ENGLISH5

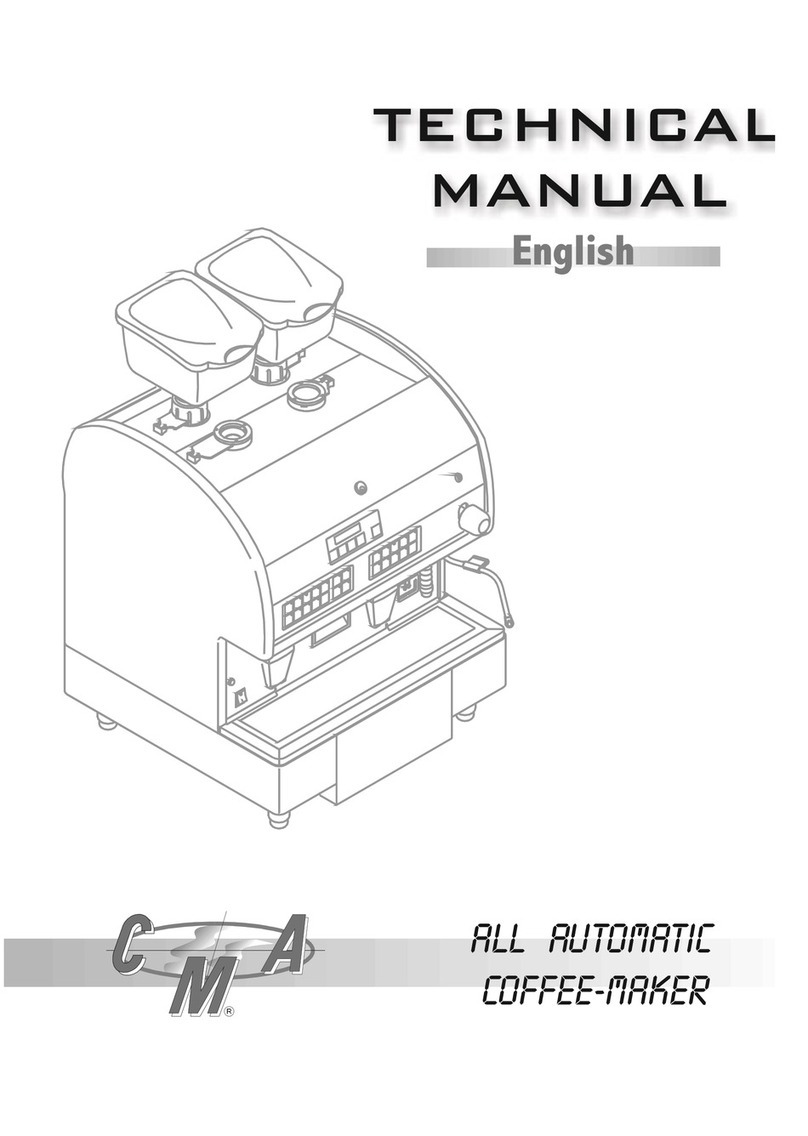

TECHNICAL MANUAL

Summary

1. GENERAL DESCRIPTION .....................................................................................................................................6

2. TECHNICAL SPECIFICATIONS ..............................................................................................................................7

3. DESCRIPTION OF THE INTERNAL COMPONENTS ..............................................................................................7

4. PREPARING THE MACHINE .................................................................................................................................8

4.1 Unpacking .........................................................................................................................................................8

4.2 Preparing the grinder-dosers ............................................................................................................................8

4.3 Positioning the machine ....................................................................................................................................8

5. INSTALLAING AND MAINTENANCE ......................................................................................................................9

5.1 Hydraulic connection .........................................................................................................................................9

5.2 aintenance and cleaning ................................................................................................................................ 9

5.3 Electrical connection ...................................................................................................................................... 10

5.4 Switching the machine on and adjusting the pump ....................................................................................... 10

6. PROGRAMMING ................................................................................................................................................. 11

6.1 Programming ENU ....................................................................................................................................... 11

6.2 GRINDING programming .............................................................................................................................. 12

6.3 ADDED WATER programming ...................................................................................................................... 14

6.4 COFFEE, ILK, TEA DOSES programming .................................................................................................. 15

6.5 CLOCK programming .................................................................................................................................... 16

6.6 Carrying out the INPUT TEST ........................................................................................................................ 17

6.7 Checking CO PONENT functionality ............................................................................................................ 18

6.8 INFO reading .................................................................................................................................................. 20

7. CONFIGURATION ................................................................................................................................................ 22

7.1 Preparing the machine ................................................................................................................................... 22

7.2 Configurating the machine ............................................................................................................................. 23

7.3 achine SIGNALS and WARNINGS ............................................................................................................. 25

7.4 achine CYCLE counting .............................................................................................................................. 26

7.5 Configuration of the servicing warning ........................................................................................................... 27

7.6 Button configuration........................................................................................................................................ 27

8. MACHINE COMPONENTS.................................................................................................................................. 28

8.1 Boiler............................................................................................................................................................... 28

8.2 Heat exchanger .............................................................................................................................................. 28

8.3 Automatic Water Inlet ..................................................................................................................................... 28

8.4 Volumetric doser ............................................................................................................................................ 28

8.5 Dispensing unit ............................................................................................................................................... 29

8.6 Checking pressure ......................................................................................................................................... 30

8.7 Anti-flooding device ........................................................................................................................................ 30

8.8 Valve unit ........................................................................................................................................................ 30

8.9 Pump system .................................................................................................................................................. 31

8.10 Cappuccino-maker ........................................................................................................................................ 31

9. ELECTRONIC SYSTEM ....................................................................................................................................... 32

10. TROUBLESHOOTING .......................................................................................................................................... 33

10.1 Indications on the display............................................................................................................................... 33

10.2 Functional failures and problems .................................................................................................................. 36

11. WIRING DIAGRAMS ............................................................................................................................................ 39

11.1 OTHER BOARD connector diagram ........................................................................................................... 39

11.2 HIGH VOLTAGE electrical circuit .................................................................................................................... 40

11.3 LOW VOLTAGE electrical circuit ..................................................................................................................... 41

11.4 OTORS and SOLENOID VALVES electrical circuit ..................................................................................... 42

11.5 ELECTRONIC CARDS electrical circuit ......................................................................................................... 43

11.6 LED electronic diagram.................................................................................................................................. 44

12. HYDRAULIC DIAGRAMS ..................................................................................................................................... 45

12.1 General hydraulic diagram ............................................................................................................................ 45

12.2 Cappuccino-maker hydraulic diagram .......................................................................................................... 46

12.3 Added water hydraulic diagram ..................................................................................................................... 47