ClearFox CU-M User manual

1

Quick Start Guide

ClearFox® Control

Unit CU-M

ClearFox®Control Unit CU-M

2

1TABLE OF CONTENTS

2 Most important information ...................................................................................................... 4

2.1 Switching the device off...................................................................................................... 4

2.2 First start............................................................................................................................. 4

2.3 Login Service Menu............................................................................................................. 4

2.4 Connecting via Wi-Fi / internal webpages .......................................................................... 4

3 Introduction................................................................................................................................ 4

4 Switching the device off.............................................................................................................. 4

5 Warnings / opening of the casing............................................................................................... 5

6 Connecting the consumers (blower, hoses, beacon).................................................................. 5

6.1 Air-SBR................................................................................................................................. 5

6.2 Pump-SBR............................................................................................................................ 6

6.3 One-Tank SBR...................................................................................................................... 6

6.4 Continuous plants (MBBR, Fixed-Bed, …)............................................................................ 6

6.5 Drippling filter (D: Tropfkörper).......................................................................................... 6

7 Connecting to Wi-Fi .................................................................................................................... 7

7.1 Connecting the control unit to the internet via Wi-Fi (ST mode) ....................................... 7

8 Alarm handling............................................................................................................................ 8

9 Process overviews....................................................................................................................... 8

9.1 Air-SBR................................................................................................................................. 8

9.1.1 Process steps.................................................................................................................. 8

9.1.2 Water level measurement ............................................................................................. 9

9.2 Pump-SBR.......................................................................................................................... 11

9.2.1 Process steps................................................................................................................ 11

9.2.2 Selectable output assignment ..................................................................................... 11

9.3 One-Tank SBR.................................................................................................................... 12

9.3.1 Process steps................................................................................................................ 12

9.3.2 Selectable output assignment ..................................................................................... 14

9.4 Continuous plants (MBBR, Fixed Bed, …).......................................................................... 14

9.4.1 Process steps................................................................................................................ 14

9.4.2 Selectable output assignment ..................................................................................... 15

10 Menu......................................................................................................................................... 15

11 Internal webpages .................................................................................................................... 15

12 Transferring the ASW / FW / Web-Pages ................................................................................. 15

12.1 Transfer via Wi-Fi .............................................................................................................. 16

ClearFox®Control Unit CU-M

4

2MOST IMPORTANT INFORMATION

2.1 SWITCHING THE DEVICE OFF

The ClearFox®Control Unit CU-M must not be switched off by disconnecting mains and

batteries. As it works with an operating system and Flash memory, it must be shut down

properly.

Shutting down must be done by pressing the OK button for > 10s. On the LCD a message will

appear. Now the mains connection can be disconnected. That’s it.

2.2 FIRST START

Please mind, that after the first start the plant type must be selected, as the demo software

contains different plant types.

The ClearFox®Control Unit CU-M will restart then, which will take some 2-3min.

2.3 LOGIN SERVICE MENU

The Service PIN is 1111.

2.4 CONNECTING VIA WI-FI /INTERNAL WEBPAGES

- SSID: WWTP-Controller

-Wi-Fi password: 12345678

-IP address (must be entered into the browser address line (=where you’d type

www.google.com): http://192.168.117.1/

oUsername for service login: service

oPassword: 1111 (same as service menu PIN)

3INTRODUCTION

The ClearFox®Control Unit CU-M platform is a powerful, free programmable control unit for

decentralized STP.

The IoT platform is equipped with a Wi-Fi module (access point (AP) and station mode (ST), even

parallel) and an integrated webserver. Thus, the Sequetrol® IoT can be either operated via the

LCD + menu or via any web browser (smartphone, tablet, PC). An internet connection is not

required. The Wi-Fi of the control unit creates a local hotspot (in access point mode).

More information about the IoT platform can be found on our webpages.

