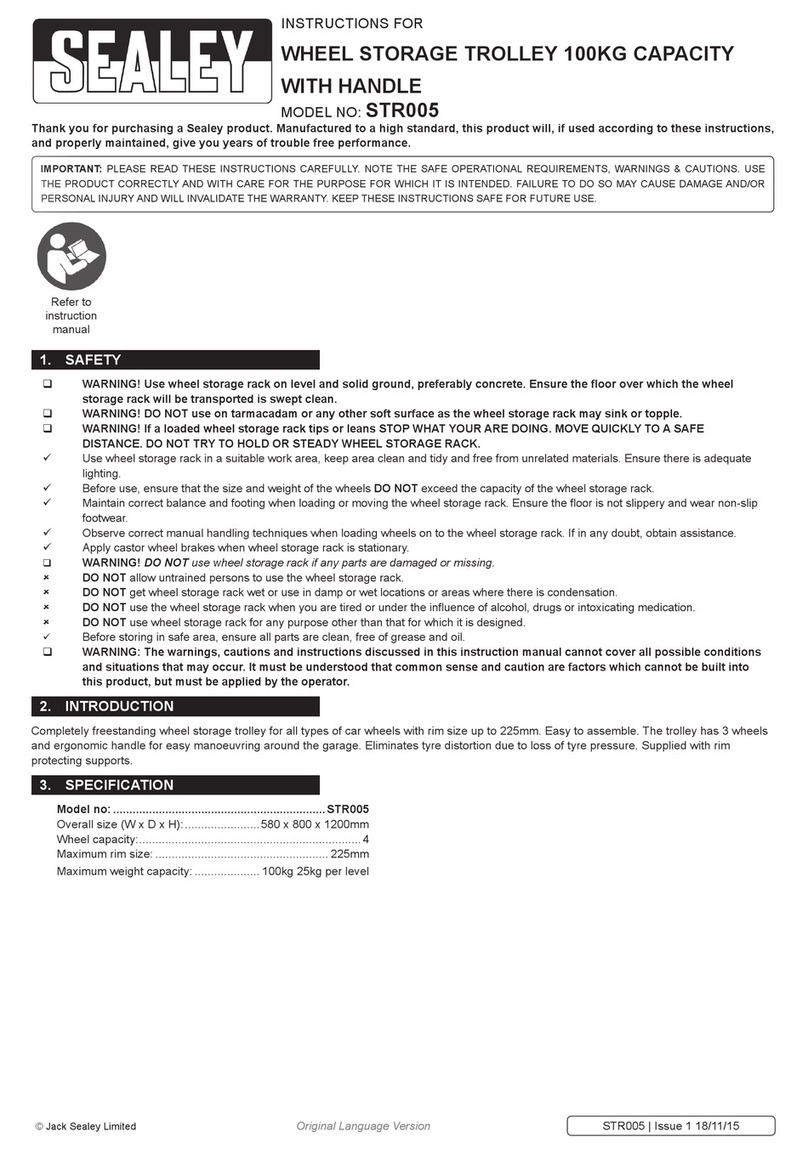

Fig. 2: Nameplate GPI 5548

4 Nameplate 6 Transport, packaging, storage

5 Specifications

392mm

Inlet/outlet thread

The water pump may only be transported in an upright

position.

Store the water pump thoroughly cleaned in a dry, clean and

frost-free environment. Water pumps must not be stacked on

top of each other .

230V

45-80L/min

Degree of protection drive motor

During transport, the water pump must be securely secured to

prevent it from tipping over.

visible transport damage. If you discover damage to the water

pump, report this immediately to the transport company or dealer.

315mm

model

area of application

1"

Step 1: Turn off the water pump and drain it completely. Wipe

down all accessible surfaces and allow the water

pump to dry.

4000 h

The foils are made of polyethylene (PE) and the upholstery parts

are made of polystyrene (PS). Hand these materials over to a

recycling center or to the disposal company responsible for you.

Width depth

flow rate

must always be sent for material recycling.

delivery head max.

liquid temperature max.

Let the water pump cool down completely and drain it

completely of water.

3500-5200 rpm

inlet/outlet diameter

160mm

11kg

6 m

40°C

Runtime at 75% load

Height

connection voltage

sound pressure level

1"

550W

60dB(A)

number of impellers

8th

clear water

All packaging materials and packing aids used for the water

pump are recyclable and

GPI 5548

suction height

Step 2: Disconnect the suction and discharge lines from the

pump and store them in a dry and frost-free place (at

least 5°C).

1.5m

Check the water pump after delivery

engine power

40 m

engine speed

IPX4

length

Dispose of shredded cardboard packaging components for

waste paper collection.

GPI series | Version 1.02

connection cable length

4

weight

No other objects may be placed on it either.

