CMA

DISH

MACHINES

1.

Upon

entering

the

facility,

make

a

preliminary

check

of

the

flatware

and

glasses, especially

stemware. This will give you a quick indication of how the machine is functioning.

2.

Go to the CMA-44, turn off the circuit breaker providing power to the machine. Open the door and

check the interior condition of the machine.

a.

The stainless on the inside of the machine should be clean and shiny,

no

dull look

or

buildup of

white lime scale.

b.

Checkthe condition

of

the scrap trays for excessive garbage. Make sure the machine operator is

cleaning the machine, explain proper cleaning procedures. ·

c.

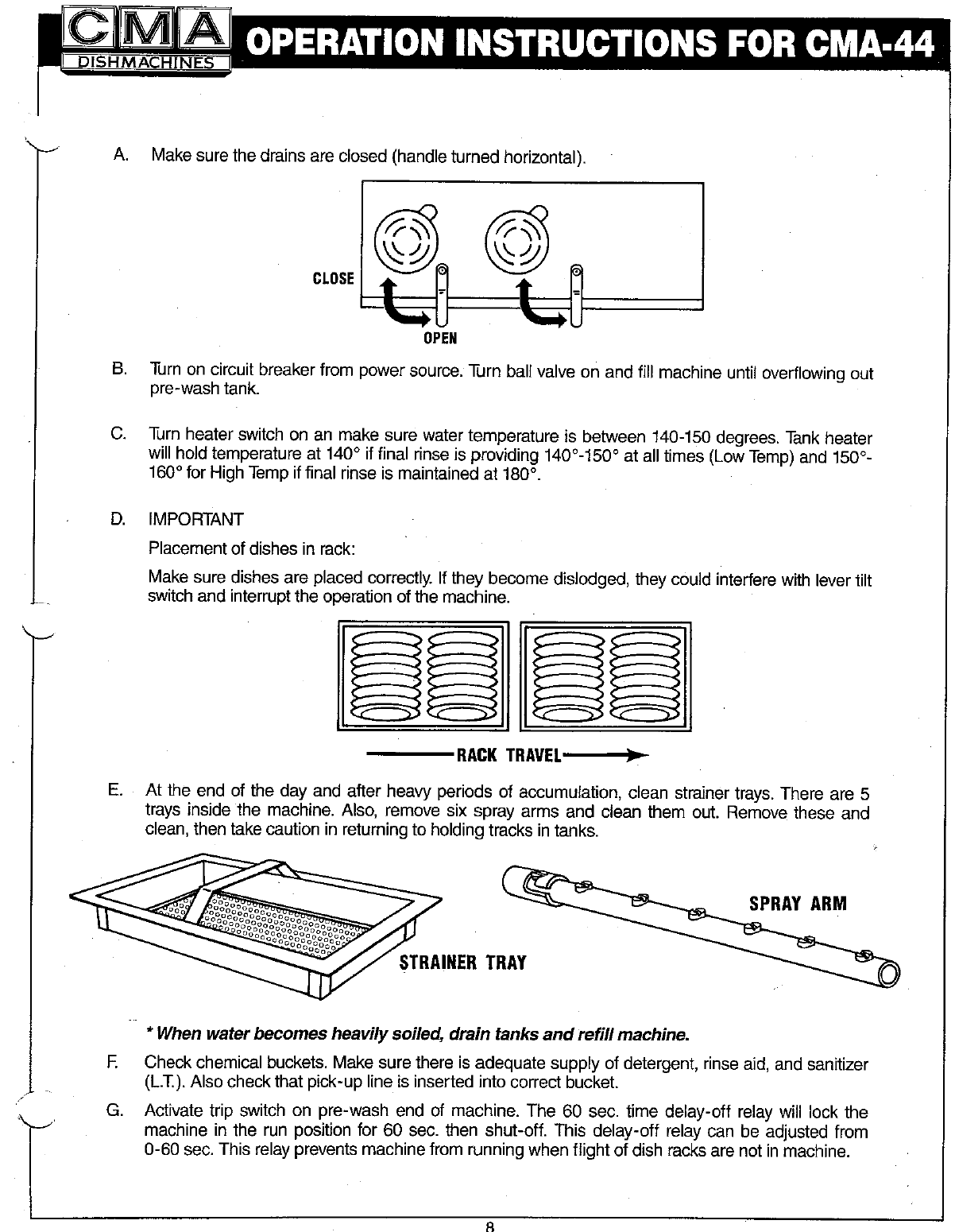

Open the drains and check to make sure

they

are all working properly.

3.

Once the machine

has

drained, remove both

end

curtains from the scrap and rinse and remove all

the scrap trays from the machine. A. Check all spray arms and jets -clean and explain cleaning

procedures to dishmen.

B.

Check the drain openings making sure they are free and clear of debris.

C. Check the heater element. It should be black with no splits, breaks, or cracks.

4. Close the drains, turn the power on and fill the machine.

a.

Checkfill vacuum breaker for leaks.

b.

This is a time to check the water hardness. Check the water at the fill while it is coming into the

machine.

c.

