CONTENTS

1 Safety Information ........................................................................................................................................................................................1

1.1 Markings and Symbols ........................................................................................................................................................................2

1.2 Dryer Model Number Identification.....................................................................................................................................................2

2 Description ....................................................................................................................................................................................................3

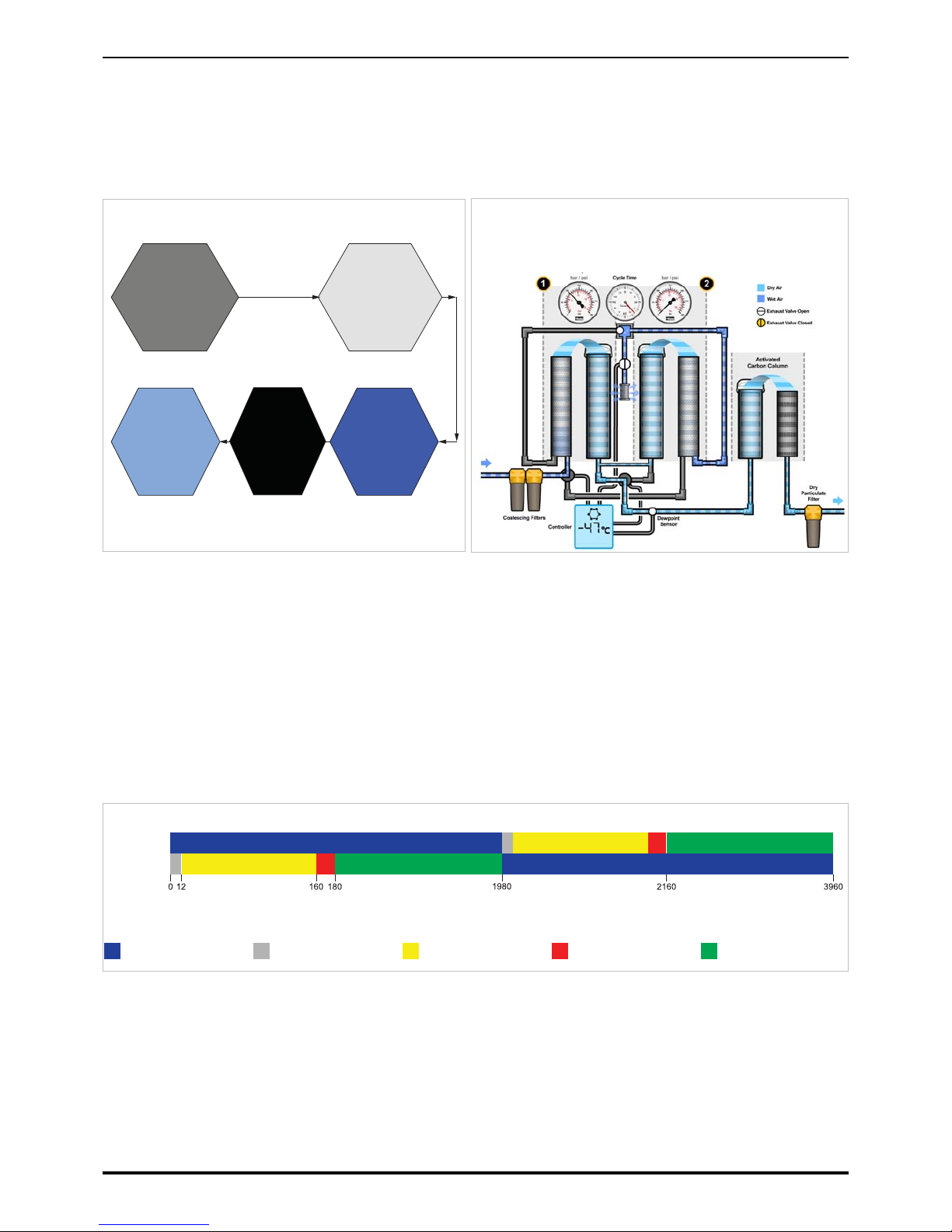

2.1 Overview of Operation .........................................................................................................................................................................3

2.1.1 Operation......................................................................................................................................................................................3

2.2 EST - Energy Saving Technology .......................................................................................................................................................4

2.3 Moisture Over-ride................................................................................................................................................................................5

