P/N 40831, Rev. 4 Page i

Table of Contents

LABELING GUIDELINES .......................................................................................................................................................................1

SAFETY ..............................................................................................................................................................................................2

PRECAUTIONS AND RULES FOR SAFE OPERATION.............................................................................................................................................. 2

ADDITIONAL WELDING SAFETY PRECAUTIONS..................................................................................................................................................2

SAFETY PRECAUTIONS: GENERAL HAZARDS.......................................................................................................................................3

RISK ASSESSMENT AND HAZARD MITIGATION.................................................................................................................................................... 4

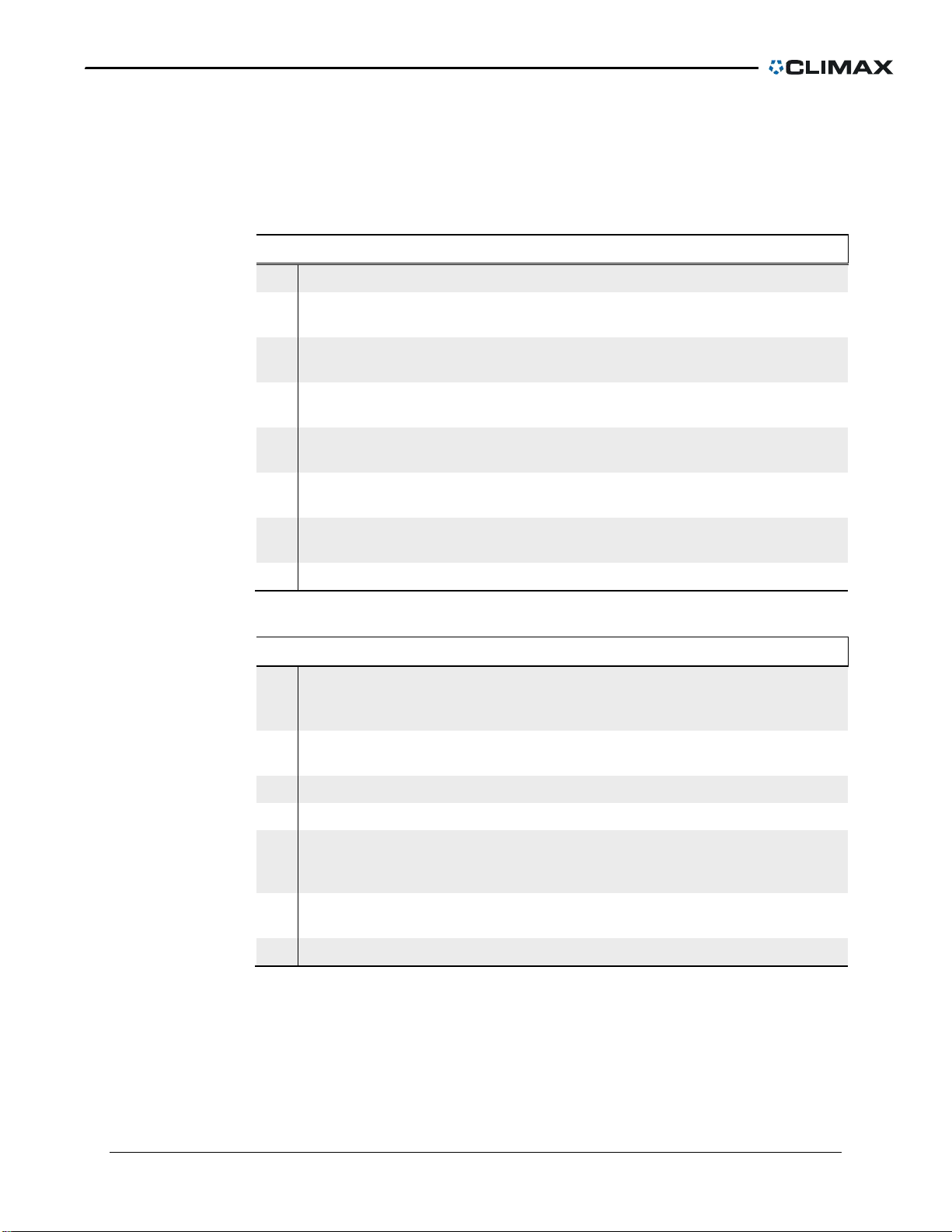

RISK ASSESSMENT CHECKLIST ........................................................................................................................................................................5

LIMITED WARRANTY .........................................................................................................................................................................6

BORTECH LIMITED WARRANTY .....................................................................................................................................................................7

CE DATA ............................................................................................................................................................................................8

DECLARATION OF CONFORMITY........................................................................................................................................................8

