CLIVET WSAT-XEM 50.4 User manual

This manual suits for next models

4

Other CLIVET Chiller manuals

CLIVET

CLIVET WSAT-XSC3 260.6-480.8 User manual

CLIVET

CLIVET WSAT-SC 75C Series Guide

CLIVET

CLIVET WSH-XSC3 User manual

CLIVET

CLIVET WSAT-YSC4 User manual

CLIVET

CLIVET WDAT-3 2.160 Guide

CLIVET

CLIVET WSH Series User manual

CLIVET

CLIVET WSHN-XSC3 70.4 User manual

CLIVET

CLIVET WSA-XEE 262 User manual

CLIVET

CLIVET MSE-SC 65D User manual

CLIVET

CLIVET WSAN-YES 18.2 Reference manual

CLIVET

CLIVET MSE-XSC3 90.4 User manual

CLIVET

CLIVET WSAT-XSC3 FC 90.4 User manual

CLIVET

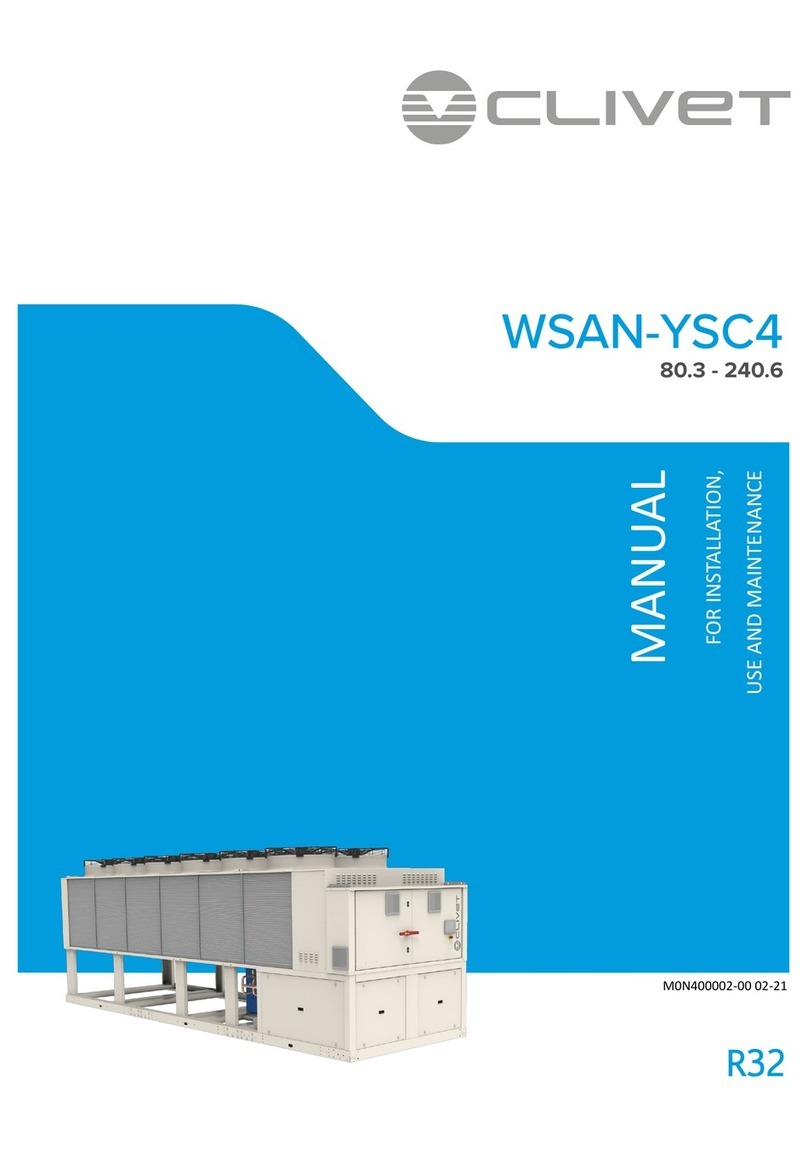

CLIVET WSAN-YSC4 User manual

CLIVET

CLIVET MV6-Xmi 252T-2700T Series Reference manual