6.4 Storage

6.2 Transportation

6.3 Packaging

6.1 Delivery

Machine Translated by Google

4

device description

1

5

3

2

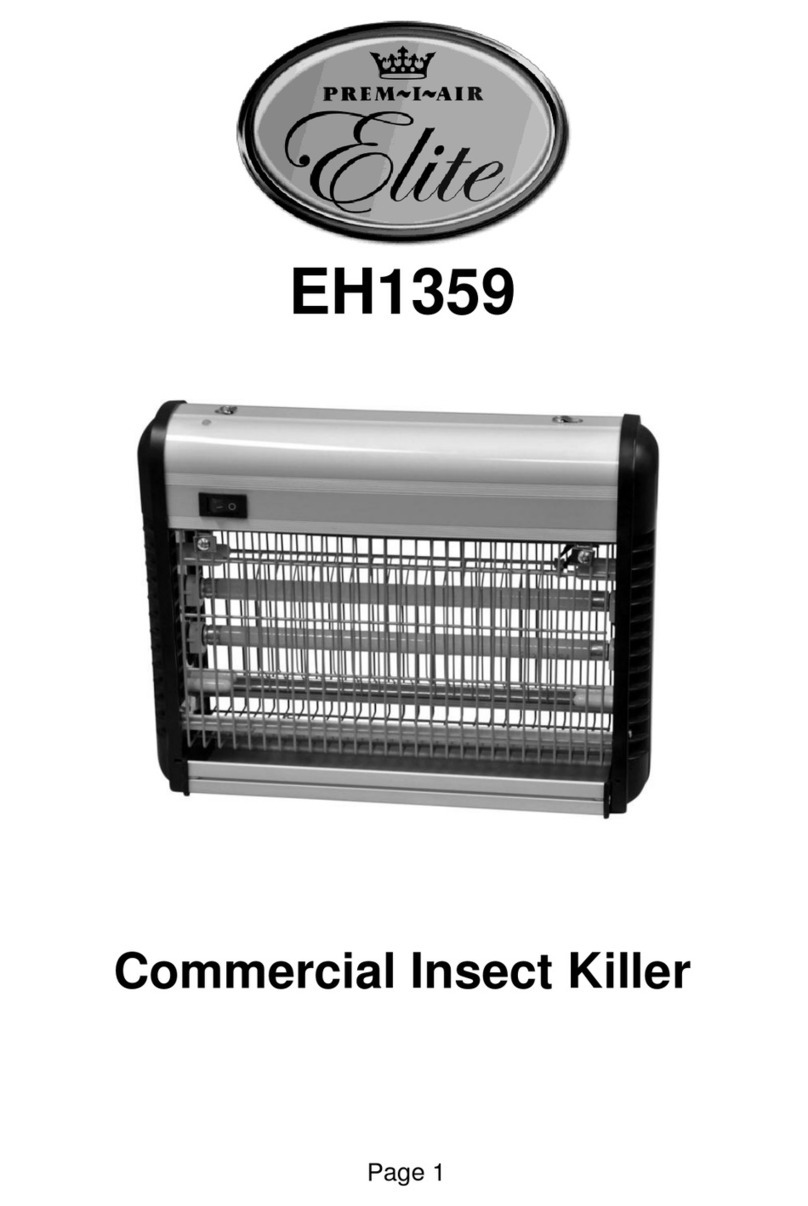

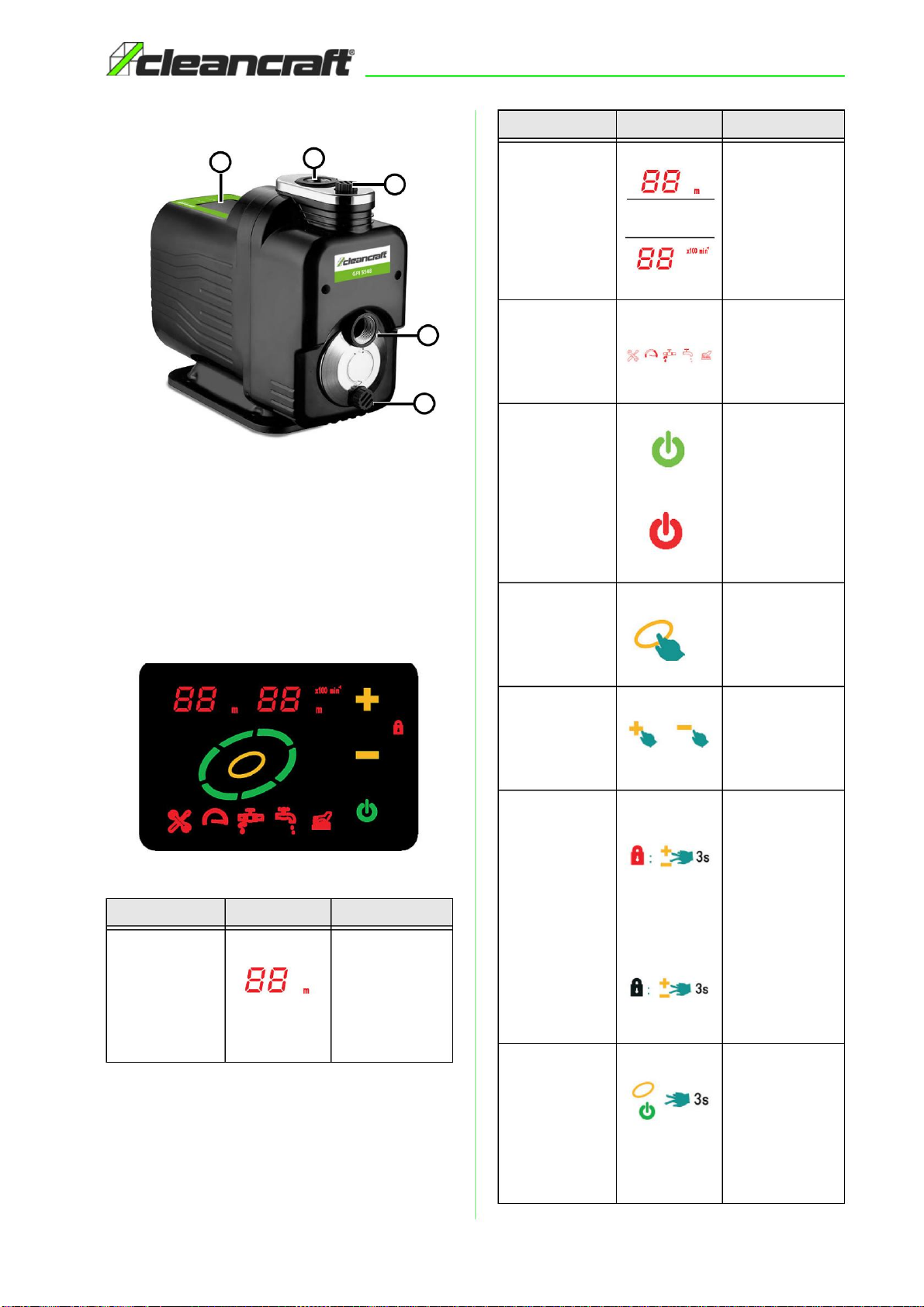

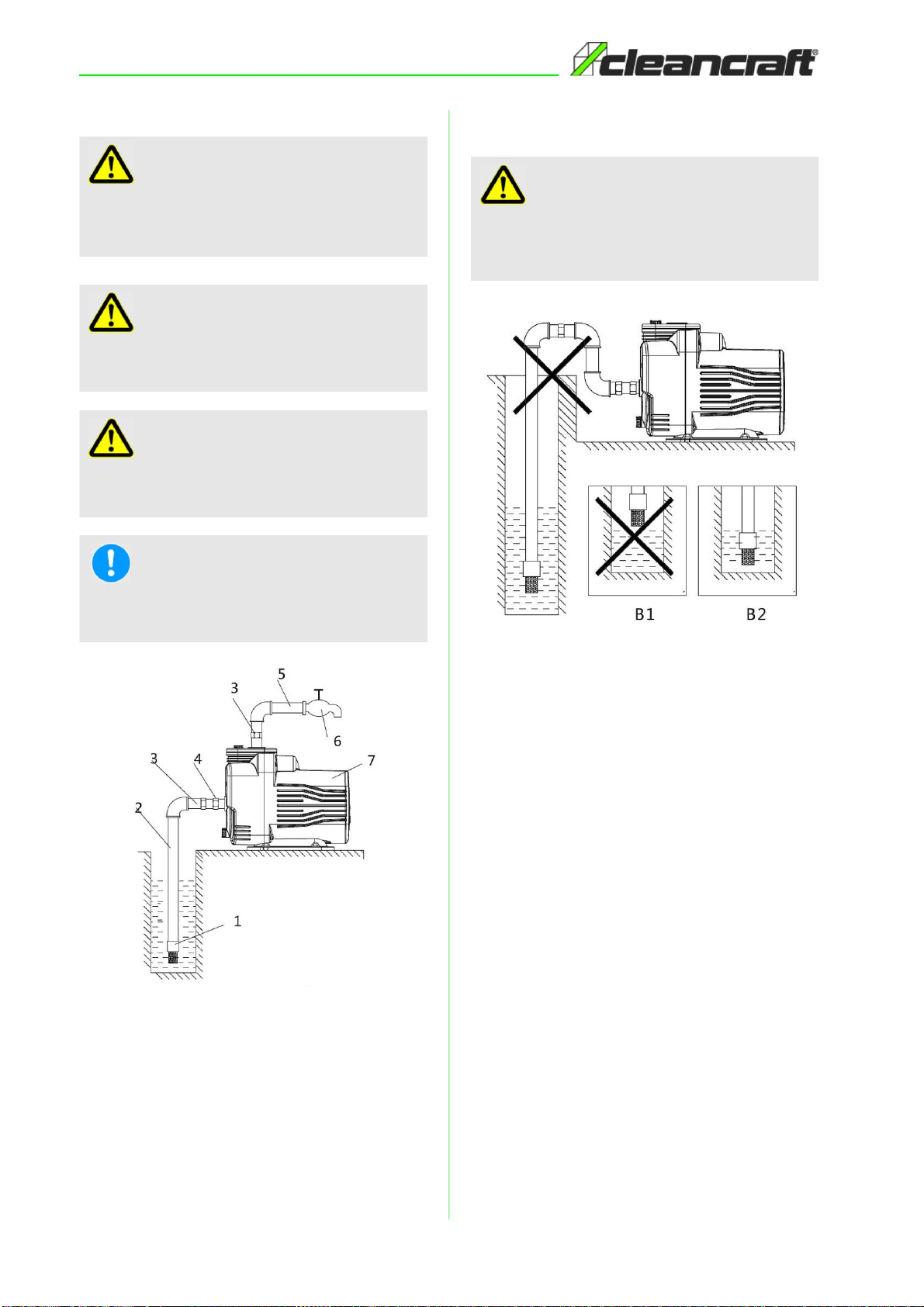

Fig. 3: Description of GPI 5548

Fig. 4: Description of the display

7 Device Description

On/off switch

constant pressure

Pump is

running or in

Hold down

the screen for

seconds

digits

manual operation, the

hold the

4 suction connection

adjustment buttons

Default

settings

description

Mistake,

switch

button

last digits

speed

regulation

lock

Hold for

seconds to

unlock the

screen

9

1 display

temperature

"+" "-" button 3

Switch between

constant pressure

mode and manual

mode

to lock

switch button

and the power

switch to switch the

mode

Display description

Standby mode

3 filler necks

First two

description

Current pressure

Pump is

switched off

designation

Manual Ge

5 water drain port

Screen

"+" "-" button 3

unit "m"

GPI series | Version 1.02

Switch between

constant pressure

mode and manual

mode

error icon

At the same

time, press the

symbol

restore default

settings

hold the

label icon

pressure

setting, leakage,

value;

2 suction port

Machine Translated by Google

device description

A NOTICE!

7.2 Functional Description

7.1 Accessories

- Pre-filter

Pressure setting protection function

The pump starts automatically when the determined

temperature is below 5 ° C. The temperature gauge

The pump now starts twice at intervals of 30 minutes for 1

minute each time to detect a flow. If no flow is detected within

these 2 interval cycles, the pump switches off.

- Filter insert

Once the constant pressure value is set, close the outlet valve. If

the actual pressure still can not reach the set pressure value, the

water pressure indicator will light up and the set pressure of the

water pump will automatically

In the event of a communication failure between

temperature protection

Function to restore default settings

Article number: 7531001

leak protection

Should the controller temperature exceed the programmed

protection temperature, the temperature display will illuminate

to warn the user. After the temperature is restored, the pump

will start automatically and the indicator will go out.

(green); When the user does not use water, press the power