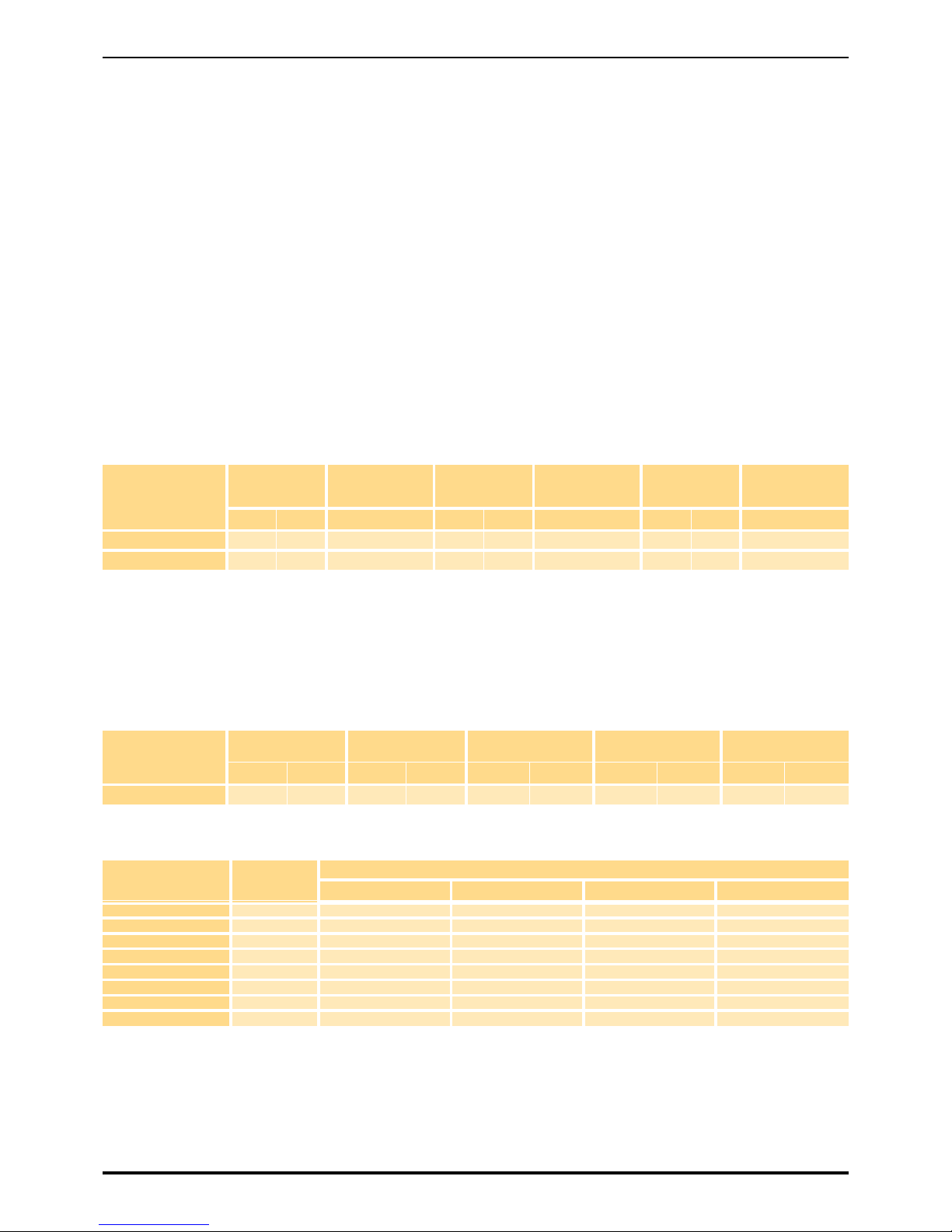

2.4 Technical Specification........................................................................................................................................................................5

2.5 Approvals Compliance and Exemptions............................................................................................................................................7

2.5.1 Approvals .....................................................................................................................................................................................7

2.5.2 3rd Party Performance Verification ..............................................................................................................................................7

2.6 Weights and Dimensions.....................................................................................................................................................................8

2.7 Receiving and Inspecting the Equipment ........................................................................................................................................10

2.7.1 Storage.......................................................................................................................................................................................10

2.7.2 Unpacking ..................................................................................................................................................................................10

2.8 Overview of the equipment................................................................................................................................................................11

3 Installation and Commissioning................................................................................................................................................................13

3.1 Commissioning Check List ...............................................................................................................................................................13

3.2 Recommended System Layout .........................................................................................................................................................14

3.3 Locating the Equipment.....................................................................................................................................................................15

3.3.1 Environment ...............................................................................................................................................................................15

3.3.2 Space Requirements..................................................................................................................................................................15

3.4 Mechanical Installation ......................................................................................................................................................................15

3.4.1 General Requirements ...............................................................................................................................................................15

3.4.2 Securing the Dryer .....................................................................................................................................................................16

3.4.3 Attach the Exhaust Silencer .......................................................................................................................................................16

3.4.4 Purge Settings............................................................................................................................................................................16

3.5 Electrical Installation..........................................................................................................................................................................17

3.5.1 Dryer Supply...............................................................................................................................................................................17

3.5.2 Dryer Auxilliary Connections ......................................................................................................................................................17

3.5.3 Remote Alarm Connection .........................................................................................................................................................18

3.5.4 Remote Start / Stop (Standby) ...................................................................................................................................................18

3.5.5 Purge Economy..........................................................................................................................................................................19