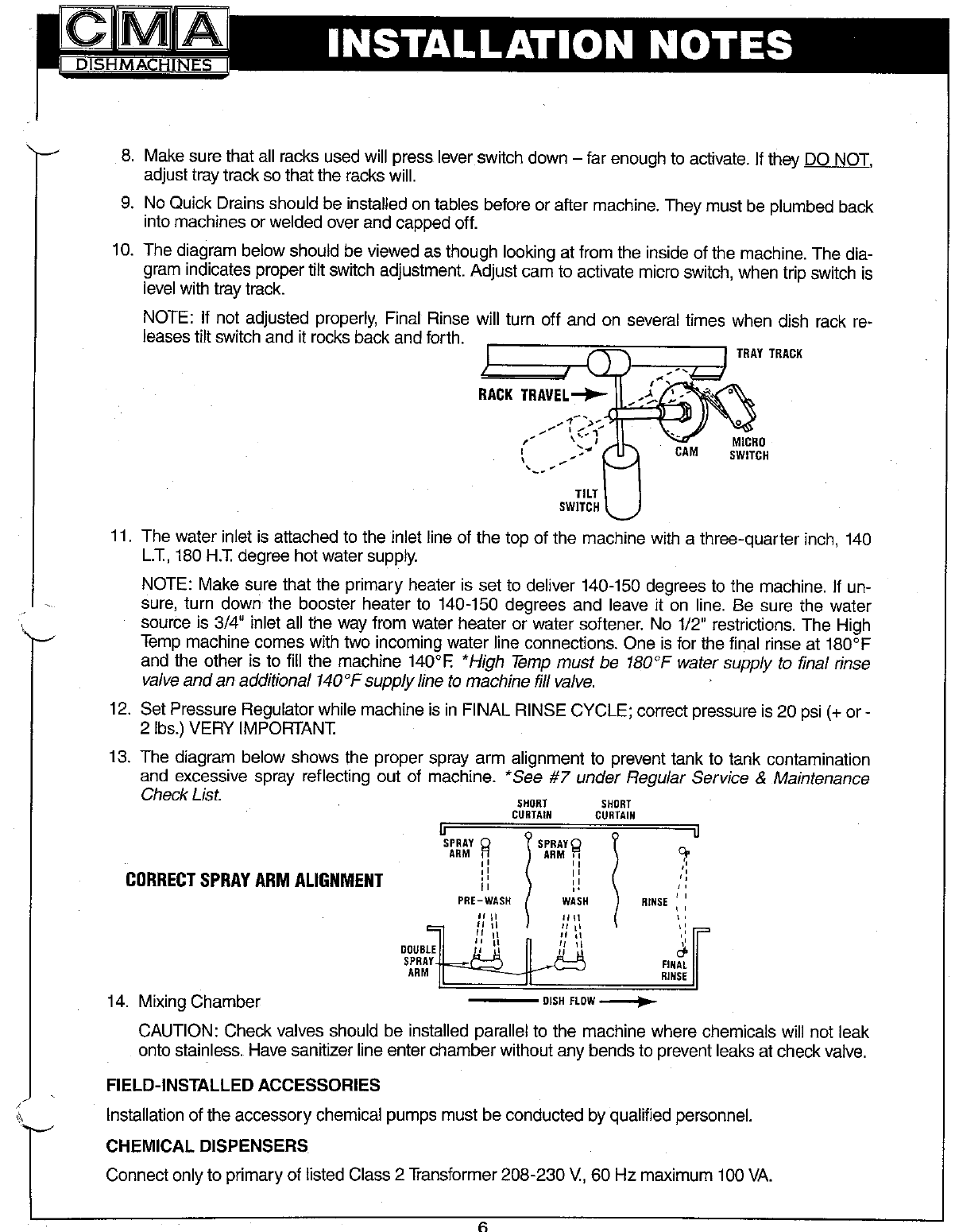

Using a curtain bar or something long, tum on the final rinse and observe the spray pattern of the

final rinse jets.

It

is easier to see while the pressure is lower. If you have any clogged rinse jets,

clean them using a bent paperclip.

5.

Check

the

heater

to

see

if it is working. If

the

temperature

is

below

140 degrees,

check

the

thermostat setting

..

Also check that

the

heater contactor has activated. The contactor plunger should

be

in

the PULLED-IN position.

Check

that the float switch is working properly.

6.

With the machine full, replace all

of

the scrap trays into the proper position.

7.

Place a rack into the machine, and observe the spray pattern of the scrap, the wash, and the final

rinse.

*The

CMA-44 has an excellent feature about it which is helpful in checking the spray pattern.

The wash pump motors and the conveyor motor can be operated independently from one

another by pushing the test switch located on the top of the mag starters. Disarm one mag

starter at a time and observe the spray arm spray pattern for needed adjustments.

By disarming the conveyor motor while a dishrack

is

in the final rinse section this makes

it convenient

in

setting the chemical levels.

a.

Checkthe titration of the wash tank at this point.

b.

While the rack is

in

the final rinse, check the chlorine for 50 ppm

in

the final rinse.

c.

Observe final rinse vacuum breakerfor leaks.

8.

Run a stemware or glass rack through the machine at this point and check the results on the glassware.

A. Observe the check valves for

the

rinse and sanitizer. Make sure they are not leaking or building

up chlorine crystals. If they are clean, leave

them

alone. B. Check the condition of the chemical

tubing from the peri pump to the check valves. C. Check the peri pump squeeze tubes to make sure

they are tight, pumping product properly and

not

leaking within the peri pump. There should be no

moisture within the peri pump itself. D.

Observe

the final rinse pressure at

20

psi

±2.

Adjust if

necessary.