Safety Instruction

WWW.CLF-LIGHTING.COM 2

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product.

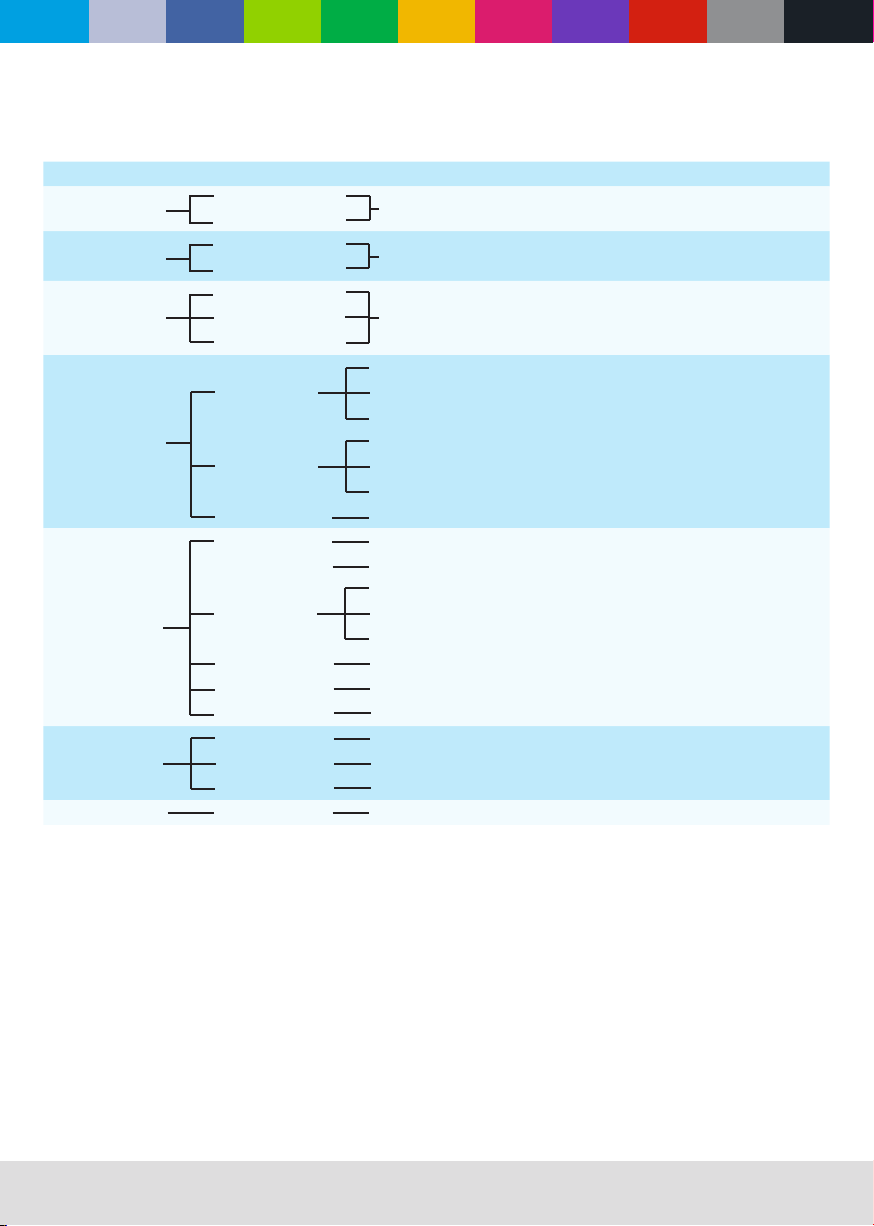

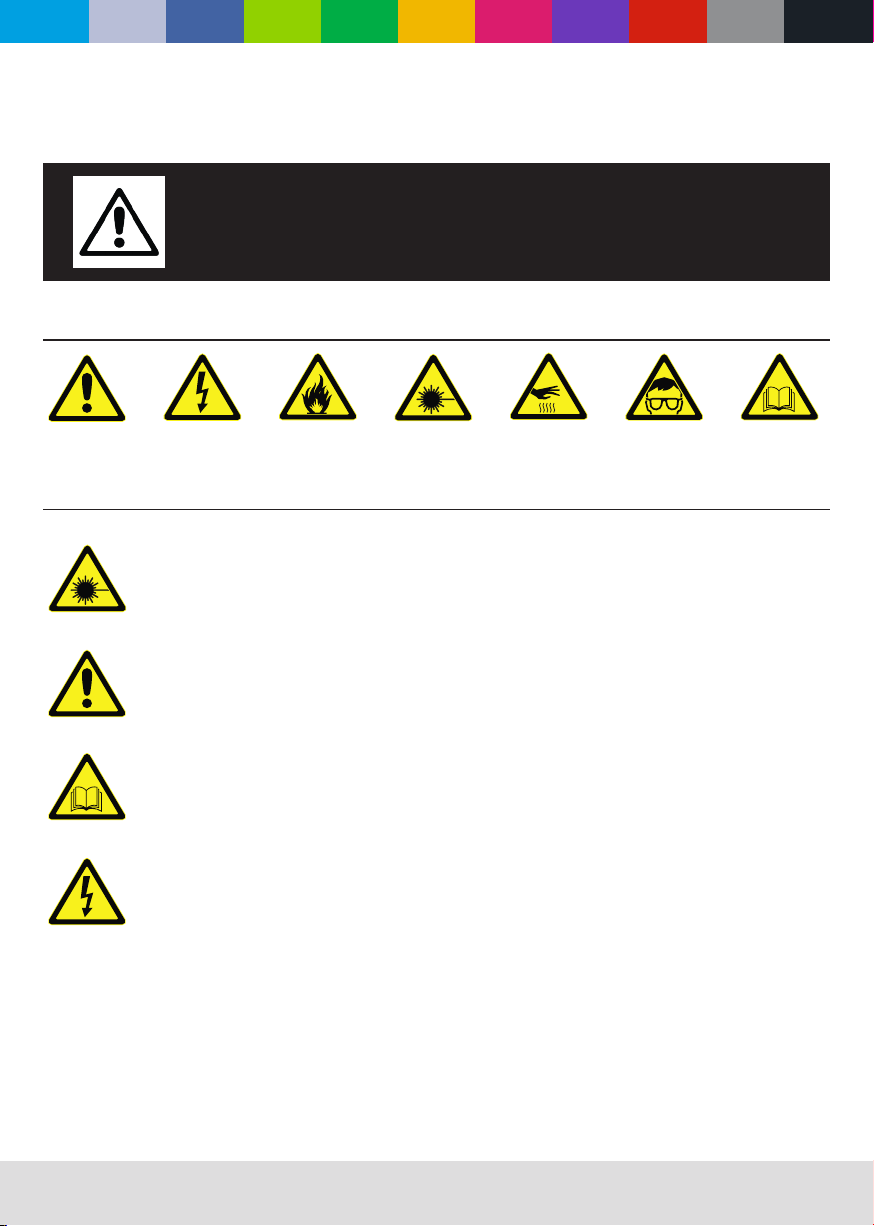

The following symbols are used to identify important safety information on the product and in this manual:

DANGER!

Safety hazard.

Risk of severe

injury or death.

DANGER!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

WARNING!

Fire hazard.

WARNING!

LED light

emission. Risk of

eye injury.

WARNING!

Burn hazard. Hot

surface. Do not

touch.

WARNING!

Wear protective

eyewear.

WARNING!

Refer to user

manual.

Warning! Risk Group 3 (high risk) LED product according to EN 62471. Do not look into the beam at a

distance of less than 8.3 meters from the front surface of the product. Do not view the light output with optical

instruments or any device that may concentrate the beam.

This product is for professional use only. It is not for household use.

This product presents risks of severe injury or death due to re and burn hazards, electric shock and falls.

Read this manual before installing, powering or servicing the xture, follow the safety precautions listed below and

observe all warnings in this manual and printed on the xture. If you have questions about how to operate the xture

safely, please contact your supplier.

PROTECTION FROM ELECTRIC SHOCK

•Disconnect the xture from AC power before removing or installing any cover or part and when not in use.

•Always ground (earth) the xture electrically.

•Use only a source of AC power that complies with local building and electrical codes and has both overload and

ground-fault (earth-fault) protection.

•Before using the xture, check that all power distribution equipment and cables are in perfect condition and rated for

the current requirements of all connected devices.

•Power input and throughput cables must be rated 20 A minimum, have three conductors 1.5 mm² (16 AWG)

minimum conductor size and an outer cable diameter of 5 - 15 mm. Cables must be hard usage type (SJT or

equivalent) and heat-resistant to 90° C minimum.

•Use only PowerCON TRUE 1 ® cable connectors to connect to power input sockets. Use only PowerCON TRUE 1®

cable connectors to connect to power through put sockets.

•Isolate the xture from power immediately if the power plug or any seal, cover, cable, or other component is

damaged, defective, deformed, wet or showing signs of overheating. Do not reapply power until repairs have been

completed.

•Refer any service operation not described in this manual to a qualied technician.

•Socket outlets used to supply xture xtures with power or external power switches must be located near the xtures

and easily accessible so that the xtures can easily be disconnected from power.