Climer HTM EVI SERIES User manual

1 V0REV5ES1218

INSTALLATION AND USER MANUAL

HTM EVI SERIES

INSTALLATION AND USER MANUAL

HTM-24E

2 V0REV5ES1218

INSTALLATION AND USER MANUAL

HTM-24E

3 V0REV5ES1218

1. INTRODUCTION

Thank you for buying a product manufactured by CLIMER TECHNOLOGY. This product, has

been manufactured according to the European Quality Standards, incorporates prime grade

materials and its correct working has been tested before it leaves our facilities.

Through this Installation and User Manual, you will be guide towards the correct and safety

installation of the product. It is necessary to carefully read this manual before make any

handling to avoid problems arising from the misuse of the product.

The company CLIMER TECHNOLOGY reserves the right to modify the information included

in this document at any time without prior notice.

2. GENERAL INDICATIONS

1. Safety notes

- The incorrect or inappropriate use of this product could lead to hazardous

situations, causing damage or injuries to the user, third parties or even to the

product itself or material goods.

- The installer has the responsibility to install the minimum safety devices

(hydraulic and electrical) set out in this Manual. In case of failure, the lack of any

device may cause burns or other injuries.

- The installer has the responsibility to inform the user about the function and

placement of the safety devices installed into the device and the installation.

- The water outlet temperature could reach 65 degrees (depending on the model).

Do not touch the pipes while the system is working to avoid any risk of burns.

- Do not use not approved anticorrosive materials in the water circuit. It may cause

damage to the components.

- The system has to be charged with R407C coolant (depending on model).

These coolants should not be released to the atmosphere. It is responsibility of

the installer to check the tightness of the installation before making the gas

charge.

INSTALLATION AND USER MANUAL

HTM-24E

4 V0REV5ES1218

2. Installer’s qualification

Since the installation of the Heating Thermodynamic Module involves handling coolant as

well as carry out welding work, it is needed the technical staff have the official certification that

accredits them as authorized to handle coolants.

The installer must explain the user the application of the product and the use and

management of the unit, and he should provide the user all the documentation supplied with

the equipment.

3. Package contents

The HTM-E system comprises the following components:

- Thermodynamic panles which number depend on the model

- Liquid distributors

- Anchoring elements

- Heating Module

- Silent-Blocks

- User Manual

4. Indications about transport and unpacking the unit

The HTM-E is supplied packed into a wooden pallet properly secured to prevent damage

during transport.

The material that CLIMER TECHNOLOGY uses to the packing are recyclables, so dispose

it in an appropriate container.

Use a forklift or hand pallet truck to transport the unit to the installation site, always

introducing the forks into the bottom of the pallet being careful not to damage the unit.

In case you identify any damage at the time of the reception of the unit, it is mandatory

to register it in the reception note of the transport company, and then, submit the complaint.

For this reason, it is recommended to make a thorough visual inspection of the goods

before signing the reception note.

INSTALLATION AND USER MANUAL

HTM-24E

5 V0REV5ES1218

3. TECHNICAL INFORMATION

The HTM-EVI is manufactured with high quality and maximum reliability materials:

- Stainless steel 316L plate heat exchanger

- High efficiency Scroll compressor

- Electronic expansion valve

- Liquid receiver

- Filter drier

- Oil separator

- High and low pressure switch

- Safety compressor thermostat

- Electric switchboard with overcurrent and short circuit protections.

- Flow switch

- Temperature sensors placed at inlet and outlet water pipe.

- Steel lacquered casing

Below are indicated the technical data of the system:

HTM24E

Heating capacity range (1), W

26210-18710

Input power range (1), W

4220-4260

Heating capacity range (2), W

26050-19610

Input power range (2), W

7600-7390

Heating capacity (3), W

12.180

Input power (3), W

7.040

Maximum temp. HP, ºC

60

Coolant

R407C

Power supply, V/ph/Hz

380 /3 /50

Number of panels

24

Panel dimensions, mm

1700x800

INSTALLATION AND USER MANUAL

HTM-24E

6 V0REV5ES1218

4. INSTALLATION STEPS

Before starting the installation, check the availability of all the necessary components and

tools:

- High and low pressure manometers

- Vacuum pump

- Scales

- Coolant bottle (R407C depending on the model)

- Nitrogen bottle

- Refrigerant quality copper pipe

- Pipe-cutter

- Tube bender

- Pipe expander

- Welder

- Copper Rods (40% Siver)