button (red) to prevent the pump from starting.

- connector

In order to be able to use the 1 1/4" drain hose (7530005),

the connecting piece (7530004) must always be ordered

as well.

When the water temperature reaches 10C or more, the water pump

will stop, the temperature display will be off and the original mode

will be restored automatically. When the water temperature is

below 10C, the pump will keep running and the temperature

display will keep running

As soon as a flow is detected, the control lamp goes out and the

pump continues to run normally.

supply closes, the pump stops automatically.

Article number: 7530005

Don't pump. The pump can be used normally.

automatic function

After the user sets the value, the system will automatically

apply it to the hardware memory. After switching off, the user's

settings are no longer affected. The automatic storage includes

the switching status, the setting value and

the working mode.

Article number: 7531002

dry run protection

lights up to remind the user that the current temperature is low.

back to.

Function communication error

After the water pump starts and no flow is detected within 1

minute, the pump will stop automatically and the indicator will be

on.

GPI series | Version 1.02

1. High temperature protection

When the user needs water, manual intervention is required,

press the power button

Article number: 7531003

set to 5 bar below the current pressure. Every 12 hours the pump

will attempt to automatically return to the original setting (press

the Set button during this time to restore the pump to its original

setting).

Press the switch button and the power button at the same

time to restore the default settings. The version number is

displayed.

the display and the main control board, the error indicator lights

up, the error code E01 is displayed and the pump stops.

memory function

Article number: 7530004

lights up.

10

- Suction hose 7 meters 1"

2. Protection against low temperatures

°

If there is a leak in the user's piping, the pump may emit a loud

noise, often 5 times. This noise affects the

- Drain hose 7 meters 1 1/4"

As soon as the user turns off the tap for water supply

When the user turns on the tap to reach the starting pressure,

the pump runs automatically

Machine Translated by Google

installation

ATTENTION!

ATTENTION!

ATTENTION!

