Cleral REFLEX Basic User manual

1

REFLEXBasic

Stand alone weighing system edition

for truck or semi-trailer

Version 1 to XXX

User Manual

Revision manual 02/17

BASIC

Caution

Your Cleral onboard weighing system is

a tool. Learning to work with it can only

make it more efficient. Read this manual

before using your Kiload.

Weigh bridge (certified)

Acquire the weights needed to calibrate

using a certified weigh bridge (Platform

scale). Whenever possible, record the

weights while sitting on the weigh

bridge.

Pneumatic connections

Make sure that all air connections are

made according to the installation dia-

grams.

Lift Axles

Lift axles should always be in the UP

position while acquiring and recording

the weights in the Kiload. If the vehicle

is equipped with an automatic lift axle

activation device, then you must acquire

and record the weights while the lift axle

is engaged (touching the ground) for

both empty and heavy calibration. And

use the system with lift axle down.

Fuel

To enhance the performance of your

Kiload, fuel tanks must be full to acquire

and record the weights.

Air leaks

A leak in the pneumatic system will fal-

sify the pressure readings for calibra-

tion. Thus , you will end up with erratic

and false weight readings. You most

likely have a leak if the readings are not

stable while your vehicle is stationary. A

frequent start of the compressor is a

good indication of an air leak.

Recalibration

Recalibration is necessary if you have

adjusted or replaced a leveling valve or

if you’ve replaced a mechanical sensor,

air transducer, or flexmeter.

Slopes

A slightly sloped terrain will not affect

the accuracy of your scale, but the big-

ger the inclination the higher the error

margin. Learning to work with your

Cleral system will ultimately give you

better precision in these conditions.

Technical Support

For technical help, consult your local

authorized Cleral dealer.

Warranty

Cleral products are warranted against

defects in workmanship for a period of

one year from the original date of pur-

chase. The defective covered product

will be repaired or replaced by the

manufacturer. The defective product

needs to be sent by your local dealer to

Cleral with proof of purchase. This war-

ranty does not cover injury or damages

caused by the use of this product. It also

does not cover all costs connected with

the replacement part ( labor, shipping

and handling or other). Cleral will not be

liable for fines issued for overweight

violations while using its products.

Contact your local Cleral dealer for re-

pairs and replacement parts.

Thank you for choosing and trusting

CLERAL CANADA

To contact Cleral Inc.

CLERAL INC.

90, des Distributeurs

Val-d’Or (Québec) Canada

J9P 6Y1

Tél. : (819) 825-5553

Fax : (819) 825-5556

Web : www.cleral.com

2

Keypad description 5

Reflex’s Flow chart 6

Turning the unit On 7

Calibration menu 8

Acquiring straight body truck weights 4X2 6X4 and 8X4 9

Acquiring tractor-trailer weights 10

Acquiring additional trailer weight 10

Acquiring steering axle weight (Instrumented or Virtual) 10

Wireless Sensor Acquisition 11

Automatic sensor acquiring 11

Selecting and Validating the channel 12

Changing channel 12

Calibration 4X2 6X4 8X4 - Empty vehicle 13

Calibration 4X2 6X4 8X4 - Full weights 14

Calibration 8(2)X4 or 8X(2)4 - Empty Weights 15

Calibration 8(2)X4 or 8x(2)4 - Full Weights 16

Calibration 8(2)X4 or 8x(2)4 - Lift Axle 17

Calibration - Empty Semi- trailer (Auxiliary instrumented) 18

Calibration - FULL Semi-trailer (Auxiliary instrumented) 19

Calibration - Semi-Trailer (Non-instrumented Auxiliary Axle INCLUDED) 20

Calibration - Semi-trailer (Auxiliary axle not instrumented EXCLUDED) 21

Multi point calibration 22

Tare 25

Freeze 26

Options menu 27

Language 28

Net weight 28

Measure units 28

Increments 28

Ton display 29

Cycle time 29

Time off 29

Hide MinAir 29

Hide N/A 30

Pause Option 30

Tare?default choice 30

Target 31

To access target weight 31

Adjust target weight 31

Configuration Menu 32

Printer 33

232 Printer 33

Wireless Printer 33

Wireless ID 33

Nb Ticket 33

3

Contents

Unit name 34

Print Header 34

Print ticket 34

Suspension 35

Maximum channel 35

Virtual steer 35

Active channels 35

Limit sensor 36

Min Air or Mec 36

MaxAir 36

M/D/Y 36

Time 37

Safety Menu 37

Password 37

Cal/Opt/Cfg/Tek 38

Tare 38

On/Off 38

Acquire 38

Acquire change address channel 39

System violation protection 39

New password 39

Multi zones 40

Technicien mode 41

Gauge A / B / C / D / E 42

Zero A / B / C / D ( or Tare) 43

Factors 44

Factor Multi-point 45

Tare 45

Error Calibration 46

Protection Calibration 46

Plucker 46

Status 47

System status 47

Channels status 47

ERROR CODES 48

Reflex connector types 49

Precision problems 50

4

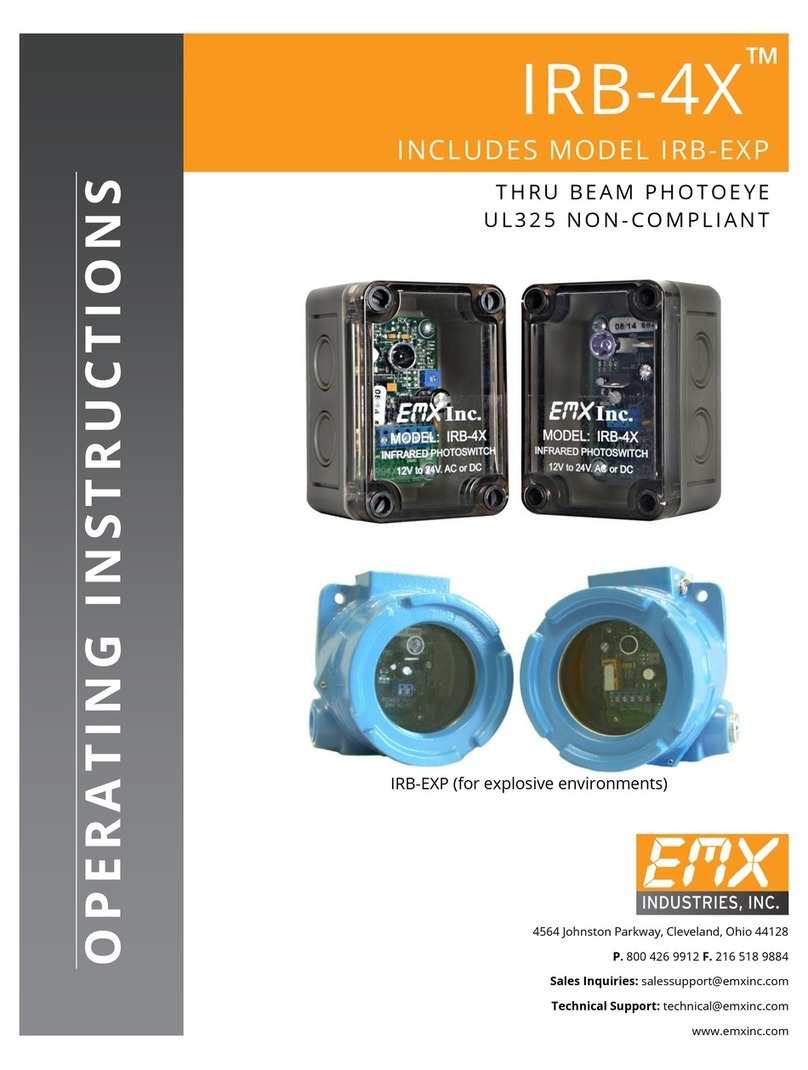

Keypad description

On/Off main power

Access to the calibration menu

To perform empty Tare or To back up while in menus

Lower values or Down while in the menu

Raise values or Up while in the menu

Change channel, right in the menu or confirm

Transmit data by RS232 or print, EXIT

Access to menu

Quick click will Freeze while in Total mode (Main screen)

