CLF BEAM 6 User manual

manual

V1.0 NOVEMBER 2017WWW.CLF-LIGHTING.COM

beam 6

WWW.CLF-LIGHTING.COM

2

Safety instructions 3

Fixture overview 4

Dimensions 4

Photometric data 5

Physical installation 5

Mounting 6

Power and signal connection 7

Power connection 8

Control mode 9

Circuit connecting diagrtam 9

Onboard control menu 10

DMX protocol 14

Cleaning and maintenance 16

Specications 16

table of CONTENTS

WWW.CLF-LIGHTING.COM

3

Safety instructions

WWW.CLF-LIGHTING.COM

Safety instructions

The following symbols are used to identify important safety information on the product and in this manual:

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product

DANGER!

Safety hazard.

Risk of severe

injury or death.

DANGER!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

WARNING!

Fire hazard.

WARNING!

LED light

emission. Risk of

eye injury.

WARNING!

Burn hazard. Hot

surface. Do not

touch.

WARNING!

Wear protective

eyewear.

WARNING!

Refer to user

manual.

3.0

NOTICE:

To guarantee proper and consistent operation, it is important to follow the

guidelines in this manual. Our company will not accept responsibility for

information printed in this manual.

In order to ensure the light could operate normally, the ambient temperature

couldn’t be higher than 38°C and no lower than -2°C. Under normal

conditions, the highest sectional surface temperature may be up to 60°C.

grounding cable should be connected with the grounding cable of the power

supply system as well. The ground mark of the light metal cover should be

connecting with the installation bricked steadily.

Don’t use the power cable when the insulation is damaged. The

manufacturer, distributor or a professional mechanic should change the

damaged power cable in order to avoid dangerous situations.

The following symbols are used to identify important safety information on the product and in this manual:

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product

DANGER!

Safety hazard.

Risk of severe

injury or death.

DANGER!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

WARNING!

Fire hazard.

WARNING!

LED light

emission. Risk of

eye injury.

WARNING!

Burn hazard. Hot

surface. Do not

touch.

WARNING!

Wear protective

eyewear.

WARNING!

Refer to user

manual.

The following symbols are used to identify important safety information on the product and in this manual:

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product

DANGER!

Safety hazard.

Risk of severe

injury or death.

DANGER!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

WARNING!

Fire hazard.

WARNING!

LED light

emission. Risk of

eye injury.

WARNING!

Burn hazard. Hot

surface. Do not

touch.

WARNING!

Wear protective

eyewear.

WARNING!

Refer to user

manual.

llowing symbols are used to identify important safety information on the product and in this manual:

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product

ER!

y hazard.

f severe

y or death.

DANGER!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

WARNING!

Fire hazard.

WARNING!

LED light

emission. Risk of

eye injury.

WARNING!

Burn hazard. Hot

surface. Do not

touch.

WARNING!

Wear protective

eyewear.

WARNING!

Refer to user

manual.

ollowing symbols are used to identify important safety information on the product and in this manual:

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product

ER!

y hazard.

f severe

y or death.

DANGER!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

WARNING!

Fire hazard.

WARNING!

LED light

emission. Risk of

eye injury.

WARNING!

Burn hazard. Hot

surface. Do not

touch.

WARNING!

Wear protective

eyewear.

WARNING!

Refer to user

manual.

To guarantee proper and consistent operation, it is important to follow the

guidelines in this manual. The manufacturer will not accept responsibility for

damages resulting from the misuse of this xture due to the disregard of the information printed in this manual.

In order to ensure the xture could operate normally, the ambient temperature must not exceed 38°C and 0°C. Under

normal conditions, the highest sectional surface temperature will be up to 60°C.

The xture is designed with electric shock protection. The xture should be connected to a power supply system with

earth grounding. The xture’s ground cable should be connected with the ground cable of the power supply system as

well.

When the isolation is damaged please ask the manufacturer, distributor or a professional mechanic for a new power

cable as replacement in order to avoid dangerous situations.

Never open the xture while power is connected.

Never look directly into the light source. You risk injury to your eyes, which may cause blindness.

Please be aware that damages caused by modications to the device are not subject to warranty.