4SWITCHING THE DEVICE OFF

The ClearFox®Control Unit CU-M must not be switched off by disconnecting mains and

batteries. As it works with an operating system and Flash memory, it must be shut down

properly.

Shutting down must be done by pressing the OK button for > 10s. On the LCD a message will

appear. Now the mains connection can be disconnected. That’s it.

ClearFox®Control Unit CU-M

5

5WARNINGS /OPENING OF THE CASING

To gain access to the screw-type terminals, the service compartment of the casing must be

opened by unscrewing the two cross slot screws marked with the red circles in Figure 1.

Figure 1: Opening the casing of the Sequetrol® IoT midi

This kind of operation may only be carried out by trained staff, since there are live

components carrying 230V mains voltage under the cover (at the underside of the printed

circuit board and close to the mains supply connectors and the fuse, mains voltage 230 V.)

Before removing the casing cover, it is necessary to pull the mains supply connector!

6CONNECTING THE CONSUMERS (BLOWER,HOSES,BEACON)

6.1 AIR-SBR

-Blower: Connected to the electric socket of the ClearFox®Control Unit CU-M.

-Valves:

oFilling: Out 2

oClearwater removal / Discharge: Out 3 –either valve or submersible pump (can

be selected via the web pages)

oSludge return: Out 4

oAeration / Denitrification: Out 5

-BonFlash alarm beacon is connected to the terminals marked with BF-C (brown cable)

and GND (white cable), (see chapter 5).

ClearFox®Control Unit CU-M

6

-Overfill Float Switch: Optional. Connected to the digital input terminal DI1 inside the

controller (see chapter 5).

6.2 PUMP-SBR

Output functions can be selected via web pages.

-Blower (+Valve) / Injection Aerator: Connected to the electric socket of the

ClearFox®Control Unit CU-M (+Out 5) / electric socket.

-Pumps / Valves:

oFilling: Direct submersible pump - Out 2; using the Sludge Pump –Sludge Pump

–Out 4

oClearwater removal: Pump Out 3 / Valve Out 3 (+Blower)

oSludge return: Pump Out 4 / Valve Out 4 (+Blower)

-BonFlash alarm beacon is connected to the terminals marked with BF-C (brown cable)

and GND (white cable), (see chapter 5).

-Overfill Float Switch: Optional. Connected to the digital input terminal DI1 inside the

Sequetrol® IoT (see chapter 5).

6.3 ONE-TANK SBR

Output functions can be selected via web pages.

-Blower (+Valve) / Injection Aerator: Connected to the electric socket of the

ClearFox®Control Unit CU-M (+Out 5) / electric socket.

-Sludge return: Pump Out 3 / Valve Out 3 (+Blower)

-BonFlash alarm beacon is connected to the terminals marked with BF-C (brown cable)

and GND (white cable), (see chapter 5).

-Overfill Float Switch: Optional. Connected to the digital input terminal DI1 inside the

ClearFox®Control Unit CU-M (see chapter 5).

6.4 CONTINUOUS PLANTS (MBBR, FIXED-BED,…)

Output functions can be selected via web pages.

-Blower (+Valve): Connected to the electric socket of the ClearFox®Control Unit CU-M

(+Out 5)

-Pumps / Valves:

oFilling: Submersible pump - Out 2 / Airlift –Out 2 (+Blower)

oClearwater removal: Pump Out 3 / Valve Out 3 (+Blower)

oSludge return: Pump Out 4 / Valve Out 4 (+Blower)

-BonFlash alarm beacon is connected to the terminals marked with BF-C (brown cable)

and GND (white cable), (see chapter 5).

-Overfill Float Switch: Optional. Connected to the digital input terminal DI1 inside the

ClearFox®Control Unit CU-M (see chapter 5).

6.5 DRIPPLING FILTER (D: TROPFKÖRPER)

Work in progress…

ClearFox®Control Unit CU-M

7

7CONNECTING TO WI-FI

The ClearFox®Control Unit CU-M can be operated and monitored via Wi-Fi. All

settings can be done comfortably in your browser (smartphone, tablet, PC).

