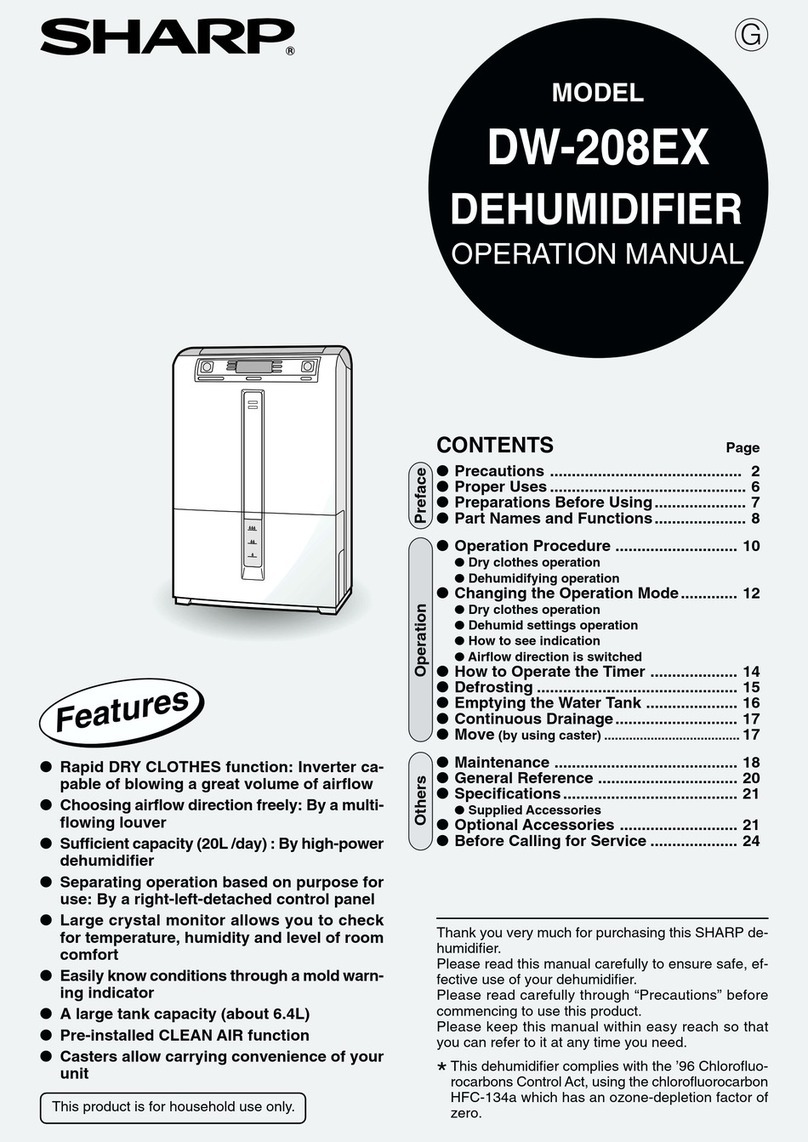

Caution symbols

Symbols are used throughout this manual to indicate the effects of negligence and improper

use. Please pay attention and read this section carefully.

Warning

Negligence could result in death or serious injures.

Attention

Negligence could result in serious injuries or loss of properties

Meaning of the

symbols EXTRA CAUTION needed.

Actions not allowed to take.

Actions that you have to take.

Keep this handy and make sure to read the safety precaution before using the dehumidifier.

When installing Attention

Important

Do not operate the unit in a closet or in a narrow space

between furniture.

Insufficient ventilation can result in overheating or combustion.

Do not install the unit at locations where it is exposed to water splashes.

This can cause electric shock or fire.

Do not install the unit at locations where oil or combustible gas leakage can

occur.

Leaked oil or gas near the unit can cause fire.

Donotputavesselcontainingwatersuchasvaseontheunit.

Dripped water on the unit can lower the rate of electric insulation,

resulting in electric shock, electrical leakage or fire.

This unit is for in-door use only. Do not install it at locations

where it is exposed to direct sunlight, rain or wind.

This can cause overheating, electric shock, electrical leakage or fire.

Do not use this unit for storage of things that require strict temperature control

such as art works or academic materials.

This can lower the quality of the stored items.

Should the supply cord be damaged, it must be replaced by

a service center approved by Sharp as special tool are

required.

This equipment complies with the requirements of

Directives 89/336/EEC and 73/23/EEC as amended by 93/

68/EEC.