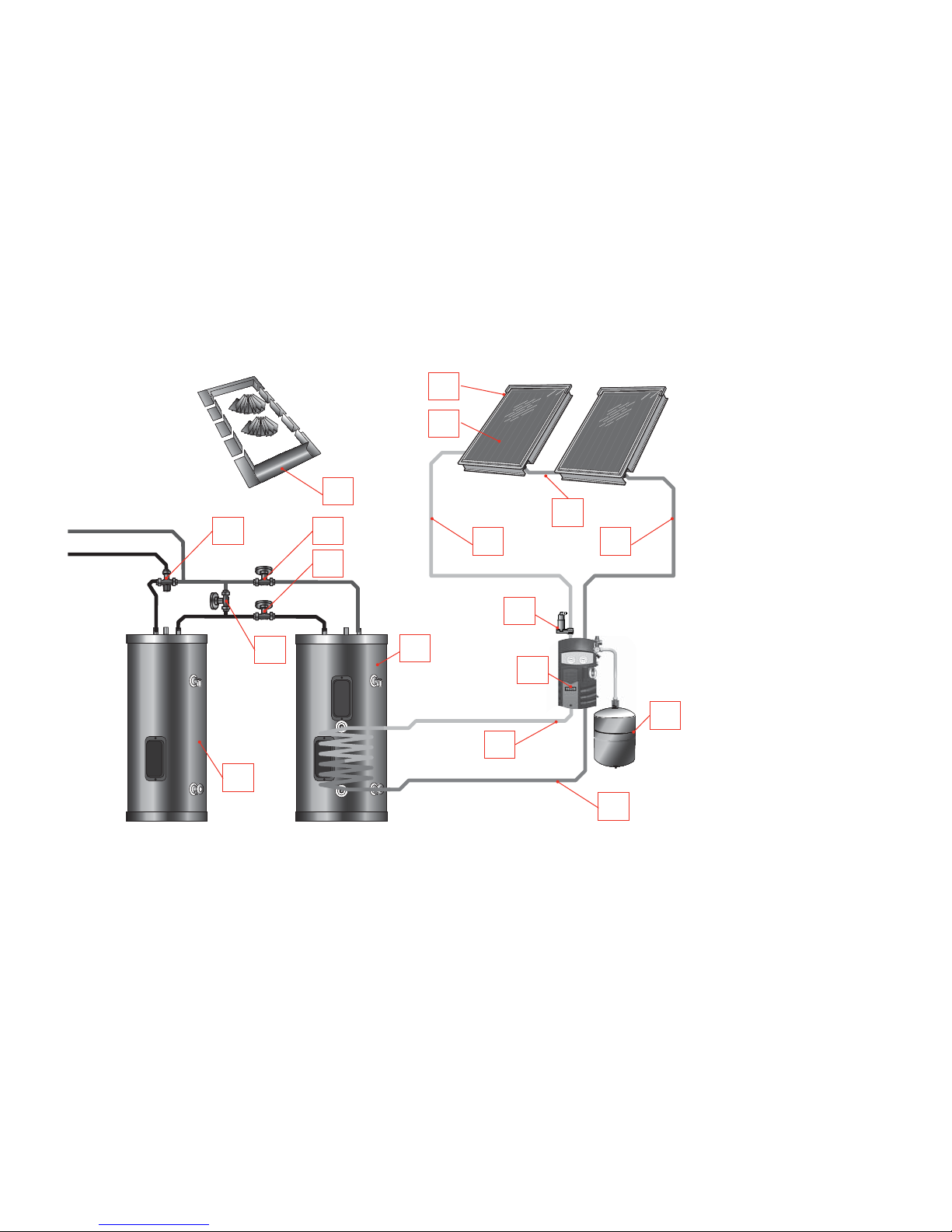

Solar storage tank – Part 2: General information – 5

systems that include flashings for integration into tile roofs. CLI U12 SDOF 118, CLI U12 SK0F 218, CLI U12 SK0F 318,

CLI U12 SD0F 119, CLI U12 SK0F 219, and CLI U12 SK0F 319

,

are systems that include rack systems for installation on flat

roofs.

