Clinton 350 Series User manual

~

©l!aLt~~®~

~

2

CrCLE

ENGINE

MARK

HOME OF

CLINTON MACHINE COMPANY

MAQUOKETA,

IOWA

_

TAB

LE

0 F

CON

TEN

TS c-

S U B JE C T PAGE NO.

FACTS-About

Your 2·Cycle Engine 3

,4

FUEL-For Clinton 2.Cycle Engines 5

STARTING-Check

list

and

Instructions 6

MAINTENANCE-Adjustments 7

Carburet

ion 7

Governor

8

Magneto

, Condenser, Coil 9

Valves 9, 10

SERVICE-REPAIRS 4, 11

TROUBLE CHART 12, 13

ACCESSORIES _ 14, 15

WARRANTY

16

2

FACTS

ABOUT

YOUR

NEW

CLINTON

2

CYCLE

ENGINE

TYPES

OF ENGINES

There are two basic types of small air

cooled gasoline engines, those operating

on four stroke cycle (commonly referred

to as four cycle) and those operating on

a two stroke cycle (commonly referred to

as two cycle) . The principal difference

between the above types is the number of

power strokes or the number of times the

engine fires for each revolution of the

crankshaft.

The

four cycle engine has a

power stroke or "fires" every other com-

plete revolution of the crankshaft, while

the two cycle has a power stroke on every

complete revolution of the crankshaft. An-

other basic difference is in the method of

lubrication.

The

four cycle engine retai ns

a reservoir of oil in the crankcase, and dis-

tributes this oil throughout the moving

parts

'of

the engine by means of a

pump

or dip finger.

The

two cycle engine is lu-

bricated solely by the correct amount of

SAE

#30

Motor oil

(Mineral)

mixed

with the Gasoline.

The

gasoline and oil

mixture is compressed and forced through-

Out the crankcase and combustion area of

the engine. Thus the oil content of the

fuel mixture lubricates the moving parts

of the engine. Your Clinton Engine is the

two cycle type, and therefore, the discus-

sion in this manual will pertain only to

this type of engine.

THE

TWO

CYCLE

PRINCIPLE

In your Clinton two cycle engine, the

piston acts as both an intake and exhaust

valve- Assume that the cylinder is filled

with a mixture of air and fuel, and the

piston is at the bottom of its stroke. As

the crankshaft revolves the piston rises,

and the mixture of air and fuel is then

compressed in the combustion chamber.

Whe

n the piston is near its highest point,

GENERAL VIEW

the 'compressed mixture is

then

ignited,

which forces the piston to descend and

gives the power stroke.

During

this up-

ward stroke of the piston a vaccum is

created in the crankcase which draws a

fresh mixture of fuel and air through the

reed valve into the crankcase

(the

crank-

case being an air tight casting containing

the crankshaft and connecting rod assern-

blies.)

With

the downward stroke of the

piston, the charge is compressed in the

crankcase. As the piston approaches the

bottom of its stroke, its movement un-

covers the exhaust port, through which

the burnt gases escape from the combus-

tion chamber, which immediately causes

the pressure within the chamber to fall.

As the piston continues its downward

motion, it then uncovers an inlet port

and a fresh charge of air and fuel forces

its way into the combustion chamber from

the crankcase. This incoming fresh charge

of fuel pushes the remainder of the burnt

gases out through the exhaust pOrt. A pro-

jection on the top of the piston deflects

the fresh charge and prevents it from

passing directly across the cylinder and

out the exhaust port.

3

PRECISION BUILT

Your Clinton Engine has been preci-

sion built and specifically engineered to

the purpose of your equipment.

It

has

been carefully inspected throughout all

phases of its production and assembly by

men who are devoting their lives to the

production of fine air cooled gasoline en-

gines. Your Clinton is the finest two cycle

gasoline engine of its type that money

can buy.

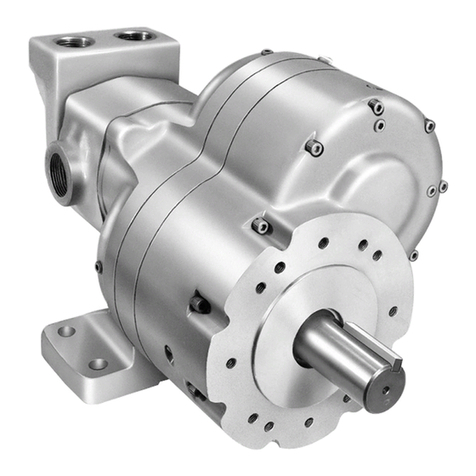

CARBURETION

The carburetor (see Fig. No

.1)

on

your engine is of the latest design, engi-

neered and, calibrated exactly for your en-

gine to assure you of the best possible

performance and efficiency. The standard

float-type carburetor or the economy suc-

tion-type, may be selected for use on your

engine, depending upon the rnanufacrurer

of your equipment and

/or

the engine ap-

plication.

