CLIMIA CTK 240 User manual

CLIMIA

CTK 240 mobile air dehumidier

Operating manual

Edition 1.0

English

3

CTK 240 mobile air dehumidier

Contents

Carefully read this operating manual prior to commissioning/using the units!

This operating manual is a translation of the German original.

This manual is an integral part of the unit and must always be kept in the vicinity of the installation location

or on the unit itself.

Subject to modications; no liability accepted for errors or misprints!

1.0 Safety instructions 4

2.0 Environmental protection and recycling 4

3.0 Guarantee 4

4.0 Intended use 4

5.0 Transport and packaging 5

6.0 Air dehumidication 5-7

7.0 Unit description 8

8.0 Set-up 9

9.0 Commissioning 9-12

10.0 Shutdown 12

11.0 Unit transport 12

12.0 Care and maintenance 13-14

13.0 Troubleshooting and customer service 14

14.0 Electrical wiring 15

15.0 Electrical wiring diagram 15

16.0 General view of unit 16

17.0 Spare parts list 17

18.0 Technical data 18

19.0 Maintenance log 19

EC Declaration of Conformity 20

4

CLIMIA

1.0 Safety instructions

Carefully read the operating manual

before commissioning the unit

for the first time. It contains useful

tips and notes, as well as hazard

warnings to prevent injury or

material damage . Failure to follow

the instructions in this manual can

endanger people, the environment

and the equipment itself and will

void any claims for liability.

This unit can be used by children

above the age of 8, as well as by

people with impaired physical,

sensory or mental capabilities or a

lack of experience and knowledge

if they are supervised or have

received instruction in the safe

operation of the unit, and if they

understand the associated potential

hazards. Children must never play

with the unit. Cleaning and user

maintenance must not be carried

out by unsupervised children.

Keep this operating manual and the

refrigerant data sheet near to the

units.

The following notes must be

observed in full:

•The units must not be operated

at an ambient temperature

below 5 °C.

•The units may not be set

up or operated in explosive

environments.

•The units must not be installed

or operated in atmospheres

containing oil, sulphur, chlorine,

salt or dust.

•Never insert foreign objects into

the units.

•The units may not be exposed to

direct jets of water.

•An unobstructed air inlet and air

outlet must be guaranteed at all

times.

•The air-inlet grille must always

be kept free of dirt and loose

objects.

•The units must not be covered

during operation.

•

The units must be installed

upright and in a stable position.

•

The units must not be

transported while they are

running.

•

The units may only be

transported upright (water will

escape otherwise).

•

Before each change of location,

the condensate container must

be emptied

•

All electrical cables on the

outside of the units must be

protected against damage (e.g.

by animals etc.)

.

•

Before each change of location,

the condensate containers must

be emptied

.

•Appropriate hazard prevention

measures must be taken to

prevent risks to people when

performing installation, repair,

maintenance or cleaning work on

the units.

•The units and components

should not be exposed to any

mechanical load, extreme levels

of humidity or direct exposure to

sunlight.

3.0 Guarantee

As a prerequisite for any warranty

claims to be considered, it is

essential that the ordering party or

its representative completes and

returns the "certificate of guarantee"

to Climia Intakt GmbH at the time

when the units are purchased and

commissioned.

The guarantee conditions are

listed in the "General terms

and conditions of business and

supply". Furthermore, only the

parties to a contract can conclude

special agreements beyond these

conditions. In this case, contact

your contractual partner in the first

instance.

Disposing of packaging

All products are packed for

transport in environmentally

friendly materials. Make a valuable

contribution to reducing waste

and sustaining raw materials. Only

dispose of packaging at approved

collection points.

Disposing of the units and their

components

Only recyclable materials are used

in the manufacture of the units and

components.

Help protect the environment

by ensuring that the units or

components (for example batteries)

are not disposed of in household

waste, but only in accordance

with local regulations and in an

environmentally safe manner,

e.g.using authorised disposal and

recycling specialists or council

collection points.

2.0 Environmental

protection and

recycling

5

CTK 240 mobile air dehumidier

The units are shipped in sturdy

transport packaging. Immediately

check the unit on delivery and make

a note of any damage (please take

photos of the damage) or missing

parts on the delivery note. Inform

the forwarding agent and your

contractual partner.

Please retain the packaging for

returns.

Claims under guarantee made at a

later date will not be accepted.

5.0 Transport and

packaging

4.0 Intended use

The units are designed exclusively

for drying and dehumidication

purposes on the basis of their

structural design and equipment.

The units must not be used for any

other purpose.

The units are only permitted to

be operated by people with the

relevant training and understanding

of how to handle them.

Any different or additional

use is a non-intended use. The

manufacturer/supplier assumes no

liability for damages arising from

non-intended use. The user bears the

sole risk in such cases.

Intended use also includes working

in accordance with the operating

and installation instructions and

complying with the maintenance

requirements.

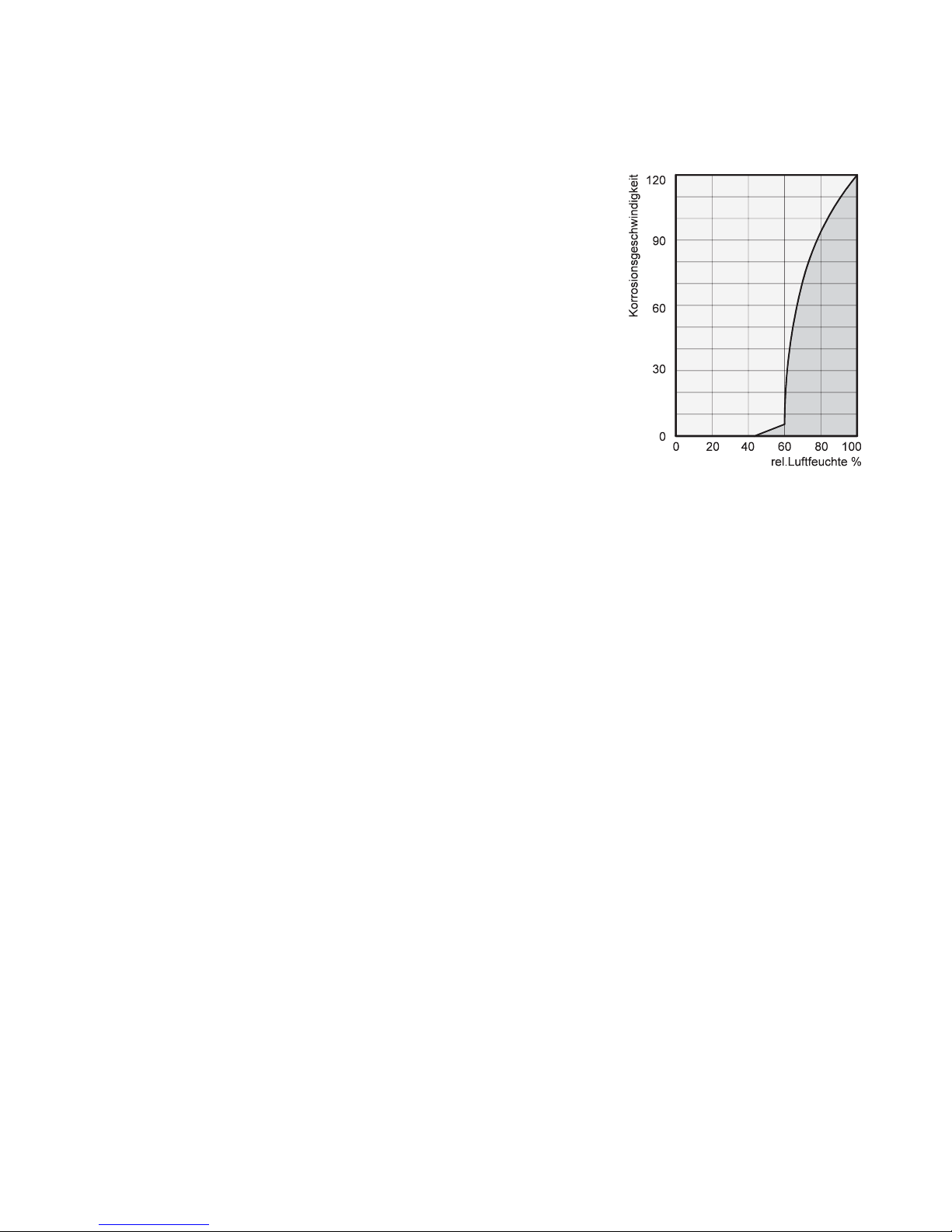

It is evident that the corrosion rate

below 50% relative humidity (RH) is

low, and below 40% is negligible.