Click and hold will Pause while in Total mode (Main screen)

Quick click, while in calibration mode, resets to 0,00

Letter A followed by a colon (:) Represents channel A

Letter B followed by a colon (:) Represents channel B

Letter C followed by a colon (:) Represents channel B

Letter T followed by a colon (:) Represents the total of all activated channels

5

A :

B :

C :

T :

Reflex’s Flow chart

Menus and sub-menus.

6

10.11.J & +

On/Off

Weight display

CAL ibration Empty

Full

Calibration Multi point

Indivudual tare

Adjuste

TARE

CYCLE

DATA

MENU

Wireless

Acquire (If wireless connected)

Options Language

Net weight

Measure unit

Increments

RS232 printer (If printer connected with wire)

Ton display

Wireless printer (If connected wired and RS232 printer disabled)

Cycle time

Wireless ID (If wireless printer is enabled)

Time off

Nb Ticket (If an active printer)

Hide MinAir

Unit name (If an active printer)

Hide N/A

Pause option Maximum channel

Tare? Default choice Virtual steer

Target Active channels

Configuration Printer Cal/Opt/Tek

Suspension Tare

LimitSensor On/Off

M/D/Y 12/30/16 Acquire(If active wireless)

Time 00:00:00

Acquire change adress channel (If active wireless)

Safety menu System violation protection

Multi zones New password

Technician Gage

Zeros

Factors

Tare

Error calibration

Protection calibration System status

Plucker Channels status

Status

Manufacturer(Access with code)

Production (Access with code)

Turning the unit On

When turning the Reflex On, the

software version is displayed.

Thereafter, the system indicates that

it initializes its memory.

If a wireless device is powered, it

indicates Wireless OK. If there are

no wireless devices powered, the

message is not indicated.

Thereafter, the serial number of the

unit will appear.

When initialization is complete, the

device returns to the weight display

mode.

7

Reflex

10.11.J

Initialize memory

Serie # 99999

Wireless OK

T : 13400 Gross

A : 5400 B: 8000

Calibration menu

Enter the Calibration menu to calibrate your Reflex.

Once in Calibration, here is what you will see by scrolling down:

Navigating in the Calibration menu :

8

T : 5000 Gross

C : 5000

Empty

➔Full

➔Empty

Full

To enter the Calibration

menu, press CAL

To reach a sub-menu,

press on down arrow.

When the cursor points to

the desired sub-menu,

press right arrow to enter

T : 5000 Gross

C : 5000

T : 5000 Gross

C : 5000

T : 5000 Gross

C : 5000

Arrow up or down:

Moving up or down.

Increase or decrease the

values.

Left arrow:

To back up and confirm.

DATA : To confirm and exit at

any time.

Right arrow:

Enter a menu.

Select an editable value, it

will start flashing.

Confirms the edited value,

stops flashing.

Exit

CAL ibration Empty

Full

Calibration Multi point

Indivudual tare

Adjuste

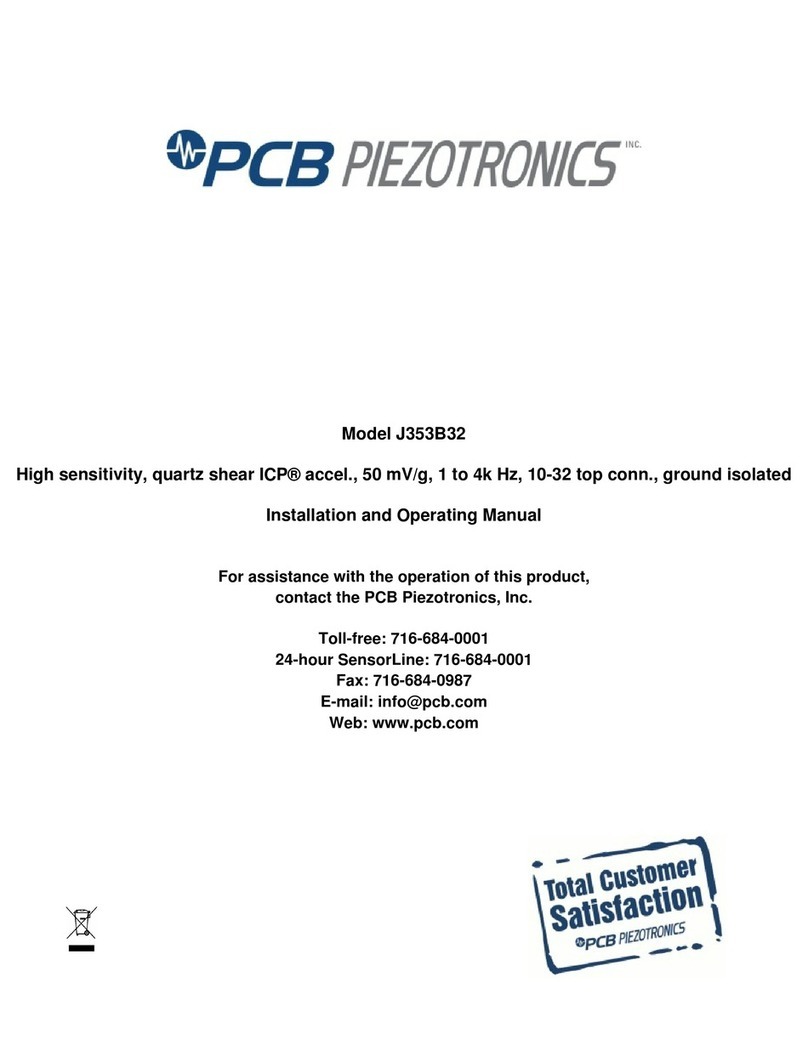

Acquiring straight body truck weights 4X2 6X4 and 8X4

The first step in the calibration of a straight body truck is to weigh the steer-

ing axle (Channel A). The next step is to weigh the entire vehicle (Total

weight) Then determine the weight of the drive axle(s) (ChannelB) by doing

the math.

In the case of a vehicle with an auxiliary axle, liftable or fixed.

9

Weigh BridgeWeigh Bridge

Weigh Bridge Weigh Bridge

CHANNEL «A» CHANNEL «B»

Weigh Bridge

CHANNEL «A»

Weigh Bridge

CHANNEL «B»

Weigh Bridge

CHANNEL «C»

Advance the truck to weigh the steering

axle only to get the weight of channel

A.

Advance the vehicle to weigh the

steering and auxiliary axles then

subtract the weight of the steer axle.