WWW.CLF-LIGHTING.COM

4

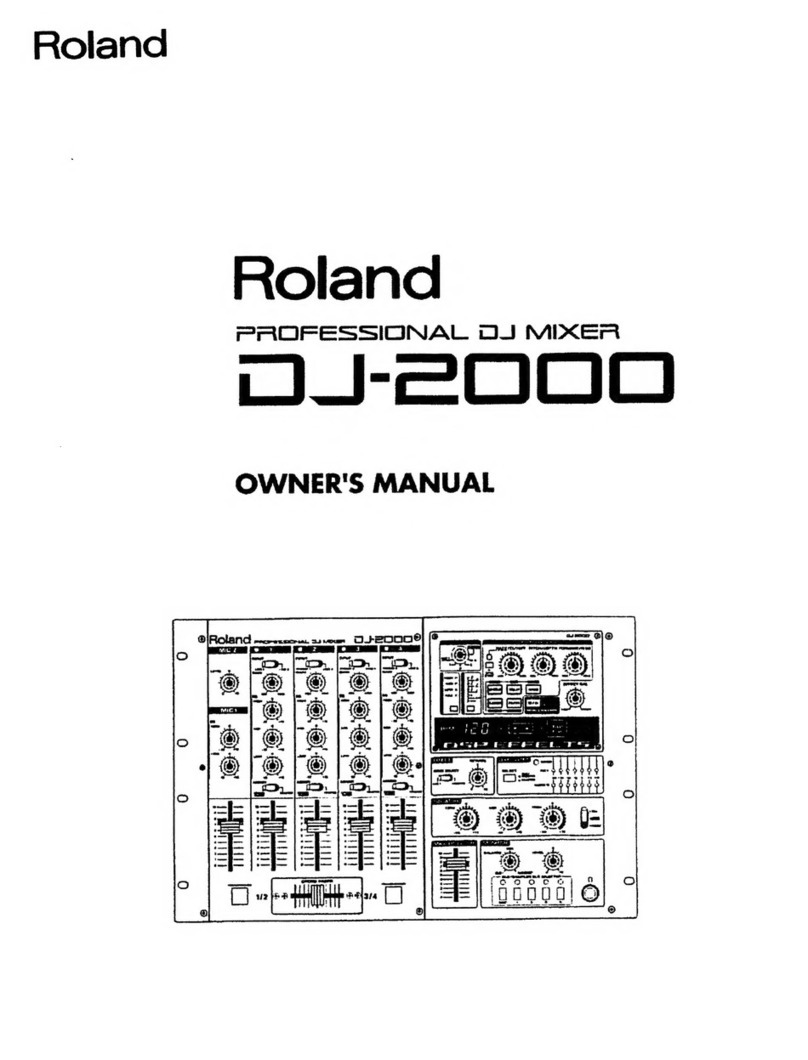

xture overview

WWW.CLF-LIGHTING.COM 6.0

operation panel

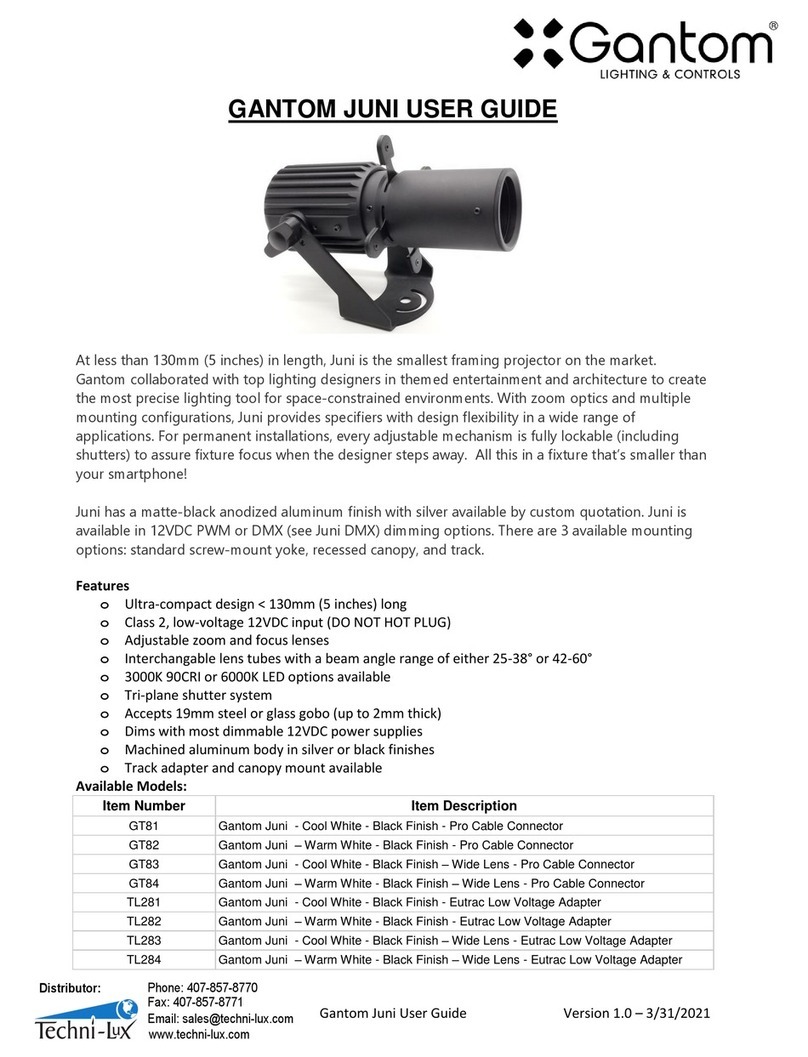

dimensional drawings

155

268

226

dimensions

WWW.CLF-LIGHTING.COM 6.0

operation panel

dimensional drawings

155

268

226

WWW.CLF-LIGHTING.COM

5

photometric data

WWW.CLF-LIGHTING.COM

photometric data

7.0

mounting and installation

CAUTION:

of 10 times the device’s weight. Fixture installation must always be secured with a

secondary safety attachment, such as an appropriate safety cable. To avoid injury, never

MOUNTING POINTS:

Overhead mounting requires experience, including calculating working load limits,

knowledge of the installation material being used and periodic safety inspection of all

the installation yourself. Wrong installation can result in injuries. Be sure to complete all

rigging and installation procedures before connecting the main power cord to the

appropriate wall outlet.

physical installation

CAUTION:

Before mounting the xture to any surface, make sure that the installation area can hold a minimum point load of 10 times the device’s

weight. Fixture installation must always be secured with a secondary safety attachment, such as an appropriate safety cable.

To avoid injury, never stand directly below the device when mounting, removing, or servicing the xture.

MOUNTING POINTS:

Overhead mounting requires experience, including calculating working load limits, knowledge of the installation material being used and

periodic safety inspection of all installation materials and the xture. If you don’t have these qualications, do not attempt the installation

yourself. Wrong installation can result in injuries. Be sure to complete all rigging and installation procedures before connecting the main

power cord to the appropriate wall outlet.

WWW.CLF-LIGHTING.COM

6

MOUNTING:

The xture is operational in any mounting position. Be sure the xture is kept at least 50cm away from any ammable materials (decoration

etc.).

When mounted with a clamp, always use and install the supplied safety cable as a safety measure to prevent accidents.

