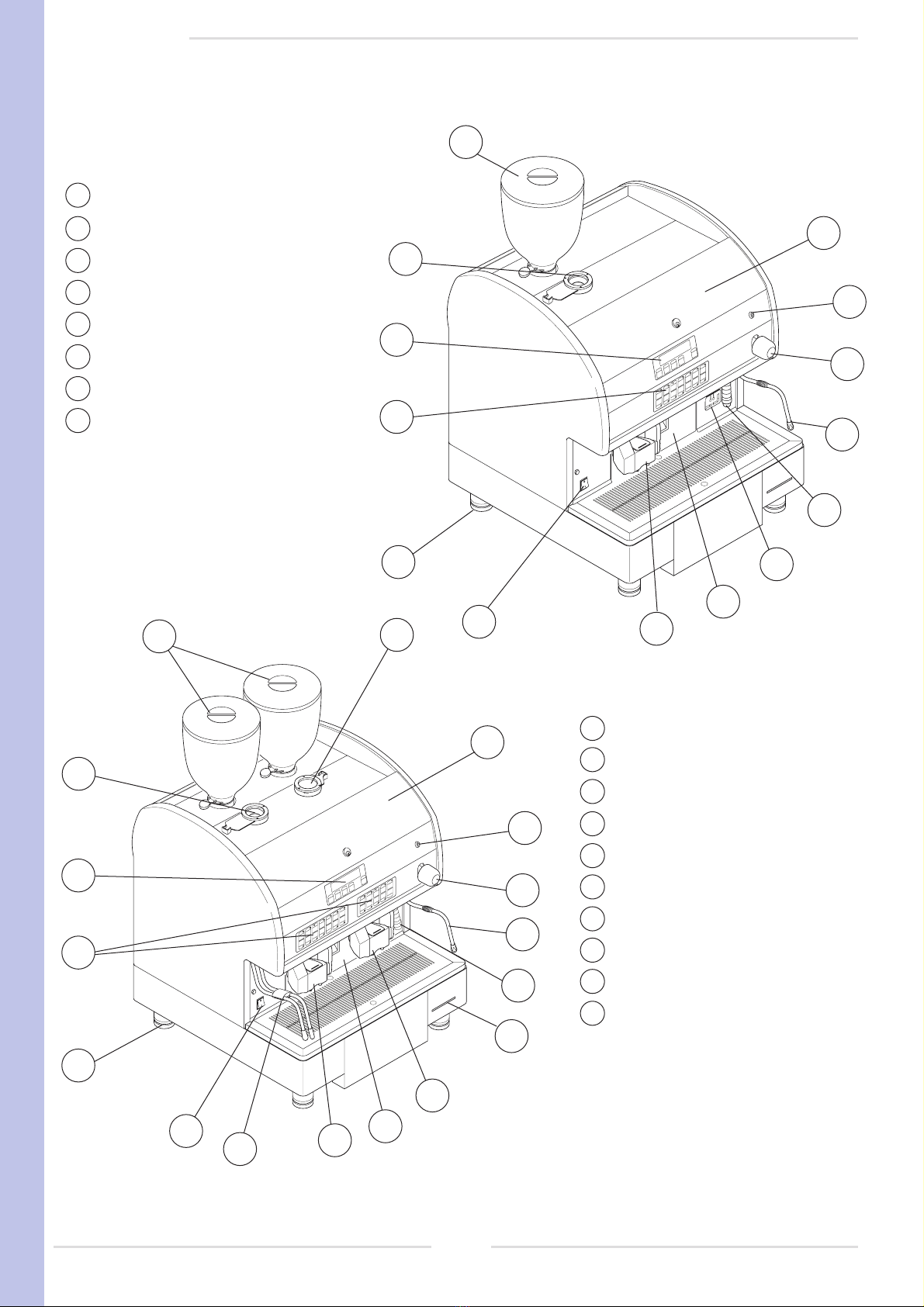

Summary

1. GENERAL DESCRIPTION......................................................................................................................... 6

2. TECHNICAL FEATURES ...........................................................................................................................7

3. DESCRIPTION OF INTERNAL COMPONENTS .......................................................................................7