The corrosion rate increases

signicantly above 60% RH.

Thisthreshold for damage as the

result of humidity also applies to

other materials, such as powdery

substances, packaging, wood and

electronic units.

Buildings may be dried in a variety

of ways:

1. By heating and air exchange:

The air in the room is heated in

order for moisture to be removed

and then this air is fed outside.

All of the energy that is involved

is lost together with the moist air

that is released.

2. By air dehumidication:

The moist air that is present

within an enclosed space is

continuously dehumidied

according to the condensation

principle.

The correlations occurring when

air is dehumidied are based on

physical laws.

These are depicted here in graphical

form in order to provide you with

abrief overview of the principles of

air dehumidication.

Using Climia air dehumidiers

•

Even if windows and doors

are well insulated, water and

moisture are still capable of

penetrating thick concrete walls.

•

The water required for setting

in the production of concrete,

mortar and plaster etc. may only

be diused after 1-2 months.

•

Even moisture trapped in the

masonry after high-water or a

ood is released very slowly.

•

The same is also true of moisture

contained in stored materials for

example.

The moisture (water vapour)

released from parts of a building

or materials is absorbed by the

surrounding air. As a result, the

moisture content increases, which

ultimately gives rise to corrosion,

mould, rot, peeling of paint and

other unwanted damage.

By way of example, the diagram

shows the corrosion rate of metal in

dierent levels of humidity.

6.0 Air dehumidication

6

CLIMIA

With regard to energy consumption,

air dehumidication has one

distinct advantage:

Energy expenditure is limited

exclusively to the air volumes

present. The mechanical heat that

is released by the dehumidication

process is fed back into the room.

Under normal use, the

air

dehumidier

uses

approximately 25% of the

energy that is required for

the

"heating and ventilating"

principle.

Relative air humidity

Our ambient air is a gaseous

mixture which always contains

acertain volume of water in the

form of water vapour. This volume

of water is specied in g per kg of

dry air (absolute moisture content).

1m3of air weighs approx. 1.2 kg

at20°C

Depending on the temperature,

each kg of air is only capable of

absorbing a certain volume of

water vapour. Once this capacity

has been reached, the air is referred

to as“saturated” and has a relative

humidity (RH) of 100%.

Relative humidity is understood to

mean the ratio between the current

quantity of water vapour in the air

and the maximum possible quantity

of water vapour at the same

temperature.

The ability of the air to absorb water

vapour increases as the temperature

rises. I.e. the maximum possible

(absolute) water content becomes

greater as the temperature rises.

Building materials and structures

are capable of absorbing

considerable volumes of water,

suchas brick 90-190 l/m³, heavy

concrete 140-190 l/m³ and

limestone 180-270l/m³.

The drying of moist materials such

as masonry is eected as follows:

•

The moisture moves

from the inside of

the material to its

surface

•

Evaporation occurs on the

surface = Transfer of water

vapour to the ambient air

•

The air containing water vapour

is constantly circulated through

the air dehumidier. The air

is dehumidied and, slightly

heated, leaves the unit in order

to re-absorb water vapour

•

In this way, the moisture

contained in the material is

reduced gradually.

The material is dried!

The accumulated condensate is

collected in the unit and drained o

from there.

Drying materials

% RH Evaporator Condenser

Air temperature

Air direction

Air humidity

Progression

As it ows through or over the evaporator, the air stream is cooled to dew

point. The water vapour condenses, and is collected in a condensate trap

from where it is drained o.

Temp. Water vapour content in g/m3at humidity of

°C 40% 60% 80% 100%

-5 1.3 1.9 2.6 3.3

+10 3.8 5.6 7.5 9.4

+15 5.1 7.7 10.2 12.8

+20 6.9 10.4 13.8 17.3

+25 9.2 13.8 18.4 23.0

+30 12.9 18.2 24.3 30.3

7

CTK 240 mobile air dehumidier

Water vapour condensation

Because the capacity for the

maximum possible volume of

water vapour increases as the air is

heated, the volume of water vapour

contained remains constant and so

relative humidity falls.

In contrast, because the capacity for

the maximum possible volume of

water vapour decreases as the air is

cooled, the volume of water vapour

contained remains constant and so

relative humidity increases.

If the temperature continues to

fall, the capacity for the maximum

possible volume of water vapour

is reduced so much so that it is

ultimately equal to the volume of

water vapour contained in the air.

This temperature is referred to as

the dew point. If the air is cooled to

below the dew point, the volume of

water vapour in the air will become

greater than the maximum possible

volume of water vapour.

At this point, the water vapour

begins to precipitate.

This condenses to water and

moisture is removed from the air.

Examples of condensation include

steamed-up window panes in

winter, or the moisture on the

outside of a cold drinks bottle.

As the relative humidity of the air

increases, so too does the dew

point, making it easier for the

temperature to fall below it.

Condensation heat

The Energy transferred to the air

from the condenser consists of:

1. The amount of heat derived

beforehand in the evaporator.

2. The electrical drive energy.

3. The condensation heat released

by liquefying the water vapour.

Energy must be supplied when

liquid is converted into a gas. This

energy is designated as evaporation

heat. It does not cause any increase

in temperature, but is required

to convert a liquid into a gas.

Conversely, energy is released when

gas is liqueed, this is designated as

condensation heat.

The amount of energy from

evaporation heat and condensation

heat is the same.

For water, this is:

2250 kJ/kg (4.18 kJ = 1kcal)

From this it is evident that the

condensation of water vapour

causes a large quantity of energy to

be released.

If the moisture that it is to be

condensed is not introduced by

evaporation in the room itself,

but from outside, e.g. through

ventilation, the condensation heat

released contributes to the heating

of the room. With drying operations,

a heat cycle is created, whereby

heat is consumed for evaporation

and released for condensation.

When dehumidifying fed air,

alarger contribution of heat is

created, which manifests itself as

atemperature increase.

Generally speaking, the time

required for the drying process is

not only dependent on the output

of the unit, but is determined to

a greater extent by the speed at

which the material or building

section loses its moisture.

8

CLIMIA

nozzle into the condensate

container below either continuously

or only during the defrosting

phases.

A oat is installed inside the

condensate container. In the event

that the container is full, the oat

will activate a microswitch which

will switch o dehumidication

mode.

The units switch o and the

“container full” indicator light on

the control panel illuminates.

Thisextinguishes again when

theempty condensate container

isre-inserted.

The units then restart.

In unattended continuous operation

with an external condensate

connection, the condensate that

occurs is drained continuously via

a hose connection. The units then

start.

In unattended continuous operation

with an external condensate

connection, the condensate that

occurs is drained continuously via

ahose connection.