Quicklock

WWW.CLF-LIGHTING.COM

7

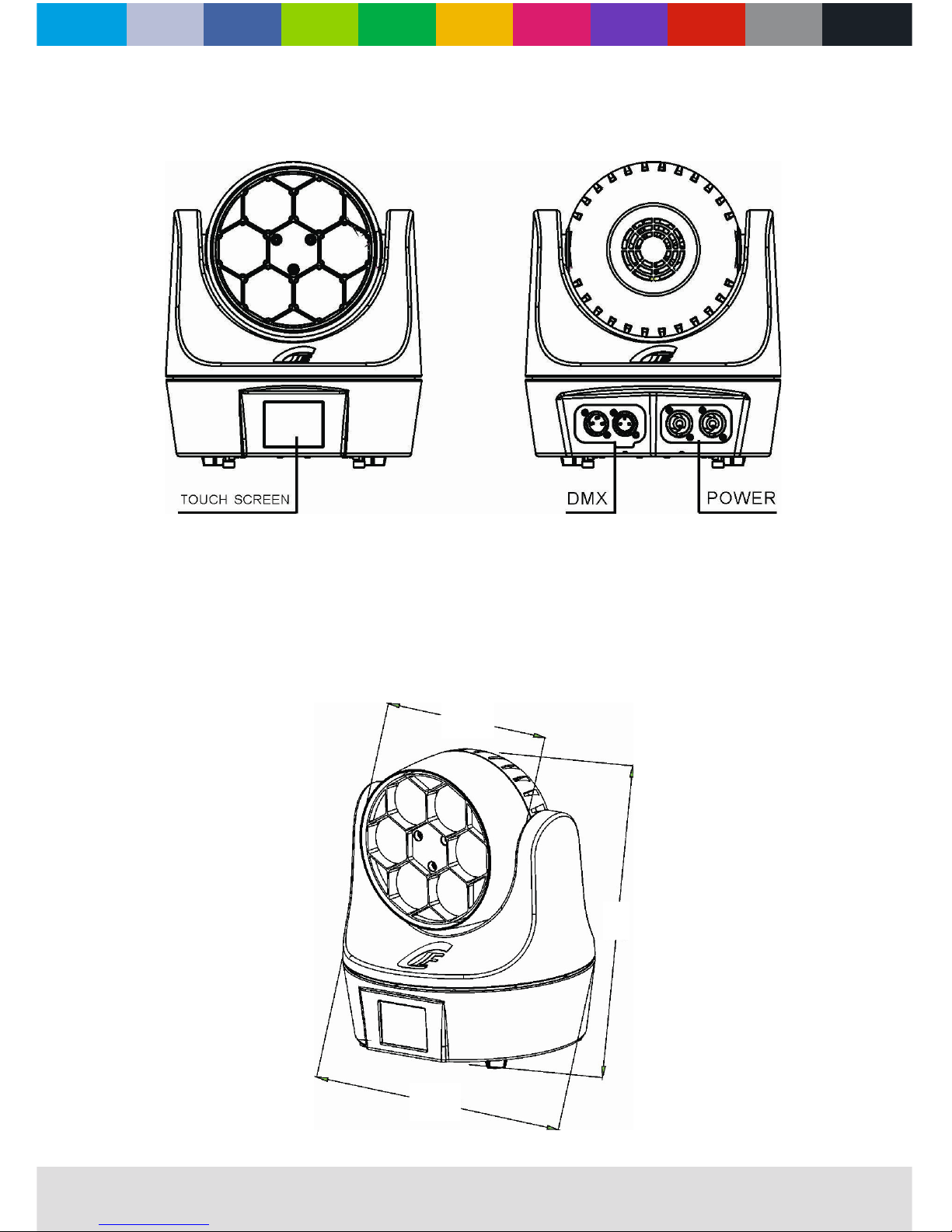

power and signal connection

POWER SUPPLY:

Use powerCON plug to connect the xture to the main power supply.

Please check if the voltage and the frequency are the same as mentioned on the xture.

SIGNAL CONNECTION:

Please use the 5 pin XLR connectors to connect the rst xture’s DMX output to the next xture’s input, and so on.

As connect in the following gure.

WWW.CLF-LIGHTING.COM 9.0

power and signal connection

POWER SUPPLY:

Use the professional plug to connect the projector to the main power supply. Please check

if the voltage and the frequency are the same as mentioned on the projector. When each

SIGNAL CONNECTION:

s output to the

s input. And

in the same way for the rest, eventually connect the last device’s output, all the devices are

The device control signal output and input uses the 5-pin XLR plug and socket.

The communicate cable is a 2-pin shielded cable of 110Ω.

The resistance of each core is at least a diameter of 0.5mm.

(Notice: The inside leading wire of the 3/5-pin XLR plug can’t

touch each other or the plinth). We recommend to use the DMX

signal terminator during the installation to avoid electronic noise

damage of the digital control signal. Simply speaking, the DMX

terminator is a XLR connector with a 120Ω & 1/2W resistor

connected across pin 2 and 3 (see picture on the right). Which

Refer to the connection as in above picture. We advise to use

a DMX signal distributor when the distance of the lights is more

then 15 meter, to prevent signal loss.

The resistance of each core is at least a diameter of 0.5mm. (Notice: The inside leading wire

of the 5-pin XLR plug can’t touch each other or the earth). We recommend to use the DMX

signal terminator during the installation to avoid electronic reection of the digital control

signal. The DMX terminator is a XLR connector with a 120Ω & 1/2W resistor connected across

pin 2 and 3 (see picture on the right). Which is plugged into the output socket on the last

xture in the chain. Refer to the connection as in above picture. We advise to use a DMX

signal distributor when the distance of the lights is more then 15 meter, to prevent signal loss.

WWW.CLF-LIGHTING.COM 9.0

power and signal connection

POWER SUPPLY:

Use the professional plug to connect the projector to the main power supply. Please check

if the voltage and the frequency are the same as mentioned on the projector. When each

SIGNAL CONNECTION:

s output to the

s input. And

in the same way for the rest, eventually connect the last device’s output, all the devices are

The device control signal output and input uses the 5-pin XLR plug and socket.

The communicate cable is a 2-pin shielded cable of 110Ω.

The resistance of each core is at least a diameter of 0.5mm.

(Notice: The inside leading wire of the 3/5-pin XLR plug can’t

touch each other or the plinth). We recommend to use the DMX

signal terminator during the installation to avoid electronic noise

damage of the digital control signal. Simply speaking, the DMX

terminator is a XLR connector with a 120Ω & 1/2W resistor

connected across pin 2 and 3 (see picture on the right). Which

Refer to the connection as in above picture. We advise to use

a DMX signal distributor when the distance of the lights is more

then 15 meter, to prevent signal loss.