- SSID: WWTP-Controller

-Wi-Fi password: 12345678

-IP address (must be entered into the browser address line (=where you’d type

www.google.com): http://192.168.117.1/

oUsername: service

oPassword: 1111 (same as service menu PIN)

In case these parameters shall be changed, please refer to the Network Settings page:

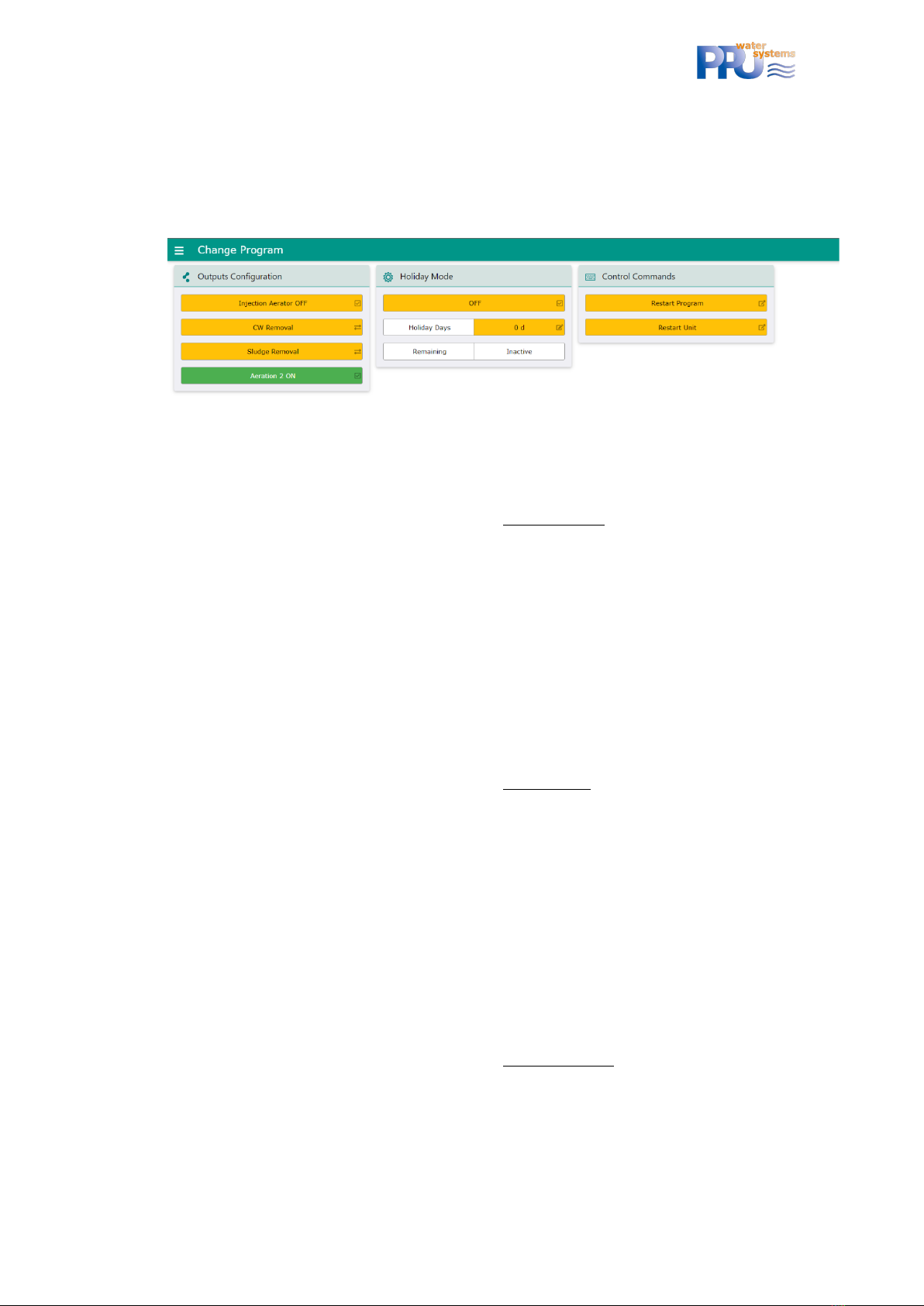

Figure 2: Wi-Fi - Access Point settings

Please do not forget to push Apply Wi-Fi Settings (control unit restarts).