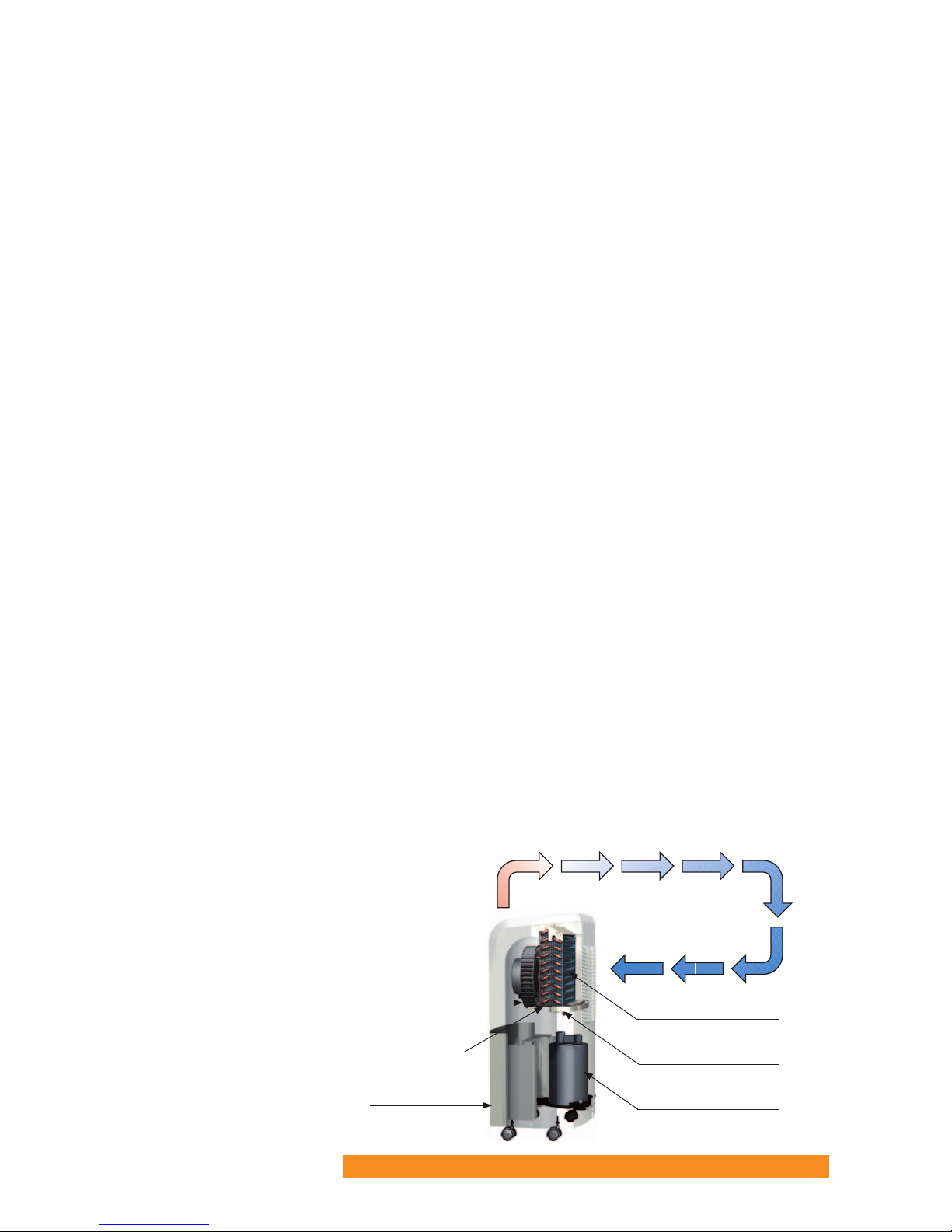

Recirculating fan

Condensate

container

Condenser

Evaporator

Condensate trap

Compressor

Moist room air

Dehumidied

room air

Fig. 1 Schematic depiction of the workings of the air dehumidier

7.0 Unit description

In dehumidication mode, one of

the“Fan stage”indicator lights on

the control panel illuminates.

The fan extracts the moist room air

through the intake grill with lter,

evaporator and the condenser

behind.

Heat is removed from the room air

on the cold evaporator. The air is

then cooled to below dew point.

The water vapour contained in

the room air is then deposited

as condensate or rime on the

evaporator ns.

On the condenser (heat exchanger),

the cold and dehumidied air is

warmed up again and discharged

back into the room via the outlet

grill with a temperature increase of

around 5 - 10°C above the room

temperature.

The processed, dry air then re-mixes

with the room air.

Continuous circulation of the room

air through the unit gradually

reduces the relative humidity (% RH)

in the room to the desired humidity

level.

Depending on the room air

temperature and the relative

humidity, condensed water will drip

into the condensate trap and then

through the integrated discharge

The units have been designed for

universal and straightforward air

dehumidication.

Their compact dimensions allow the

unit to be transported and set up

with ease.

The units operate in accordance

with the condensation principle and

are equipped with a hermetically

sealed refrigerant system, heat gas

defrosting, low-noise and low-

maintenance fan and connection

cable with plug.

The fully automatic control, the

variable hygrostat, the condensate

container with integrated overow

protection and the connection

nozzle for condensate drainage

guarantee fault-free continuous

operation.

The units conform to the

fundamental health and safety

requirements of the appropriate EU

stipulations.

The units are dependable and oer

ease of operation.

The units are used in all locations,

where dry air s a must and where

economic consequential damage

(such as that caused by mould)

must be prevented.

The units may be used for the

drying and dehumidication of

areas such as:

•

Living rooms, bedrooms, shower

rooms or cellar rooms

•

Laundry rooms, weekend homes,

caravans

•

Warehouses, archives,

laboratories

•

Bathrooms, wash rooms and

changing rooms etc.

•

Basements, storage rooms

Operating sequence

The units are switched on and o by

the power key.