WWW.CLF-LIGHTING.COM

8

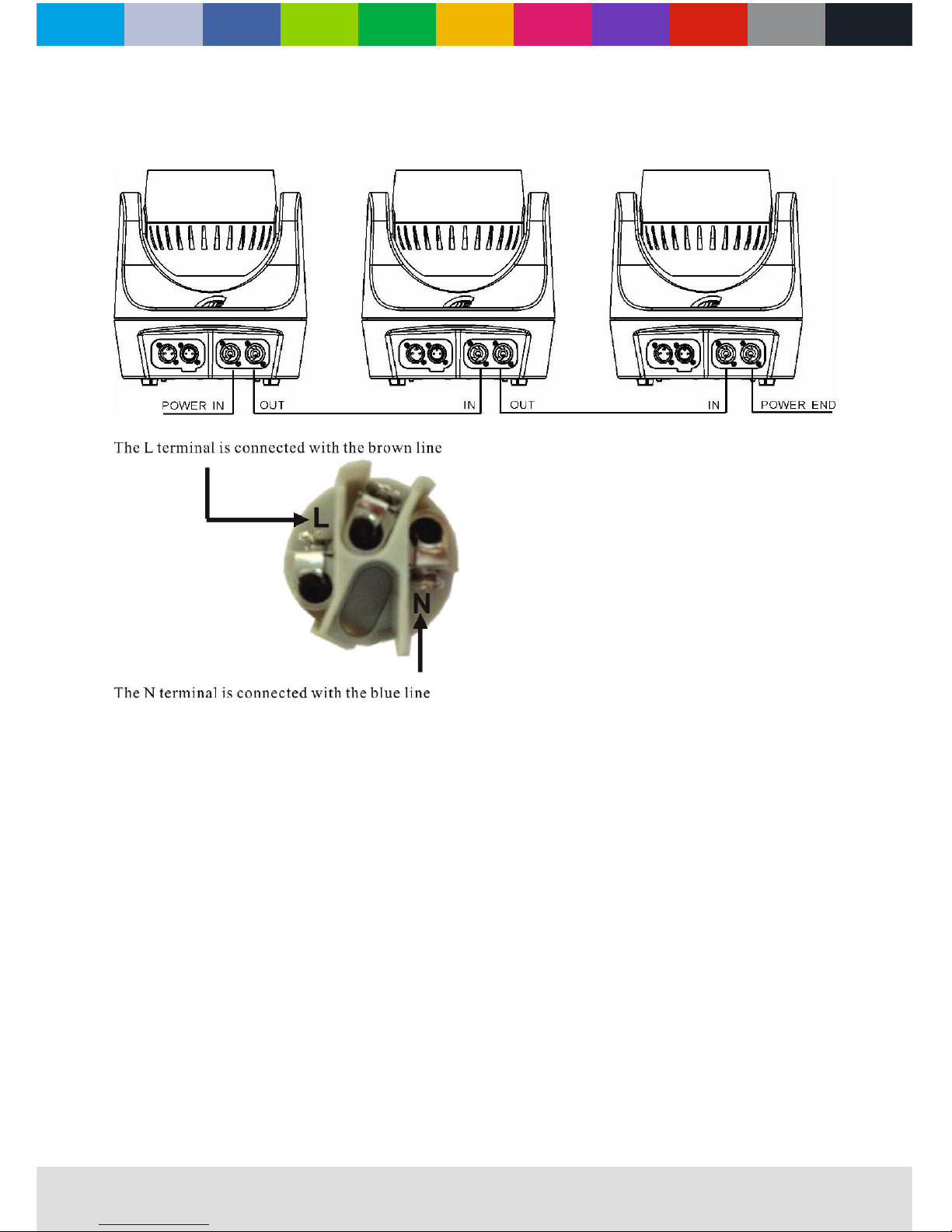

power connection

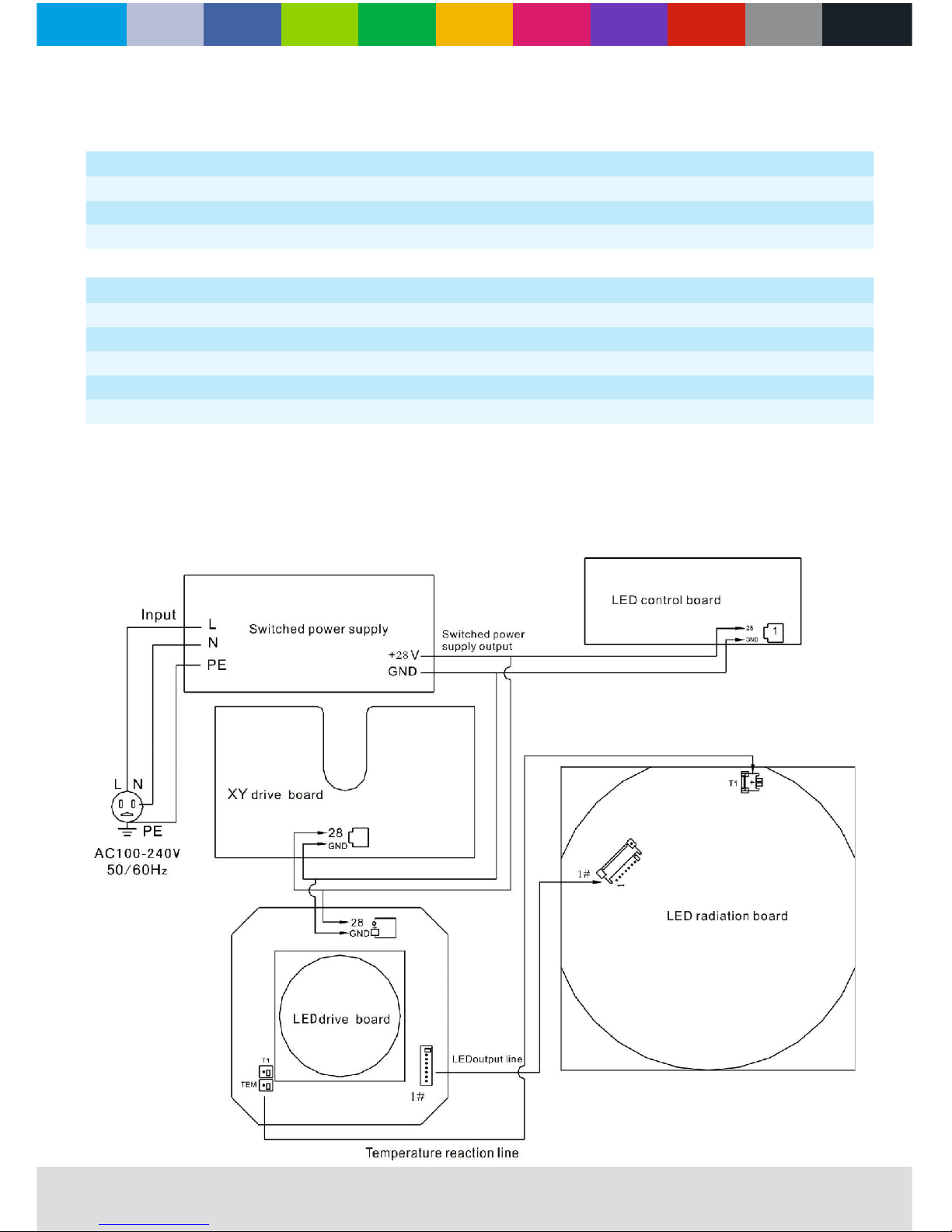

WWW.CLF-LIGHTING.COM 10.0

light power connection

working normally.

Do not daisychain more then 6 xtures.