Installation and operation must comply with local regulations

The pump must be mounted horizontally on the floor and

screwed through the holes in the base plate.

and conform to recognized company guidelines.

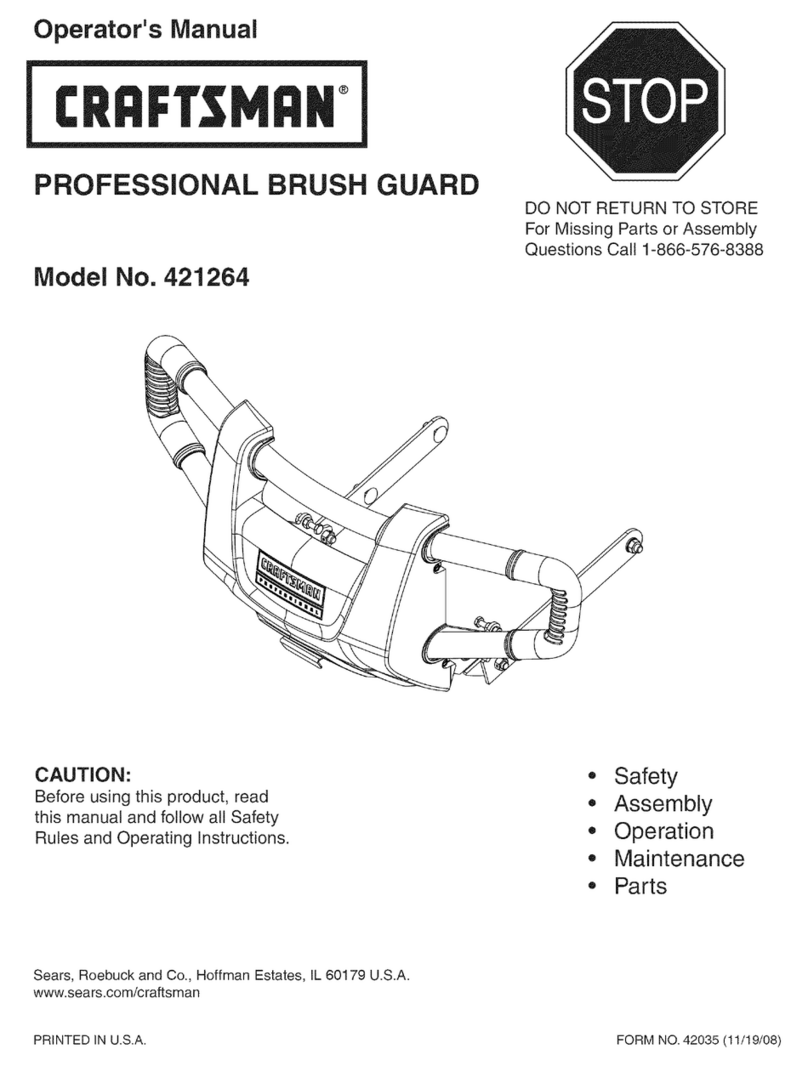

155mm W

324mm

B

anti-lock function

After the voltage returns to the 180V to 260V range, the

pump will automatically return to normal operation, the

voltage indicator will turn off, and the error code will

clear.

If the motor has a phasing problem (the motor cable is

not properly connected, the motor is defective, etc.), the

error indicator lights up, error code E05 is displayed and

the pump stops.

Step 3: After starting the pump, press the "+" and "-"

buttons to adjust the pressure value.

The pump restarts 5 times with an interval of 30

seconds. If this is unsuccessful, the pump will stop

again.

GPI series | Version 1.02

Tighten the filler plug after the air has been

released.

L1

As soon as a pressure sensor error is detected,

the error indicator lights up, the error code E04 is

displayed and the pump stops.

Error controller function

measure

Step 2: Turn on the pump according to the on the

When setting up the device, make sure that the motor

is adequately ventilated. measure

145mm

Overcurrent, the error indicator lights up, error code E05

is displayed and the pump stops.

396mm H

191mm

If the input voltage is higher than 270 V or lower than

140 V, the error indicator lights up, the error code E03

is displayed and the pump stops.

A

166mm

Step 1: Loosen the filler plug and fill the pump chamber

with clean water.

Enter the voltage specified on the rating plate.

code

108mm H1

If the pump stops, the error indicator lights up and the

error code E02 is displayed on the screen.

11

code

Do not start the pump until the pump chamber is

filled with water and do not remove the pump until

the water in the pump chamber has been drained.

Pressure sensor function

Step 4: If the pump suction depth is more than 6 meters,

water should be added several times.

Overvoltage and undervoltage protection functions

If the controller detects an error such as standstill or

L

8.2 Assembly of the pump

8.1 Notes on installation

The pump must be installed in a dry place

where the ambient temperature must not exceed

40 °C and not fall below 5 °C. The pump and the

entire connection system must be protected

from frost and weather influences.

8 installation

Fig. 6: Dimensions of the pump

Fig. 5: Filling the pump with water

Machine Translated by Google

ATTENTION!

installation

ATTENTION!

ATTENTION!

ATTENTION!

A NOTICE!

