Clements HiVac SUC 84109 User manual

Other Clements Water Pump manuals

Popular Water Pump manuals by other brands

Einhell Royal

Einhell Royal RGP 1300 Niro operating instructions

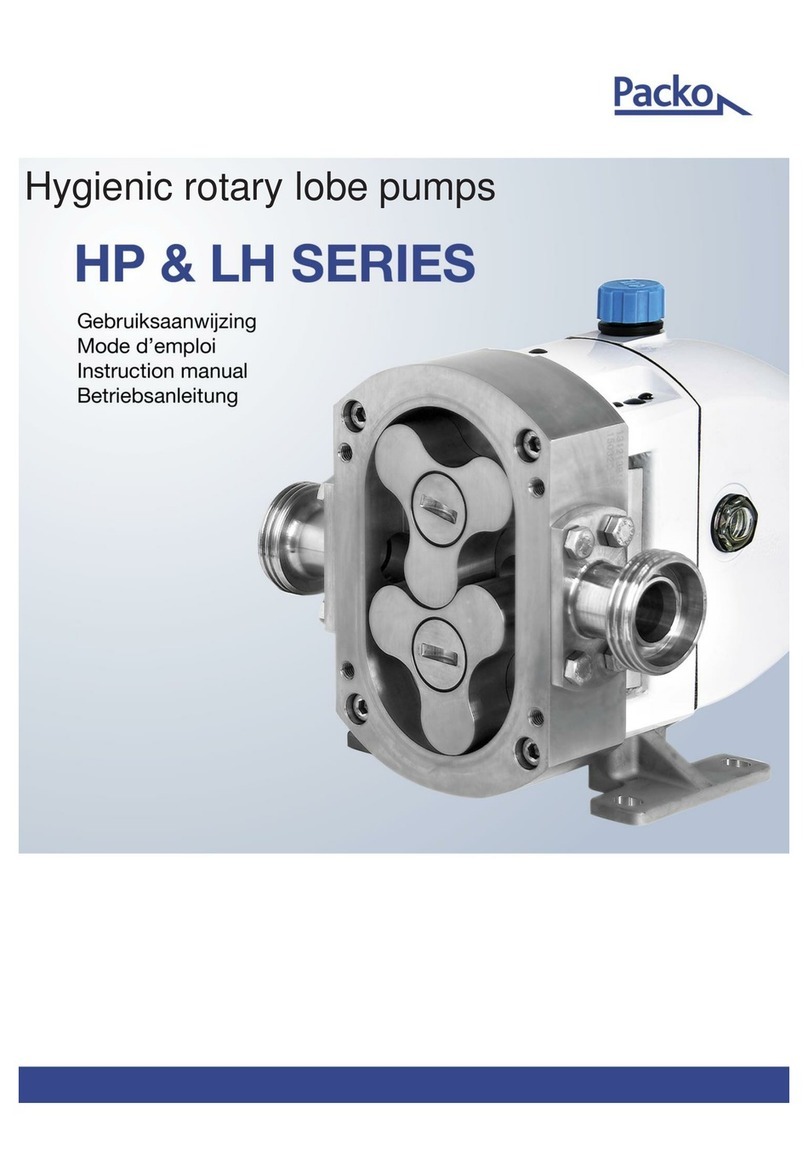

Packo

Packo HP Series instruction manual

Xylem

Xylem LOWARA ResiBoost MMW Installation, operation & maintenance manual

GORMAN-RUPP

GORMAN-RUPP 02K11-B Installation, operation, and maintenance manual with parts list