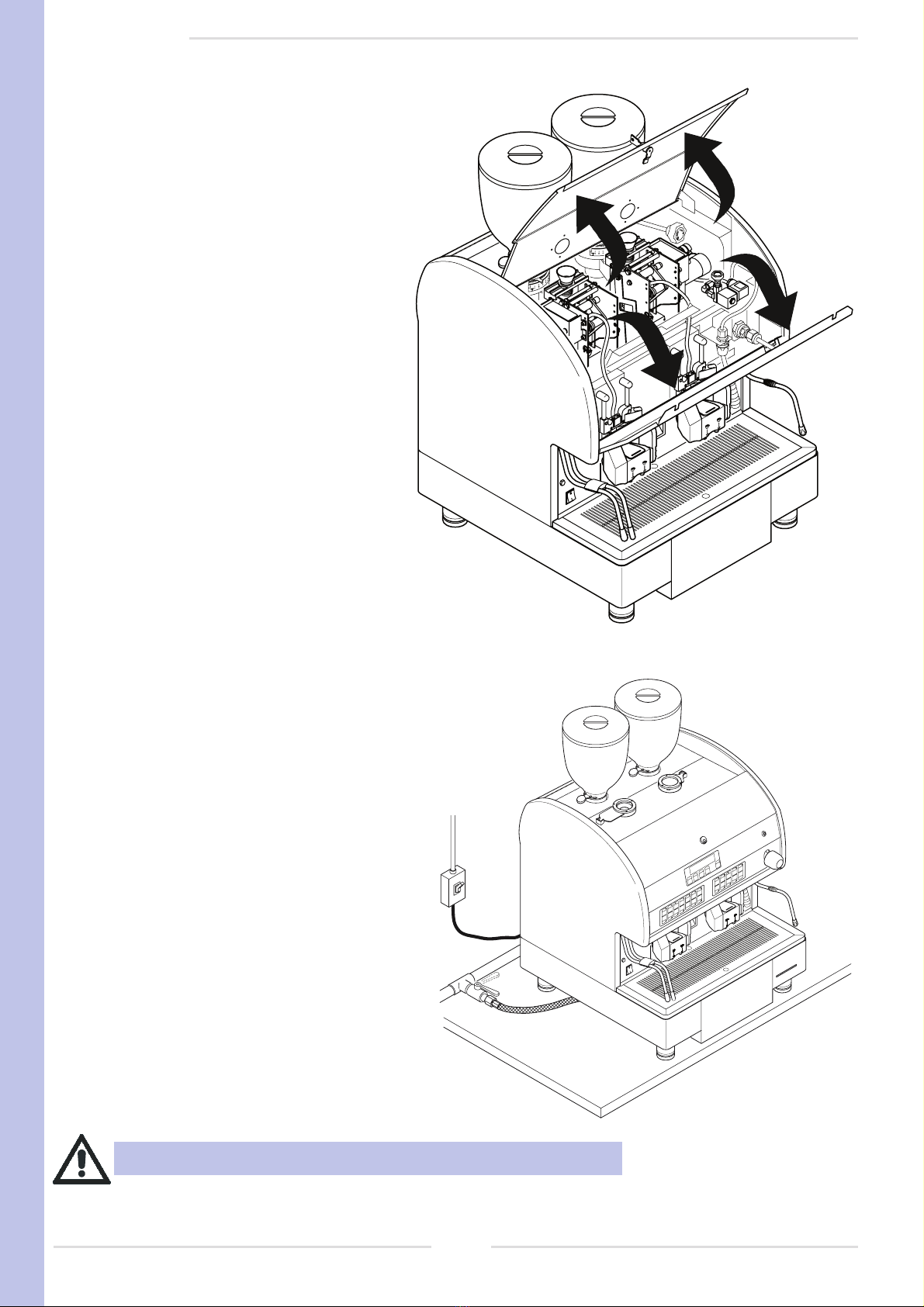

4. INSTALLATION .......................................................................................................................................... 8

4.1 Unpacking .....................................................................................................................................................................................8

4.2 Preparation of the coffee grinder...................................................................................................................................................8

4.3 Positioning the machine ................................................................................................................................................................8