8.3 Connection of the suction line

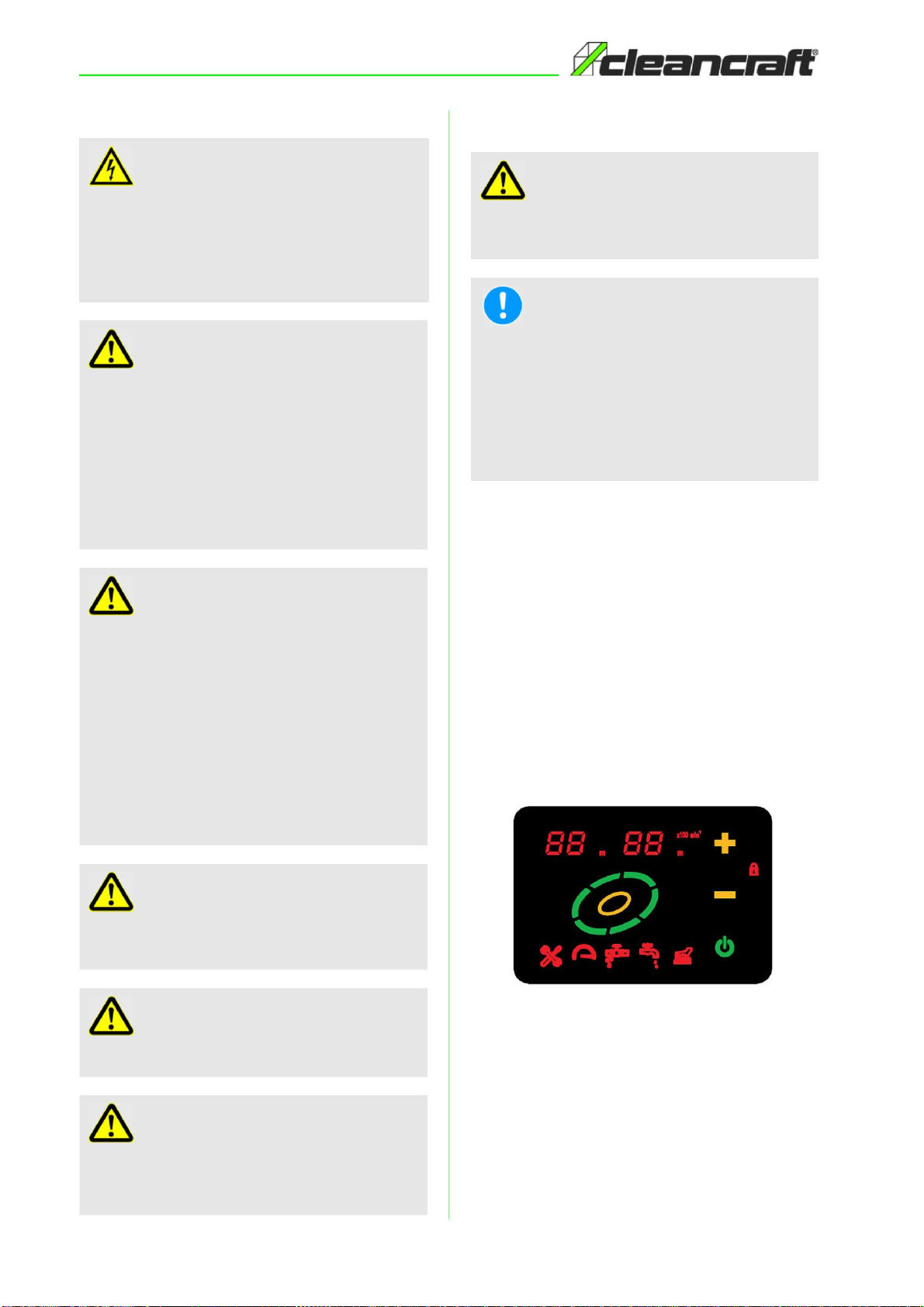

Fig. 8: Incorrect installation of the suction line

Fig. 7: Connection of the suction line

pump to use a rubber hose that is too small for

the water inlet pipe.

5 water drain

GPI series | Version 1.02

The suction line must be installed in such a way that

it cannot exert mechanical forces or distortions on

the pump.

- To prevent solid particles from getting into the

electric pump, the suction line must be fitted with

a filter.

It is recommended to install a non-return valve to

prevent water from flowing back when the pump is

switched off.

water supply line

7 pump

The diameter of the outlet pipe should be min

- Pay attention to the water level during use, the

bottom valve must not protrude out of the water

(B 1, Fig. 8).

2 suction line

- It is forbidden when installing the electric

ter, the diameter of the inlet pipe must be

larger than the diameter of the inlet of the

electric pump.

When pumping dirty liquids, install a suction

strainer to protect the pump from sand and dirt.

away from the water to prevent dirt and foreign

bodies from being sucked in (B2, fig.8).

that the electric pump is not exposed to pipeline

pressure.

4 one-way valve

12

Precautions for installing the

- When the length of the inlet pipe is more than 10

meters or the height of the inlet pipe is more than 4 meters

6 faucet

- The diameter of the suction line should at least

correspond to the diameter of the inlet.

- The bottom valve is vertical and 30 cm from the ground

- The sockets of the inlet pipes must be sealed,

otherwise they can absorb water.

Make sure there is sufficient distance (30 cm)

between the suction line and the ground and the

shore to avoid damage caused by sucking in sand or

stones.

1 bottom valve

- When laying the pipe, make sure

as close as possible to the diameter of the outlet

to reduce pressure drop and minimize high flow

rates and noise.

3 connectors

Machine Translated by Google

ATTENTION!

Risk of death!

WARNING!

Wear safety glasses!

Wear safety shoes!

ATTENTION!

Installation

ATTENTION!

Wear protective clothing!

A NOTICE!

ATTENTION!

ATTENTION!

ATTENTION!

8.4 Electrical connection

- Never operate the water pump when you are under

the influence of alcohol, drugs or medication and/

or when you are overtired

Make sure that the water pump can only pump

fresh water. Using the water pump for other liquids

will damage the pump.

be equipped with a sensitive residual current circuit

breaker (FI switch): 30 mA.

13

Only the use of sealing material such as Teflon tape

ensures that the assembly is airtight. When tightening

fittings, avoid using excessive force that can result in

damage.

When operating the pump outdoors, the electrical

connections must be splash-proof. the

The device has a mains connection cable with a

mains plug. Mains connection cable and mains plug

Check the general condition of the hoses.

Make sure the hoses are not damaged before

connecting them.

When laying the connecting lines, ensure that no

weight, vibrations or stresses affect the pump. In

addition, the connecting lines must not be damaged or

have a counter slope to the pump.

may only be replaced by qualified personnel in order

to avoid hazards. Lift and carry the

Connections must not come into contact with

water.

Only use an extension cable with a cross-section

and rubber sheathing that corresponds at least to

that of the device's connecting cable and is marked

with the corresponding VDE abbreviation.

Pump not on the power cord, and use

Mains plugs and couplings must be splash-proof.

If the mains cable is damaged, it must be replaced

by the manufacturer, its customer service or a

similarly qualified person in order to avoid a hazard.

are or suffer from a concentration-disturbing illness

All connection lines must be absolutely tight, since

leaky lines can impair the performance of the pump and

cause considerable damage. It is therefore essential to

seal the threaded parts of the lines with one another

and the connection to the pump with Teflon tape.

suffer.

not to pull the mains plug out of the socket. Protect the

power plug and power cord

The electrical connection must be marked with a high

GPI series | Version 1.02

There is danger to life if you do not follow these

rules.

from heat, oil and sharp edges and do not use the pump

in a damp environment.

- The water pump may only be operated by one

person. Other people must register during the

To avoid fire hazards, keep the pump at least

1 meter away from building walls and other

equipment during operation. Do not place

flammable objects nearby

Keep operator away from water pump.

