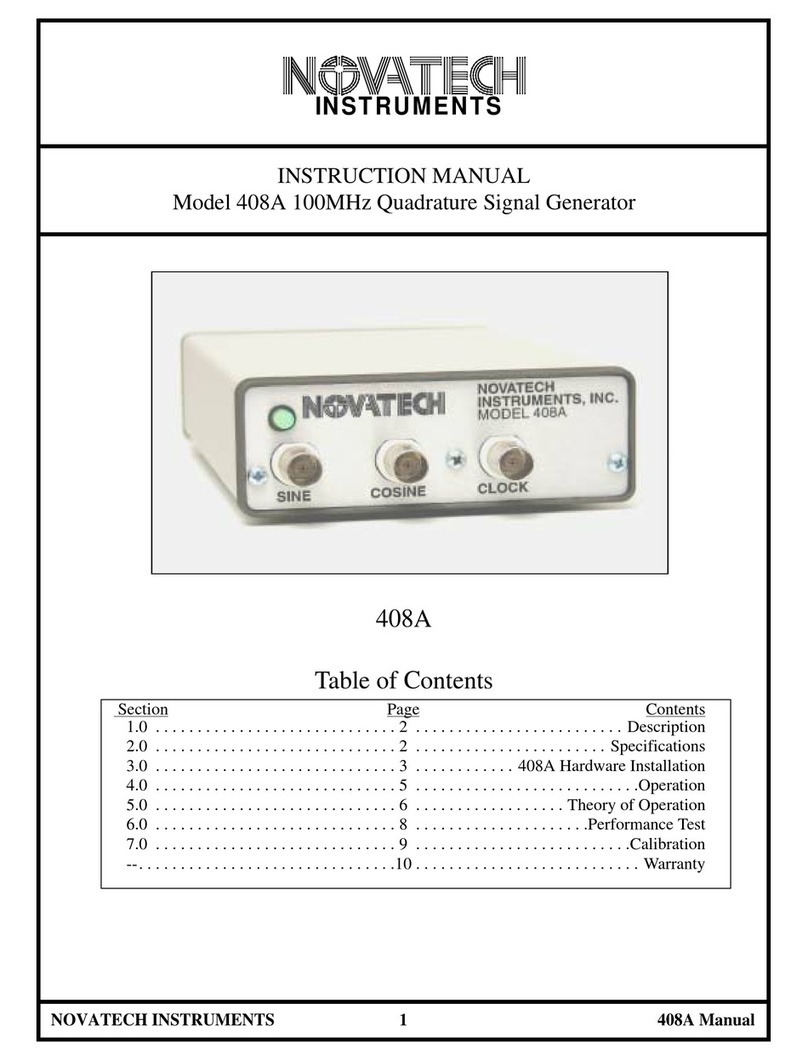

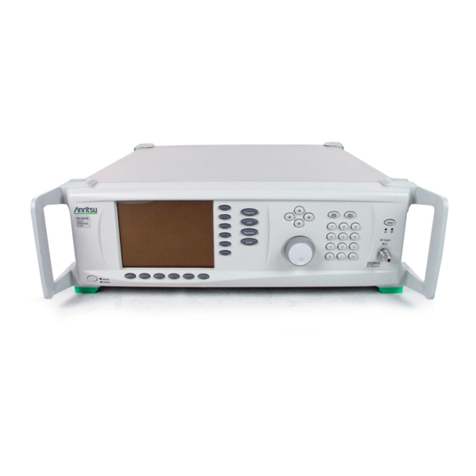

Novatech Instruments 440A User manual

NOVATECH INSTRUMENTS, INC.

206.301.8986 Voice

United States of America http://www.novatechsales.com/

sales@novatechsales.com

400MHz Programmable Signal Source

Model 440A

Specifications:

INSTRUMENTS

OUTPUT

TYPE: Sine. (optional ECL/TTL)

IMPEDANCE: 50Ω.

RANGE: 200kHz to 400MHz in 1Hz steps.

AMPLITUDE: approximately 0dBm (630mV

pp

set at

10MHz) into 50Ω.

CONTROL

Output frequency (32-bits) and phase (14-bits) are con-

trolled by sending simple text commands over a bit-serial

interface port (RS232) at 19.2kBaud. Settings can be

saved in EEPROM via the serial port.