WWW.CLF-LIGHTING.COM

9

WWW.CLF-LIGHTING.COM

circuit connection diagram

17.0

STANDARD 11CH

1. Dimmer 4. Green 7. Pan 10. Rota speed

2. Shutter 5. Blue 8. Tilt 11. Fixture control

3. Red 6. White 9. Rota lens

channels

STANDARD 17CH

1. Dimmer 6. Blue 11. Tilt 16. Calibration

7. White 17. Slave ID

3. Shutter 8. Macro color 13. Rota lens

4. Red 9. Pan 14. Rota speed

5. Green 15. Fixture control

circuit connection diagram

STANDARD 11CH

1. Dimmer 4. Green 7. Pan 10. Rota speed

2. Shutter 5. Blue 8. Tilt 11. Fixture control

3. Red 6. White 9. Rota lens

control mode

STANDARD 17CH

1. Dimmer 6. Blue 11. Tilt 16. Calibration

2. Dimmer ne 7. White 12. Tilt ne 17. Slave ID

3. Shutter 8. Macro color 13. Rota lens

4. Red 9. Pan 14. Rota speed

5. Green 10. Pan ne 15. Fixture control

WWW.CLF-LIGHTING.COM

10

onboard control menu

MENU REMARK

Setting

DMX address 001 - 512

Fixture ID 000 - 064

Channel mode

Standard 11CH Default

Extended 17CH

DMX Function

Hold

Black

D. scene

Program 1

Program 2

Program 3

Program 4

Program 5

Program 6

Program 7

Program 8

Slave - Master

Slave mode

Master mode

Info

Fixture times

Power on time ****H

Lamp on time ****H

Fixture temperature Lamp_tem ****°C

RDM UID ********

DMX live

1. Dimmer

0 - 255

2. Dimmer ne

3. Shutter

4. Red

5. Green

6. Blue

7. White

8. Macro color

9. Pan

10. Pan ne

11. Tilt

12. Tilt ne

13. Rota lens

14. Rota sp

15. Fixturecontrol

16. Calibration

17. Slave ID

Version info

LED_XY_SOFT:V2.00

LED_DPY_SOFT:V4.00

WWW.CLF-LIGHTING.COM

11

onboard control menu

MENU REMARK

Personality

Pan / Tilt

P/T swap

OFF Default

ON

Pan invert

OFF Default

ON

Tilt invert

OFF Default

ON

DMX reset

ON Default

OFF

Reset System reset

Quick closedown

ON Default

OFF

P/T angle limit

Close

Open

Program on/o

Close

Open

Set P/T angle

Pan start

Pan end

Tilt start

Tilt end

Display

Display sleep Light always

2 minutes

4 minutes

6 minutes

Display intensity 10 - 100

Display rotation Rotate 180

Normal

TFT calibration

WWW.CLF-LIGHTING.COM

12

onboard control menu

MENU MENU I REMARK

Manual control

1. Dimmer

0 - 255

2. Dimmer ne

3. Shutter

4. Red

5. Green

6. Blue

7. White

8. Macro color

9. Pan

10. Pan ne

11. Tile

12. Tilt ne

13. Rota lens

14. Rota sp

15. Fixturecontrol

16. Calibration

17. Slave ID

MENU MENU IV

Program Edit program Edit program 1

Scene 0 - 100

1. Dimmer

0 - 255

2. Dimmer ne

3. Shutter

4. Red

5. Green

6. Blue

7. White

8. Macro color

9. Pan

10. Pan ne

11. Tilt

12. Tilt ne

13. Rota lens

14. Rota sp

15. Fixturecontrol

16. Calibration

17. Slave ID

Save scene

WWW.CLF-LIGHTING.COM

13

onboard control menu

MENU MENU IV

Program

Edit program

Edit program 2

Same as ‘Edit program 1‘

Edit program 3

Edit program 4

Edit program 5

Edit program 6

Edit program 7

Edit program 8

Set program

Set program 1

Start step 0 - 100

End step 0 - 100

Step time 0 - 255

Save

Set program 2

Same as ‘Set program 1‘

Set program 3

Set program 4

Set program 5

Set program 6

Set program 7

Set program 8

Run Running program

Fixed scene Scene 001 - 100

Service

Error list

Adjust

Pan ±5.00%

Tilt ±5.00%

Rotatable lens ±5.00%

Factory

Default

Adjust default

Firmware update ****

WWW.CLF-LIGHTING.COM

14

dmx protocol

CHANNEL DMX VALUES % EFFECT

1. Dimmer 0 - 255 0 - 100

2. Dimmer ne 0 - 255 0 - 100

3. Shutter

0 - 9 0 - 3

10 - 49 4 - 19 Light --> dark, slow --> fast

50 - 89 20 - 34 Dark --> light, slow --> fast

90 - 119 35 - 46 Dark --> light --> dark, slow --> fast

120 - 179 47 - 70 Random fast --> slow strobe

180 - 250 71 - 98 In-phase, slow --> fast

251 - 255 99 - 100 Unused range

4. Red 0 - 255 0 - 100

5. Green 0 - 255 0 - 100

6. Blue 0 - 255 0 - 100

7. White 0 - 255 0 - 100

8. Macro color

0 - 1 0 - 1

2 - 254 1 - 99 Shadow

255 100

9. Pan 0 - 255 0 - 100

10. Pan ne 0 - 255 0 - 100

11. Tilt 0 - 255 0 - 100

12. Tilt ne 0 - 255 0 - 100

13. Rotatable lens

0 - 127 0 - 49

128 - 135 50 - 52

136 - 231 53 - 90

232 - 255 91 - 100

14. Rota sp 0 - 255 0 - 100

15. Fixture control

0 - 9 0 - 3

10 - 14 4 - 5

15 - 19 6 - 7

20 - 24 8 - 9

25 - 29 10 - 11

30 - 34 12 - 13

35 - 239 14 - 93

240 - 244 94 - 95

245 - 249 96 - 97

250 - 255 98 - 100

16. Calibration 0 - 255 0 - 100

WWW.CLF-LIGHTING.COM

15

CHANNEL DMX VALUES % EFFECT

17. Slave ID

0 - 2 0

3 - 5 1 - 2 ID:1 eective

6 - 8 2 - 3 ID:2 eective

--- ---

192 - 194 75 - 76 ID:64 eective

195 - 197 76 - 77 ID is (2xn) + 1 eective, (n=0 - 31)