9

CTK 240 mobile air dehumidier

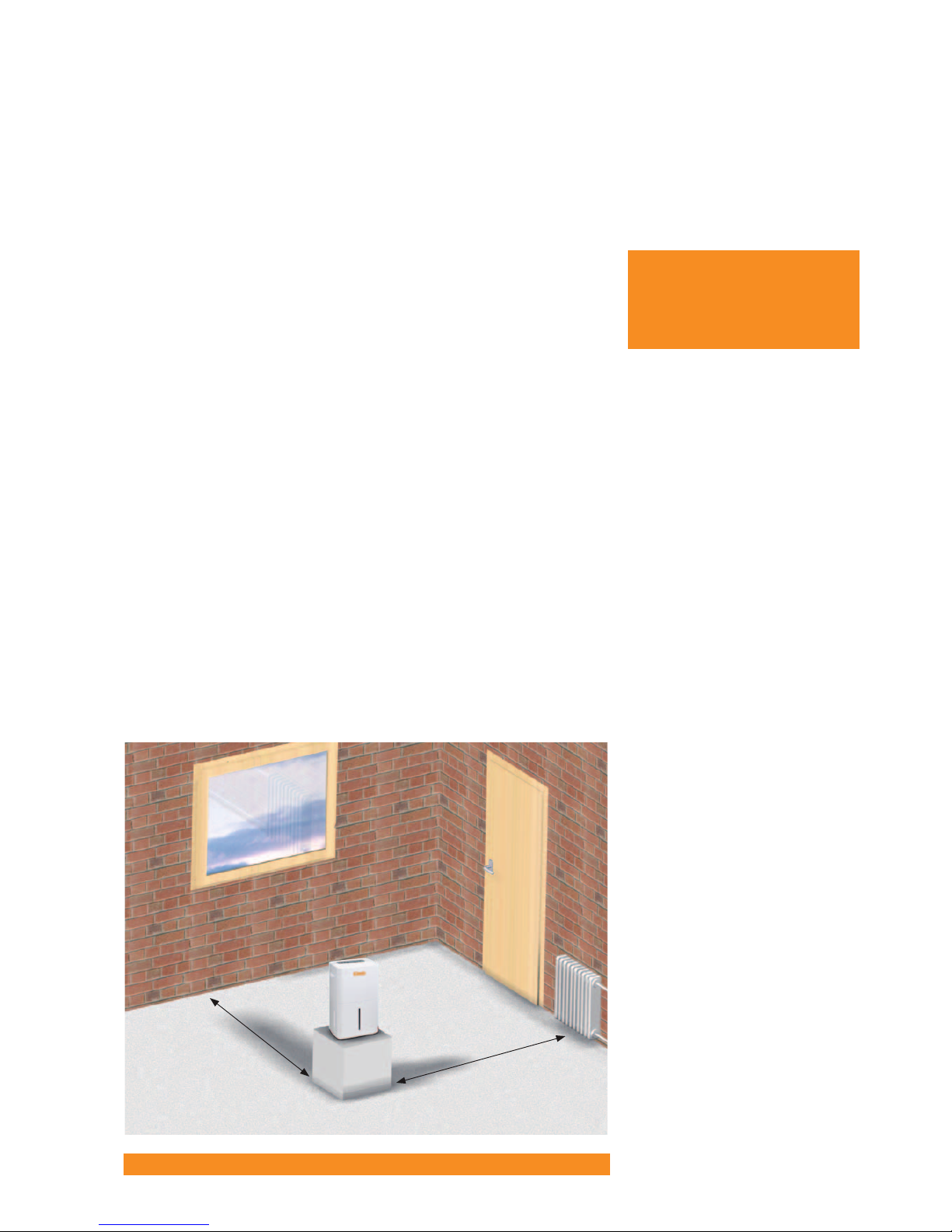

8.0 Set-up

For the best economic and safe use

of the units, the following notes

must be followed in full:

•

The units must be set up in an

upright and level position, to

ensure that the condensate can

drain freely

•

To ensure optimum air

circulation, the units should be

set up in the centre of the room,

where possible

•

Ensure that the room air can

be sucked in and discharged

without hindrances

•

Observe a minimum clearance of

50 cm from walls at all times

•

Units must never be set up in the

immediate vicinity of heaters or

other sources of heat

•

Air circulation is improved if the

unit is set up approx. 1 m above

the ground

•

The room being dried or

dehumidied must be closed to

the surrounding atmosphere

•

Avoid having opened windows

and doors etc., and avoid

frequent entry to or exit from the

room as much as possible

•

The units may not be used in

environments containing a

great deal of dust or chlorine,

or in places with atmospheres

containing ammonia

•

The output of the unit is

entirely dependent on the

conditions inside the room, room

temperature, relative humidity

and observance of the set-up

instructions

Min. 0.5m

distance to wall

Maintain adequate clearance from

heaters or other sources of heat.

Keep windows and doors closed!

Fig. 2 Schematic depiction of how to set up the air dehumidier

9.0 Commissioning

Before commissioning the unit or if

local requirements dictate, the air-

inlet grill and air-outlet grill must be

checked for contamination.

Important notes prior to

commissioning

•

All extensions to the electrical

connection must be of

asucient cable size and must

only be used fully rolled out or

unrolled

•

Never use the power supply

connection cable as a pull cord

•

After being switched on,

theunits operate fully-

automatically until switched o

by the hygrostat or oat when

the condensate container is full

•

The condensate container must

be inserted properly

The unit cannot be operated

if the condensate container

isnot inserted properly!

•

In order to prevent damage to

the condenser, the units are

equipped with a mechanism that

prevents the compressor being

immediately switched back on

after it is switched o

The units do not switch back

on until a waiting time of

around 3 minutes has elapsed!

•

If the units work in continuous

operation with an external

condensate drainage

connection, refer to the relevant

section

NOTE

A contaminated grille or lter

must be cleaned or replaced

immediately.

10

CLIMIA

1. The power key switches the unit

on and o.

2. The speed key sets the fan stage.

The min/max fan stage indicator

lights indicate the fan stage at

which the unit is running.

3. If required, the unit can be

switched to manual timer mode

using the timer key.

4. Use the“Humidity/Time”arrow

keys to set the required air humidity

in the installation room or the

required air humidier operating

time.

5. After an operating time of

250hours, the“Check Filter”

indicator light illuminates and the

lter must be removed and cleaned

according to the instructions. The

unit can be reset using the lter

reset key after inserting the lter.

6. The display shows the current

air humidity or the required air

humidity during regulation, or the

required operating time. The display

shows the current air humidity

again 10 seconds after the setting is

made.

NOTE

In room temperatures below

10°C

and relative humidity

below

40%

, economical use

of the unit can no longer be

guaranteed.

NOTE

After setting the required air

humidity, the display shows

this for another 10 seconds

before displaying the current air

humidity again.

NOTE

Note that the compressor does

not switch on until a waiting

time of 3 minutes has elapsed.

Restart protection!

Control panel

The control panel contains various keys, indicator lights and a display.

7. The bucket full indicator light

indicates when the condensate

bucket is full and must be emptied.

8. The unit is in defrost mode while

the“Defrost” operating light is

illuminated.

Commissioning the units

1. Connect the unit's electrical

connection to a properly installed

mains socket.

2. Press the power key once to

switch on the unit.

3. Use the arrow keys to set the

required air humidity of the

installation room.

The air humidity can be set at

increments of 5 %.

The recommended approximate

setting values are listed in the

adjacent section.

Adjusting units/moisture

The unit’s dehumidication power

is entirely dependent on the

conditions inside the room, the

room temperature, the relative

humidity and observance of the

notes in the“Setting up”chapter.

11

CTK 240 mobile air dehumidier

The following notes must also be

observed in full:

•

Ensure that the air can discharge

without hindrances

This is the only way to

guarantee optimum unit

operation!

•

Ensure that sensitive objects

such as house plants are not

placed directly in the air ow

emerging from the unit.

Automatic defrost system

The moisture contained in the

room air condenses when cooling

and coats the evaporator ns with

rime or ice depending on the

air temperature and the relative

humidity (% RH).

The automatic defrost system that is

integrated in the unit switches the

defrost cycle on if required.

The rime or ice that has

accumulated on the exchanger

surfaces is defrosted using

electronic circulation mode as

required.

This tried and tested defrosting

method guarantees high

dehumidication performance.

Dehumidication mode is paused

during the defrost phase.

The“Defrost mode” indicator light

indicates that the defrost cycle is

running.

The higher the room temperature

and relative air humidity, the higher

the dehumidication power.

A relative humidity of around

45to60% is sucient in living

rooms. The air humidity should not

exceed 40 to 45% in

warehouses, archives, etc.

Timer function

The units feature an integrated

timer function.

Pressing the timer key switches the

unit’s automatic mode on and o.

If automatic mode is switched o,

the arrow keys can be used to set

the required operating time.

The operating time can be set for a

maximum of 24 hours in increments

of an hour.

The unit will switch itself o

automatically after the set time has

elapsed.

NOTE

If the room temperature is

suciently high (>12 °C), the

surface of the ns will not be

cold enough for rime formation

to occur, rendering defrosting

unnecessary.

Therefore, the air dehumidier

works economically.

Emptying the condensate

container

The integrated condensate

container must be emptied from

time to time.

Dehumidication mode is switched

o if the condensate container is

full.

The“BUCKET FULL” indicator light

indicates that the unit has switched

o.