The ClearFox®Control Unit CU-M can run Wi-Fi in Access-Point (AP) and in Station Mode (ST)

- AP: Wi-Fi hotspot without internet connection (intranet only)”

- ST: Connection to another Wi-Fi hotspot or router (e.g. your company Wi-Fi), often used

to connect the Sequetrol® IoT to the public internet (e.g. for telemetry)

7.1 CONNECTING THE CONTROL UNIT TO THE INTERNET VIA WI-FI (ST MODE)

The control unit can be run simultaneously in Access Point (AP) and Station (ST) mode.

-Access Point mode means, the control unit behaves as a “Wi-Fi hotspot”. You can

connect with any device and view the internal webpages.

-Station mode means, the control unit connects to another Wi-Fi network (mostly with

internet access).

ClearFox®Control Unit CU-M

8

The necessary setting can be set performed on the Network Settings page:

Figure 3: Wi-Fi - Station Mode settings

If DHCP is activated (recommended), only the SSID and the Wi-Fi Password must be entered.

Please do not forget to push Apply Wi-Fi Settings (control unit restarts).

8ALARM HANDLING

The ClearFox®Control Unit CU-M monitors different alarm states like blower pressure and

overfill alarm.

All alarms can be acknowledged by pressing <OK> short. Acknowledging the alarm deactivates

the Buzzer and the BonFlash output. The red LED remains on, and the last alarm remains in the

Status Screen, until the reason for the alarm is gone (e.g. float switch is down again) or until the

alarm is deleted.

The alarm will be deleted automatically when the alarm reason disappears. It can also be

deleted by pressing <OK> for 1-2s or via the web pages. Please mind that if the alarm reason is

still active, the alarm will reappear.

9PROCESS OVERVIEWS

Please note that these are demo / sample programs. They can either be completely replaced by

your process, menu, and web pages. Or we can adopt these programs to your requirements and

preferences.

9.1 AIR-SBR

9.1.1 Process steps

-Normal mode

ClearFox®Control Unit CU-M

9

oLevel measurement via Filling. If below switching level 1 => eco

oFilling

oLevel measurement via Filling. If above switching level 2 => overfill alarm

oDenitrification (can be deactivated by setting step time to 0s)

oAeration

oSludge (before Settling, option, can be deactivated by setting step time to 0s) –

sludge return will not take place within the first 90 days after bringing into

service. This value can be changed, the parameter is called Biology Build-Up

Time.

oSettling

oSludge (after Settling, option, can be deactivated by setting step time to 0s) –

sludge return will not take place within the first 90 days after bringing into

service. This value can be changed, the parameter is called Biology Build-Up

Time.

oClearwater removal

oOption: Check DI1, if closed => overfill alarm (if no float switch is connected,

there will not be an alarm)

- Eco mode

oAeration

oLevel measurement via Filling. If above switching level 1 => normal

oEach 6 eco cycles (frequency can be changed) => At least one normal mode

9.1.2 Water level measurement

Water level measurement at this process is performed using the filling airlift in the pretreatment

tank.

If the level before filling is higher than the calibrated value plus Offset 1, filling will be

performed, and the control unit will follow the normal mode program. If the level is lower, filling

will not be performed, and the program follows the eco mode process.