CLI U12 SDOP 118, CLI U12 SK0P 218, CLI U12 SK0P 318, CLI U12 SD0P 119, CLI U12 SK0P 219, and CLI U12 SK0P 319

,

are

systems that include rack systems for installation on flat roofs. You must reference your VELUX collector installation manual

for instructions for mounting collectors with each roof type.

Solar storage tank

All VELUX solar water heating systems will include a solar storage tank with the solar heat exchanger located in the bottom

section of the tank to heat the entire water volume of the tank. The thermostatic controls for the electric, gas, or boiler back

up shall be located in the upper portion of the tank to provide back up heat if the solar collector is not providing enough heat

to maintain the upper operating set point of the tank. The solar tank is equipped with a control well located a third of the way

from the bottom of the tank located near the heat exchanger coil to monitor the solar heat input.

Collector loop piping

VELUX solar water heating systems are designed for use with the pre-insulated corrugated stainless steel flexible piping

provided with the VELUX system kit. Collector piping installation requires the use of copper and brass fittings in the collector

loop. Piping in new solar installations may have dirt, grease, or other impurities that over time aect the quality of the

propylene glycol heat transfer fluid. A thorough cleaning is required before charging the system with glycol. All vertical piping

between the storage tank and the collector shall be supported at each story or at maximum intervals of ten feet (10’) using the

pipe hangers provided. If additional supports are needed, copper plumbers tape or tube strap may be used. The pipe insulation

may not be compressed or crimped by the strapping material. The installation of all horizontal and vertical piping may not

reduce the performance or rating of any structural member or fire rated assembly. Adhere to all applicable local codes and

ordinances.

The collector loop cold supply and hot return lines must be well insulated with the high quality flexible closed cell insulation

provided to minimize heat loss. There shall be no exposed piping or fittings. The wall thickness of the pipe insulation should

not be less than ¾”. To the extent possible, slide the insulation material over the pipe without cutting or taping. All butt joints

must be sealed with contact adhesive. The use of rigid polyethylene pipe insulation is prohibited. The temperatures generated

by your collector in the summer months or under stagnation conditions can melt this type of material. Any above ground

exterior pipe insulation that may be subject to UV degradation must be wrapped with foil tape or painted with two coats of

high quality water-based acrylic resin coating as supplied by the insulation manufacturer. Rubatex UV Protective Coating or

equal is the required coating material.

Pump station controller

All VELUX solar water heating systems include a pump station controller that include the temperature and pressure gauges,

check valves, ball valves, flow meter, fill and drain valves, and dierential controller required to properly operate the VELUX

solar water heating system. The system temperatures for the collector and storage tank can be read from the dierential

controller. Typical tank operating temperatures can range from the cold supply of 40°-80° F up to 180° F which represents

the high limit of the tank. This will vary depending on the climate where the system is installed. The collector temperature

sensor should be 5°-20° F above the tank sensor during normal operation. During idle periods, when there is no sun, the

collector will read the ambient temperature and when there is full sun upward to 250° F.

Balance of systems

The balance of components in all VELUX solar water heating systems: solar loop pipe and fittings, temperature sensors,

expansion tank, microbubble air separator, mixing valve, and non-toxic propylene glycol heat transfer fluid components carry

temperature and pressure ratings required of the VELUX solar water heating system design.

The VELUX solar water heating system can be operated down to ambient temperatures of –40°F using proper concentrations

of propylene glycol. Freeze tolerance limits are based upon an assumed set of environmental conditions. Refer to the propylene

glycol specification sheet in the back of this manual for recommended concentrations. The dierential controller uses

temperature sensors to monitor the temperature dierence between the collector and the solar storage tank. The controller

turns on when the collector is 18–20° F above tank temperature and turns o when the dierential drops below 12° F.