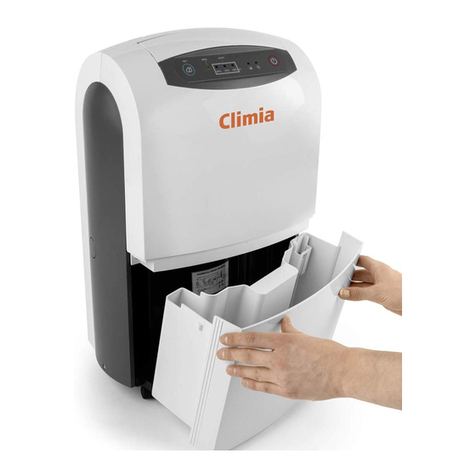

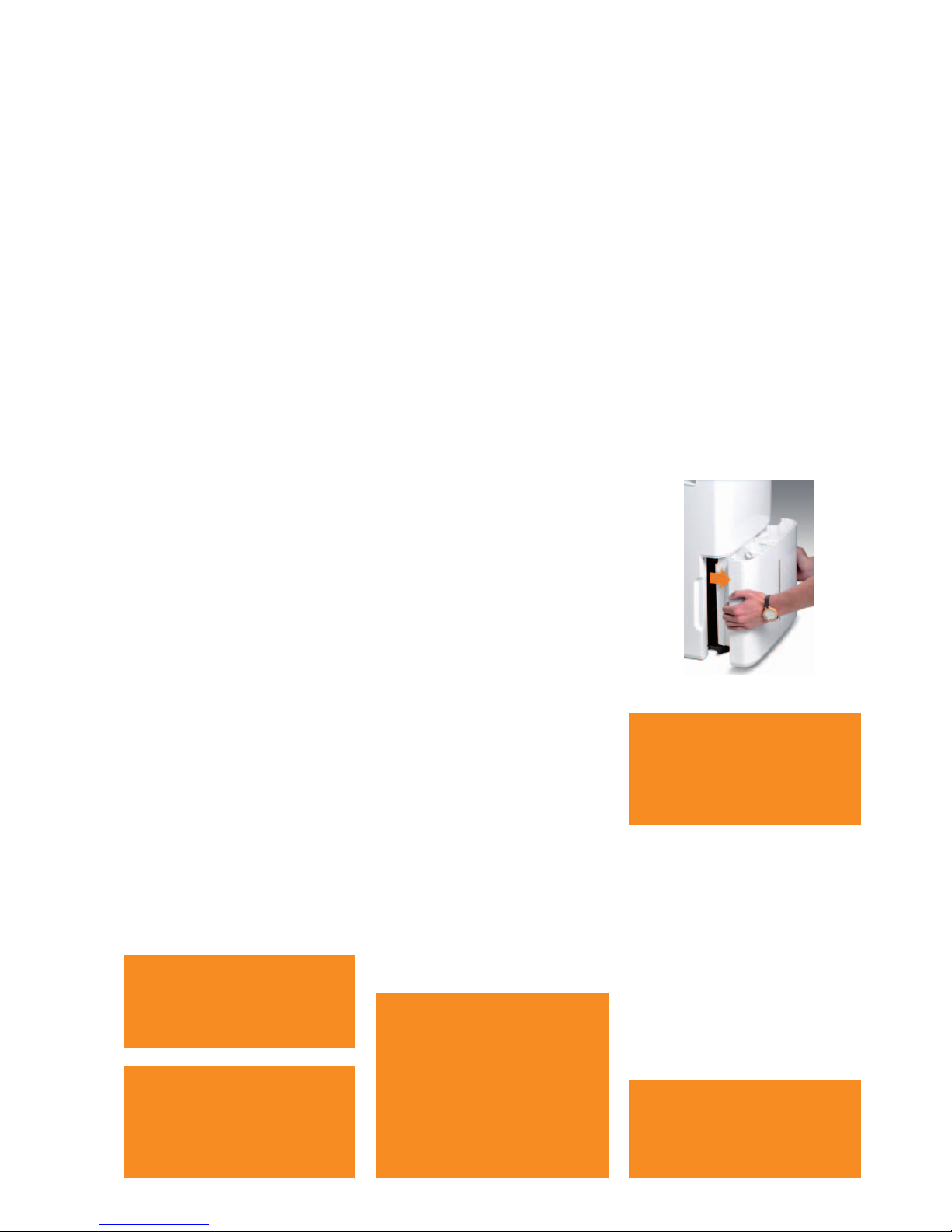

1. Pull the full container forwards

and out carefully.

2. Pour the water into a drain.

3. Re-insert the emptied container

carefully into the unit.

The“BUCKET FULL” indicator light

extinguishes and the unit continues

to run automatically.

NOTE

For economical and technical

reasons, the units must not

be operated at an ambient

temperature below 5 °C.

NOTE

After being emptied, the

condensate container incl. oat

must be checked for damage,

contamination etc.

NOTE

The unit can only be started once

the condensate container has

been inserted correctly.

NOTE

The devices can be switched ON

and OFF via an external timer or

a Smart Home socket if required.

12

CLIMIA

Press the power key once to switch

on the unit.

If the units are inactive for long

periods, disconnect them from the

mains power supply.

Empty the condensate container

completely and dry with a clean

cloth.

Beware of dripping condensate!

The units must be cleaned and

dried completely before storing.

When storing the unit, cover with

a plastic sheet/foil if necessary

andstore in an upright position

inasheltered and dry location.

The units are only permitted to be

stored upright in a suitable storage

location that is protected against

dust and direct sunlight.

Continuous operation with

external condensate outlet

The units are equipped with a

special connection nozzle on the

rear.

A standard 1/2”water hose can be

connected to this.

1. The condensate hose connection

must be switched o rst for this

purpose. The rubber stopper can

then be removed.

2. Pull the condensate hose

connection over a suciently long

and suitable drain hose.

3. Connect the drain hose to the

connection nozzles and tighten the

condensate hose connection by

hand.

In unattended permanent operating

mode, the condensate should

preferably be drained into a lower-

level drain.

If using an external collection

container (pan, bucket, etc.),

theunit must be placed at a correct

height.

10.0 Shutdown

The units are equipped with four

foot rollers and two additional

handles for easy and convenient

transport.

•

Before each change of location,

switch o the unit and remove

the power plug from the mains

socket

•

Empty the condensate bucket

completely.

•

If residual moisture remains on

the evaporator or water remains

in the condensate container, the

units must only be transported in

an upright position

•

The transport rollers are only

suitable for use on level and

smooth ground

•

The units must be carried when

transporting on rough terrain or

uneven surfaces

11.0 Unit transport

CAUTION!

There is no unit overow

protection in this variant.

CAUTION!

Ensure that the drainage hose is

placed at an incline to the drain

to allow the condensate to drain

without hindrance!

NOTE

Beware of dripping condensate.

After switching o the units, the

evaporator may continue to

defrost under the inuence of the

ambient temperature.

CAUTION!

The mains cable must never

be used as a pull cord or xing

device.

13

CTK 240 mobile air dehumidier

All moving parts have a low-

maintenance permanent

coat of lubricant. The entire

refrigerant system is designed as

a maintenance-free, hermetically

sealed system and may only be

repaired by a specialist.

•

Observe the regular care and

maintenance intervals

•

In accordance with the operating

conditions, the units must be

checked as required but at least

yearly by a specialist to ensure

that they are in a condition that

is safe to use

•

Only clean the units with a dry or

damp cloth

Do not use a water jet!

•

Never use abrasive or solvent-

based cleaners

•

Even with heavy contamination,

use only suitable cleaners

•

Check the inlet and outlet grille

for contamination on a regular

basis

Clean or replace if required!

12.0 Care and maintenance

Cleaning the condenser and

evaporator

The unit housing must be opened

to allow the inside of the unit to be

cleaned and to provide access to

electrical components.

•

Clean the condenser and

the evaporator by blowing,

vacuuming or using a soft brush.

Do not use water jets!

•

Clean the interior surfaces on the

units, the condensate traps with

hose connection, the fan and the

fan housing carefully

•

Check all unit components for

damage and repair if necessary

•

Carefully ret all parts that were

removed in reverse order

NOTE

Regular care and maintenance

is fundamental to a long service

life and fault-free operation of

the unit.

CAUTION!

Before undertaking any work on

the units, the power plug must be

removed from the mains socket.

NOTE

Adjustment and maintenance

work may only be carried out

by authorised and qualied

technicians.

NOTE

When cleaning the exchanger,

particular care must be taken

because the ne aluminium ns

bend very easily.

CAUTION!

An electrical safety check must

be carried out in accordance with

VDE0701 after any work on the

units.

