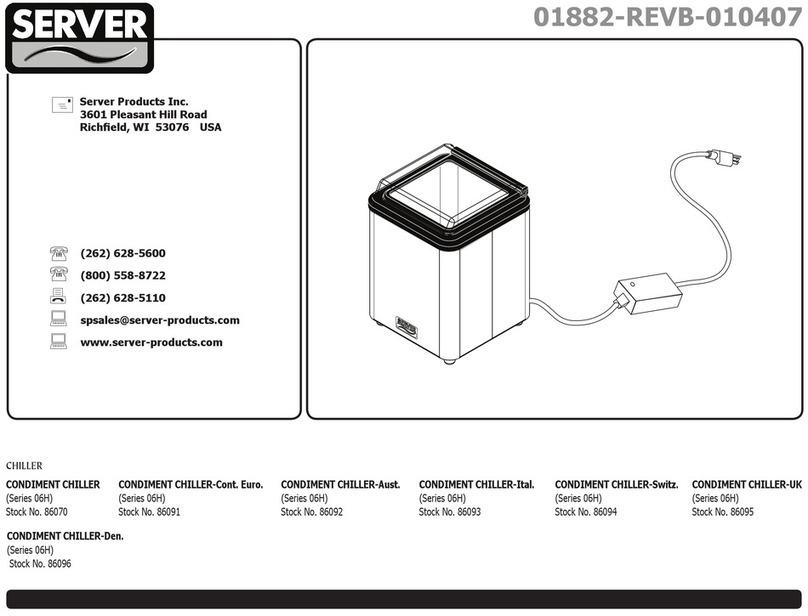

2 1882

Unit Set-Up

ALWAYS CLEAN UNIT THOROUGHLY BEFORE EACH USE.

SeeUnitTake-Down,CleaningandSafetyGuidelines.

1 Powerunitupallowingittopre-coolfor20minutes.

2 Lift lid and ll with product vessel in place. Do not overll.

Maximumcapacityistwo(2)quarts.

3 Closelidtomaintainmaxiumumcoldtemperature.Temperature

stripislocatedonfrontofproductvessel.

It is recommended to keep unit running 24-7 to prevent

pre-cool period and improve performance.

Unit take-Down

1 Detachpowerinletcordfromunit.

2 Liftuplid,removeanyremainingproduct.Productvesselcan

beremovedforcleaning.

Cleaning

Beforerstuseandafterusedaily,removeproductvesseltoclean,

andwipedownunit.Metalpartscancorrode.Itisimportanttoclean,

rinse,sanitize,anddrythesepartsdailyandproperly.Failureto

complywithanyoftheseinstructionsmayvoidunitwarranty:

1 SeeUnitTake-Down.

2 Makesureunitisunpluggedfrompowersupply.

Warning: Neverimmersebaseorshroudofunitintowater.Never

use any water jet or pressure sprayer on base or shroud of unit.

Electricalshockcouldoccurorelectricalcomponentsinsidetheunit

basecouldbedamagedfromwaterexposure.

3 Washproductvesselandlidwithdishwashingdetergentandhot

waterdaily.(Lidcanberemovedbygentlypullinghingetabs

outandliftingoff.)

Rinsethoroughlyanddrywithacleansoftcloth.

• Youmayuseamildlyabrasivenylonorbrassbrushto

removeanyfoodormineraldepositsontheinterior

ofthevessel.

• Donotuseanyhighlyalkalineoracidicsolvents,steel

wool,orotherharshabrasivestocleanvessel.

4 Wipeexternalsurfacesofbaseorshroudwithacleandamp

clothdaily.Drywithacleansoftcloth.Youmayuseageneral

purpose,nonabrasivecleaneronhardtoremovefooddeposits.

Cleaning (ContinUeD)

• Do not use abrasive cleansers, scrapers, steel pads,

steelwool,orothercleaningtoolsthatcanscratchany

polishedsurfaces.

• Anontoxicglasscleanermaybeusedforcleaningany

stainlesssteelparts.

5 Sanitizepartsfollowingyourlocalsanitizationrequirements.

Allpartsincontactwithfoodmustbesanitized.

6 Allowpartstofullyairdryaftersanitization.

• Various elements and minerals, such as chlorides in

tapwater,canaccumulateonmetalpartsandcreate

corrosion.

• Topreventcorrosiononmetalparts,itisimportantto

fullyairdry,asrequiredaftersanitization,ortofully

drywithacleansoftclothregularly.

NOTE: Ifunitwillnotbeusedorpoweredupforanextendedperiod

aftercleaning,removelidandvesseltoallowunittowarmtoroom

temperature and air dry to prevent condensation from developing

betweenvesselandbasin.

Unitcanremainassembledifpoweredupandcoolingaftercleaning

andsanitizing.

2 01882

1

2

3

3

1