IGNITION

The magneto used on your Clinton

(see Fig.

,No.7)

is a flywheel type which

produces high voltage at cranking speeds

to insure easy starting. This magneto gives

positive protection from dirt, dust and

moisture accumulating in the magneto

and assures trouble-free performance in

starting your Clinton when it is subjected

to high humidity and dusty conditions

COOLING

An air blast created by the rotation of

the finned flywheel is directed over the

cooling fins on the cylinder block and

head. This results in an exceptionally cool

running engine.

LUBRICATION

The oil (SAE

#30

motor oil-mineral),

which is combined with gasoline in the

proper amount in the fuel mixture (see

"Fuel Preparation for Clinton 2-Cycle

Engines") , is distributed to the bearings

and moving parts of the engine requiring

lubrication. Since clean fresh oil is being

continuously supplied to the engine in

the fuel mixture, there is no necessity for

re-circulation of used oil. After the oil in

the fuel is once used for lubrication, it is

immediately burned up in the combustion

chamber and discharged through the ex-

haust pOrt.

GOVERNOR

Your Clinton engine is equipped with

a positive automatic

(air

controlled ) gov-

ernor which insures a controlled and con-

stant speed under all operating condi-

tions. The governor allows the engine

to

operate at the same speed with or without

the load to which the engine is being sub-

jected. The engine speed will not exceed

the predetermined setting". This means

that your engine will always operate at

the proper speed and will not run "wild,"

resulting in less wear and fewer repairs.

SERVICING FACILITIES FOR YOUR CLINTON ENGINE

If your

engine

requires

expert

adjusting

and

repair

service,

contact

your

local factory

approved

Clinton

authorized

service station, which you will find

listed in the classified section of

your

telephone

directory

under

"Engines-Gasoline."

You may also

refer

to the

authorized

service directory

that

comes with

your

en-

gine. It lists

the

more

than

3500

authorized

service stations -

deale

rs who

carry

a

complete

stock of genuine

replacement

parts

and

a re

factory

trained

to give

you

the

best possible service for your engine.

Only

the listed factory

approved

service stations a re a uthori

zed

to perform

warranty

repairs

and

adjustments.

4

ENGINE SPEED

ADJUSTMENT SCREW

~---

FUEl TANK -

(SEE INSTRUCTIONS

ON

OTHER SIDE FOR

FUEl MIXTURE)

CHOKE LEVER

POSITIONS RUN

HIGH SPEED

NEEDLE VALVE

CARBURETOR CHOKE

.a

ADJUSTMENTS

FOR YOUR

CLINTON

2·CYCLE

GASOLINE

ENGINE

FIGURE

No.

1

FUEL

PREPARATION

FOR

CLINTON

TWO·CYCLE

ENGINES

Your

Clinton

2·cycle

engine

is

built

to give you years of

trouble-free performance, if

properly

used

and

cared for.

A very

important

point

is fuel

mixture

and

lubrication.

By carefully following

the

instructions below, you

will

have

long

and

dependable

service from

your

Clinton

2-cycle en-

gine.

DO

NOT

POUR

UNMIXED

GASOLINE

OR

OIL

INTO

THE

FUEL

TANK.

TYPE

OF OIL MIXING RATIO OF OIL TO GASOLINE

Use'SAE # 30 motor oil f-mineral), For the first five hours of operation

such as Mobiloil, or a comparable straight mix % of a pint of oil with each gallon

mineral oil. DO

NOT

USE A DETER· of gasoline. Thereafter reduce the quan-

GENT OIL OR AN OIL CONTAINING tities of oil to

Y:2

pint to each gallon of

ADDITIVES. gasoline.

TYPE

OF GASOLINE

CAUTION

Use a good grade of regular gasoline

that is available at your local filling sta-

Do

not

start

a

new

engine

before

tion. High ocraine or leaded fuels will you

make

a

thorough

visual check for

give no advantage and are

NOT

rec- dents or

oth

er

damage

which

might

ommended. IT IS RECOMMENDED interfere

with

the

moving

parts of

the

THAT

ALL GASOLINE BE POURED

engine

and

which

might

be covered by

THROUGH

A FINE MESH STRAINER

TO REMOVE

ANY

WATER OR

DIRT

.