- Insulating hose

- Drill

- Screwdriver

- Hydraulic installation components

- Electric installation components

Once it has been checked that it is available all the necessary components and tools, the

installer should follow the next steps:

1. Placing and anchoring panels

2. Installation of the liquid distributors

3. Installation of the gas manifold

4. Joining and welding the refrigerant pipes

5. Placing the Heating Module

6. Joining and welding liquid and suction line between heating module and panels.

7. Nitrogen pressure test (maximum10 bar)

8. Vacuum

INSTALLATION AND USER MANUAL

HTM-24E

7 V0REV5ES1218

9. Pre-load coolant

10. Hydraulic installation

11. Electric installation

12. Commissioning

13. Adjustment of refrigerant load

5. THERMODYNAMIC SOLAR PANELS INSTALLATION

1. Site selection

The choice of the installation site of thermodynamic panels is a key factor in the final

performance of the heating module. For this reason, we recommend to follow the indications in

order to achieve the best performance:

- South orientation is indeed the best to take the maximum advantage of solar

radiation. Panels may also have other orientations, but northerly orientation is

the worst to receive solar radiation.

- Inclination: The minimum inclination of the panel is 15 º in order to ensure the

correct evaporation of the coolant. It is recommended to install the panel with

an inclination between 45º and 90 º.

- Orientation: It is possible to install the panel both in vertical or horizontal

position

When the panel is installed in vertical

position, always the inlet and outlet

connection has been at the bottom. (It is not

allow to install the reverse)

If the panel is installed at horizontal

position, it is recommended to install pair of

panels confronted for having less piping

towards the distributor.

1700

800

1700

800

1700

800

1700

800

1700

800

1700

800

8 V0REV5ES1218

IMPORTANT: If the panel is installed at horizontal position, refrigerant inlet pipe should be

connected into the bottom connection.

- Distances to heating module:

• The maximum allowed distance from the farthest panel to the

heating module is 15 meters.

• It is recommended not to exceed 20 meters of total length from

the heating module to the panels.

- Gap between panels: A minimum distance of 50 cm between panels should be

kept in order to have enough space to fit the pipes and collectors.

In the picture below is shown the dimensions of the panel:

2. Anchoring panels

Beside the panels is supplied a bag with anchoring elements that contain the following

pieces (per each panel):

- 6 x Aluminium support (L shape)

- 6 x Screws M5

- 12 x Nuts M5

- 18 x Washer 5

- 18 x Sheet Metal Screws

- 18 x Blocks M6

Anchor the panels using the lateral and front holes to the suitable surface.

c. Liquid distributor connections

1700

800

INSTALLATION AND USER MANUAL

HTM-24E

9 V0REV5ES1218

IMPORTANT: It is recommended to weld pipelines by oxyacetylene welding.

Welding is a critical step in the installation and to do it well ensures that the system will run

properly along its useful life.

Only expert staff should make this step by using proper tools and high quality materials.

Once panels are anchored, the next step consists on the installation of the liquid

distributor. Its function is to ensure the homogeneous refrigerant flow in the whole panel

installation.

Possible distributor scheme is shown in the next picture:

Install the distributor vertically, face upwards according to the picture.

IMPORTANT: To ensure the same flow of refrigerant in every panel and consequently take

advantage of the evaporation surface entirely; you should install the same tube length from the

distributor to every panel. If a pipe is too long for the length require, it must be rolled up.

Panels are supplied with two nuts at the inlet and outlet connection. The inlet to each panel is

1/4 inch diameter. The installer has to insert the nut into the copper pipe, flare the pipe and

then use the nut to fit it.

Repeat the procedure with the outlet connection using 3/ 8 inch copper pipe.

3/4’’

1/2 ‘’

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

8

1/4 ‘’

8

3/8‘’

3/4’’

5

1/4 ‘’

4

1/4 ‘’

4

1/4 ‘’

4

1/4 ‘’

4

1/4 ‘’

4

3/8‘’

3/4’’

5

3/8‘’

3/4’’

4

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

6

3/8‘’

3/4’’

6

1/4 ‘’

6

1/4 ‘’

6

1/4 ‘’

66

1/4 ‘’ 1/4 ‘’

6

1/4 ‘’

6

HTM 20

HTM 30 HTM 36

HTM 24

HTM 12 HTM 16

1/2’’

1/2 ‘’

INSTALLATION AND USER MANUAL

HTM-24E

10 V0REV5ES1218

L: Liquid line

3. Collector

Join every panel outlet to a secondary collector in a simple way. All the secondary collectors will

be joined to the main suction line.