If the level after filling is higher than the calibrated value plus Offset 2, this means, filling could

not be performed. Likely the problem was that the reactor is (still) full because clearwater

removal did not work and thus the water pumped from the pretreatment to the reactor during

filling simply flowed back. An overfill alarm will be signalized in this case.

calibrated minimum

Offset 1

(Eco / Normal)

Offset 2

(overfill alarm)

Figure 4: Pretreatment tank with filling airlift and calibrated minimum, Offset 1 and 2

ClearFox®Control Unit CU-M

10

To be able to run the water level measurement, the “calibrated minimum” must be calibrated

(takes place automatically 14-days after bringing into operation, see chapter 9.1.2.1).

9.1.2.1 Automatic calibration

If ClearFox®Control Unit CU-M is simply installed to a plant, the automatic calibration will be

performed after 14 days. This delay shall ensure, that the pretreatment tank is filled at least to

the minimal level of the filling airlift and the reactor is filled at least to the minimal level for the

sludge return airlift.

After these 14 days, this process will be performed:

1) Clearwater removal

2) Filling with longer filling time to make sure that the level in the pretreatment is pumped

down to the minimum that can be reached using the filling airlift. The filling airlift now

“slurps” (does not pump properly, anymore, as it cannot suck anymore water).

3) “Sludge return” for some 60s to increase the level in the pretreatment so that the filling

airlift can pump properly, again.

4) Filling for 20s –the pressure at this minimal water level will now be stored as “calibrated

minimum”.

Now the ClearFox®Control Unit CU-M is able to measure the water level in the plant.

9.1.2.2 Manual calibration

In case the automatic calibration shall not be used for any reason, for example because the level

measurement shall be tested “instantly” (not after 14 days), the calibration can also be

performed manually. The manually entered values will not be overwritten by automatic

calibration.

To do so, the user must empty the water level in the pretreatment until there is only some 0.5-

1cm of water above the inlet of the filling airlift (the airlift must still be able to pump properly,

no slurping or sucking air). Now the filling airlift is activated in the manual control menu or web

page. The displayed pressure must now be noted. This pressure can now be entered in the

“Minimum” text field:

ClearFox®Control Unit CU-M

11

Figure 5: Parameters for water level measurement in the web pages of the IoT control unit

9.1.2.3 Changing the levels for Normal- / Eco-Mode and Overfill Alarm

The offsets can be changed in the web pages (Pressure measurement / Calibration, see Figure 5)

or in the Service Menu / Pressure.

9.2 PUMP-SBR

9.2.1 Process steps

- Normal mode

oFilling

▪Via dedicated pump: ON (15min) or until DI1=closed. On timeout (step

time over, DI1=open) => Eco

▪Via Sludge Pump: ON (10s)+OFF (14:50min) or until DI1=closed. On

timeout (step time over, DI1=open) => Eco

oDenitrification (0:40min ON / 9:20min OFF / 60min Total)

oAeration (8min ON / 12min OFF / 9.5h Total)

oSludge (before Settling) (2min)

oSettling (1.5h)

oSludge (after Settling) (0min)

oClearwater removal (20min)

oCheck DI1, if closed => overfill alarm. Else, continue

- Eco mode

oAeration (2min ON / 8min OFF / 8:45h Total)

oFilling (only ON (15min) at “Pump”, ON (10s)+OFF (14:50min) at “via Sludge

Pump”). If DI1=closed => Normal, on timeout (step time over, DI1=open) =>

continue Eco

oEach 6 cycles => Normal mode

9.2.2 Selectable output assignment

FUNCTION/

SELECTABLE

ClearFox®Control Unit CU-M

12

OPTION AND

CONSEQUENCE

FILLING

Pump

Out 2

Current limits for pump

(300/1800mA) applied

Via sludge pump (Out 4)

Current limits for pump

(300/1800mA) applied

Instead of pumping only 10s + pause

(adjustable)

AERATION

Blower (+ valve)

Out 1 (+ 5)

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits (7/350mbar)

for Blower applied

Injection aerator

Out 1

Current limits for aerator

(300/2500mA) applied

SLUDGE

Blower + valve

Out 1 + 4

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits (7/350mbar)

for Blower applied

Via sludge pump (Out 4)

Current limits (300/1800mA) for

pump applied

CLEARWATER

Blower + valve

Out 1 + 3

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits (7/350mbar)

for Blower applied

Pump

Out 3

Current limits (300/1800mA) for

pump applied

9.3 ONE-TANK SBR

9.3.1 Process steps

For the level measurement (overfill alarm) a manual calibration must be performed. In case this

calibration was not performed (yet), there will be no overfill alarm.