Warranties.

(See following

page

...

)

5

CAUTION

BEFORE

STARTING

A quick visual inspection of your en-

gine is recommended before you atte

mpt

[()operate it. Inspect for possible damages

that may have occurred

dur

ing shipment

and handling. Examine the blower hous-

ing and shrouds for possible dents or dis-

rorrions that may interfere with the mov-

ing parts , Check the gas line and fuel sys-

tem .

to

be sure that they are properly

intact; the spark plug high tension lead is

securely fastened

to

the spark plug termi-

nal, air cleaner is securely fastened so as

to

properly filter the air. Be sure the

engine is firmly mounted

to

the equip-

ment so as not

to

create any vibration

when the engine is operated.

STARTING

INSTRUCTIONS

1.Make sure you have a sufficient supply

of fuel mixture in gas tank.

2.Open stop cock on bottom of gas tank.

3. Adjust speed

COntrol

lever

to

position

the lever toward the spark plug which

will give approximately one-half throt-

tle opening of the carbure tor.

4.

Turn

choke lever on the carburetor into

choke position

...

horizontal.

5.

If

your engine is equipped

with

a tog-

gle shut-off switch, turn switch

to

"on"

position before cranking.

6.Crank engine by use of rope starter

(s

ee

Fig.

No

.2)

, or recoil

(au

tomatic re-

tractable) starter (see Fig. No. 3).

(Pull rope with a quick

but

steady pull

in order

to

prevent any possibility of

the rope fouling on the engine st

art

er

pulley.)

7. After engine has started, release choke

gradually to vertical position.

8. Allow engine to run at approximately

half throttle for a period of one

minute

,

thus giving your engi ne an opportunity

to establish uniform temperature and

pressure throughout.

9.Set speed adjustment screw (see Fig.

No

.1

) to position throttle control lever

for desired operating speed.

The

gov-

ern

or will then maintain a constant

speed' and will automatically compen-

sate for any engine loads that your

equipment may be subjected to during

operation. You may reset the speed ad-

justment screw, whenever it is neces-

sary, for a heavier or lighter work

load.

The

governor will then maintain

the selected speed at all times.

FIGURE

No.2

FIGURE

No

.3

6

STOPPING

INSTRUCTIO~S

,

The engine may be sropped in one of

two manners depending upon the equip-

ment found on your particular engine.

1. Press shorting clip firmly against

the

rop of the spark plug terminal until

engine has completely sropped running.

(There

is no danger of the operator

being shocked as long as the clip is

held firmly against the spark plug ter-

minal.)

-MAl

NTE

NA

NC

E

AND

ADJ

US

TMENTS

FI

GU

RENo. 4

2.

If

engine is equipped with switch, move

switch

to

"off" position.

MAGNETO

COIL

HIGH

SPEED

NEEDLE VALVE

I

BREAKER

POINT COVER

t BEARING PLATE

Giil--:;

';"'---i

GOV

ERNOR AIR VANE

AND

SPR

ING ASSY.

--

--

..:

'\:'-

_..

~

fl

YWHE

el

SCRE

EN - . . . .. .

STARTING ROPE PULLEY t

F

IGURE

No. 5

CARBURETOR-POWER RANGE

ADJUSTMENT (Flout Type Carburetor)

Start your engine and let it run a few

minutes until the engine has acquired uni-

form temperature and pressvre. Then

open throttle about 1

/3

to

give about

2/3

of the full speed of the engine. Slowly

turn the needle valve (see Fig. No

.1)

clockwise until engine begins

to

lose

speed.

The

n turn the needle in the oppo-

sire direction until the engine begins

to

accelerate. The leanest mixture between

these two points will allow a satisfactory

acceleration and steady governor action.

This will give the proper adjustment.

(Clockwise movement of needle will lean

mixture; coumer clockwise .rnovement

will richen mixrure.)

IDLE M

IXTURE

ADJUSTMENT

This adjustment is made, following the

power range adjustment, with

the

engine

7

idling at approximately 2200 r.p.m.'s.

Slowly turn the idle adjusting needle

clockwise until the engine begins to miss

or lose speed. Then turn needle in counter

clockwise direction until the engine 'runs

smoothly again. The point at which the

engine is running smoothly will deter-

mine the proper setting.

flOODING

(Excessive fuel mixture

in combustion

chamber)

This condition can be created by over-

choking, tipping the engine to an extreme

forward angle or cranking a hot engine

with the use of the choke which may

cause

toO

much fuel to be drawn into the

crankcase and combustion chamber. The

fuel mixture therefore becomes too rich

for combustion. Also it may be possible

that the shut-off needle in the carburetor

does not seat properly and allows the fuel

to flowunrestricted into the crankcase. To

correct-turn

shut-off cock to "off" posi-

tion under fuel tank, continue to crank

the engine until it starts and re-open shut

off cock fuel valve under fuel tank.