Sealey

Sealey TP94 instructions

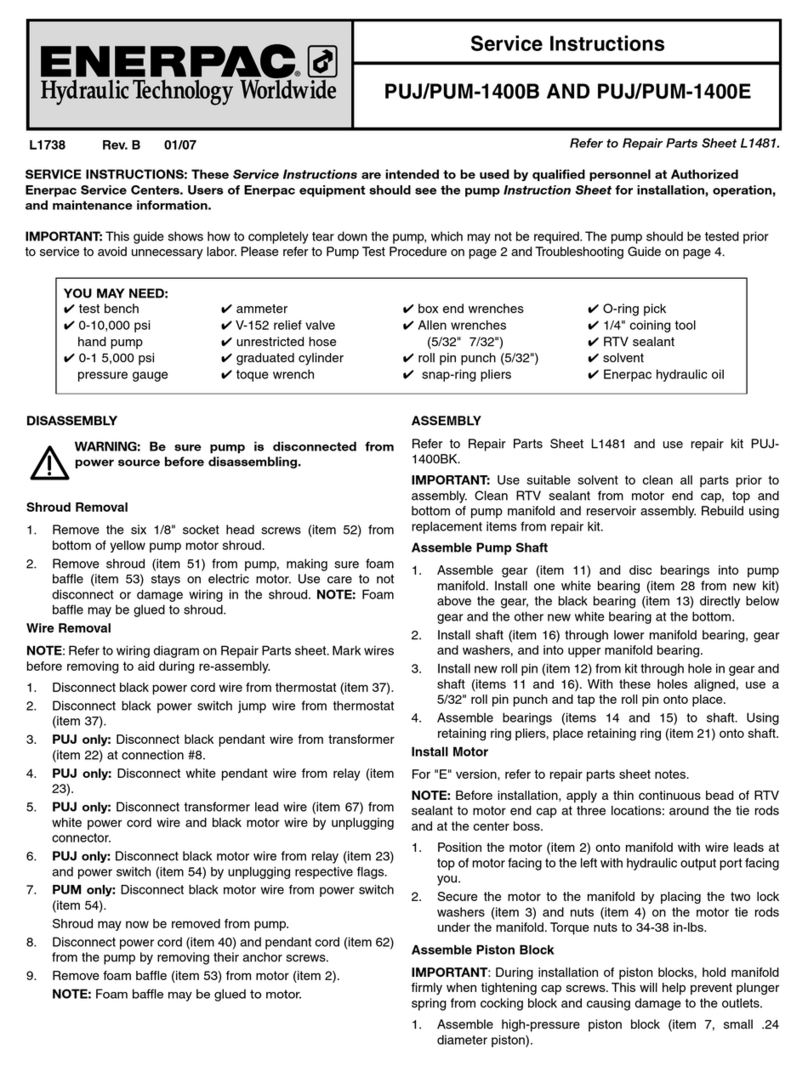

Enerpac

Enerpac PUJ-1400B Service instructions

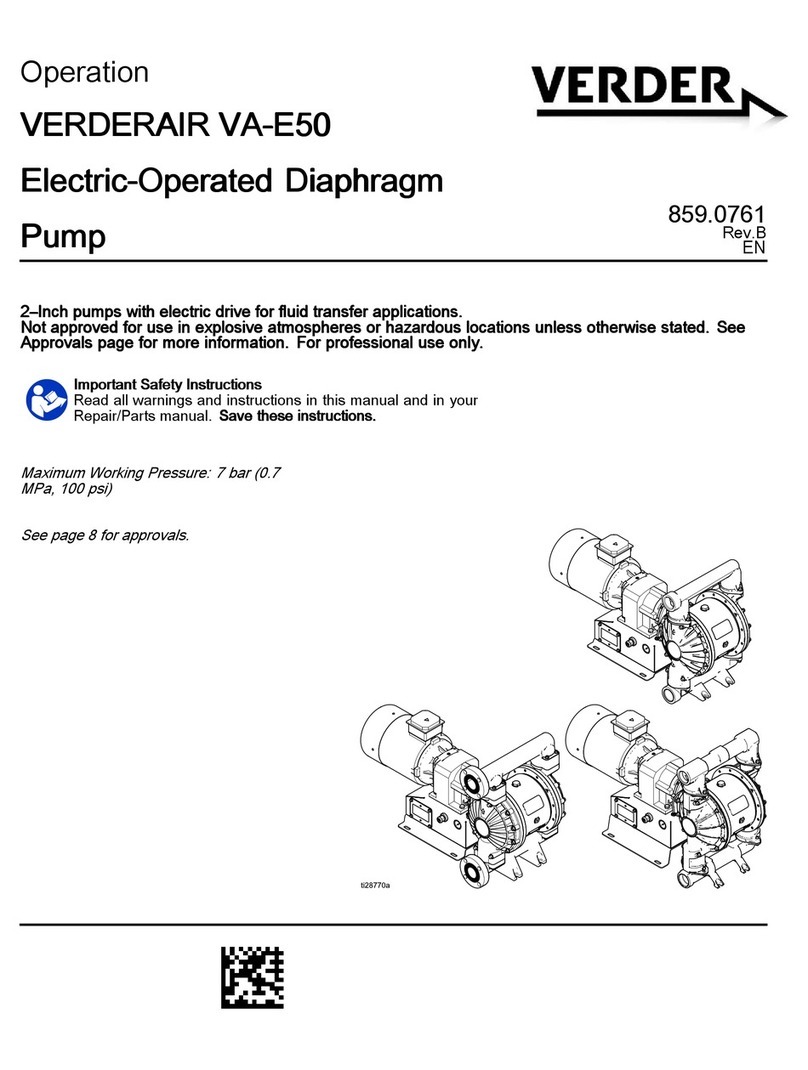

VERDER

VERDER VERDERAIR VA-E50 Operation

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS PRIME-AIRE PA6B Series MAINTENANCE AND REPAIR WITH TROUBLESHOOTING

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 13D-L70W FT4 Installation, operation, and maintenance manual with parts list

TotalPond

TotalPond 52325 quick start guide