You get the weight of channel B.

(A + B) -A) = B

Advance the entire vehicle on the

weighbridge then subtract the weight of

channels A and B from the Total weight.

You get the weight of channel C.

T - (A+B) = C

Total

- Channel A

= Channel B

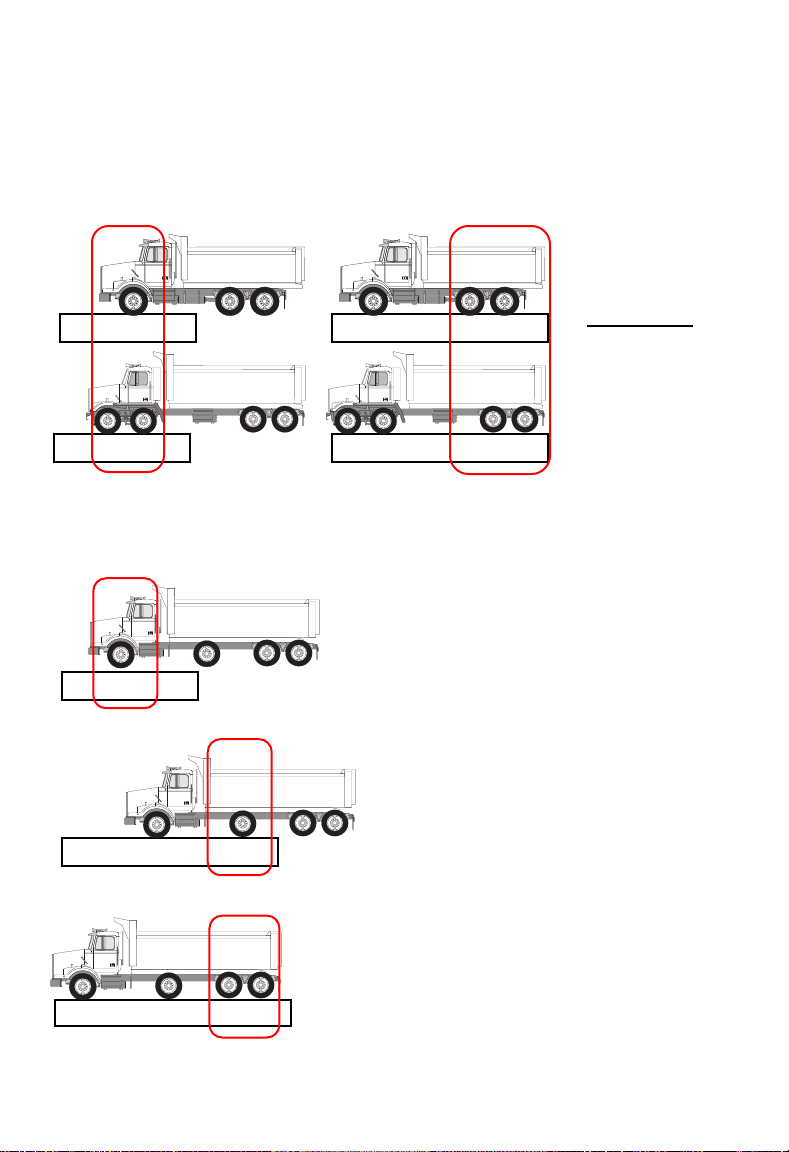

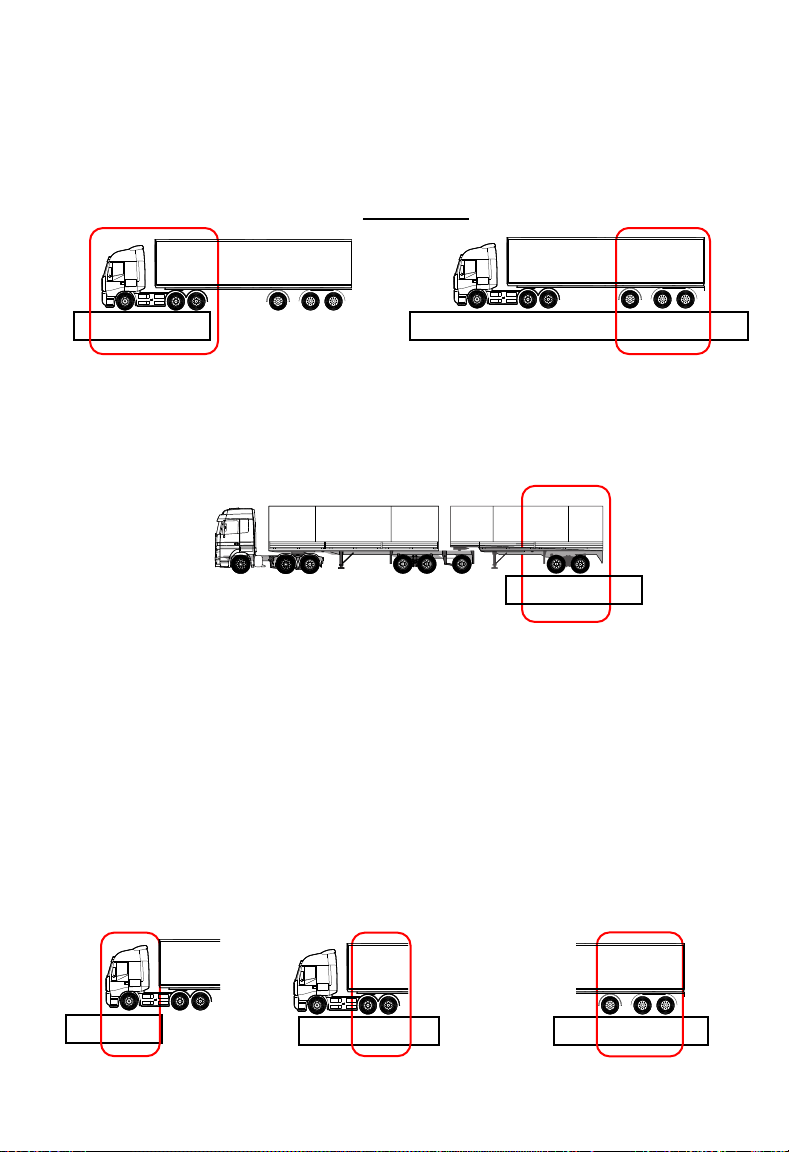

Acquiring tractor-trailer weights

The first step is to weigh the tractor (Channel A) then weigh the entire rig

(Total). The difference between the total weight and the weight of channel A

is the weight of the semi-trailer (Channel B).

Acquiring additional trailer weight

Simply weigh the additional trailer alone (Channel C)

Acquiring steering axle weight (Instrumented or Virtual)

The first step is to determine the weight of the steering axle (Channel A or S)

and then weigh the tractor. The tractor weight minus the weight of the steer-

ing axle gives you the weight of the drive axle(s) (Channel B). The weight of

the trailer is acquired by weighing only the semi-trailer or by taking the total

weight of the rig and subtracting the total weight of the tractor.