If

the

carburetor continues to overflow with

fuel after the ' engine has started, gently

tap the body of the carburetor which will

usually unseat the needle if it should be

temporarily stuck. The disassembly and

cleaning may be necessary to correct this

condition if not remedied by above

method. Extreme cases of flooding occur

when the engine has been allowed to

stand with the spark plug in a downward

position causing a large quantity of .fuel

to run into the crankcase and combustion

chamber.

If

this occurs, remove the spark

plug and drain the fuel from the combus-

tion chamber, because you will not be

able to turn the engine over by hand with

a large amount of fuel in the combustion

chamber.

Wipe

spark plug terminals dry

with a rag.

(Be

sure to tighten spark plug

sufficiently to eliminate the danger of a

compression leakage around the plug.)

ENGINE

SPEED

ADJUSTMENT

SCREW

---

-

--

REMOTE

CON

TROL

CABLE

LINKAGE FORTIlLOTSON

CARBU

RETOR

SHOWN TOP VIEW (WITH Fl

FIGURE

GOV

ERNOR (Pneum

atic

or

air

velocity type)

Whe

n the governor is operating prop-

erly, the air vane will be activated by an

air stream created from the finned fly-

wheel in the blower housing. The forces

of the air against the air vane are counter-

balanced by the tension created by a cali-

brated governor spring. Loss of engine

speed will decrease the air velocity against

the air vane and allow the air vane to be

moved counter-clockwiseby the calibrated

governor spring tension which will open

the throttle on the carburetor to imme-

diately restore the engine speed to the

constant governor setting. The opposite

is true when the engine increases speed.

The

air blast is immediately increased

against the air vane and forces the air

vane clockwise which in turn closes the

throttle in the carburetor to reduce the

engine speed thus created, and maintain a

constant setting of the speed on the en-

gine at all times. To insure proper opera-

tion, the governor spring must be free to

move. The linkage connecting the air

vane and carburetor must be free from

dirt deposits so as not to disturb the bal-

8

vERNOR LINKAGE

(WHEEL REMOVED)

INSTALLATION FOR CARTER

CARBURETOR

No.6

ance between the air vane ,and ·the cali-

brated governor spring.

The

cleaning of

the air vane and the lever 'linkage is ac-

cessible when the blower housing is re-

moved.

The governor normally requires very

little servicing unless the engine has been

exposed to very dusty and dirty operating

conditions ' that may cause an excessive

amount of dirt to be sucked in through

the blower housing and deposited on the

moving partS of the governor linkage

within the blower housing.