RTC sync for beginning of settling phase can be set (mostly around 3am).

Number of cycles per day can be set (1-4).

Holiday period (number of days can be entered that is counted down) can be entered, where the

controller uses different ON/OFF times for the aeration.

Cycle 1 of the day (also for bringing into operation) has a different Aeration step.

Aeration

- first cycle of the day: Infinite until RTC sync time reached

- next cycles of the day: Infinite until total Aeration Total Time (calculated out of

cycles per day and the remaining step times) reached

Aeration 1 (6min ON / 14min OFF) –via valve on Out 5 –primary aeration of the reactor

after one ON/OFF cycle jump to

ClearFox®Control Unit CU-M

13

Aeration 2 (4min ON / 6min OFF) –via valve on Out 4 –optional aeration of another part of

the reactor or the sludge tank.

after one ON/OFF cycle jump to Aeration 1

If Aeration 2 shall not be used, it can be deactivated via the web pages:

Figure 6: One-Tank SBR program individualization via internal web pages

Sludge return

Time taken from the settling time –example: Settling = 2h, sludge = 2min => settling will be

1:58h in reality and sludge 2min –sludge return before settling can be deactivate via a

parameter via the Patch file (please ask PPU in case you want to deactivate it). All sludge

returns have the same step times.

Max. step duration that can be entered is 30min., default step duration is 0min (!)

Settling (1.5h)

OPTIONAL Sludge return

This sludge return can be activated via a parameter via the Patch file (please ask PPU in

case you want to activate it)

Time taken from the settling time –example: Settling = 2h, sludge = 2min => settling will be

1:58h in reality and sludge 2min –sludge return after settling can be deactivate via a

parameter via the Patch file. All sludge returns have the same step times.

Max. step duration that can be entered is 30min., default step duration is 0min (!)

Clearwater removal

Max. step duration that can be entered is 1h., default duration is 15min

OPTIONAL Sludge return

This sludge return can be activated via a parameter via the Patch file (please ask PPU in

case you want to activate it)

Time taken from the settling time –example: Settling = 2h, sludge = 2min => settling will be

1:58h in reality and sludge 2min –sludge return after clearwater can be deactivate via a

parameter via the Patch file. All sludge returns have the same step times.

Max. step duration that can be entered is 30min., default step duration is 0min (!)

Water level measurement

Via CW (only if calibrated!) –must be below “calibrated value + offset”. Else overfill alarm.

ClearFox®Control Unit CU-M

14

In parallel via digital input 1 –if up after CW-Rem. => overfill alarm.

9.3.2 Selectable output assignment

FUNCTION/

SELECTABLE OPTION

AND CONSEQUENCE

AERATION

Blower (+ valve)

Out 1 (+ 5)

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

Injection aerator

Out 1

Current limits for aerator

(300/2500mA) applied

Offset and calibrated value for

overfill = 0mbar

AERATION 2

(OPTION)

Blower (+ valve)

Out 1 (+ 4)

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

NO

SLUDGE

Blower + valve

Out 1 + 3

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

Via sludge pump (Out 3)

Current limits for pump

(300/1800mA) applied

CLEARWATER

Blower + valve

Out 1 + 2

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

Pump

Out 2

Current limits for pump

(300/1800mA) applied

9.4 CONTINUOUS PLANTS (MBBR, FIXED BED,…)

9.4.1 Process steps

RTC sync for day/night mode. Beginning and end of the night period can be changed. During

night other ON/OFF times can be applied for the particular outputs than during the day.