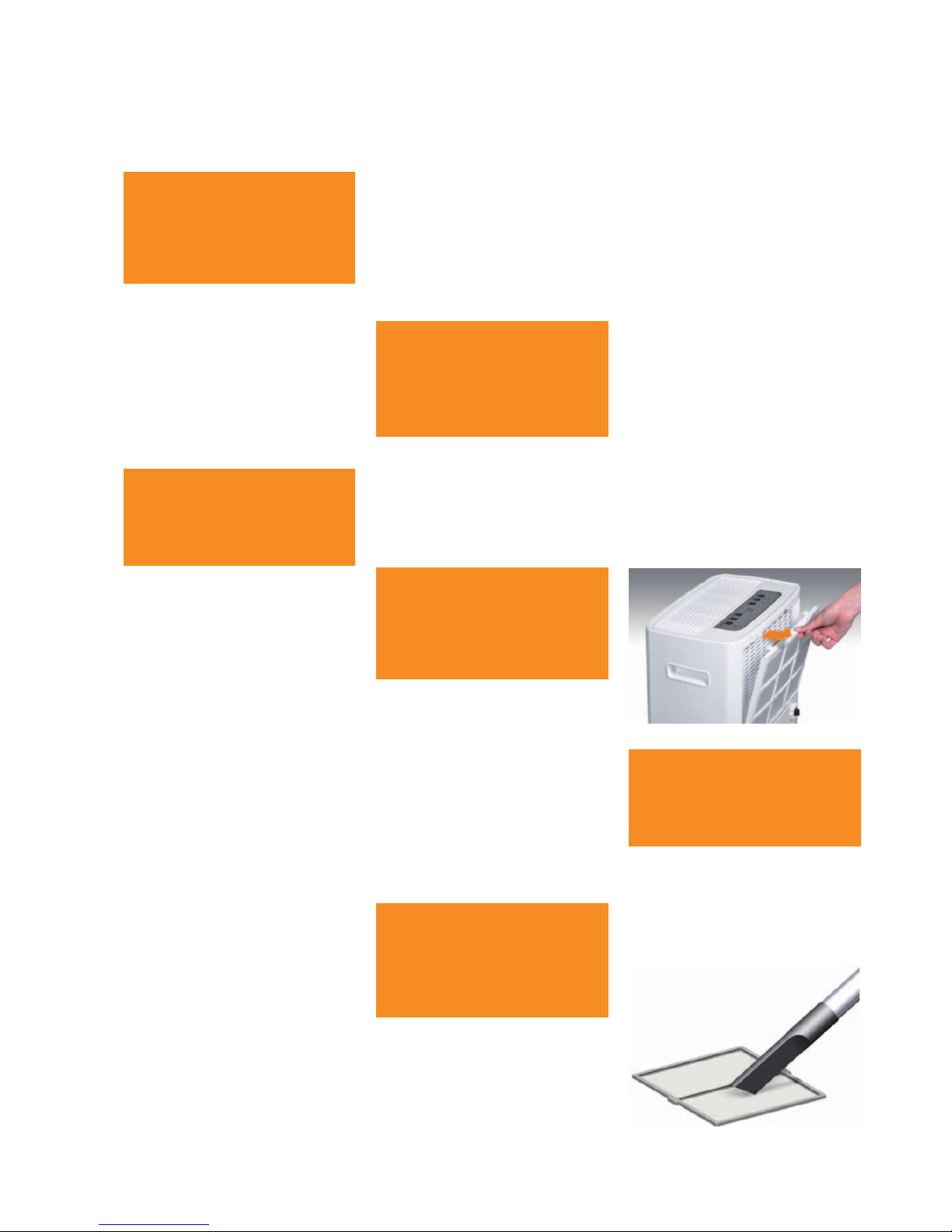

Filter cleaning

To prevent damage to the unit, it is

equipped with an intake grill with

integrated air lter.

In order to prevent power losses

or unit faults, the intake grill with

lter must be inspected as required,

but every 2 weeks at the latest,

andcleaned if necessary.

1. Use the“POWER" key to switch

the unit o.

2. Remove the power plug from the

mains socket.

3. Reach into the recessed grip and

remove the air lter.

4. Clean the air lter with lukewarm

water or a vacuum cleaner.

CAUTION!

The unit is not permitted to be

operated without the air lter

tted!

14

CLIMIA

13. 0

Troubleshooting

The units are manufactured

using state-of-the-art production

methods and tested several times to

verify their correct function.

However, if a functional fault

should occur, the unit should rst

be checked in accordance with the

following list.

5. Heavier contamination may be

remedied by rinsing the lter

in a lukewarm (max. 40°C) soap

solution.

Finally, always rinse the lter

carefully with clear water and

allow to dry!

6. Also check the intake grill for

contamination and clean if

necessary.

7.Before retting grill and lter,

ensure that they are fully dry

and that no damage has been

sustained.

The unit runs but condensate is

not formed:

•

Check the room temperature.

The operating range of the unit is

between 5 °C and 32°C

•

Check the air humidity

min.30%RH required

•

Check the intake grill and air

lter for contamination

Clean or replace if required!

•

Have the heat exchanger ns

checked for contamination

This work requires the unit to

be opened and must therefore

only be carried out by an

authorised specialist company!

The unit is loud or condensate

runs out:

•

Check whether the unit is on

astable and even base

•

Check whether the unit is

standing upright and stably

•

Have the condensate trap or

the connection nozzles checked

to see whether there are dirt

deposits on them

This work requires the unit to

be opened and must therefore

only be carried out by an

authorised specialist company!

NOTE

Heavily contaminated or

damaged air lters must be

replaced with new parts.

Only original spare parts may be

used.

NOTE

Adjustment and maintenance

work may only be carried out

by authorised and qualied

technicians.

The unit does not start:

•

Check the hygrostat’s setting

The set value must be lower

than the relative humidity in the

installation room!

•

Check the power supply and

the power fuse provided by the

customer 230V/1~/50 Hz

•

Check the power plug and the

cable for damage

•

Check the condensate bucket’s ll

level and seating

The “Bucket full” indicator light

must not be illuminated!

•

Check that the microswitch [MS]

on the condensate bucket is

functioning

•

Check that the inlet and outlet

are free Overheating!

•

Check the fuse on the control

board NOTE

The units work with

environmentally-friendly and

ozone-neutral R134a refrigerant.

The mixture of refrigerant and oil

within the unit must be disposed

of properly in accordance

with the statutory or locally-

applicable regulations.

NOTE

If the unit fails to function

correctly after the checks have

been carried out, contact an

authorised specialist.

CAUTION!

Work on the refrigerant system

and on the electrical equipment

must only be conducted by a

specially authorised specialist!