Always fill the pump with water before starting it

up. Running dry can cause damage.

9 Commissioning

Machine Translated by Google

Danger to life from electric shock!

ATTENTION!

WARNING!

A NOTICE!

ATTENTION!

operation

WARNING!

ATTENTION!

DANGER!

ATTENTION!

Fig. 9: Starting the pump

10 operation

There is a risk of fatal injury if you come into contact

with live components. Electrical components that are

switched on can perform uncontrolled movements and lead to

very serious injuries.

will. Furthermore, it must be checked that the filter elements

are installed correctly and are efficient. The device should only

be operated, installed, repaired and transported on a firm, level

surface. to fill with water.

Step 3: Connect the suction or suction hoses to the pump.

- Pull out the mains plug before making any adjustments to the

water pump.

Make sure that the electrical data marked on the engine block

matches that of the mains to which the water pump is to be

connected and that the water pump's mains plug fits the

socket.

Step 4: After filling with water, turn on and start after 3 seconds

delay. Make sure that no water escapes.

Make sure the pump is properly placed and ready for use.

Check whether all hose connections are screwed tight and

undamaged.

Step 1: Remove the locking screw on the in

Before starting the engine, the pump must be completely

filled with water. A dry start of

Before starting up the device, make sure that the voltage

specified on the rating plate corresponds to the mains

voltage

14

filler neck and pour in clean water until the pump is

completely filled with water.

GPI series | Version 1.02

Pump can cause serious damage.

Step 2: Cap the filler neck

Around the switch button, the green symbols light up

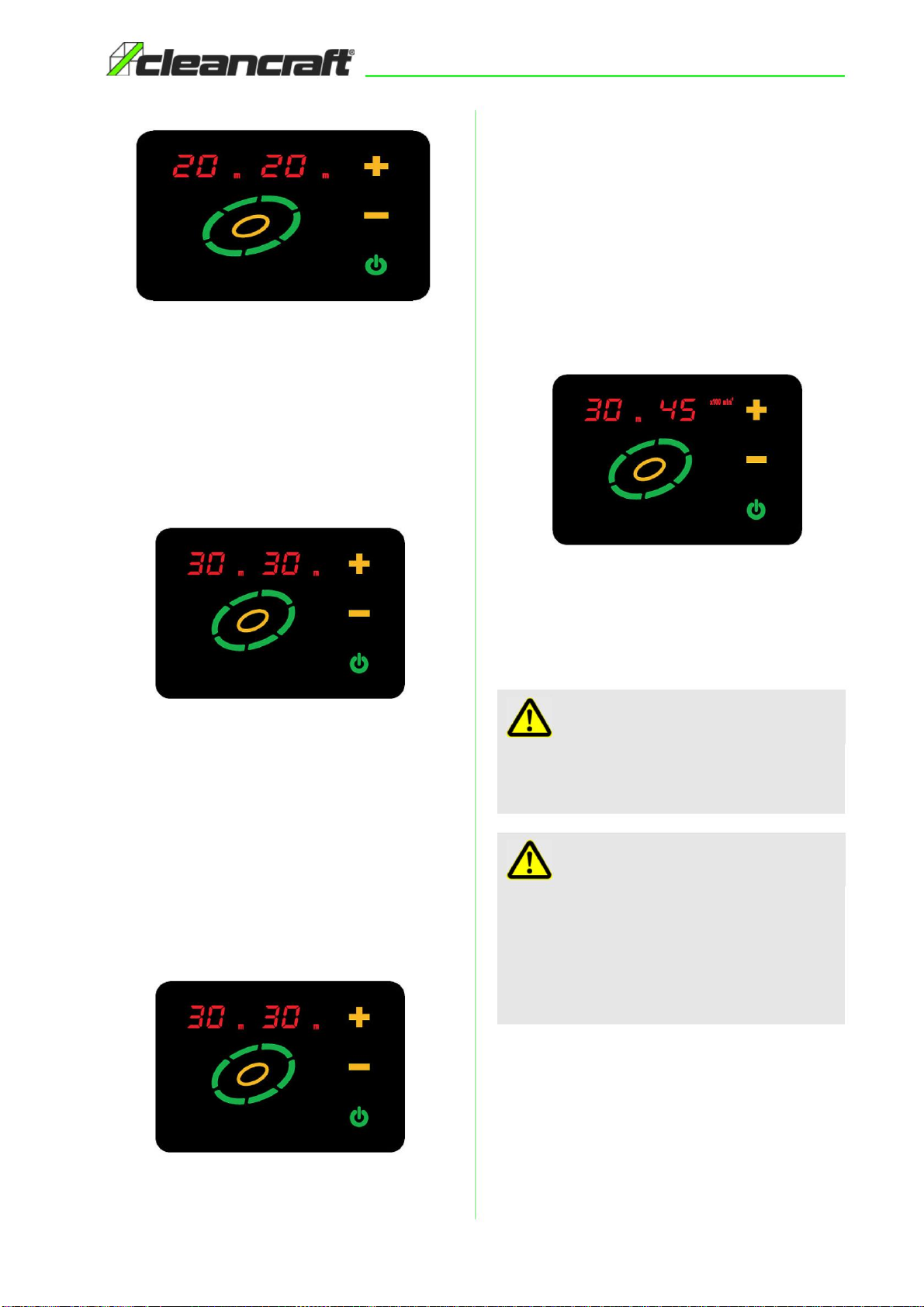

symmetrically counterclockwise. The light switch button, the

yellow switch button indicator and the "+", "-" buttons light up.

The first digits show the current pressure, the last digits show

the standard value 20 m.

When starting up for the first time, it is essential to ensure

that the pump housing is completely vented, i.e. filled with

water, even in the case of self-priming pumps. If this venting

is omitted, the pump will not suck in the liquid to be pumped.

It is recommended, but not necessary, to additionally bleed or

drain the intake line.

again with the locking screw.

Before starting the engine, the pump must be completely filled

with water.

The device must be correctly assembled before use

Always pull the mains plug out of the socket before

handling the switched off water pump. Always check the

supply cable for damage such as cracks or signs of age. If

necessary, replace the cable before using it again. The

replacement of a defective power cable must be carried out

by the technical service or by qualified personnel. If you

use an extension cable, make sure that it has the same

cable dimensions as the power cable of the pump, and avoid

contact of the cables with liquids or conductive surfaces.

10.1 Operation of the water pump

Machine Translated by Google

ATTENTION!