Holiday period (number of days can be entered that is counted down) can be entered, where the

controller uses different ON/OFF times for the particular outputs.

For functions (Filling, Aeration, Sludge, Clearwater) the ON/OFF times for day, night and holiday

operation can be set. If ON time = 0s, the output is deactivated. If OFF time = 0s, the output is

permanently on.

Overfill alarm via digital input 1 (e.g., float switch).

ClearFox®Control Unit CU-M

15

9.4.2 Selectable output assignment

FUNCTION/

SELECTABLE OPTION

AND CONSEQUENCE

FILLING

(ON DAY/OFF DAY //

ON NIGHT/OFF

NIGHT // ON

HOLIDAY / OFF

HOLIDAY)

Pump

Out 2

Current limits for pump

(300/1800mA) applied

Airlift

Out 1 + 2

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

AERATION

(ON DAY/OFF DAY //

ON NIGHT/OFF

NIGHT // ON

HOLIDAY / OFF

HOLIDAY)

Blower (+ valve)

Out 1 (+ 5)

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

-

SLUDGE

(ON DAY/OFF DAY //

ON NIGHT/OFF

NIGHT // ON

HOLIDAY / OFF

HOLIDAY)

Blower + valve

Out 1 + 4

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

Via sludge pump (Out 4)

Current limits for pump

(300/1800mA) applied

CLEARWATER

(ON DAY/OFF DAY //

ON NIGHT/OFF

NIGHT // ON

HOLIDAY / OFF

HOLIDAY)

Blower + valve

Out 1 + 3

Current limits for Blower

(250/900mA)+ valve (50/150mA)

applied

Generic pressure limits

(7/350mbar) for Blower applied

Pump

Out 3

Current limits for pump

(300/1800mA) applied

10 MENU

PPU used its “standard menu” for the sample.

PPU assumes, that the menu is mostly self-explaining. For questions, please do not hesitate to

contact us via [email protected].

11 INTERNAL WEBPAGES

PPU used its “standard webpages” for the sample.

PPU assumes, that the webpages are mostly self-explaining. For questions, please do not

hesitate to contact us via [email protected].

12 TRANSFERRING THE ASW /FW /WEB-PAGES

The ASW, FW and the web pages can be transferred by USB or Wi-Fi.

16

ClearFox®Control Unit CU-M

12.1 TRANSFER VIA WI-FI

Please mind that the batteries must be connected.

Please

- connect to the Wi-fi of the Sequetrol® IoT

- open the webpage http://192.168.117.1/

- login as serviceman

- go to FW & ASW Update

- select the *.pkg (Pack) file that you have received from PPU here:

- click on Start update process

- done!

12.2 TRANSFER VIA USB

Please mind that the batteries must be connected.

Please record the *.pkg (Pack) file into the root folder of a common USB stick formatted with

FAT16 or FAT32 (NOT NTFS).

a. Shut-off the control unit (see chapter 0)

b. insert the USB stick

c. connect the control unit to mains and to have the batteries connected.

d. Follow the instructions on the LCD

Some (cheap) USB sticks might not be recognized. In that case please use a brand stick.