salmson

salmson MINI SUBSON Installation and operating instructions

Rem

Rem Air System replacement pump instruction manual

Silverline

Silverline UK-917615 Original instructions

Samoa

Samoa 150 000 Parts and technical service guide

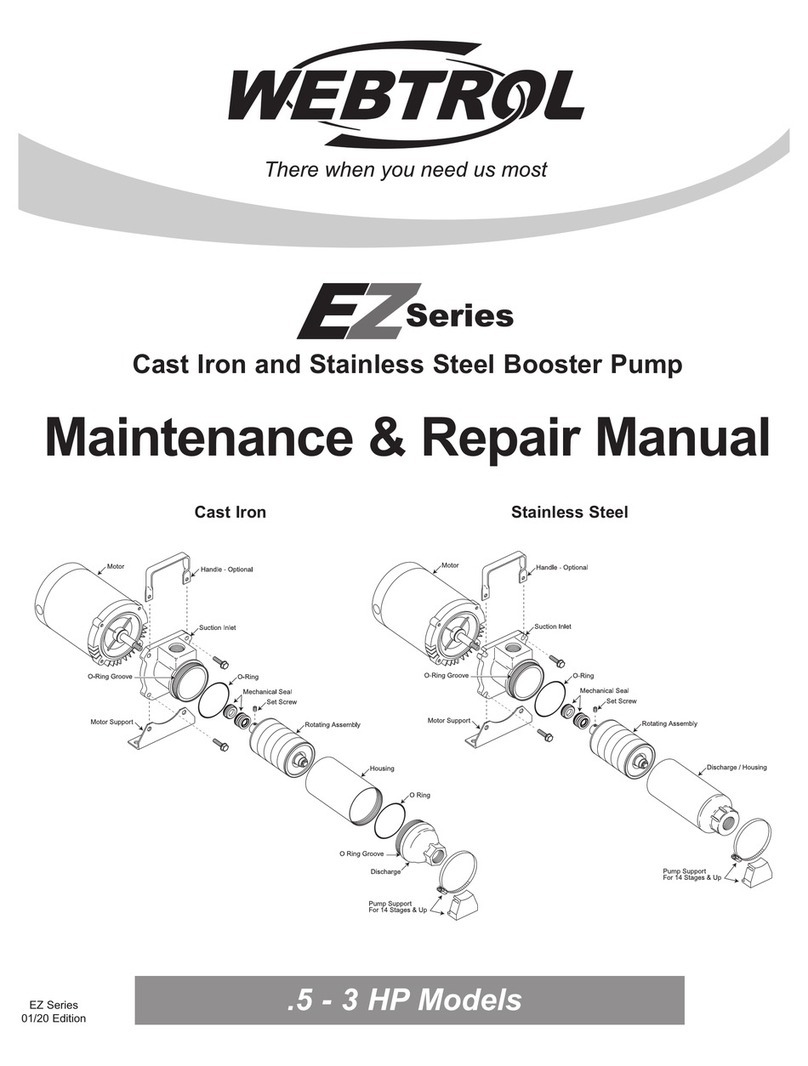

webtrol

webtrol EZ Series Maintenance & Repair Manual

HEISSNER

HEISSNER P1100E-00 Instructions for use

Dover

Dover HydroSystems Superdos 15 0.3 operating manual

Wilo

Wilo TOP-Z 20/4 EM Installation and operating instructions