15

CTK 240 mobile air dehumidier

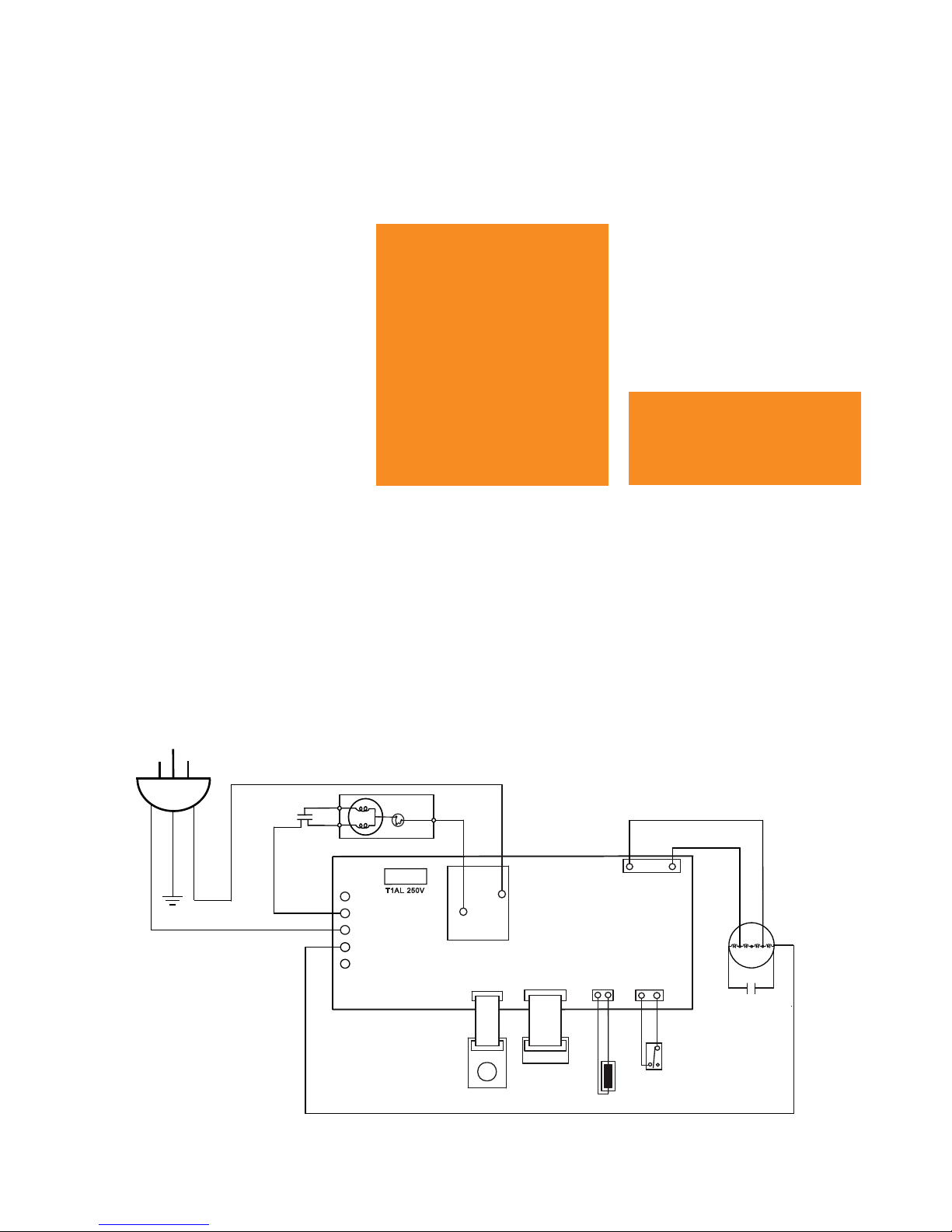

15.0 Electrical wiring diagram

•

The units are operated with

230V / 50 Hz alternating current

•

The electrical connection is

established using a built-in

mains cable with earthed safety

plug

•

Extensions to the connection

cable may only be carried out by

authorised electricians, subject

to the length of the cable,

connected load of the unit and

taking into consideration how

the unit is used at its location

CAUTION!

All cable extensions must only be

used in fully unreeled or reeled

o condition.

NOTE

The electrical connection to the

units must be made at feedpoints

with residual current devices

in accordance with VDE 0100,

Section 704.

When installing the units in

extremely damp environments

such as laundry rooms, showers

etc., the unit must secured

with aresidual current device

provided by the customer in

accordance with the regulations.

14. 0 Electrical wiring

CN 1

NO

HUMIDITY SENSOR /

HYGROSTAT

COM.

CN 3

L

L

N

E

CN 4

CN 2

CN 1

POWER SUPPLY

T1AL 250V

H

COMPRESSOR

OLP

CN 7

N

N

P6

P3

P4

P5

TEMPERATURE PROBE

SWITCH

FAN

MOTOR

CONDENSER

CONDENSER

CONTROL BOARD

FUSE

BLUE

BLUE

BLUE

YELLOW / GREEN

BROWN

WHITE

RED

YELLOW

RED

BLUE

WHITE

BLACK

16

CLIMIA

16.0 General view of unit

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

2

1

4

3

5

6

7

8

10

11

12

37

3

32

31

30

26

47

45

44

43

41

39

38

49

50

51

9

46

40

42

16

33

21

13

23

24

22

17

CTK 240 mobile air dehumidier

17.0 Spare parts list

When ordering spare parts, please always state the EDP no. and unit number (see name plate)!

No. Designation EDP no.