1, 3, 5, 7, 9 ... 63

198 - 200 77 - 78 ID is (2xn) + 2 eective, (n=0 - 31)

2, 4, 6, 8, 10 ... 64

201 - 203 78 - 79 ID is (3xn) + 1 eective, (n=0 - 21)

1, 4, 7, 10, 13 ... 64

204 - 206 80 - 81 ID is (3xn) + 2 eective, (n=0 - 20)

2, 5, 8, 11, 14 ... 62

207 - 209 81 - 82 ID is (3xn) + 3 eective, (n=0 - 20)

3, 6, 9, 12, 15 ... 63

210 - 212 82 - 83 ID is (4*n) + 1 eective, (n=0 - 15)

1, 5, 9, 13, 17 … 61

213 - 215 83 - 84 ID is (4*n) + 2 eective, (n=0 - 15)

2, 6, 10, 14, 18 … 62

216 - 218 84 - 85 ID is (4*n) + 3 eective, (n=0 - 15)

3, 7, 11, 15, 19 … 63

219 - 221 85 - 86 ID is (4*n) + 4 eective, (n=0 - 15)

4, 8, 12, 16, 20 … 64

222 - 224 87 - 88 ID is (5*n) + 1 eective, (n=0 - 12)

1, 6, 11, 16, 21 … 61

225 - 227 88 - 89 ID is (5*n) + 2 eective, (n=0 - 12)

2, 7, 12, 17, 22 … 62

228 - 230 89 - 90 ID is (5*n) + 3 eective, (n=0 - 12)

3, 8, 13, 18, 23 … 63

231 - 233 90 - 91 ID is (5*n) + 4 eective, (n=0 - 12)

4, 9, 14, 19, 24 … 64

234 - 236 91 - 92 ID is (5*n) + 5 eective, (n=0 - 11)

5, 10, 15, 20, 25 … 60

237 - 239 93 - 94 ID is (6*n) + 1 eective, (n=0 - 10)

1, 7, 13, 19, 25 … 61

240 - 242 94 - 95 ID is (6*n) + 2 eective, (n=0 - 10)

2, 8, 14, 20, 26 … 62

243 - 245 95 - 96 ID is (6*n) + 3 eective, (n=0 - 10)

3, 9, 15, 21, 27 … 63

246 - 248 96 - 97 ID is (6*n) + 4 eective, (n=0 - 10)

4, 10, 16, 22, 28 … 64

249 - 251 97 - 98 ID is (6*n) + 5 eective, (n=0 - 9)

5, 11, 17, 23, 29 … 59

252 - 254 98 - 99 ID is (6*n) + 6 eective, (n=0 - 9)

6, 12, 18, 24, 30 … 60

255 100 All ID’s are valid

dmx protocols

WWW.CLF-LIGHTING.COM

16

• In order to ensure the xture could work normally it should be kept clean always .The lens should also be regularly cleaned to

maintain an optimum light output. Do not use any type of chemicals on the lens. It will damage the lens.

• Please disconnect the power supply of the xture when you start maintenance.

CAUTION: Disconnect the xture from the main power before you start with the maintenance.

cleaning and maintenance

specications

Voltage 240VAC 50/60Hz

Power 91W

LED chips 6x RGBW 4 in 1 LED chip

Lens degree Standard 1.5°

Beam angle Minimum 6°, maximum 51°

Color RGBW

Strobe 1-30 times / second electronic strobe and

random strobe

Pan 540°

Tilt 180°

Control mode DMX512, RDM ready

Channel Standard CH11 & extended CH17

Display menu 2.4 inch TFT touch screen

Software Upgrade by XLR cable

Fixture size 226 x 226 x 286 mm

Netto weight 3,8 kg

Fixture size 226 x 268mm

Ambient temperature 0°C - 38°C

WWW.CLF-LIGHTING.COMCLFLIGHTING

beam 6

Table of contents

Other CLF Dj Equipment manuals