A: Main suction line

4. Pipe connections

Once the panel scheme is made, proceed to join the liquid and suction line.

Refrigerant quality copper pipe is used to make the connection, with a diameter specified in the

following table:

Model

Suction Line

Liquid Line

HTM-24E

1 1/8’’

3/4’’

INSTALLATION AND USER MANUAL

HTM-24E

11 V0REV5ES1218

6. PLACING HEATING MODULE

Firstly check the dimension of the heating module and the connections disposition:

Models

A

mm

B

mm

C

mm

W1

Water

Outlet

W2

Water

inlet

G

L

E

Electric

connection

HTM-24E

690

658

734

1 ‘’

1 1/8’’

3/4’’

4 wires

The place where the module will be installed should allow an easy access to it in order to

make maintenance work or inspection. It is recommended to leave at least 400 mm of free space.

INSTALLATION AND USER MANUAL

HTM-24E

12 V0REV5ES1218

Beside these factors, it is important to take into account the following indications regards

the installation site:

- The system has been designed and manufactured for it indoors utilization. In

case the system has to be placed outdoors, it must be protected against the

adverse weather conditions (direct solar radiation, rain, snow…)

- Since the Heating Module could cause vibrations and noise, it is recommended

to install it far away from bedrooms or resting places.

- Try to place the heating module as near as possible of the panels’ installation,

and also near to the buffer tank.

- Installer must install the supplied Silent blocks to avoid the transmission of

vibration.

7. CONNECTION BETWEEN HEATING MODULE AND PANELS

CAUTION: Heating Module is preload with a 20 kg of Nitrogen to ensure its tightness

during the transport. Liquid and suction connection are sealed, so before handle the module,

the installer must discharge the nitrogen through the charge ports located at the high and low

pressure line.

a. Check the tightness

Firstly, put the pressure gauge into the charge ports of the high pressure line and low

pressure line.

L

E

G

W1

W2

B

77

884

86

A150

1700

800

400

400

400

INSTALLATION AND USER MANUAL

HTM-24E

13 V0REV5ES1218

Then, check that the pressure at the module is not lower that 15 bar. If the pressure has

decreased, check the installation looking for leakages before continuing with the procedure.

b. Discharge Nitrogen

Discharge the nitrogen preload, opening the load ports until empty.

c. Cut the refrigerant pipes

Inlet and outlet refrigerant pipes are protected by insulating hoses. Firstly, remove the

isolation and through the use of pipe cuter, cut the ends of each tube.

d. Expand tubes

Use the tube expander for expanding the inlet and outlet refrigerant pipe in order to

proceed with the welding. Another option is to install a coupler between pipes.

e. Welding

Join the suction line that comes from the panels to the coolant inlet, and the liquid line to

the coolant outlet. Then weld it by the oxyacetylene welding.

f. Nitrogen load

In order to check the tightness, introduce nitrogen by using the pressure gauge already

installed into load ports.

CAUTION: Never exceed a nitrogen load greater than 10 bars.

Use soapy water at every welding and even in panel’s connections to verify the absence of leaks.

g. Vacuum

Connect the vacuum pipe to the pressure gauge to carry out a vacuum of the whole installation.

The recommended vacuum time is shown in the table below:

Model

Vacuum time

HTM-24E

2 h 30 min

INSTALLATION AND USER MANUAL

HTM-24E

14 V0REV5ES1218

h. Coolant load

Depending on the model of the heating module, the installer has to fill a minimum load

of refrigerant according to the following table:

Standard

Models

Refrig.

Minim.L

oad (kg)

HTM-24E

R407C

3,1

IMPORTANT: Refrigerant 407C, is a zeotropic mix that is composed by 3 different

components. For this reason, the refrigerant has to be in liquid state at the moment of the

loading to ensure the homogeneous charge of each compound.

Do the load always taking the refrigerant of the bottom of the recipient

Load the refrigerant ALWAYS WITH THE MODUEL SWITCH OFF and using the load port

located at the high pressure line, always in liquid state.

Once the initial load has been done, make hydraulic and electric installation.

When the heating module has been connected to the grid, switch on the grid voltage via

the line circuit breaker.

DO NOT ACTIVE TH SYSTEM BY THE THERMOSTAT: The heating module must be

switch off at least 10 minutes, while the crankcase heater is heating the compressor in order to

avoid any risk of liquid hammer in the compressor.