ACCURACY AND STABILITY

Accuracy: <±1.5ppm at 10 to 40

o

C. Stable to an addi-

tional ±2ppm per year, 18 to 28

o

C. (Internal Clock)

REFERENCE CLOCK IN

LEVEL: 0.75-3.0Vrms Sine or Square Wave. 50Ω.

FREQUENCY: Programmable from 1MHz to 25MHz, in

8kHz steps. The 440A will track the externally supplied

reference as long as the external frequency is within

±5ppm. When locked the output frequency maintains the

accuracy and the stability of the reference clock with no

binary round-off. The external reference can be disabled

to use the internal oscillator in free-run mode.

SPECTRAL PURITY

(Typ. 50Ωload, 10MHz ref.)

Phase Noise:

<-120dBc, 10kHz offset, 10MHz output.

Spurious: <-55dBc below 10MHz (typ. 500MHz span)

<-50dBc below 80MHz

<-45dBc below 160MHz

<-35dBc below 400MHz

Harmonic: <-60dBc below 1MHz

<-55dBc below 20MHz

<-50dBc below 80MHz

<-40dBc below 160MHz

<-35dBc below 400MHz

POWER REQUIREMENTS

+5VDC (+4.75 to +5.25) @<1.0A. (90-240VAC with

provided AC-adapter)

SIZE

39mm H, 107mm W, 172mm L, not including connectors.

Shielded aluminum case.

ENVIRONMENTAL

Temperature: 0oC to +50oC operating.

Humidity: 80% to 31oC, decreasing linearly to 50% at

40oC.

CONNECTORS

Sine: front panel SMA; Reference In: rear panel BNC.

RS232 control: DE9F on rear panel. +5V DC Power:

2.5mm power receptacle, center positive.

The Model 440A Programmable Signal Source generates a low dis-

tortion sinewave signal from 200kHz to 400MHz with 1Hz resolu-

tion. The 440A contains an internal temperature compensated crystal

oscillator that can be locked to an external reference in 8kHz steps,

allowing the 440A to lock to common telecom signals, such as T1

and E1 rates, as well as common instrumentation frequencies such as

5MHz and 10MHz without external hardware. When locked, the

accuracy and stability of the 440A will match that of the reference.

The relative phase of the 440A can be controlled with 14-bits of res-

olution. The 440A is set by sending simple text commands over a

19.2kBaud serial interface. Four 440A can be mounted in a 1U rack

and eight in a 2U rack with optional rack adapters. The 440A oper-

ates from a single +5VDC power supply (AC-line adapter provided).

RS232 Command

Function

F0 xxx.xxxxxx

Set Frequency Zero in MHz to nearest 1Hz. Decimal point required. Maximum

‘F0’

setting is 402.653183MHz

Fr xx.xxx

Sets the Reference Frequency in MHz in 8kHz steps. Decimal point required. Range:

1MHz to 25MHz. This value is used to phase lock the internal master clock to the

externally supplied clock. Software rounds down to lowest 8kHz multiple.

P0 N

Set Phase Zero. N is an integer from 0 to 16383. Phase is set to N*360/16384 degrees

(N*

π

/8192 radians). This command sets the relative phase of the output sine wave. This is

useful for adjusting the phase of the output after the 440A has obtained lock. Factory

default is N=0.

C x

E

nable (x=E) or

D

isable (x=D) external lock. When disabled, the internal TCXO is used

without locking to an externally supplied clock.

E x

Serial Echo Control. x=D for Echo

D

isable, x=E for Echo

E

nable. Default is

E

nabled.

T x

ECL Output Control. x=D for ECL

D

isable, x=E for ECL

E

nable. Default is

D

isabled.

(requires internal configuration)

S

Save current state into EEPROM and sets the EEPROM valid flag. The state saved is used

as default upon next power up or reset.

STOP

Turns off the internal microprocessor. The

“STOP”

command automatically saves all

present settings. Use this command in embedded applications for lowest system noise and

power. A logic low (open collector) pulse must be applied to the CLR_STOP* connector

pin to restore normal operation. After a CLR_STOP* pulse, factory defaults are restored.