Table of contents

Popular Control Unit manuals by other brands

Moen

Moen M-CORE U130CI installation guide

Motorline professional

Motorline professional MC102 User& installer's manual

HYDAC International

HYDAC International FMMHP Operating and maintenance instructions

Fanstel

Fanstel BlueFan BT680E manual

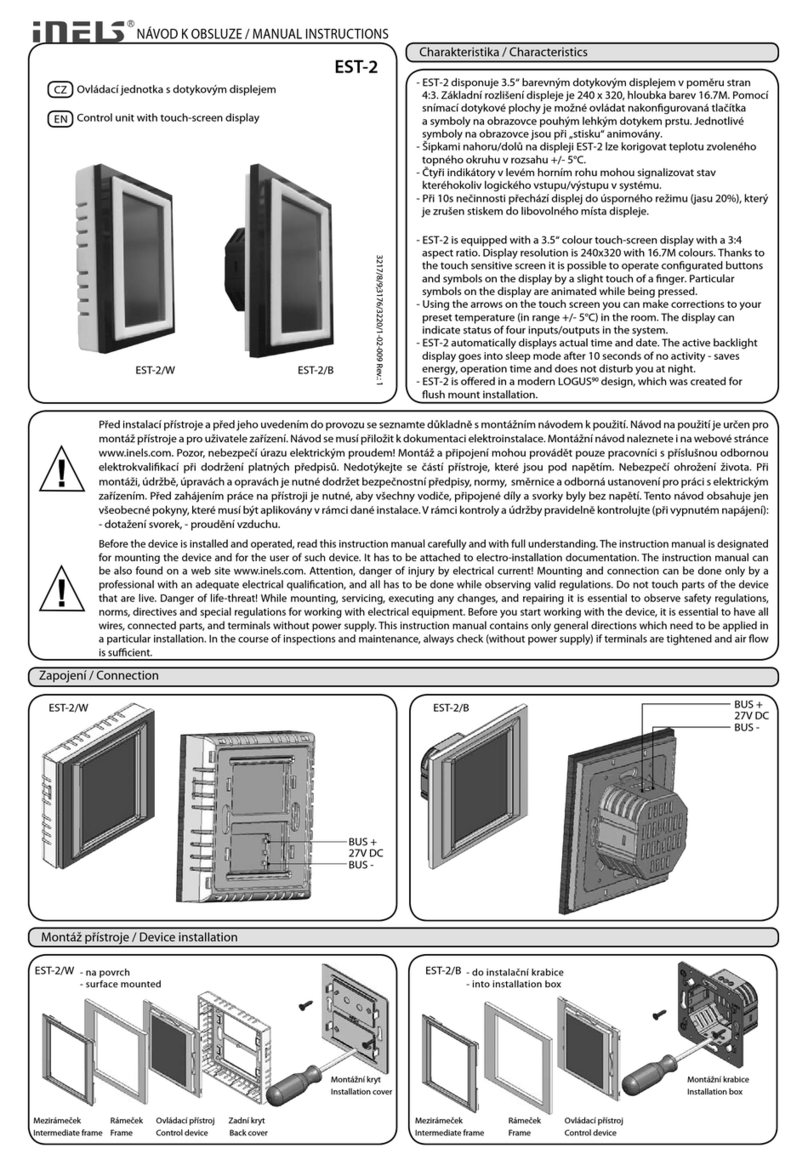

iNels

iNels EST-2 Series Manual instructions

Lincoln industrial

Lincoln industrial MP1 owner's manual

Siemens

Siemens TRI-S installation instructions

INOXPA

INOXPA INNOVA F Installation, service and maintenance instructions

Burkert

Burkert 6213 EV operating instructions

Vimar

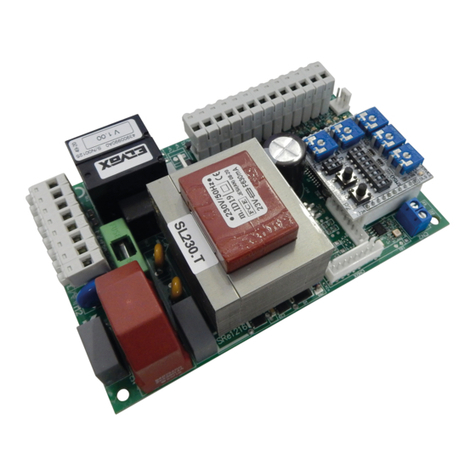

Vimar ELVOX SL230.T Connection and operating manual

Eaton

Eaton 11 Series Installation and start-up guidelines

Gantner

Gantner E Series Communications guide