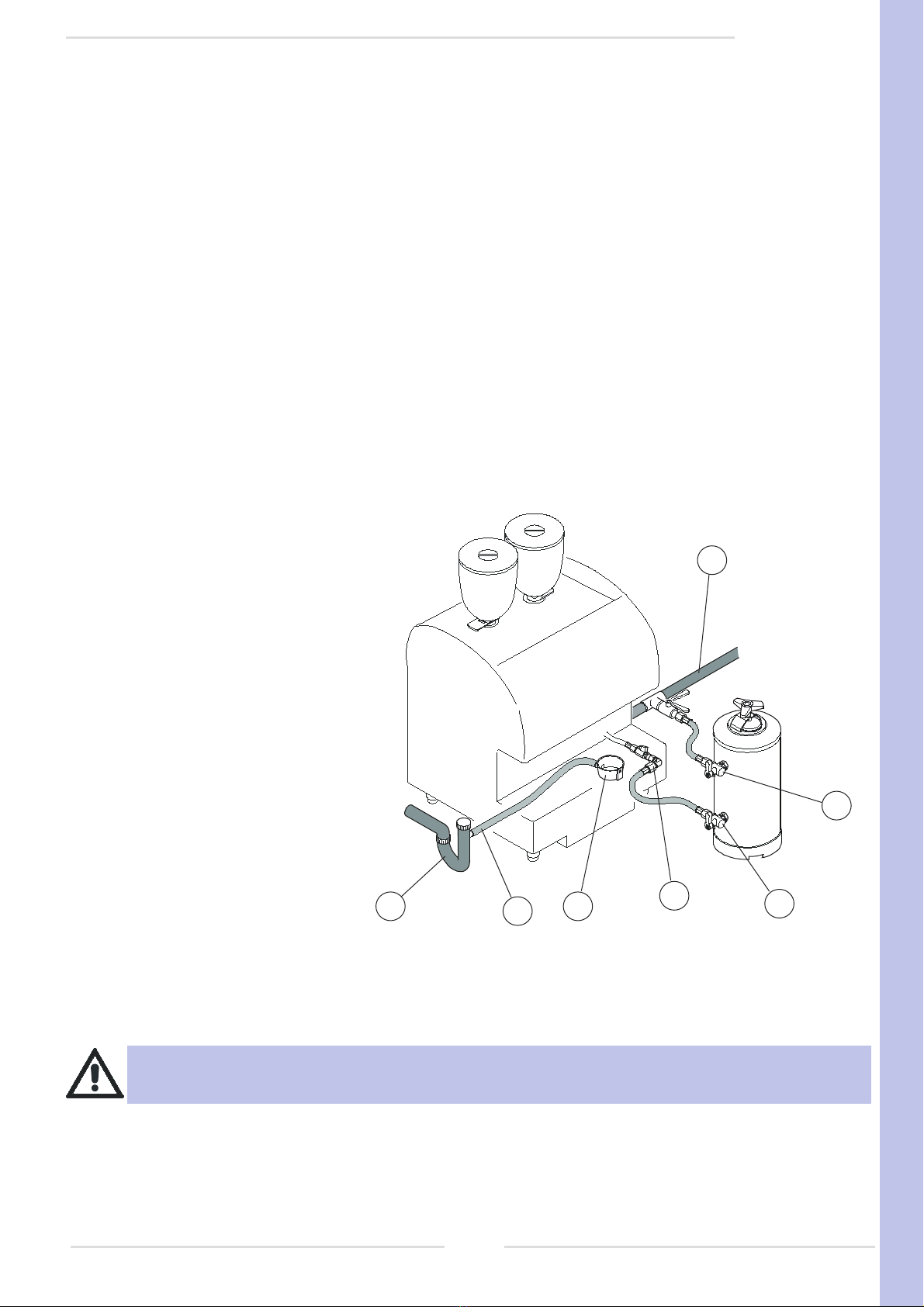

5. CONNECTIONS & OPERATIONS .............................................................................................................9

5.1 Hydraulic connection....................................................................................................................................................................9

5.2 Maintenance and cleaning .........................................................................................................................................................10

5.3 Electrical connection ..................................................................................................................................................................10

5.4 Machine start-up ........................................................................................................................................................................12

5.5 Adjustment of the pump .............................................................................................................................................................12

6. MACHINE PROGRAMMING....................................................................................................................13

Programming MENU ..........................................................................................................................................................................13