(an internal on-board push button implements the “CLR_STOP*” pulse)

R

Reset. This command resets the unit. EEPROM data is preserved and, if valid, it is used

upon restart. This is the same as cycling power or toggling the open collector RES* line

on the connector. (an internal on-board push button implements a “RES*” pulse)

CLR

Clear. This command clears the EEPROM valid flag and restores all factory default

values.

QUE

Read present frequency, phase and status. Returns a character string of internal settings,

lock status and software revision number. Hexadecimal format. See operating notes for

details.

Pin

Number

Function

Type

Pin

Number

Function

Type

1

Ground (Power Supply Common)

PS

2

NC (open: for LPO30A compatibil-

ity)

-

3

TX, serial ASCII data FROM mod-

ule, TTL level (3.3 V CMOS)

Out

4

Ground (Power Supply Common)

PS

5

NC (open: for LPO30A compatibil-

ity)

-

6

RX, serial ASCII data TO module,

TTL level (3.3 V CMOS)

In

7

+3.3 VDC

INPUT

PS

8

RES*, Open Collector Reset Pin,

normally left open.

In

9

Ground (Power Supply Common)

PS

10

CLR_STOP*, Open Collector Input

Pin. Pulsing low clears module to

factory default outputs and settings.

In

11

INLOCK (TTL level, 3.3 V CMOS),

Out

12

Ground (Power Supply Common)

PS

13

RF_IN, Reference Clock Input, 50

Ω.

In

14

Ground (Power Supply Common)

PS

P1 Header Pinout (LPO400A only)

Serial Commands

Operating Notes for assembly LPO400A/440A, with REV 1.x Software

.

(August 23, 2005)

1:

The ‘

QUE

’ command has be rewritten to provide data specific to the LPO400A. The command returns

a thirty-three character ASCII string terminated by a CRLF. Values are in Hexadecimal:

0000 02625A00 2710 00000078 03 10

Decoding:

0000

Relative phase in Hex. Maximum value of ‘

3fff

’. Set by

“P0”

command.

02625A00

32-bit Frequency data (4-bytes), as hexadecimal. This value is the frequency in

0.25Hz steps. 10.0MHz default value. Set by

“F0”

command

2710

Reference frequency

set by ‘

Fr

’ command. Software sets to lowest 8kHz bound-

ary. Saved as a hex value as kHz. 10000 (as hexadecimal), for 10MHz reference

frequency, default.

00000078

Control Register values. These are internal setup values.

03

This byte contains status bits. The LSB is the lock bit. If an out-of-lock condition

is detected, the bit will go low (even). ‘

03

’ means that the LPO400A has been

locked. The on-board microcomputer reads the lock pin every millisecond and

sets this value low upon detection of a out-of-lock. Approximately one minute is

required for complete lock detection.

10

Software revision as ‘

x.x

’ or Rev 1.0 for this example.

2:

The InLock Pin on the interface connector, pin 11 of P1, will be steady logic high during lock. During

the locking process, this pin may be erratic. It is suggested that, if you use this pin, it be polled. The on-

board microprocessor reads the lock status each millisecond and requires 2

16

in-lock levels in a row for

lock detection (approximately one minute). The lock detect process cannot detect minor changes in the

reference input or the lock frequency setting (>±100ppm error may still indicate lock). This pin is not

accessible on the Model 440A. On the 440A, the lock condition is indicated by the front panel LED.

When illuminated GREEN, the unit is in lock, or using internal clock. When illuminated RED the unit is

out of lock (missing external reference, or internal failure).

3:

Commands return ‘

OK

’ if parsed and executed correctly.

4:

The on board green LED is illuminated when both on-board loops are in “Lock,” or the external refer-

ence has been disabled. If the LED is not illuminated, then a lock error is indicated. See 2 (above) for

front panel LED indications for the Model 440A.

The LPO400A evaluation board is similar to the 440A, but is supplied without a case to make evaluation

of the LPO400A module easier. See the board parts placement diagram and schematic below for details

on the evaluation board.

