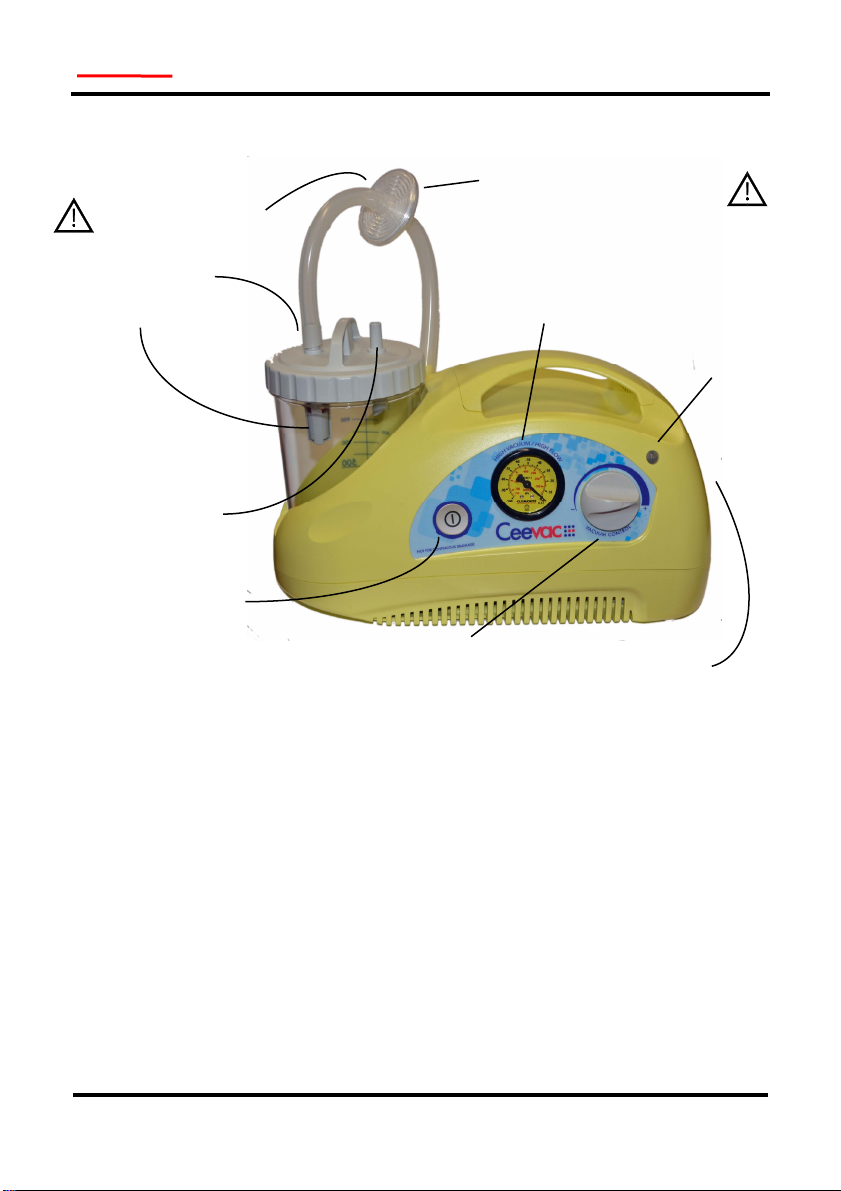

Clements SUC 81030 User manual

Table of contents

Other Clements Water Pump manuals

Popular Water Pump manuals by other brands

Goulds Pumps

Goulds Pumps 5500 Installation, operation and maintenance manual

Pfeiffer Vacuum

Pfeiffer Vacuum HIPACE 10 operating instructions

Wayne

Wayne 321602-001 Operating instructions and parts manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 80 Series Installation, operation, and maintenance manual with parts list

Pentair

Pentair Hydromatic SHEF30 Installation and service manual

Pond Boss

Pond Boss PF185AS quick start guide

PSG Dover

PSG Dover WILDEN PRO-FLO P2 Engineering, operation & maintenance

STERWINS

STERWINS 3276005711914 instructions

RODEX

RODEX RDX863 instruction manual

Sealey

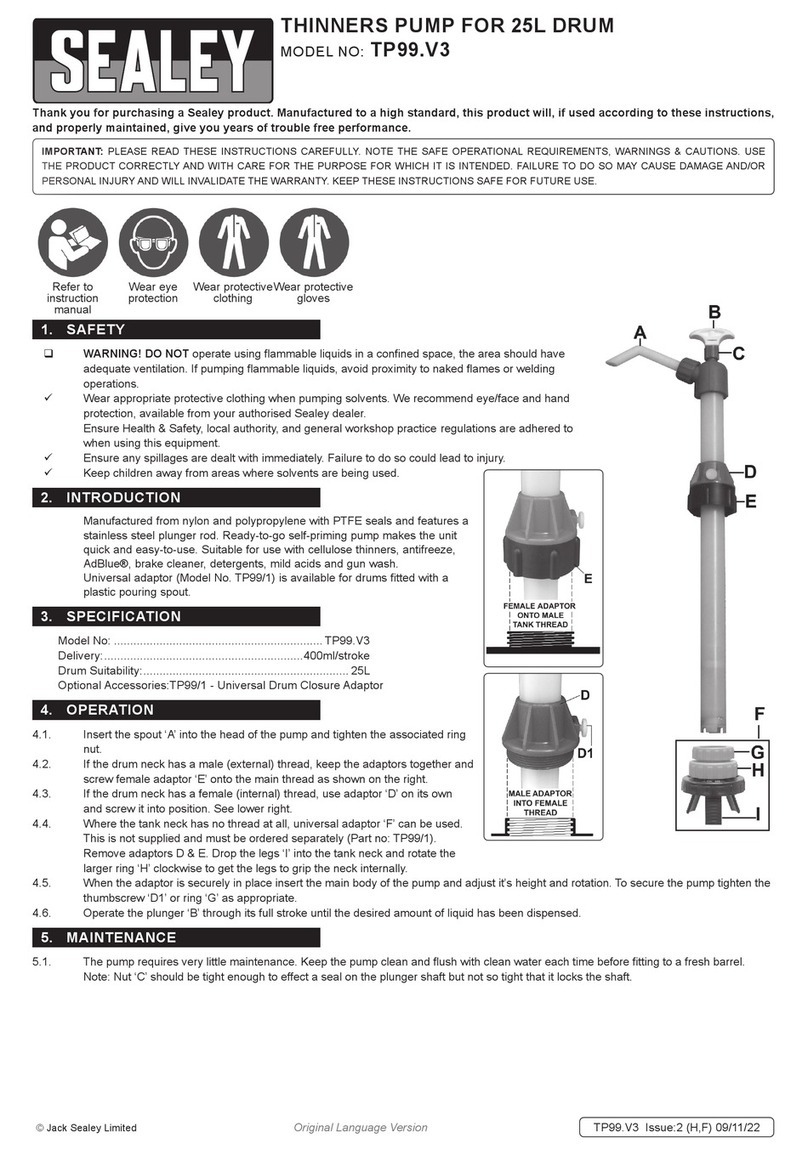

Sealey TP99.V3 manual

Wilo

Wilo YONOS ECO 25/1-5 BMS Installation and operating instructions

vacuubrand

vacuubrand MZ 2C NT+2AK Instructions for use