SAFETY...................................................................................................................................................................................................10

OPERATION .....................................................................................................................................................................................11

SPECIFICATIONS ..............................................................................................................................................................................12

BUILDUP DIAMETER RANGES......................................................................................................................................................................12

POWER SUPPLY COMPATIBILITY......................................................................................................................................................13

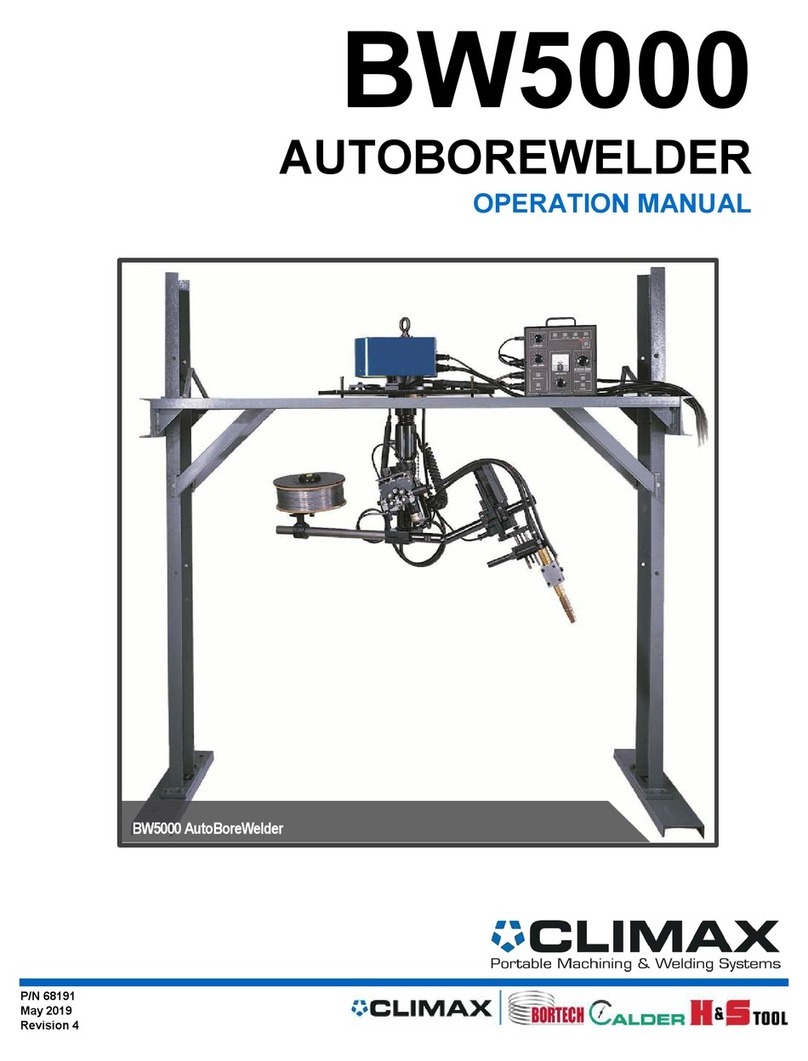

MAJOR ASSEMBLIES ........................................................................................................................................................................14

OPTIONAL EQUIPMENT ...................................................................................................................................................................15

ADJUSTABLE BASE ....................................................................................................................................................................................15

RADIAL MOUNT....................................................................................................................................................................................... 15

EXTENSION .............................................................................................................................................................................................15

TRAMMEL TORCH..................................................................................................................................................................................... 15

HEADLESS SUPPORT KIT.............................................................................................................................................................................15

BEARING CLEARANCE TORCH...................................................................................................................................................................... 15

QUICK SET-UP PROCEDURE .............................................................................................................................................................16

USING .035" WIRE................................................................................................................................................................................... 17

SETTING ROTATION SPEED .................................................................................................................................................................. 18

OPERATION .....................................................................................................................................................................................19

USE OF ACCESSORIES.......................................................................................................................................................................21

Use as follows:................................................................................................................................................................................22

MAINTENANCE ................................................................................................................................................................................23

REPLACING LINERS ................................................................................................................................................................................... 23

OPERATOR TRAINING ......................................................................................................................................................................24

WELDING POINTERS ........................................................................................................................................................................25

WIRE AND GAS........................................................................................................................................................................................25

WIRE FLIP............................................................................................................................................................................................... 25

VOLTAGE................................................................................................................................................................................................ 25

SPINDLE FEED AND WIRE LOCATION ............................................................................................................................................................ 25

WELDING IN THE HORIZONTAL AXIS.............................................................................................................................................................26

WELDING PROBLEMS AND TROUBLESHOOTING ..............................................................................................................................28