Ext Reference Input

RS232 POWER

SINE OUT

LPO400A Evaluation Board TOP

LOCK

LED

Date: August 4, 2005Sheet 1 of 1

Size Document Number REV

BA

Title

Test Board for LPO400A

Proprietary Information

Seattle, Washington 98155 USA

Copyright 2005 Novatech Instruments, Inc.

J5

SMA

OUT+

12

W1

HDR2

12

11

10

U3C

10H350

9

10

6

7

U4B

10H116

12

13

14

15

U4C

10H116

+5D

C13

0.1

R5

10k

LPO400A TEST INTERFACE FIXTURE

C14

0.1

+5D

4

3

2

11

6

89

U3A

10H350

NOT USED

+5D

OE

13

14

15

U3D

10H350

J7

MCX

+5D

FROM LPO400A

R6

51

C15

0.1

C16

0.1

4

5

2

3

11

6

81

1

U4A

10H116

U4 and U3

SOCKETS ONLY

5

6

7

U3B

10H350

J6

SMA

12

W3

HDR2

OUT+

OUT-

12

W4

HDR2

OUT-

12

W2

HDR2

+5

C10

0.1

C

1

R

1

2

R

2

3

R

3

4

R

4

5

R

5

6

R

6

7

R

7

8

Z1

270z

+3.3

VI G

N

D

VO

U1

LM1086CT-3.3V

HS

+5

1

2

L6

BEAD

+5D

C17

10/16

TANT

O3

I

1G

2

L4

EMI BEAD

1

2

P4

MOLEX

R3

RUE185

+5V

C3

0.1 FILM

O3

I

1G

2

L5

EMI BEAD

C4

0.1 FILM

CR2

90SQ045

C5

470/10

FM

C6

470/10

FM

C9

0.1

C1+

1

C1-

3

C2+

4

C2-

5

V

C

C

1

6

V+ 2

V- 6

T1O 14

T2O 7

R1I 13

R2I 8G

N

D

1

5

R2O

9

R1O

12

T2I

10

T1I

11

U2

MAX243

C11

0.1

C12

0.1

RF OUT

J3

MCX

J4

SMA

TRAN

C2

100p

FROM LPO400A

CR1

1N5711

C8

0.1

LD

RX

+3.3

12

34

56

78

910

11 12

13 14

A1

SOCK14

TX

REF_IN

J1

BNC

METAL

+3.3

R2

0.0

C7

10/16

TANT

LD

RESc-

7x2 0.1" GRID

CLR-

SOCKET PIN STRIP

RES*

S2

PB

R1

1.00k

C1

100p

REC

R4

1.0k

J8

NL

12

W5

NL

12

W6

NL

FOR ON BOARD

MCX. NL.

1

2

P5

HDR2

F_LED

lpo400ev.sch

CLR_STOP*

S1

PB

P1

MIN BANANA

0.138 HOLES

P6

MIN BANANA

19.2kBaud

TO PC

12

L1

BEAD

5

9

4

8

3

7

2

6

1

J2

DB9-F

12

L2

BEAD

12

L3

BEAD

REC

TRAN

P2

MIN BANANA

NOT INSTALLED

P3

MIN BANANA

0

0

2.35

2.35

PIN 1, SQUARE PAD,

(1.475,0.225), P1. MCX,

JOHNSON COMPONENTS

133-3701-133

(1.825,0.175)

Mounting Holes at:

(0.175,0.175), (2.175,0.175),

(2.175,2.175), (0.175,2.175)

LPO400A, COMPONENT SIDE VIEW

P1 two rows by seven pos.,

on 0.1 (2.54mm) grid. FCI

Dubox #68683-307 or Amp

#534998-7.

WARRANTY

NOVATECH INSTRUMENTS warrants that all instruments it manufactures are free from defects in

material and workmanship and agrees to replace or repair any instrument found defective during a

period of one year from date of shipment to original purchaser.

This warranty is limited to replacing or repairing defective instruments that have been returned by

purchaser, at the purchaser's expense, to NOVATECH INSTRUMENTS and that have not been

subjected to misuse, neglect, improper installation, repair alteration or accident. NOVATECH

INSTRUMENTS shall have the sole right to final determination regarding the existence and cause of a

defect.