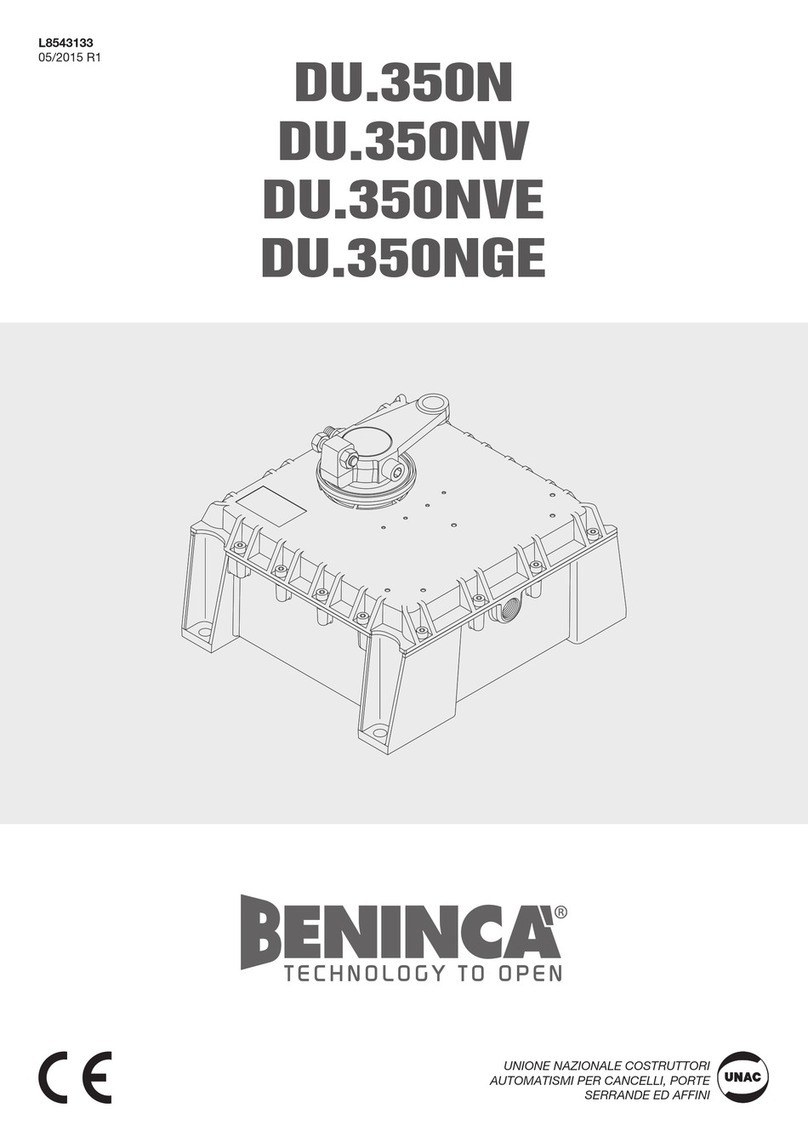

MAGN

ETO

ASSEMBLY

(Flywheel Type)

The

magneto assembly is readily acces-

sible by removing the blower housing,

flywheel, and breaker point dust cover.

Removal of these parts makes it very easy

/ to check the breaker

point

setting and do

any cleaning that may befound necessary

in the entire magneto assembly (see Fig.

No.7).

BREAKER

POINTS

The breaker point clearance gap can be

easily adjusted by the removal of

the

dust cover from

the'

point assembly.

9

This gap should beadjusted with a feeler

gauge at .018 to .020 of an inch (see Fig.

No

.7)

.

CONDENSER

It

is generally advised to replace the

condenser whenever the contact points

show signs of pitting or oxidation. The

condenser has a capacity of 13 mfd and

should be tested for capacity, resistance,

and leakage whenever magneto difficulty

is experienced (see Fig.

No.7).

COIL

Check the terminal connections from

the coil (see Fig. No. 7.) for good con-

MAGNETO

HIGH TENSION

COIL ILEAD

t

..

SPARK

~~-PLUG

~

--CONDENSER

BEARING

-PLATE

tl?1.

BREAKER

POINTS

FIGURE

No.7

tact

and proper insulation. Coil windings

will not normally give difficulty unless

mechanical damage has been experienced.

A check for possible grounds within the

coil is easily identified by the use of a

conduity meter-,

SPARK

PLUG

A clean spark plug contributes to easy

starting, economy of operation, and maxi-

mum power..

When

the spark plug be-

comes fouled, replace with new plug,

rather than attempting

to

reclaim the used

plug through various cleaning methods.

Replace with either Champion

H-ll

or

Auto Lite AL7. Adjust gap of plug

to

.025 of an inch.

CLEANING OF VALVE

PORTS-

EXHAUST

The only service required to the valve

ports is an occasional cleaning to remove

carbon deposits. Remove muffler assembly

from engine (see Fig.

No.8)

which will

expose the exhaust valve ports and clean

with suitable instrument capable of scrap-

ing and removing the carbon deposits

within these ports, The engine should be

turned over by hand until piston moves

below the POrt openings which will al-

low greater access for the cleaning of these

parts. (Care should be taken so as not to

damage or score the porr when cleaning.)

FIG

UREN

o.

8

CLEANING OF VALVE PORTS- INTAKE

To clean the intake portS (see Fig.

No

.9)

, it is necessary to remove the

bearing plate assembly which will then

expose these ports for easy cleaning. The

cleaning of these

POrtS

will be accom-

plished in the same manner as described

in the cleaning of the exhaust valve pOrts.

The intake ports will normally require

very little servicing.

FIGURE

No.9

sion, poor carburetion, and low efficiency

in the general operation of the engine. It

is recommended, whenever the reed valves

are found to be distorted or bent out of

shape so as to cause leakage, that they be

replaced.

It

is not recommended to re-

bend or invert the reed valve in repairing

and servicing this assembly.

The reed valve can be visually checked

for leakage by looking into the intake port

side of the reed plate and if light is de-

tected at the point where the reed valve

seats on the reed plate, it is then recom-

mended that the reed valve be replaced.