3.5.6 Dewpoint Selection / Alarm Values ............................................................................................................................................19

3.5.7 Temperature Units......................................................................................................................................................................20

3.5.8 Configuring Inlet Valves .............................................................................................................................................................21

3.6 First Time Start Up .............................................................................................................................................................................21

4 Operating the Dryer ....................................................................................................................................................................................22

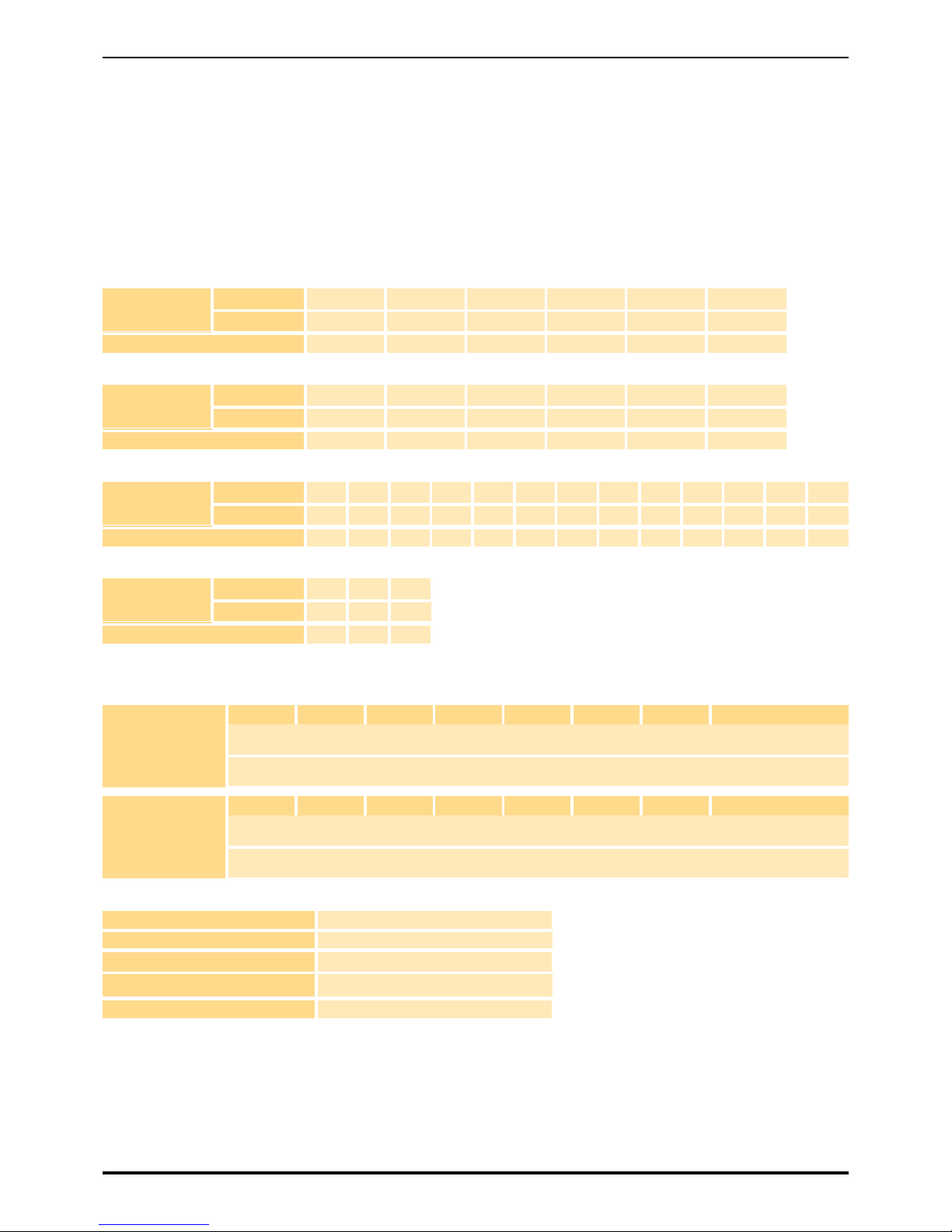

4.1 Displays and Indicators .....................................................................................................................................................................22

4.1.1 Column Status Indicators ...........................................................................................................................................................22

4.1.2 Status and Warning Indicators ...................................................................................................................................................23

4.2 Starting the equipment ......................................................................................................................................................................24

4.3 Dryer Shutdown..................................................................................................................................................................................24

5 Servicing......................................................................................................................................................................................................25

5.1 Service intervals ................................................................................................................................................................................25

6 Troubleshooting..........................................................................................................................................................................................29

6.1 Dewpoint Failure.................................................................................................................................................................................29

6.2 High Pressure drop ............................................................................................................................................................................30

6.3 Downstream air supply interrupted ..................................................................................................................................................30

7 Declaration of Conformity..........................................................................................................................................................................31

8 Schematics..................................................................................................................................................................................................32