This warranty is in lieu of any other warranty, either expressed or implied, including but not limited to

any warranty of merchantability or fitness for a particular purpose. In no event shall seller be liable for

collateral or consequential damages. Some states do not allow limitations or exclusion of consequential

damages so this limitation may not apply to you.

All instruments manufactured by NOVATECH INSTRUMENTS should be inspected as soon as they

are received by the purchaser. If an instrument is damaged in shipment the purchaser should

immediately file a claim with the transportation company. Any instrument returned to NOVATECH

INSTRUMENTS should be shipped in its original shipping container or other rigid container and

supported with adequate shock absorbing material.

This warranty constitutes the full understanding between NOVATECH INSTRUMENTS and the

purchaser and no agreement extending or modifying it will be binding on NOVATECH INSTRUMENTS

unless made in writing and signed by an authorized official of NOVATECH INSTRUMENTS.

NOVATECH INSTRUMENTS

United States of America

TEL: 206.301.8986

http://www.novatechsales.com

sales@novatechsales.com

Table of contents

Other Novatech Instruments Portable Generator manuals

Popular Portable Generator manuals by other brands

SDMO

SDMO I-PRO 3000 Series Instruction and maintenance manual

Sincro

Sincro ER Series Use and maintenance manual

Aremeca

Aremeca CEH Series operating instructions

BANDELIN

BANDELIN SONOREX TECHNIK TG Series Assembly instructions

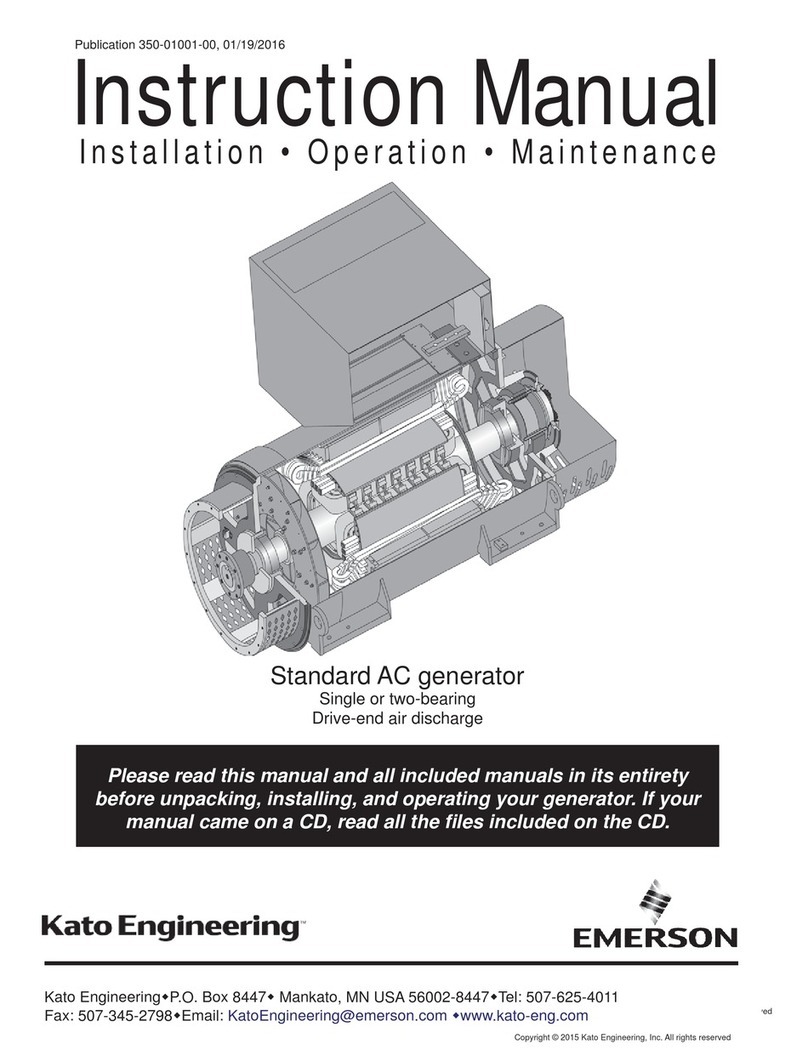

Kato Engineering

Kato Engineering Standard AC Generator instruction manual

Intermatic

Intermatic IPURE installation manual