1 Floor pan

2 Conveyor rollers

3 Compressor, cpl.

4 Vibration dampers

5 Suction pipe

6 Drain line

7 Centre wall

8 Condensate trap

9 Evaporator, complete.

10 Condenser, complete.

11 Capillary

12 Y-pipe

13 Condenser, (for compressor), complete)

16 Microswitch

21 Condensate trap cover

22 Fan housing

23 Fan wheel

24 Fan motor

26 Distribution block

30 Control board

31 Conductor board / board

32 Probe (evaporator/EVAP)

33 Hygrostat

34 Condenser (fan motor)

37 Mains cable with plug

38 Front wall

39 Back wall

40 Transport handle

41 Top cover

42 Intake grill

43 Air lter

44 Condensate bucket cover

45 Condensate container

46 Float, cpl.

47 Transport handle (condensate bucket)

49 Rubber stopper

50 Condensate hose connection

51 Control panel

18

CLIMIA

18.0 Technical data

1) Contains greenhouse gas according to Kyoto protocol

2) Noise level measurement DIN 45635 - 01 - KL 3

Series CTK 240

Operating range, temperature °C 5 to 32

Operating range, humidity % RH 30 to 90

Dehumidication capacity max. l/day 30

At 27 °C/60 % RH l/day 18

Fan stages 2

Max. airow volume m3/h 240/186

Condensate container capacity Litres 6.3

Refrigerant 1) --- R134A

Refrigerant quantity g 200

Power supply V/~/Hz 230/1/50

Max. rated current consumption A 4.1

Max. power consumption kW 0.57

Sound pressure level LpA 1m 2) dB (A) 46/41

Dimensions

Depth mm 272

Width mm 384

Height mm 610

Weight kg 17

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

19

CTK 240 mobile air dehumidier

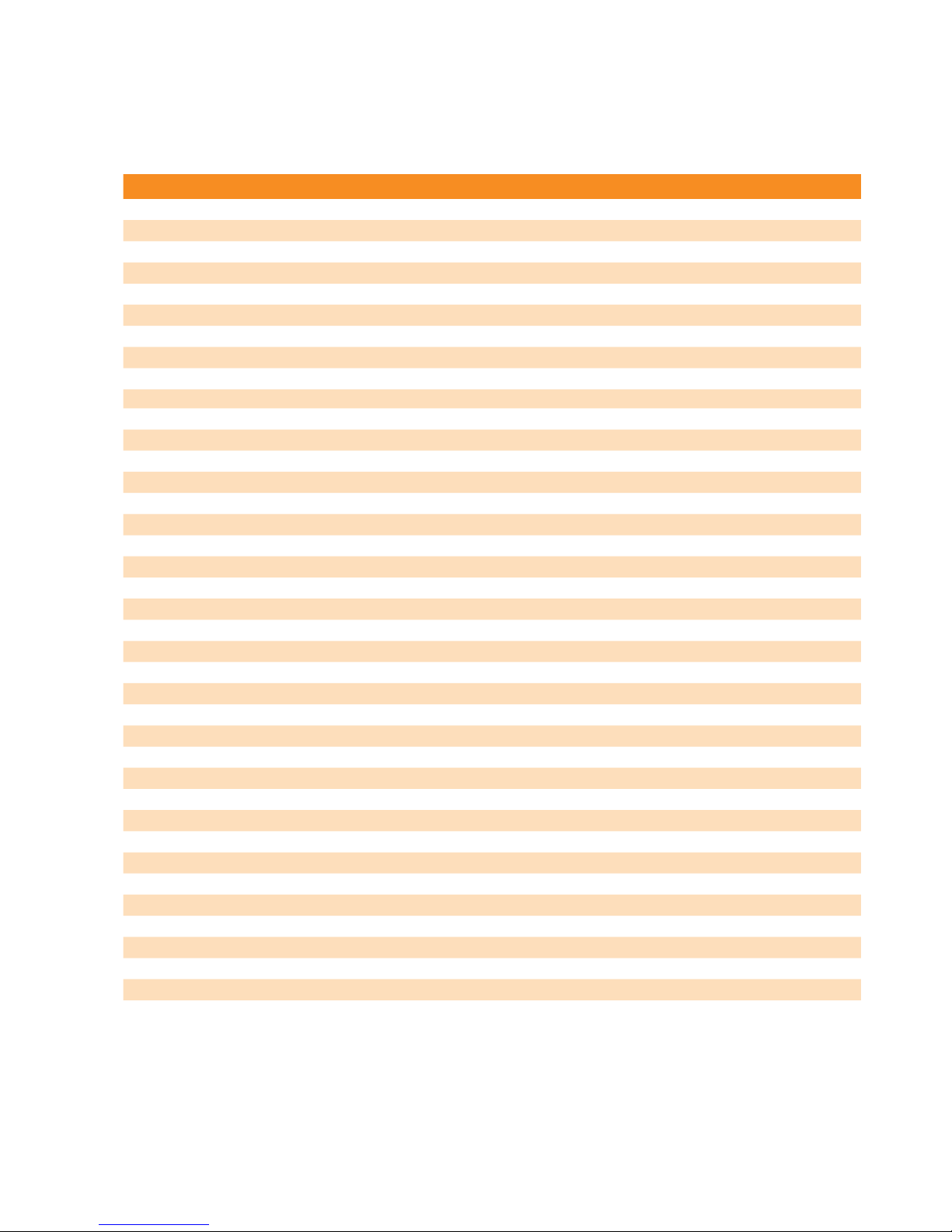

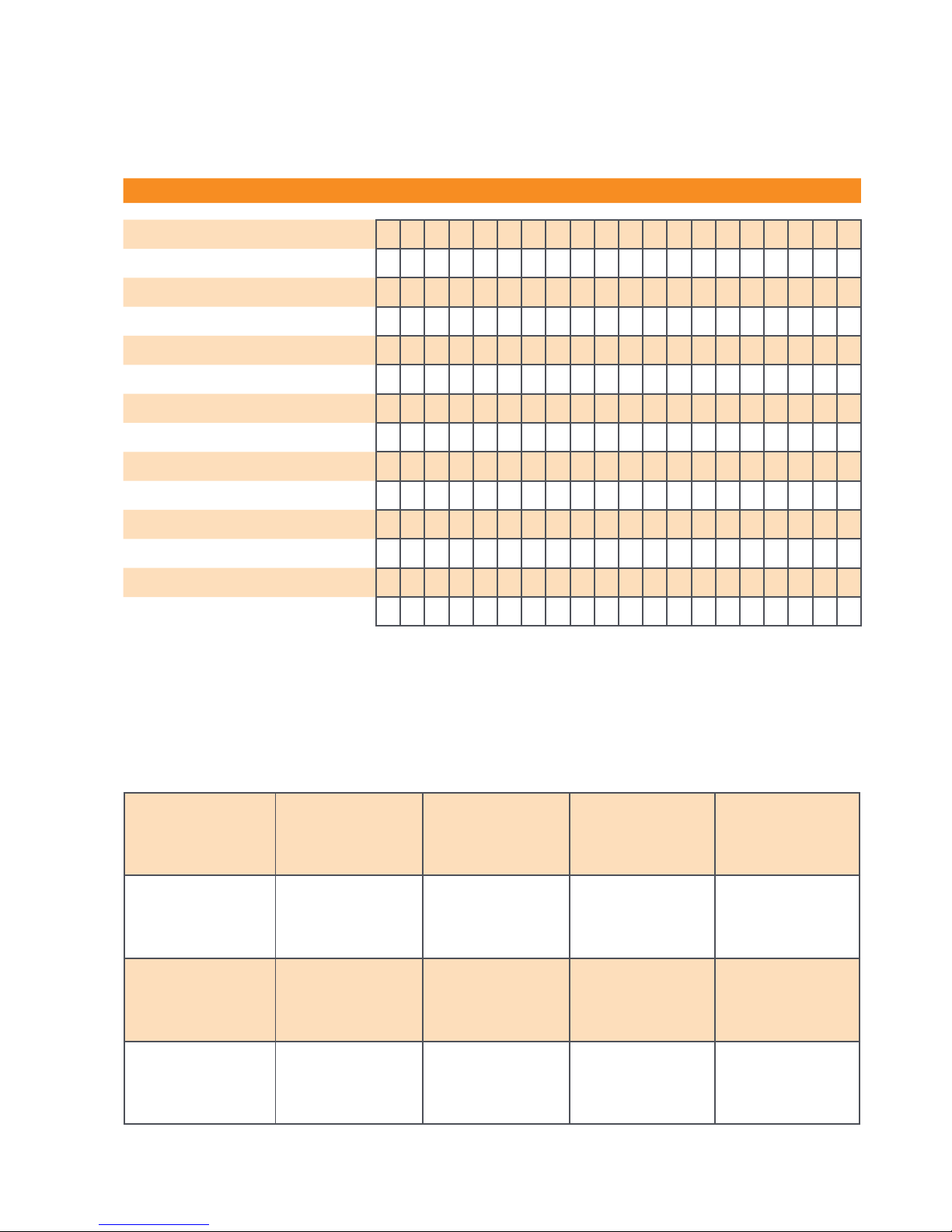

19.0 Maintenance log

Unit to be maintained only by authorised specialists in accordance with the statutory regulations.

✍

Unit type: .................................. Unit number: ...................................

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Unit cleaned - outside -

Unit cleaned - inside -

Fan blade cleaned

Fan housing cleaned

Condenser cleaned

Evaporator cleaned

Fan function checked

Air-inlet grid with lter cleaned

Unit checked for damage

Safety devices checked

All fastening screws checked

Electrical safety check

Test run

1. Date: ..............

..............................

Signature

2. Date: ..............

..............................

Signature

3. Date: ..............

..............................

Signature

4. Date: ..............

..............................

Signature

5. Date: ..............

..............................

Signature

6. Date: ..............

..............................

Signature

7. Date: ..............

..............................

Signature

8. Date: ..............

..............................

Signature

9. Date: ..............

..............................

Signature

10. Date: ............

..............................

Signature

11. Date: ............

..............................

Signature

12. Date: ............

..............................

Signature

13. Date: ............

..............................

Signature

14. Date: ............

..............................

Signature

15. Date: ............

..............................

Signature

16. Date: ............

..............................

Signature

17. Date: ............

..............................

Signature

18. Date: ............

..............................

Signature

19. Date: ............

..............................

Signature

20. Date: ............

..............................

Signature

Comments: .....................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

20

CLIMIA

EC – Declaration of Conformity

Original Declaration of Conformity

We do hereby declare that the units named below, produced and sold by us, satisfy the relevant basic requirements

of the EC Directives, the EC safety standards and other product-specic EC standards.

Name of Manufacturer: Intakt GmbH

Climia - Air conditioning and heating technology

Niemeierstraße 13

D - 32758 Detmold, Germany

Name of the CE representative: Intakt GmbH

Climia - Air conditioning and heating technology

Niemeierstraße 13

D - 32758 Detmold, Germany

Unit (machinery) model: Air dehumidier

Series/ Class: CLIMIA CTK 240

Series/ Class Number: 1803...

Delegated regulations (EU): 2011/65/EU:2011

2014/30/EU:2014

2014/35/EU:2014

Applicable standards: DIN EN 12102-1:2018

DIN EN 55014-1:2017; DIN EN 55014-2:2015

DIN EN 60335-1:2012; DIN EN 60335-2-40:2014

DIN EN 61000-3-2:2015; DIN EN 61000-3-3:2014

DIN EN 62233:2008

Detmold, 19th June 2018 Intakt GmbH

................................................................

Managing Director’s signature

Table of contents

Other CLIMIA Dehumidifier manuals