CLEANING OF MUFF

LER

W hen power loss is observed this may

be due to excessive carbon accumulation

in the exhaust ports of the muffler. These

-

RE

ED VALVES

The

reed valves are one of the more

important functioning parts of your en-

gine and if not set and working properly

can cause many difficulties-such as dif-

ficulty in starting, lack of sufficient fuel

in combustion chamber, lack of compres- FI

GU

RE

No.

10

10

,....

....,

.-:-..-

~

s

~·

·_

·

...

REE

D STOP VALVE SETTING 3·

»i::.:

VALVE

REED---

[11\

'-

_,

' L.

..

-

carbon restrictions may be cleaned by the

use of a screw driver tip or any suitable

instrument that will remove carbon de-

posits from these ports. In extreme cases

it may be necessary to remove the muffler

from the engine and clean from within

(see Fig. N

o.8)

. Proper cleaning and

removal of all carbon accumulations is

'. necessary to eliminate the possibility of

creating back pressure from the restric-

tion of the exhaust POrt of the muffler.

MAJOR

REPAIRS

It is not the intention of this manual

to be complete within itself and give all

the necessary recommendations and toler-

ances required for the major repairing of

the Clinton rwo cycle engi ne.

It

is, there-

fore, our recommendation that when you

find your Clinton Engine needs repairs

and adjustments of a major nature you

refer to your authorized service station

directory or the classified section of your

telephone directory

to

determineyour near-

est Clinton factory authorized service

Sta-

tion. AU of these 3500 factory authorized

service stations employ skilled mechanics,

factory trained in the proper servicing and

repairing of our engines, and stock a com-

plete line of genuine Clinton replacement

parts for repairing your engine when it

may need attention.

DO NOT HESITATE TO WR

ITE

US

If

you should desire more complete

and detailed information pertaining to

your Clinton Engine, please do not hesi-

tate to contact us here at the factory.

Our

entire organization is at your disposal for

this purpose and we will be very happy

to forward to you u

pon

request, any

additional information you may desire

pertaining to our Clinton Engines. Please

address your correspondence to: Service

Division, Clinton Machine Company,

Maquoketa, Iowa.

v-

I

WORLD

·

WIDE

SERVICE

There

are

over

3500

Authorized

Clinton Service Stations

w hich

offer

the

owne

rs of Clinton engines an

unparalleled

service on a

world-w

ide

basis. Consult the Classified sec-

tion

of

your

telep

hone directory

for

the

nea

rest one for a

free check-up.

11

TROUBLE

SHOOTING

CHART

TROUBLE

PROBABLE

CAUSE

1.

ENGINE

FAILS

No

fuel

in

tank.

TO

START

Fuel

shut-off

valve

closed

Sediment

in

carburetor

Air

lock

in

fuel

line

Fuel

line

clogged

Broken

high-tension

lead

Reed

valve

not

seating

2.

ENGINE

HARD

Water

in

fuel

TO

START

Loose

or

defective

wiring

Defective

reed

valve

Spark

plug

cracked

Spark

plug

fouled

Dirty

or

corroded

breaker

pts.

Poor

compression

resulting

from:

Loose

spark

plug

Defective

reed

valve

Worn

rings

3.

ENGINE

Spark

plug

fouled

MISSING

Spark

plug

cracked

Improper

spark

plug

gap

Shorted

high

tension

lead

Magneto

or

condenser

terminal

loose

Dirty

or

corroded

breaker

pts.

Water

in

fuel

4.

ENGINE

Carburetor

choke

partly

OVERHEATING

closed

Air

flow

obstructed

Insufficient

lubrication

12

REMEDY

Fill

Tank

Open

Valve

Drain

carburetor

bowl

Bleed

fuel

line

Clean

out

the

line

Replace

lead

Contact

nearest

Clinton

Service

Station

Drain

and

refill

entire

fuel

system.

There

may

be

ice

in

cold

weather

Check

high-tension

lead

for

breaks

or

loose

connections

Contact

nearest

Clinton

Service

Station

Replace

plug

Clean

plug;

reset

gap

to

.025

Clean

or

replace;

reset

points

to

.018

or

.020

inch

Tighten

plu

-g

Contact

nearest

Clinton

Service

Station

Contact

nearest

Clinton

Service

Station

Clean

plug;

reset

gap

to

.025

Replace

plug

Reset

to

.025

Replace

lead

Tighten

terminals

Clean

or

replace

and

reset

points

to

.018

to

.020

inch

Drain

and

refill

entire

fuel

system

See

that

choke

setting

is

wide

open

Check

to

see

that

all

air

passages

around

cylinder

and

head

are

free

from

dirt

and

weeds.

