59

english

ENGLISH

GUARANTEE

15 months on all components except electrical and electronic components and expendable pieces.

i

When using the electrical appliance, several safety standards must be observed:

- do not touch the appliance when hands or feet are wet or damp;

- do not use the appliance in bare feet;

- do not use extensions in rooms where there are showers or baths;

- do not pull on the power cord to disconnect the appliance from the power outlet;

- do not leave the appliance exposed to atmospheric agents (rain, sun, etc.);

- do not allow the appliance to be used by children or the disabled.

Make sure that the machine is used in a room that is suciently lit, aerated, and hygienic.

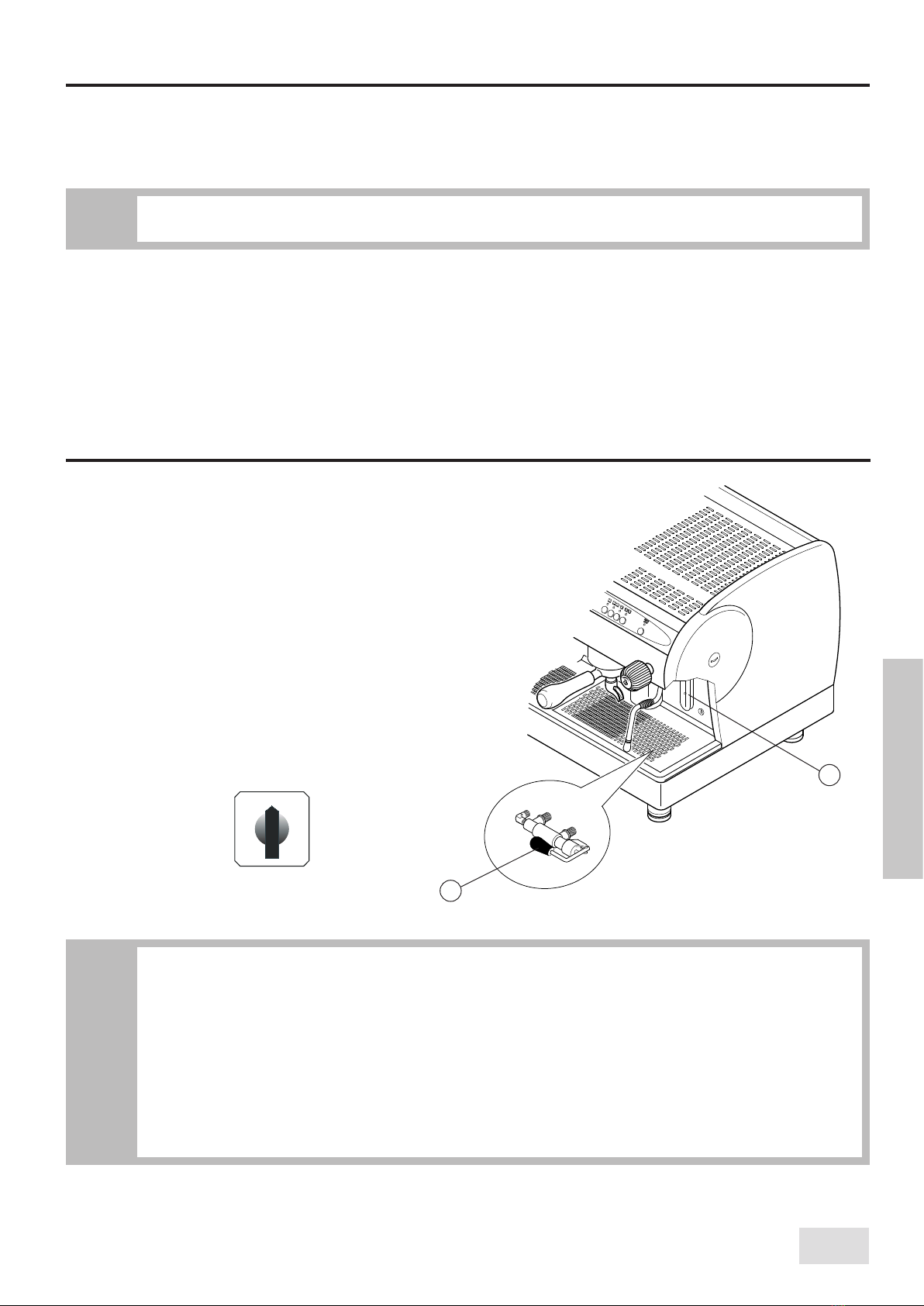

The spaces accessing the machine and the main switch must be left left clear, in order to allow the user to intervene

without any constriction and to be able to leave the area immediately in the case of necessity.

Do not spray water on the machine to clean it. Clean daily following the instructions given in this manual.

Before any maintenance, disconnect the appliance from the electrical mains through the main switch.

For daily cleaning, follow the instructions in this manual.

In case of breakdowns or poor functioning, turn o the appliance and unplug it. Do not attempt any repairs; call

for specialised technical service.

Any repairs must be done only by the manufacturer or an authorised service centre using original spare parts only.

If this requirement is not observed, the safety of the appliance is compromised and the guarantee becomes void.

The power cord of the appliance must not be replaced by the user. If the cord is damaged, turn the machine o and

contact professionally qualied personnel only.

Inside the device is a lithium button battery to prevent programming data loss.

If you should decide not to use the appliance any longer, unplug it and have it drained of water by qualied personnel.

To guarantee that the machine is ecient and to keep it operating correctly, it is indispensable to follow the manu-

facturer's instructions, having periodical maintenance and a check of all the safety devices performed by qualied

personnel.

Do not expose your hands or other body parts in the direction of the coee dispensing spouts or in the direction

of the steam and hot water dispensing terminals. The steam and the water that exit the nozzles can cause burns.

When in operation, the steam and water nozzles and the lter-holder cups are extremely hot and

should be handled with care only in the indicated parts.

Cups must be placed on the special cup-heating surface only after having been thoroughly dried.

The dishes belonging to the machine itself are to be placed on the cup-heater surface. It is incorrect to place any

other object on this surface.

The appliance must not be used by people (including children) with reduced physical, sensorial or mental

capacities or by people without experience or knowledge, unless they can be supervised by or receive instructions

regarding appliance use from a person who is responsible for their safety.

Children must be supervised, to make sure they do not play with the appliance.

The coee machine must be used at a temperature between 5°C and 40°C.

Any unauthorised tampering with any parts of the machine renders any guarantee null and void.

WARNING: consuming beverages that have been prepared in this espresso machine will expose you to lead, a chemi-

cal known to the State of California to cause birth defects or other reproductive harm.