6.1 Programming of grinding times ..................................................................................................................................................14

6.2 Programming of group temperatures .........................................................................................................................................15

6.3 Programming of Autosteamer temperature................................................................................................................................15

6.4 Programming grounds................................................................................................................................................................16

6.5 Programming piston compression..............................................................................................................................................16

6.6 Loading/saving data on Smart Card...........................................................................................................................................17

6.7 Added water option ....................................................................................................................................................................18

6.8 Programming doses ...................................................................................................................................................................18

6.9 Adjustment of doses...................................................................................................................................................................20

6.10 Programming date......................................................................................................................................................................22

6.11 Alarm signals ..............................................................................................................................................................................23

6.12 Input test ....................................................................................................................................................................................25

6.13 Actuator test ...............................................................................................................................................................................28

6.14 Data reading...............................................................................................................................................................................30

6.15

Resetting data

.............................................................................................................................................................................32

6.16 Programming wash requests .....................................................................................................................................................32

7. MACHINE CONFIGURATION..................................................................................................................34

7.1 Preparation of configuration mode ..............................................................................................................................................34

7.2 Configuration of staff keys...........................................................................................................................................................34

7.3

Configuration of coin slot.............................................................................................................................................................35

7.4

Configuration of cappuccino maker.............................................................................................................................................35

7.5

Configuration of language ...........................................................................................................................................................35

7.6

Activation / De-activation of group 1............................................................................................................................................35

7.7

Activation / De-activation of group 2............................................................................................................................................35

7.8

Configuration of double cycle gr.1...............................................................................................................................................36

7.9

Configuration of double cycle gr.2...............................................................................................................................................36

7.10 Confi

guration of PRESET DEFAULT .........................................................................................................................................36

7.11 Configuration of technical service..............................................................................................................................................36

7.12 Push button panel configuration.................................................................................................................................................37

7.13 Confi

guration of RS 232.............................................................................................................................................................38

7.14 Confi

guration of degrees centigrade or Fahrenheit....................................................................................................................38

7.15 Configuration for lack of coffee in decaffeinated ........................................................................................................................39

7.16 Configuration of washing............................................................................................................................................................39

8. MACHINE COMPONENTS ...................................................................................................................... 40

8.1 Boiler ...........................................................................................................................................................................................40

8.2 Heat exchanger...........................................................................................................................................................................40

8.3 Automatic Water Refill .................................................................................................................................................................40

8.4 Volumetric doser .........................................................................................................................................................................40

8.5 Pressure control ..........................................................................................................................................................................41

8.6 Maintenance of groups................................................................................................................................................................42

8.7

Pressure control ..........................................................................................................................................................................45

8.8

Anti-flooding device .....................................................................................................................................................................45

8.9

Valve unit.....................................................................................................................................................................................45

8.10 Pump system .............................................................................................................................................................................45

8.11 Cappuccino-maker .....................................................................................................................................................................46

9. ELECTRONIC SYSTEM ..........................................................................................................................47

10. TROUBLESHOOTING .............................................................................................................................48

10.1 Indications on the display..........................................................................................................................................................48

10.2 Failures and functional problems ..............................................................................................................................................52

11. ADJUSTMENT of the DISPENSING GROUP..........................................................................................56

11.1 Positioning the cams .................................................................................................................................................................56

11.2 Control the adjustment ..............................................................................................................................................................58

12. CLEANING ............................................................................................................................................... 61

13. WIRING DIAGRAMS................................................................................................................................ 64

13.1 POWER diagram.......................................................................................................................................................................64

13.2 HIGH VOLTAGE diagram..........................................................................................................................................................65

13.3 LOW VOLTAGE diagram...........................................................................................................................................................66

13.4 CPU card - 2003 version...........................................................................................................................................................67

13.5 CPU card - 2005 version...........................................................................................................................................................68

13.6 DRIVER card - 2003 version.....................................................................................................................................................69

13.7 POWER SUPPLY card - 2003 version ......................................................................................................................................70

13.8 MOTHER BOARD connector diagram - 2003 version ..............................................................................................................71

13.9 INTERFACE CONNECTION diagram .......................................................................................................................................72

14. HYDRAULIC DIAGRAMS ........................................................................................................................76

SUMMARY