If the steering axle is instrumented : CHANNEL A B C

If the steering axle is virtual : CHANNEL S A B

10

Weigh Bridge

CHANNEL «C»

Weigh Bridge Weigh Bridge

CHANNEL «B»

CHANNEL «A»

Weigh Weigh Bridge Weigh Bridge

CHANNEL «B or «A» CHANNEL «C» or «B»

CHANNEL «A» or «S»

Total

- Channel A

= Channel B

Wireless Sensor Acquisition

If you have a wireless sensor, this

function allows you to acquire and

pair it with the Reflex. It must be

associated before calibration.

Before calibrating the instrument, a

sensor must be associated for each

channel. To do this, you must ac-

quire the sensors and anchor them.

Each sensor has a unique address.

Automatic sensor acquiring

*** Operate the brake or backup

lights. *** (depending on the white

wire power source)

Press Menu to enter.

The Acquire message appears.

Press right arrow to confirm.

➔Wireless

Options ↓

❶

➔Acquire

❶

The monitor displays "Search".

Search

Here is an example of what the Re-

flex will have found. The curser

points to the first device found. Dis-

played is the type of device (Air-

mechanical-or flexmeter), the «ID»

and the channel associated with the

given device.

Explanation:

Sensor channel (a/b/c/d/e/f/g/h/x)

Sensor «ID»

Curser

Type of sensor(Air/Mec/Flx)

➔1: Air 01872F B

Order of reception

Note!

If the PS2 displays «None» this

means that it has not found any de-

vice. If this happens, try an auto-

matic acquiring again. If this fails, try

a manual acquiring. In case nothing

has changed, refer to the Acquiring

problems section.

➔1: Air 4BCE56 A

2: Mec 4A11F8 C

3: Flx DD1258 X

11

Important!

If a sensor is Fixed on a channel, it

does not appear in the search re-

sults when acquiring. To see if your

channel is fixed, refer to the section

Fixing a channel.

Acquiring procedures:

↳Validate and anchor the channel

↳Changing the channel

↳Exit

Selecting and Validating the

channel

If the sensor is on the correct chan-

nel, anchor. Press right arrow to con-

firm. The sensor line becomes high-

lighted and the cursor moves down.

Do this for each sensor to be an-

chored. To move to the next address

press the down arrow. To move up-

wards press the up arrow.

1: Air 4BCE56 A

➔2: Mec 4A11F8 C

3: Flx DD1258 X

➔1: Mec 4A11F8 C

➔Ancrer capteur

Changing channel

When the cursor points to the ad-

dress, press Data. The Channel

flashes indicating that it can be

changed. Up or Down arrow to

change the channel. To confirm,

press the Right arrow.

If you try to confirm a channel that is

already configured inside the Reflex

the INT message will be indicated.

If you try to configure a sensor with

a fixed address, the Reflex will not

change the channel.

Note!

12 channel possibilities (A B C D E

F G H I J K L).

Important!

There is only one channel available

on a truck configuration. It is not

possible to anchor the same chan-

nel twice in the monitor.