Clean

flywheel

fins

Check

for

proper

ratio

of oil

and

gas

mixture

in

fuel

tank

TROUBLE

PROBABLE

CAUSE

REMEDY

5.

ENGINE

LACKS

Carburetor

choke

partly

closed

See

that

choke

is

wide

open

POWER

Air

cleaner

clogged

Clean

or

replace

Improper

carburetor

setting

Adjust

carburetor

Muffler

clogged

Clean

exhaust

ports

of

muffler

Governor

out

of

adjustment

Readjust

and

tighten

linkage

Exhaust

port

clogged

Clean

ports

Poor

compression

Contact

nearest

Clinton

Service

Station

Reed

valve

leaking

Contact

nearest

Clinton

Service

Station

Piston

worn

Contact

nearest

Clinton

Service

Station

6.

ENGINE

Loose

flywheel

Tighten

retaining

nut

NOISY

Excessive

carbon

deposits

Clean

exhaust

ports

and

muffler

Eng

ine

loosely

mounted

to

Tighten

bolts

equipment

7.

ENGINE

SPEED

VARIES;

OR

ENGINE

FAILS

TO

ADJUST

ITSELF

TO

LOADS

Faulty

governor

linkage

Faulty

governor

spring

Improper

adjustment

of

governor

Check.

straighten

and

tighten

linkage

as

necessary

Check,

replace

if

stretched

or

kinked

Readjust

Improper

carburetor

Contact

nearest

Clinton

Service

Station

adjustment

Governor

linkage

binding

Clean,

make

sure

all

linkage

free

to

due

to

dirt

move

properly

Overloading

Reduce

load.

Don't

crowd

mower

in

high

or

thick

grass

....

13

Recoil

Starter

Kil

AllY

,

Part

No

,

Descr

iption

Slarler

AllY

.

Kit

Used

On

Engine

Ser

ies

(

·6311

(

·6312

Schnacke

Type

Schnacke

Type

350,

A300,

moo

B700

,

moo

(

·6313

(

·6314

Schnacke

T

ype

Schnacke

Type

800,

moo

,D

IlDO

moo

,

A3

·

100

17

10

18

8

/

~

-

--

5

Ref.

Part

Nu

mher

Application

No.

Part

Description

(linton

Schnack

e (·

6311

(

·6312

(

·6313

(

·6314

1

Axle

.

(lutch

&

Pin

Allembly

(-4840

11

50·19A 1. _ 1 1. 1

2

Brace

-B

lo

we

r

Hous

ing

11

64 1. ..

3 (

able.

Handle

& Anti·Fray

Tube

Alle

mbly

(·4839

11

50·22 1. 1. 1. 1

4 (able-W

ire-4

8"

long

(

·4838

11

50·6 1. 1. 1 1

5

(over

-Cable

Shea

ve

-Assembly

C·4848

11

50·7A 1. 1. 1 1

6

Sheave

Drum

Assembly

(

·4842

1150·5

1 1. 1 1

7

Housing

-S

tarler (

·4843

115O

·8A

1. 1. 1

(·4844

1160

·8 1. ..

8

Nut

-He

x. 5/16

-24

(Axle &

Clutch

Assembly

) (

·5454

1150

·14 1. 1. 1. 1

9

Nut

-He

x.

lock

:::i:

10

-32

5453

__

4.. 4 4 4

10

Nut

-Driven

Membe

r (·4

833

7·20·75 1 , ,

(·4834 7·20·53 1. , ..

(·

483

5 7·2

0·59

1. ..

(·4829 7·20·90 1

11

Plate

&

Bushing

Allembly-Mou

nti

ng

(·4846

1150

·17 1. 1 1 1

12

Ring

-R

eta

ining

,

Reco

il

Assembl

y (

·4845

1150·15 , 1. 1 1 t

13

Rivet

-Blo

wer

Hous

ing

Brace

361

9 2.. ..

14 Screw-l0-32x3/8 (Recoil

As

sembl

y

10

Start

er

Hou

sing)

3210

4 4 4 4

15

16 Screw-l0·32x5/16 (Recoil

Starter

to

Engine

)

Spring-Recoil

4832

(·4837

115

0·4.. 4

1. 4

1 4

1. 4

1

17

Shim-Re

coil

Starter

Nut

4836 3 3 3 3

18

Washer

-Cable

Clamp

(·5487

115

0·20A

1 1 1 1

19

Washer

-No

. 10

lock

3285 4 4 4 4

14

Ca

rbureto

r

Pa

rt

No

. Carter

Pa

rt

No.