ATTENTION!

operation

If the user does not operate the control panel for 5 minutes,

the screen will be locked and the red lock indicator will be on.

there is very hot water in the system with the risk of

scalding. If the pump has overheated, unplug the power cord

and allow the system to cool.

15

The pump must be prevented from running dry without

pumping water, since a lack of water causes the pump to

overheat. This can lead to significant damage to the device.

Besides that

As shown in Figure 13. The current mode is manual control, the

current pump outlet pressure is 30m and the speed is 4500rpm.

GPI series | Version 1.02

By tapping "+" or "-" you can set the constant pressure value

(default value 20 m) directly. The adjustment range is: 15-55m, the

increment is 5m. The user can adjust the pressure value as needed

to meet actual needs (the value is 30, as shown in Fig. 11). Please

note that the pressure value must not be too high.

Once the pump is running, flip the switch and the pump will toggle

between constant pressure and manual control modes. The main

difference is the unit displayed. Display m is constant pressure

mode and X100min-1 is manual control mode.

Press and hold the "+" "-" button simultaneously for 3 seconds

until the red lock indicator turns on to lock the screen. Pressing

the "+" or "-" keys separately is invalid. Once the lock indicator is

on, press and hold the "+" "-" button at the same time for 3

seconds. The lock indicator is unlocked as soon as the "+" and

"-" buttons are no longer lit. if

If the lock indicator is off, touch the "+" or "-" button to adjust the

speed setting value. The increment is 100 and is automatically

saved after the adjustment.

Difference between manual mode and constant pressure mode

After a power failure (in manual mode) the pump does

not stop (regardless of whether the valve is closed or not).

Intervention is required in order not to damage the pump.

Fig. 13: Set print mode

Fig. 11: Set pressure value

Fig. 10: Pump switch buttons

Fig. 12: Lock screen

Machine Translated by Google

ATTENTION!

Wearing safety gloves!

A NOTICE!

Care, maintenance and repair/repair

ATTENTION!

ATTENTION!

A NOTICE!

ATTENTION!

repair

11 Care, maintenance and repair/

will.

To prevent possible malfunctions, it is advisable to regularly

check the suction hoses for water leaks.

careful starting of the pump.

All protective and safety devices must be reassembled

immediately after the repair and maintenance work has been

completed.

The warranty does not cover the parts of the water pump, If the water pump does not work properly, contact a specialist

dealer or

before attempting any maintenance or repair work

skilled personnel are executed; any damaged parts are only

to be replaced with original spare parts

Periodic adjustments must be made to ensure proper

operation of the water pump.

to keep. Always keep the cooling fins clean and free.

When storing the pump in winter, make sure that there is no

water in the device, otherwise the frost would destroy the

device. The pump must be disconnected from the power supply

for any transport! The pump must be completely drained and

stored in a frost-free place

Never use solvents to clean plastic parts or painted surfaces.

A dissolving of the surface and consequential damage

resulting from this can occur.

cleaned and coated with anti-corrosion oil before storing

in a well-ventilated and dry place.

men.

Water that has stood for a longer period of time can

corrode the pump housing due to the design! (brown coloring)

Chapter 1.2 Customer Service.

the risk of possible malfunctions and help to extend the life

of your device.

Only a regularly serviced and well cared for device can be a

satisfactory tool. Lack of maintenance and care can lead to

unforeseeable accidents and injuries.

Zen.

cleaned with a soft, damp cloth and a little neutral detergent.

GPI series | Version 1.02

If the device is not used for a long time, the water in the pump

should be drained. The pump body, impeller and bracket

should

Maintenance and repair work may only be carried out by

qualified personnel.

Make sure the pump is turned off

All plastic parts and painted surfaces should be

16

Maintenance and repairs must always be carried out by

which have been treated abusively or negligently by the

operator. For full warranty coverage, the operator must

operate the water pump as described in the instructions.

The water pump is always in a clean condition

Before maintenance work, the pump must be disconnected

from the power supply. If the power supply is not

disconnected, there is a risk of accidental

our customer service. The contact details can be found in

Reduce regular maintenance and careful care

11.2 Maintenance and repairs

11.1 Care through cleaning

Machine Translated by Google

A NOTICE!

Disposal, recycling of old devices

A NOTICE!

ATTENTION!

Fig. 14: Inspection of the pump

12.2 Disposal of Electrical Equipment

12.3 Disposal of lubricants

12.1 Decommissioning

11.3 Inspection of the pump

12.4 Disposal at municipal collection points

Disused devices must be professionally

decommissioned immediately in order to avoid later

misuse and endangering the environment or people.

- If necessary, dismantle the machine by hand

If necessary, the help of a specialized waste disposal

company should be used for the treatment.

accessible and usable assemblies and components.

12 Disposal, recycling of

measures

13 Malfunctions, possible causes and

old devices

be checked regularly. The inspection method

your fellow human beings. The environment and health are

endangered by incorrect disposal. Material recycling helps to

reduce the consumption of raw materials. For more information

about recycling of this product, please contact your municipality,

your municipal waste disposal service or the shop where you

can get it

do not exceed cash. The ideal pressure in the tank should

GPI series | Version 1.02

Otherwise serious injuries could result. All repairs or

replacement work may only be carried out by qualified and

trained specialist personnel.

If you are unable to rectify the problems with your water

pump yourself, please contact your nearest CLEANCRAFT

dealer.

be kept in the range of 1.4 to 1.6 bar.

Please note that electrical equipment contains a variety of

recyclable materials as well as those that are harmful to the environment

Disposal of used electrical and electronic equipment (Applicable

in the countries of the European Union and other European

countries with

Please ensure that the coolants and lubricants used are disposed

of in an environmentally friendly manner. Observe the disposal

instructions of your municipal authority

- Remove all environmentally hazardous operating materials

- Dispose of the machine components and operating materials

in the intended disposal routes.

After starting the pump, the pressure in the tank should

By helping to ensure that this product is disposed of correctly,

you are protecting the environment and human health

Help ensure that these components are separated and disposed

of properly. If in doubt, please contact your municipal waste

disposal service.

is shown in Figure 14. If the pressure in the gas tank is below

1.2 bar, the tank can be inflated using an inflation device as

shown in Figure 14. The maximum pressure in the tank should

be 1.6

bought the product.

If one of the following errors occurs, stop working with the

water pump immediately. Before you begin troubleshooting,

turn off the water pump and unplug the power cord.

- Serial number of the device

Please write down the following information from the water

pump or the operating instructions beforehand so that you

can get the best possible help with your problem.