12

1: Air 4BCE56 A

➔2: Mec 4A11F8 C

3: Flx DD1258 X

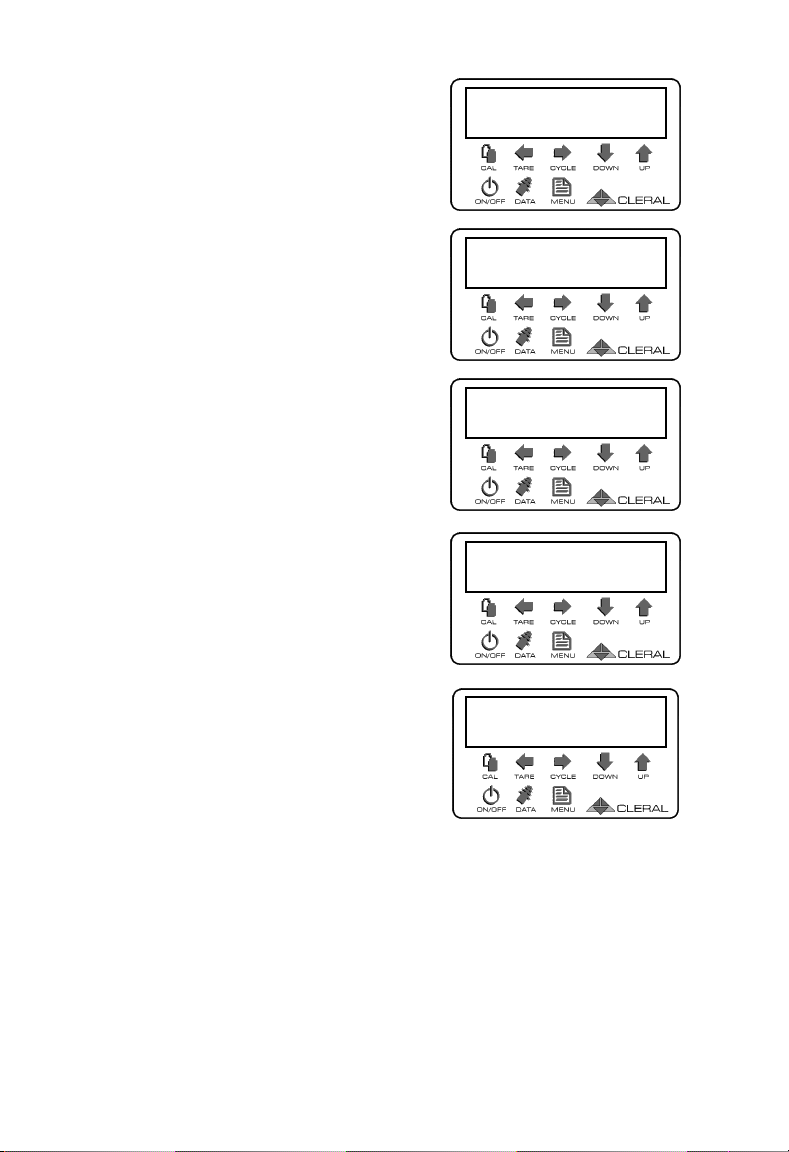

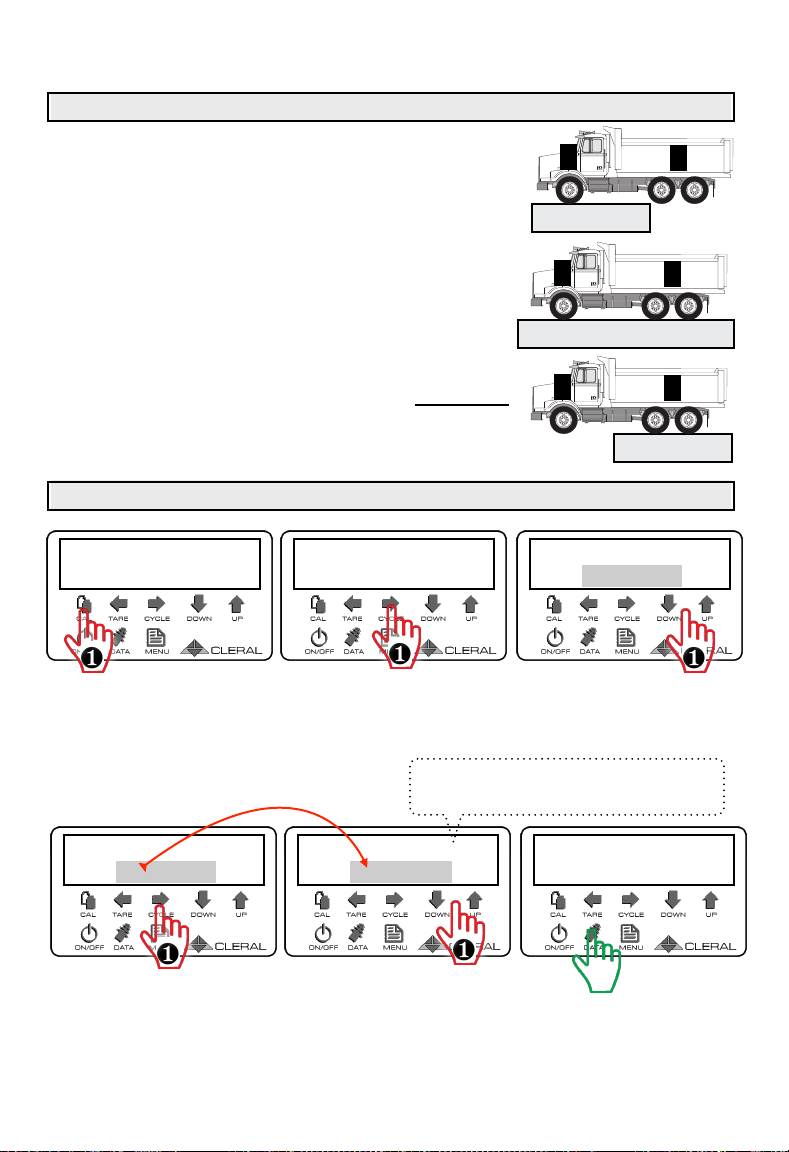

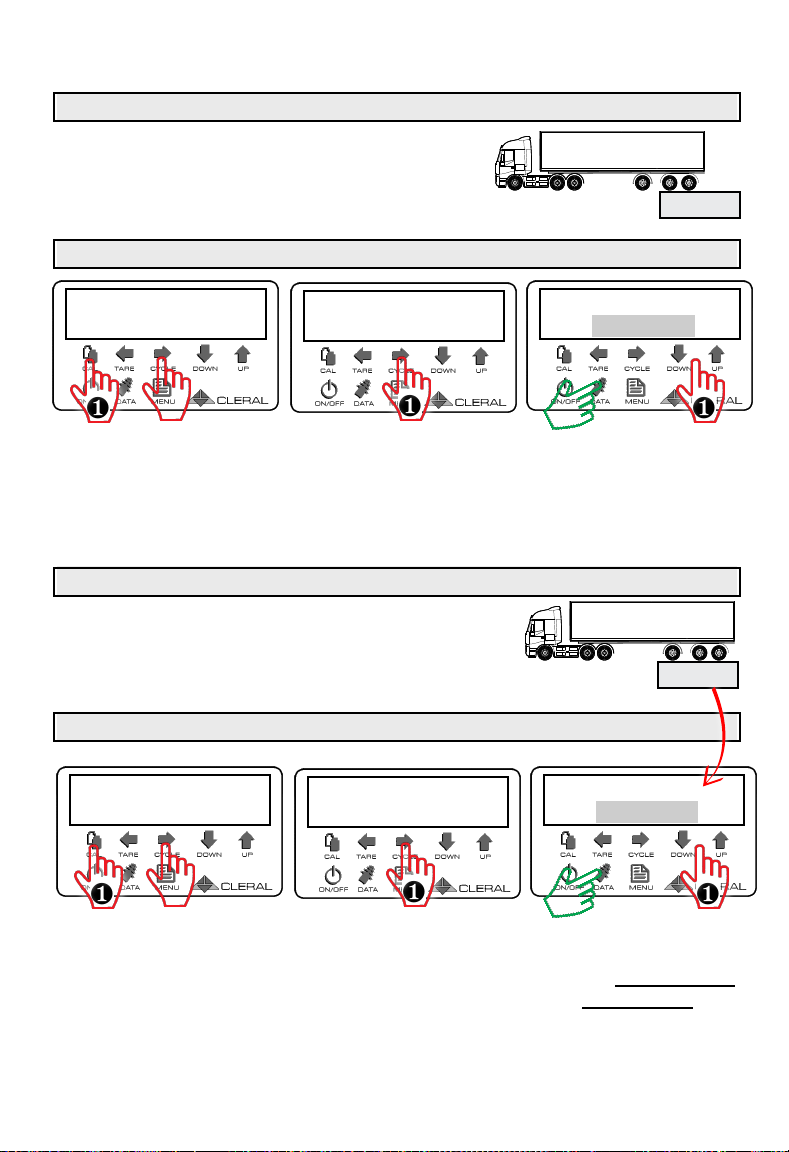

Calibration 4X2 6X4 8X4 - Empty vehicle

Acquiring empty vehicle weights

Move the empty truck onto the weigh bridge. The

wheels of the drive axles must not touch the plat-

form of the weigh bridge.

Note the empty Axle Weight "A".

Move the Total truck on the platform.

Note the total weight of the truck.

Subtract the Channel A weight from

the Total. You get the weight of chan-

nel B.

Go to the calibration menu

13

➔Empty

Full

❶

Empty T : 4000

A : 4000

❶

Empty T : 5400

A : 5400

❶

A: 5400 kg

AB

Empty T : 5400

A : 5400

❶

Empty T :13400

B : 8000

❶

B: 8000 kg

AB

T : 13400

AB

Press CAL to enter the

calibration mode

The cursor shows empty,

press Right Arrow to en-

ter the menu

«A:» flashes. Use the

arrows to record channel

A empty weight.

Press Right arrow to go

to «B:». Press Data to exit.

«B» flashes. Use the

arrows to record channel

B empty weight.

T : 13400 Gross

A : 5400 B: 8000

EXIT

Note!

If the weight of Channel A is correct; You can

adjust the weight of channel B with Total.

Total weight

- Channel A

= Channel B

Calibration 4X2 6X4 8X4 - Full weights

Acquiring Full vehicle weights

Move the Full truck onto the platform. The wheels

of the drive axles must not touch the platform of

the weigh bridge.

Note the full Axle Weight "A".

Move the entire vehicle onto the weigh bridge.

Note the total weight of the truck.

Subtract the Channel A weight from

the Total. You get the weight of chan-

nel B.

Recording Full weight values

14

Full T : 4000

A : 4000

❶

Full T : 14400

A : 9000

❶

B: 18000 kg

AB

Press CAL to enter in

calibration mode and

down arrow to go to Full

menu.

«A» flashes. Use the

arrows to record Chan-

nel A Full weight.

Press Data to exit.

«B» flashes. Use the

arrows to record channel

B full weight.

T : 27000 Gross

A : 5400 B:18000

EXIT

T: 27000

AB

A: 9000 kg

AB

Note!

If the weight of Channel A is correct; You can

adjust the weight of channel B with Total weight.

Press right arrow to go

to channel A.

Empty

➔Full

❶

➋

Full T :27000

B : 18000

❶

Full T : 14400

A : 9000

❶

Press Right arrow to go

to «B:».