Rebuild

Kit

Clinton

Engine

Series

C-2078

-1

N

·2029S

C·6315

VS

·200

9

Clinton

Carter

Re

f.

No.

PAR T

DESCRIPTIDN

Part

No.

Part

No. Quan

.

1

BDWL

... . C·

3948

23

·42

2

BALL

- C

ho

keS

ha

ft. .. C

·3988

1

16

·16

3

BODY

-

Car

buretor . Not

Supplied

4

FLOAT

AND

LEVER

ASSEMBLy

..

C·3998

21·

1395

1

5

GASKET

-

Ne

edle

Se

at. ..

C-3975

20

-22

1

6

GASKET

- Bowl Nut . C

-3976

20·1

10 1

7

GASKET

- Bowl. .

C·3979

23A

-19

1

8

JET

ASSEMBLY

- L

ow

S

pe

ed . C

·3995

11-2

465

1

9

NEEDLE

ASSEMBLY

-

Ma

inAdjustment.. .

C·3962

159

-1585

1

10

NEEDLE

- Idle

Adju

sting

.. . .. C

-3997

30A-57

1

11

NEEDLE

AND

SEAT

ASSEMBLY

.

C·3922

25-219S

1

12

NOZZLE

ASSEMBLY

-

Ma

in .

C·3956

12·398

1

13

PACKING

- Hi

gh

Sp

eed Adjust

ing

Ne

ed

le .. C·3

923

163

-53

1 •

14

PLUG

- E

xpans

ion

.. . ..

C-3989

47·" 1

15

SCREW

- ValveAttaching .. C

-3960

101

-320

4

16

SPRING

- IdleAdjustment. ..

C-3959

61

-475

1

17

SPRING

-C

ho

ke

Shaft

. C

·3985

61-369

1

18

SHAFT

- Throttle. . .. .

C·3993

3·833

1

19

SHAFT

AND

LEVER

ASSEMBLY

- C

hoke

.. C

-3996

14

-4635

1

20

SHAFT

- Float. .

C-3980

24

-23

1

21

VALVE

- Throttle . C

-3953

2

-139

1

22

VALVE

- Choke.. .. .. C

-3969

7

-152

1

15

WARRANTY

The Clinton Machine

Company,

Maquoketa,

Iowa, U.S.A.,

warrants

each

new en-

gine it manufactures

against

defects in material

and

workmanship

under

normal

use

and

service.

Our

obligation

under

this

warranty

is limited to

make

good

at

our factory or

authorized

service station,

any

part

or ports th

ereof

which shall,

within ninety

days

after

delivery of such eRgine to the original purchaser,

be

returned

to us or our factory

authorized

service station, with

transportation

charges

prepa

id,

and

with' our exa mination shall disclose to our own satisfaction to

have

been

thus defective; this

warranty

being expressed in lieu of all

other

warranties

expressed or implied

and

of all

other

obligations or liabilities on our

part,

and

we

neither assume, nor

authorize

service stations to assume for us

any

other

liabilities

in connection with the sale of our

engine

.

This

warranty

shall not

apply

if

any

engine which sholl

have

been

repaired

or

altered

outside of our own factory or our

factory

a uthorized service station in

any

way

so as in our judgement to affect the stability or liability, nor which has

been

subjected to misuse, negligence, or occident, nor

any

engine

made

by us

which

does

not

have

a

governor,

or sholl

have

been

operated

at

a

speed

or

load

beyond

the factory specified

capacity

.

Carbureto

rs,

magnetos,

and

other

trade

accessories

are

guaranteed

separately

by their respective manufacturers.

The Clinton Machine

Company

reserves the right to

make

changes

in design,

and

changes

or improvements upon this product without imposing

any

obligation

upon

itself to install the

same

upon its products previously

manufactured.

CL

·INTON

MACHINE

COMPANY

SERVICE

DIVISION - MAQUOKETA,

IOWA

Printed in U.S.A. 16 Part No.

2150

This manual suits for next models

13

Other Clinton Engine manuals

Popular Engine manuals by other brands

BAFANG

BAFANG FM G320.250.R user manual

E-FLITE

E-FLITE EFLM4015A instructions

Fiamma

Fiamma 06275-01 Installation and usage instructions

Motorline professional

Motorline professional ROLLING Series User's and installer's manual

Briggs & Stratton

Briggs & Stratton 440000 Professional Series Operator's manual

MTU

MTU 20V4000L32FB operating instructions