After this period, switch on the heating module using the thermostat key (or the switch)

and start the refrigerant load until achieve the appropriate load. For this issue, check the

ambient temperature and load refrigerant until the evaporation pressure (indicated in the

pressure gauge) match with the values at the table below:

INSTALLATION AND USER MANUAL

HTM-24E

15 V0REV5ES1218

Refrig.

Tem.

Ext. ºC

Evapor.

Pressure

bar

R407C

0

1,6

5

2,15

10

3

15

3,6

20

4,5

25

5,4

30

6,55

8. HIDRAULIC CONNECTION

In Annex 1 is shown two recommended hydraulic schemes.

The installer must install the following components of the hydraulic circuit:

- Circulation pump

- Ball valves

- Lined Filter Strainer (Y Type)

- Pressure reducing valve

- Expansion vessel

- Safety valve

For the selection of the circulating pump it is needed to take into account the pressure

loss in pipes and accessories (pipe elbow, filter, valves).

In the following table is shown the water flow that must flow at least through the heat

exchanger :

Standard

models

Water

flow

(L/h)

Pressure

loss (kPa)

HTM-24E

5.158

52

Once the hydraulic connections are made, vent the circuit to avoid the air inside the

installation.

INSTALLATION AND USER MANUAL

HTM-24E

16 V0REV5ES1218

Temperature probe

The installer has to install the temperature probe B1 in one of the following points:

- Inside the buffer tank

- Return water pipe

- If the buffer tank has a coil, in the return water pipe of the coil

9. ELECTRICAL CONNECTION

The electric switchboard is located in the front of the module. The installer has to make

the following connections:

1.

Power supply:

Connect the system directly from the general control panel. The minimum wire section

and the characteristics of the circuit breaker that the installer has to install are shown in the

following table:

These data are calculated based on a maximum distance of 15m. In case of higher

distances contact with technical department for a new dimensioning.

2.

Circulator pump

Connect the circulator pump to the heating module. The system will control

automatically the operation of the pump when it is needed.

The connection is single-phase 230V/ 50 Hz. Pump must not exceed 5 A current.

In the Annex 2 and 3, are shown electric schemes. Connect the pump in the terminals 0-0.

Models

Power Supply

mm2

Circuit breaker

HTM-24E

380 V/ 3ph

/50 Hz

6

20 A- curve D

INSTALLATION AND USER MANUAL

HTM-24E

17 V0REV5ES1218

3. Remote start/stop

There is the possibility of connecting an external switch to control the ON/ OFF of the

system. It is a zero-voltage contact, that must be connected to the terminals 7-7.

If the installer does not use an external switch, jumper connect the terminal blocks 7-7. In

this case, the module will be switch on through the thermostat (see section 10. Comminisioning).

INSTALLATION AND USER MANUAL

HTM-24E

18 V0REV5ES1218

10. COMISSIONING. CONTROLLER.

1. Meaning of the buttons/ controller symbols

2. Use of buttons

A C

IH

G

F

E

B D

Symbol

Meaning ON

E

Compressor ON

F

Heating mode ON

G

Alarm

H

Pump ON

I

Compressor ON

Button

Meaning

A

Programming button

B

Select button

C

Increase buton

D

Decrease button

Button

Mode

Pressing

Function

Mode normal

Press for 5 sec.

Access to USER parameter

Navigation menu

Once pressing

Select item in programming and

visualising environmentvalue of USER

parameters

Confirmation

Navigation menu

Once pressing

Select upper item in menus

Mode modify

Once pressing

Increase parameter value

Mode normal

Press for 5 sec.

Swicht on/off the system if the remote

swicht is not installed

Navigation menu

Once pressing

Select lower item in menus

Mode modify

Once pressing

Decrease parameter value

+

Alarm

Press for 5 sec.

Manually reset alarm

Navigation menu

Press for 5 sec.

Immediate zero set of hour counter

INSTALLATION AND USER MANUAL

HTM-24E

19 V0REV5ES1218

3. Modifying parameters

Below is shown in the picture the procedure to change the parameters:

- r03: Change the hot water temperature set point

- r04: Change temperature differential

5 s

menu

INSTALLATION AND USER MANUAL

HTM-24E

20 V0REV5ES1218

11. ALARMS

To reset manually the alarms, press for 5 seconds +

Alarms

Reset

HP1

High pressure

Manual

LP1

Low pressure

Automatic 5 times in one hour. Once

exceeded, manually reset.