Total weight

- Channel A

= Channel B

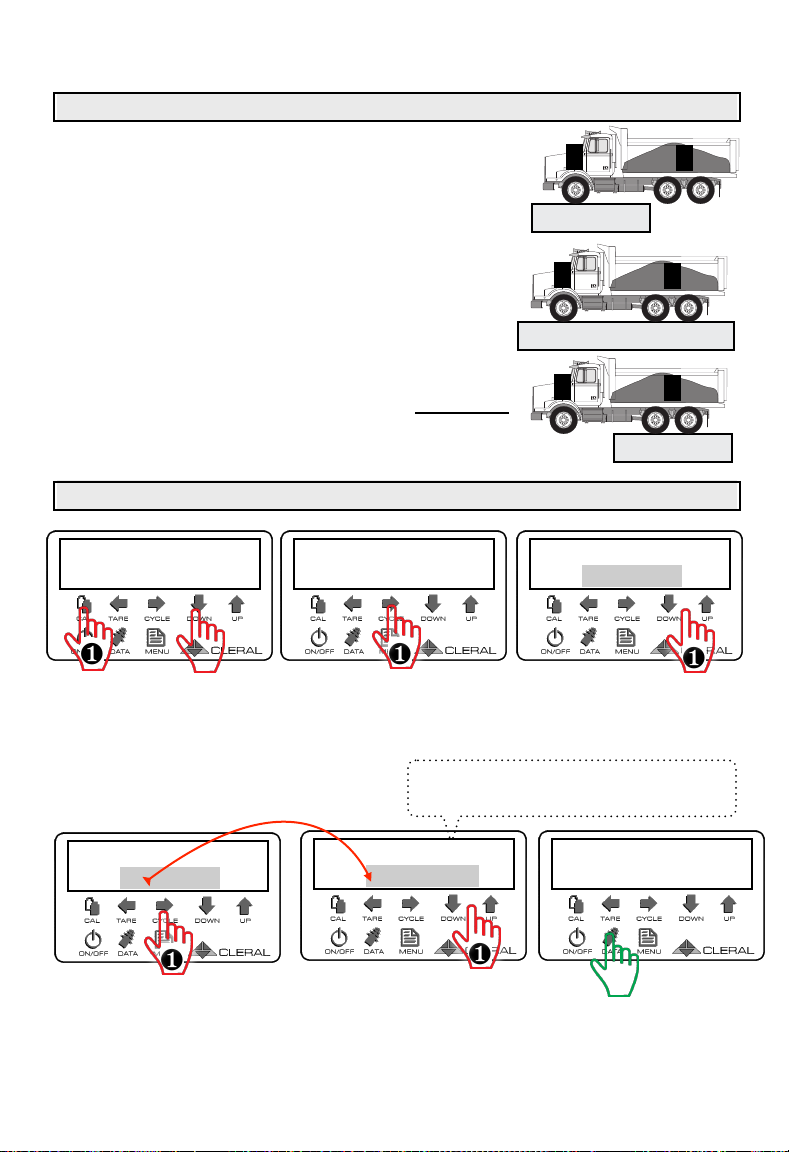

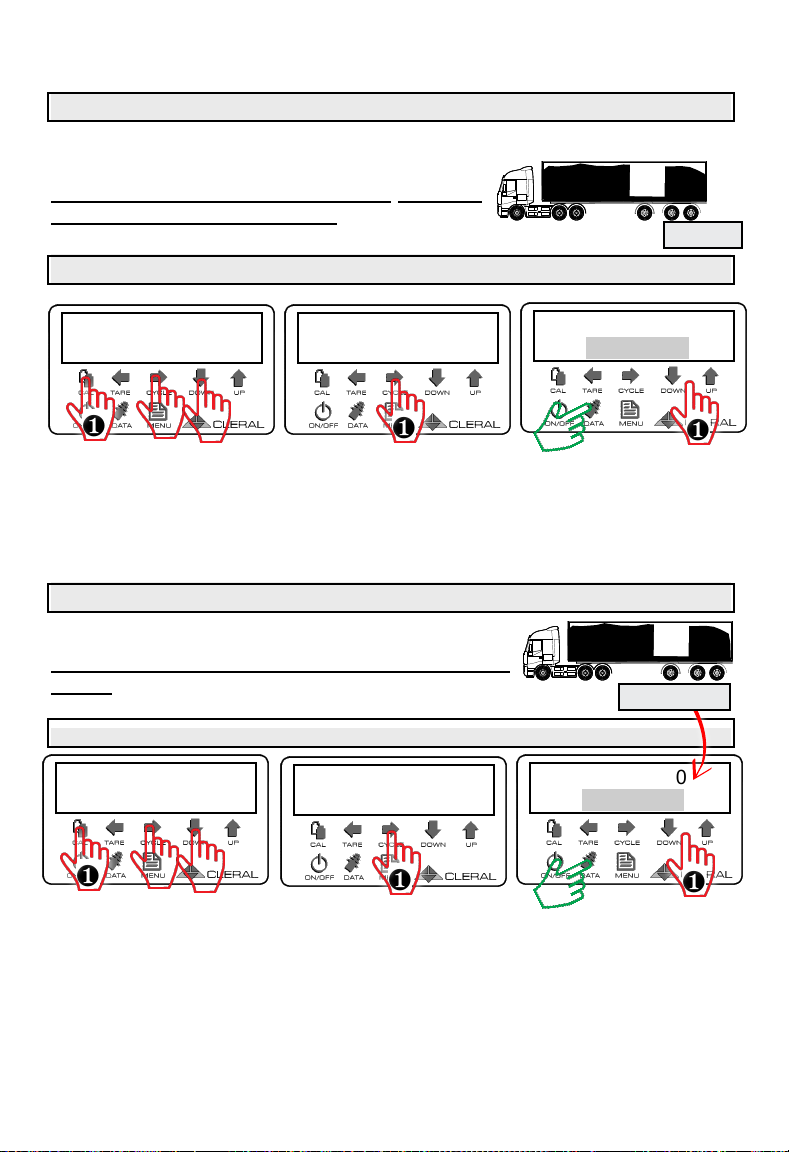

Calibration 8(2)X4 or 8X(2)4 - Empty Weights

Acquiring empty vehicle weights

Move the empty truck onto the platform. The

wheels of the drive axles must not touch the plat-

form of the weigh bridge. The lift axle must be in

the raised position.

Note the empty Axle Weight "A".

Move the entire vehicle over the weigh bridge.

Note the total weight of the truck.

The Total weight minus the weight

of Channel A. You get the weight of

Channel C.

Recording empty weight values

15

➔Empty

Full

❶

Empty T : 4000

A : 4000

❶

Empty T : 5900

A : 5900

❶

A: 5900 kg

Empty T : 5900

A : 5900

❶

Empty T :14400

C: 8500

❶

T: 14400

Press CAL to enter in

calibration mode.

The cursor shows empty,

press Right Arrow to en-

ter the menu.

«A:» flashes. Use the

arrows to record channel

A empty weight.

Press Right arrow to go

to «C:». Press Data to exit.

«C» flashes. Use the

arrows to record channel

B empty weight.

T : 14400 Gross

A : 5900 C: 8500

EXIT

Note!

If the weight of Channel A is correct; You can

adjust the weight of channel C with Total weight.