CLIVET

CLIVET WSAT-XEE Series Guide

CLIVET

CLIVET WSAT-2.230 User manual

CLIVET

CLIVET WiSAN-YSE1 10.1 User manual

CLIVET

CLIVET WDATA Series Guide

CLIVET

CLIVET WSH-EE Series Guide

CLIVET

CLIVET SCREWLINE3 MDE-SL3 Series User manual

Popular Chiller manuals by other brands

Carrier

Carrier 19DG Start up & operation manual

AERMEC

AERMEC NRV 0550 Installation and maintenance manual

S&A

S&A CW-6000AN250S01 user manual

TATA Motors

TATA Motors TSH Series INSTALLATION, USE AND MANTEINANCE MANUAL

Cold Shot Chillers

Cold Shot Chillers ACWC-180-EM-DR-LT-0-5 Installation, operation and maintenance instructions

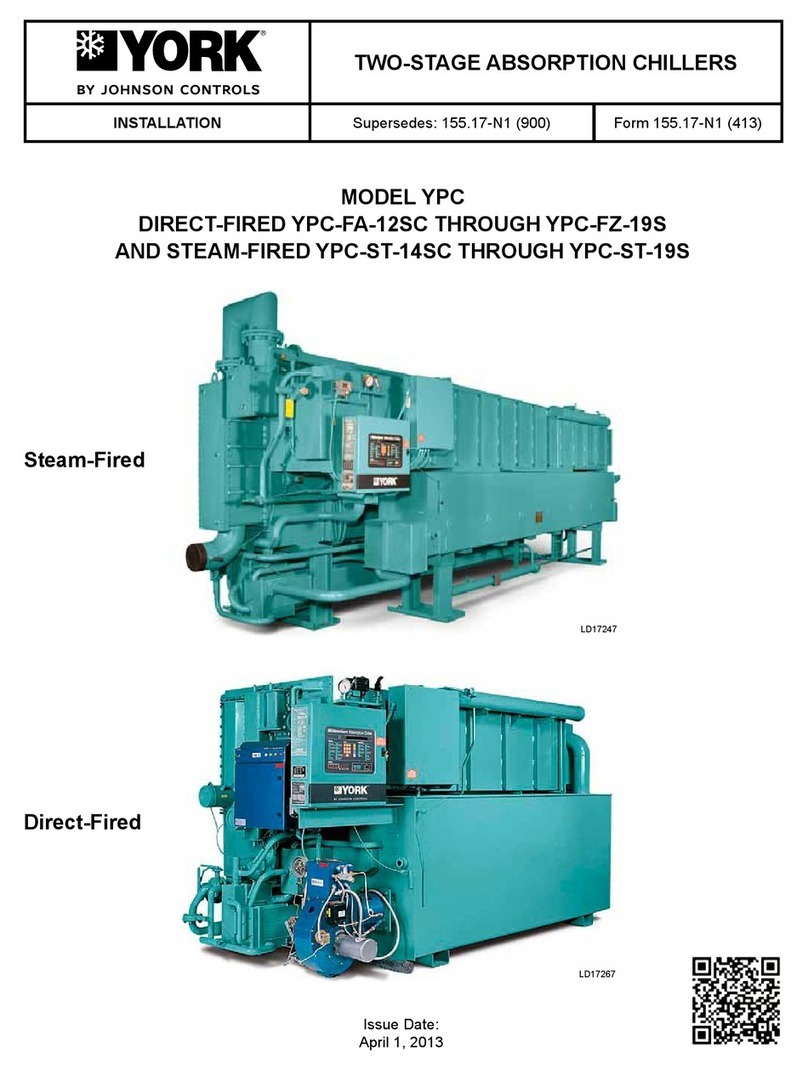

Johnson Controls

Johnson Controls YORK YPC Series Installation