TC1

Circuit thermal

overload

Manual

E1

Probe B1

Automatic reset

E2

Probe B2

Automatic reset

FL

Flow switch

Automatic 5 times in one hour. Once

exceeded, manually reset.

ELS

Low supply voltage

Automatic

EHS

High supply voltage

Automatic

CP1

Hours of compressor

working

Manual Reset. The system does not stop.

This manual suits for next models

1

Table of contents

Popular Heating System manuals by other brands

flamco

flamco Flexcon P Installation and operating instructions

Viessmann

Viessmann Vitotronic 200 KW2 operating instructions

aerauliqa

aerauliqa QR180ABP installation manual

Velux

Velux CLI U12 SD0(W/L/F/P) 118 El B/U instruction manual

Amana

Amana APG14 M Series manual

Ducasa

Ducasa AVANT-DGi+ 350 Operating and installation instructions

Energotech

Energotech EnergoCassette ENC 300 Fitting instructions

Lindab

Lindab PENNY QN Instructions for installation, use and maintenance manual

GammaSwiss

GammaSwiss RoofMate Assembly, installation and operation instructions

Monitor

Monitor M2200 owner's guide

Sentinel

Sentinel ELIMINATOR installation manual

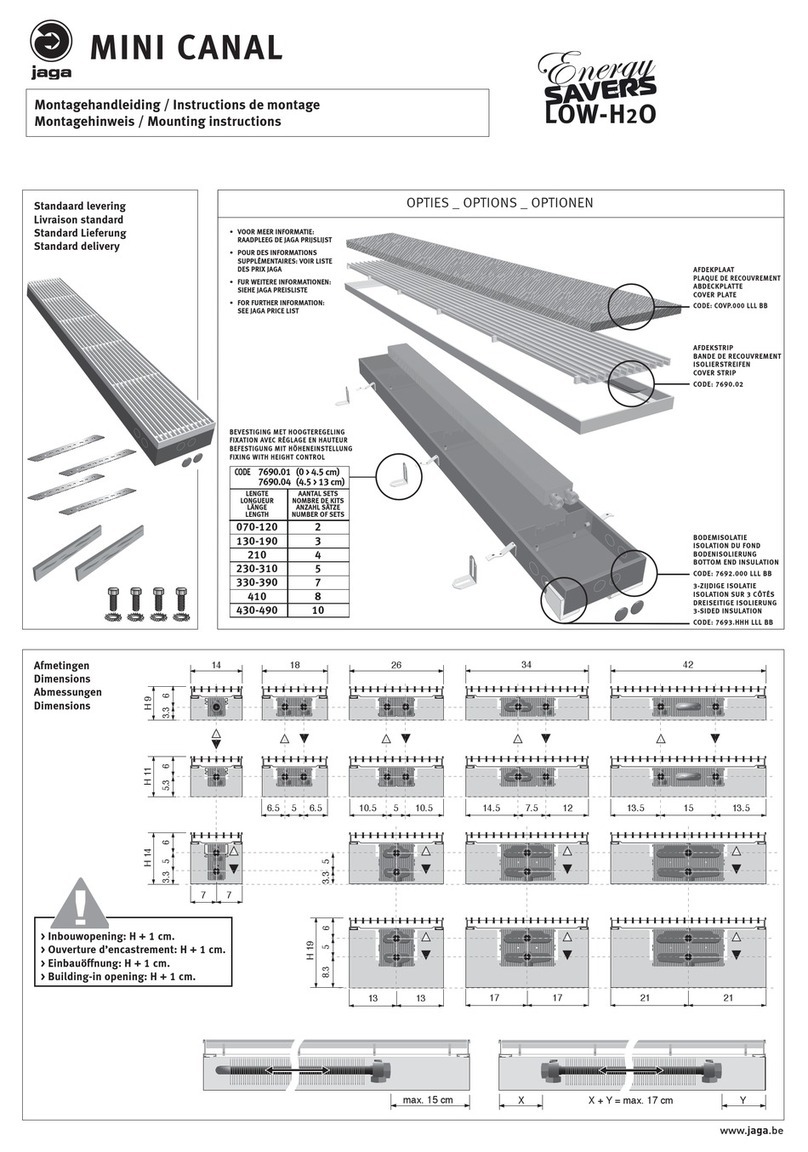

Jaga

Jaga Mini Canal Mounting instructions