C: 8500 kg

AC

➲

B

AC

➲

B

AC

➲

B

Total weight

- Channel A

= Cahnnel C

Calibration 8(2)X4 or 8x(2)4 - Full Weights

Acquiring full vehicle weights

Advance the full truck on the weigh bridge. The

wheels of the drive axles must not touch the plat-

form of the weigh bridge.

Note the Full Axle Weight "A".

Move the entire vehicle over the weigh bridge.

Note the total weight of the truck.

The Total weight minus the weight

of Channel A. You get the weight of

Channel C.

Recording Full weight values

16

Full T : 4000

A : 4000

❶

Full T : 20900

A : 12400

❶

C: 22000 kg

Press CAL to enter in

calibration mode and

down arrow to go to Full

menu.

«A» flashes. Use the

arrows to record Chan-

nel A Full

Press sur Data to Exit.

«C» flashes. Use the

arrows to record channel

C full weight.

T : 34400 Gross

A : 12400 C: 22000

EXIT

Note!

f the weight of Channel A is correct; You can

adjust the weight of channel C with Total

Press right arrow to go

to channel A.

Empty

➔Full

❶

➋

Full T :34400

C: 22000

❶

Full T : 20900

A : 12400

❶

Press Right arrow to go

to «C:».

A: 12400 kg

A

➲

BC

T: 34400

A

➲

BC

A

➲

BC

Total weight

- Channel A

= Channel C

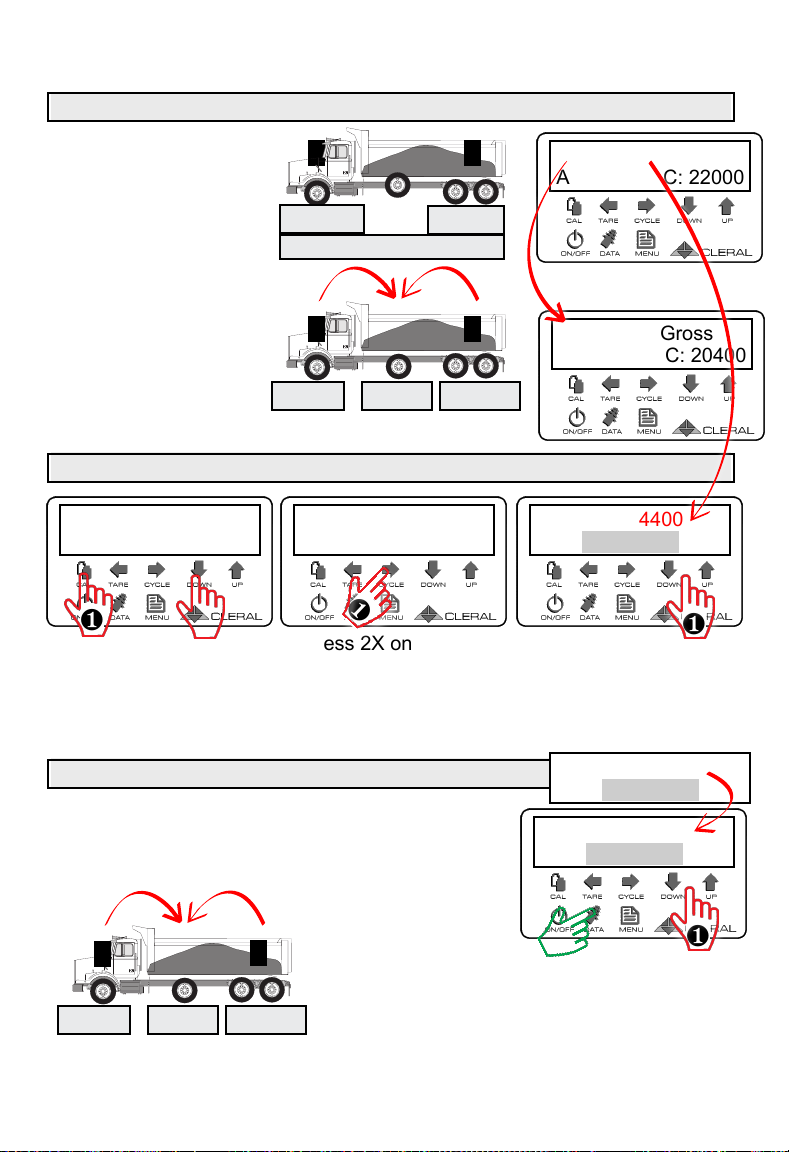

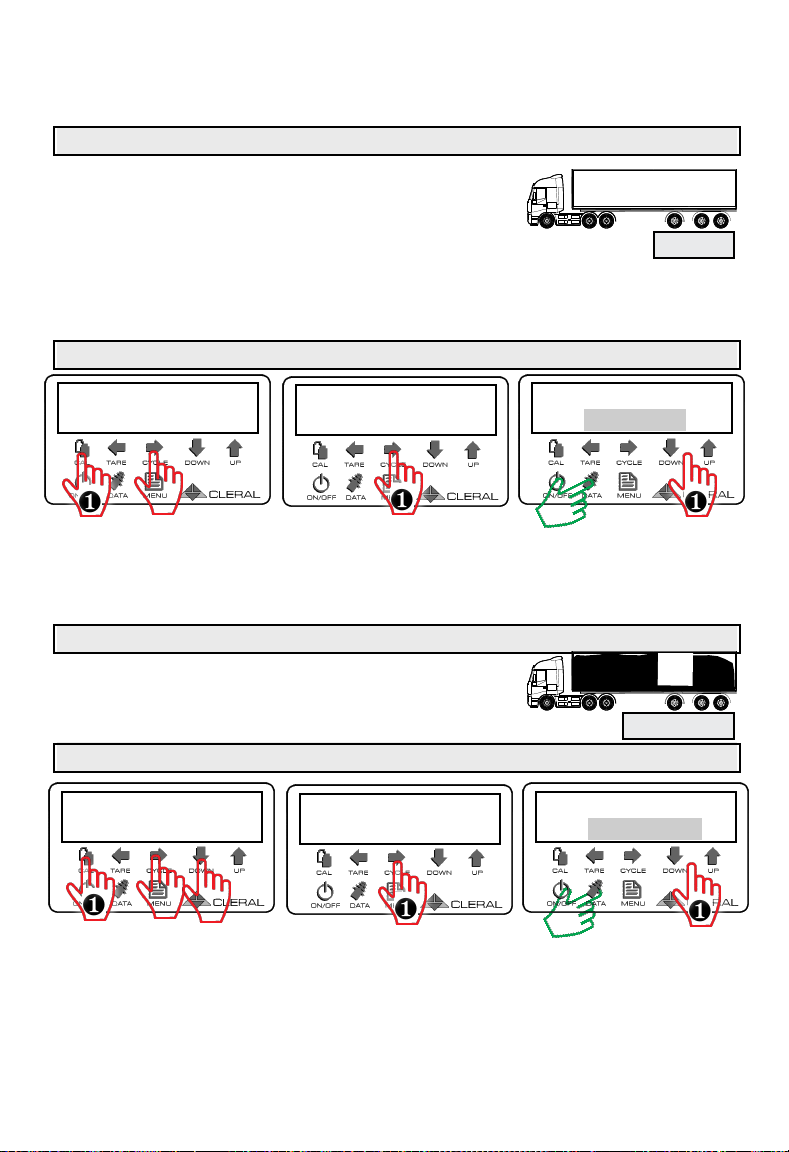

Calibration 8(2)X4 or 8x(2)4 - Lift Axle

Acquiring full vehicle weights

On the weigh bridge,

note the Total weight

on the Reflex.