17

from the old device.

In your own interest and that of the environment, please ensure

that all components of the machine are only disposed of in the

intended and approved ways.

components included.

a separate collection system for these devices).

disposal companies. The lubricant manufacturer provides the

disposal instructions for the lubricants used. If necessary, ask

for the product-specific data sheets.

- Model designation of the device

The symbol on the product or its packaging indicates

that this product is not to be treated as normal household waste,

but must be taken to a collection point for the recycling of

electrical and electronic equipment.

Put the pump in a safe position to prevent the pump from

falling and being damaged.

- Year of

construction - exact error description

Machine Translated by Google

Malfunctions, possible causes and measures

7. Check the pump for leaks

4. Contact customer service

4. Clean suction line

pump

pumped liquid and the environment does not

exceed the maximum permitted values.

3. Pump running dry.

1. Check bottom valve and remove blockage if necessary

8. Intake pipe leaking

2. Remove blockages.

tion

sensor off.

1. There is no electricity

4. Clear blockage

1. Bottom valve is not open or

blocked.

does not match the information

given on the rating plate.

1. The pump rotates in the wrong

direction

Check if the pressure sensor cable is properly

connected or swap the pressure

5. Suction lift and/or delivery

head too high.

3. Mounted on a stable base.

3. Motor shaft or bearings blocked

4. Replace the suction line

4. Fluid or ambient temperature is

too high.

5. Water level is too low

Disturbance

Pump does not run properly

and is very noisy

2. Pump damaged

remedy

8. Check for proper installation

4. Circuit board defective

5. Modification of the installation so that the

suction lift and/or delivery head does not

exceed the maximum value.

tion.

18

2. There are foreign objects in the

pipeline or in the pump chamber.

2. The pump is not filled with water

to

9. Bottom valve is not open or

blocked.

2. Defective suction line

3. Eliminate the causes of dry running.

2. Contact customer service

1. Clean or replace the mechanical seals

5. Change the installation height of the pump

2. Solids clog the

Suction power decreases.

6. The pump check valve is

sticking.

Engine will not start

1. Inadequate water supply

3. Bearing damaged

1. With a GS-compliant device, the voltage

2. Check suction line and replace if necessary

The pump does not

start if the starting

pressure is fallen below

9. Check that the valve is free of obstructions.

1. Check the direction of rotation of the motor.

2. Contact customer service

1. The electrical connection

GPI series | Version 1.02

3. Defective seal

2. Check and clean the lines and

4. Make sure that the temperature of the ge

2. Fill the pump with water

1. Use a GS compliant device to verify that

voltage is present. Check mains plug.

pump or the suction line.

Blockages in the suction nozzle,

suction pipe, suction hose

3. Pump not properly secured

3. Impeller defective

Pressure sensor defective.

3. Check the cause and free the pump from

the blockage.

water leak at the

6. Check whether the valve is defective or stuck

3. Check seal and replace if necessary

The motor is running

but the pump is not

delivering any liquid.

7. Pump is leaking

Possible Cause

4. Impeller blocked

1. Check water supply

check the lines of the connection cable

3. Replace the impeller

2. Capacitor defective

3. Replace bearings

Pump vibrates

The pump stops after

a short period of

operation

1. Dirt wears out the mechanical

seal.

4. Suction line leaking

remove clogs.

the pump running system.

4. Clogged suction line

Machine Translated by Google

error codes

14 error codes

E02

2. Extend the inlet pipe.

1. The water line is leaking.

2. Desoldering the conn

E04

Readjust the settings or restore the

default settings.

1. Check the water line.

undervoltage

protection

etc.;

mistake

2. The cable connection

of the communication

cable or the pressure

sensor is loose.

4. Check valve

blocked;

1. Disassemble and clean the pump

body.

2. The faucet is not

closed.

Possible Cause

water

Input supply voltage is

too high or too low.

Control error

5. Check water supply

service

communication

2. The water level

GPI series | Version 1.02

Contact customer service for

inspection and repair.

mistake

1. The pump sucks in

impurities and blocks

the impeller.

3. Check communication

line or pressure

sensor line.

1. After 1 minute of power failure,

check whether the connection is

faulty.

2. The motor cable is

service

1. The suction line is not

in the water;

2. Connect the water tap.

remedy

3. Review and improve

Contact Customer Service to review

and replace the controller.

5. No water supply

code

2. Bearing damage, shaft

jams.

1. The setting value is too

high or too low.

19

drain line.

pressure sensor

sinks;

not connected.

ZERO Pipeline is leaking

on error

2. Contact the customer

the leaking part.

Contact customer service to replace

the pressure sensor

3. The pump voltage is incorrect.

1. Put the suction line into the water;

ZERO setting range for

constant

pressure

1. loose connection

cable;

Standstill

error

tion.

E01

Overvoltage

and

E05

E03

screen

1. Pressure sensor

damage;

3. Inlet pipe leaking;

2. Contact the customer

1. Motor blocked, controller

overcurrent

4. Clean the check valve.

ZERO inflow without

Machine Translated by Google

DANGER!

spare Parts

Risk of injury through the use of incorrect

spare parts!

loss of warranty

15.1 Ordering Spare Parts

15 spare parts

ren.

- If anything is unclear, always contact the manufacturer

Specify the following key data when ordering spare parts:

The use of incorrect or faulty spare parts can pose a

risk to the operator

- device type

- Serial number

- Crowd

When ordering spare parts, send a copy of the spare

parts drawing (1) with marked component (bearing) and

item number (48) to the authorized dealer or to the spare

parts department and provide the following information:

- Designation

Information on the device type, article number and year

of manufacture can be found on the type plate attached

to the device.

20

as well as damage and malfunctions.

- Desired shipping method (post, freight, sea, air,

GPI series | Version 1.02

The use of unapproved spare parts will void the

manufacturer's warranty.

Express)

- Only original spare parts from Her

- Delivery address

- Device type: water pump GPI 5548

example

- Article number: 7521400

The spare parts can be obtained from the authorized

dealer or directly from the manufacturer. The contact

details are in Chapter 1.2 Customer Service.

Spare parts orders without the above information

The bearing for the water pump GPI 5548 must be ordered.

The bearing has the number 48 in the spare parts drawing

1.

- Drawing number: 1

cannot be taken into account. If there is no information

about the type of shipping, shipping will be at the

discretion of the supplier.

manufacturer or manufacturer-approved spare parts.

- Position number: 48

Machine Translated by Google

This manual suits for next models

1

Table of contents