Deploy the auxiliary

axle and adjust its

pressure gauge to 30

psi. The weight trans-

f e r r e d t o a x l e B

changes the total

weight.

Step 1- Calibration at 30 PSI to determine empty weight

Step 2- Calibration at 90 PSI to determine full weight

Adjust the pressure to 90 psi. Weight transferred

to axle B modifies the total weight. Adjust the

weight of Channel B in reference to the Total Full

weight.

17

Empty T : 34400

B : 3100

❶

Press CAL to go to

calibration and right

arrow to go to empty

calibration.

«B» Flashes, Adjust the

weight of this Channel by

bringing the total weight

back to the one noted

Press 2X on the right

arrow to go to channel B.

➔Empty

Full

❶

➋

T : 31300 Gross

A : 10900 C: 20400

T : 34400 Gross

A : 12400 C: 22000

C: 20400A:10900

AC

➲

B

B: 3100

A

➲

BC

A:12400 C:22000

T: 34400

Empty T : 4000

B : 4000

❶

C: 18000A:9000

AC

➲

B

B: 7400

Full T : 34400

B : 7400

❶

1-Go to Calibration Full on Channel B.

2- When it flashes, adjust the weight

of this Channel in reference to the

Tot a l fu l l we i gh t .

Full T : 30100

B : 3100

EXIT

Calibration - Empty Semi- trailer (Auxiliary instrumented)

Acquiring primary axle weight

Advance the empty semitrailer on the weigh

bridge. The wheels of the auxiliary axle must not

touch the platform of the weigh bridge.

Calibration of primary axle weight

Acquiring auxiliary axle weight

Move the empty semitrailer on the weigh bridge.

The wheels of the auxiliary axle must be on the

weigh bridge.

Calibration of auxiliary axle

18

Empty T : 4000

C : 4000

❶

Empty T : 6000

C : 6000

❶

Press CAL to go to

calibration and right

arrow to go to Empty

calibration.

Press 2X on Right Arrow

to go to Channel C

"C" flashes, Adjust the

weight of this channel.

DATA to exit

➔Empty

Full

❶

➋

Empty T : 6000

B : 1500

❶

Empty T : 8000

B : 2000

❶

Press CAL to go to

calibration and right

arrow to go to Empty

calibration.

Press Right Arrow to go

to Channel B

Channel B flashes,

Adjust the weight of this

channel relative to the

Tot a l we i gh t .

➔Empty

Full

❶

➋

6000 kg

AC

➲

B

AC

➲

B

8000 kg

EXIT

EXIT

Calibration - FULL Semi-trailer (Auxiliary instrumented)

Acquiring primary axle weight

Move the Full trailer to on the weigh bridge.

The wheels of the auxiliary axle must not touch

the platform of the weigh bridge.

Calibration of primary axles

Acquiring the weight of the auxiliary axle

Move the FULL trailer on the weigh bridge. The

wheels of the auxiliary axle must be on the weigh

bridge.

Calibration of auxiliary axle

19

Full T : 21000

B : 3000

❶

Full T : 23000

B : 5000

❶

Press Right Arrow to go

to Channel B.

"B" flashes, Adjust the

weight of this Channel

relative to the Total

weight.

1- Press CAL to go to

calibration.

2- Down Arrow to go to

Full.

3- Right Arrow to enter

Full Calibration.

Empty

➔Full

❶

➋

❸

Full T : 17000

C : 14000

❶

Full T : 21000

C : 18000

❶

Press 2X on Right Arrow

to go to Channel C.

"C" flashes, Adjust the

weight of this channel.

DATA to exit.

1- Press CAL to go to

calibration.

2- Down Arrow to go to

Full.

3- Right Arrow to enter

Full Calibration.

Empty

➔Full

❶

➋

❸

➲

B

A

C

23000 kg

➲

B

A

C

18000 kg

EXIT

EXIT

Calibration - Semi-Trailer (Non-instrumented Auxil-

iary Axle INCLUDED)

Acquiring Empty weight

Method Included Auxiliary: The weight of the auxil-

iary axle is INCLUDED in the weight of the semi-

trailer; The calibration is carried out with the auxil-

iary axle DEPLOYED.

Move the empty semitrailer on the weigh bridge. The tractor wheels must not

touch the weigh bridge platform.

Calibration of the empty semi-trailer

Acquiring Full weight

Advance the empty semitrailer on the weigh

bridge. The wheels of the auxiliary axle must be on

the weigh bridge.

Calibration of the loaded semi-trailer

20

Empty T : 4000

B : 4000

❶

Empty T : 8000

B : 8000

❶

Press CAL to go to

calibration and right

arrow to enter Empty

Calibration.

Press Right Arrow to go

to Channel B

Channel B flashes,

Adjust the weight of this

Channel.DATA to Exit.

➔Empty

Full

❶

➋

EXIT

EXIT

➲

X

A

B

23000 kg

Full T : 8000

B : 8000

❶

Full T : 23000

B : 23000

❶

Press Right Arrow to go

to Channel B

"B" flashes, Adjust the

weight of this Channel

relative to the Total

weight.

1- Press CAL to go to

calibration.

2- Arrow down to go to

Full.

3- Right Arrow to enter

Full Calibration.

Empty

➔Full

❶

➋

❸

AB

➲

X

8000 kg

Table of contents

Popular Accessories manuals by other brands

M&C

M&C EC Series instruction manual

Lutron Electronics

Lutron Electronics Maestro MS-B102 Series manual

Eriez

Eriez HS-5 Installation, operation and maintenance instructions

SKF

SKF CMSS 60 User's & technical manual

Carrier

Carrier WIRELESS STANDARD SENSOR installation guide

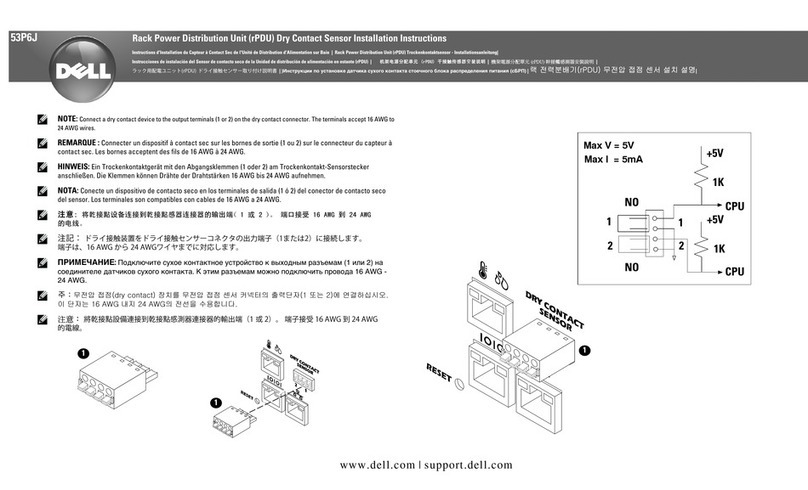

Dell

Dell 53P6J installation instructions