EVAPCO Mr. GoodTower EAW-FD Series Manual

for

LIFE

Operation and

Maintenance Instructions

For eco-Air Dry, Adiabatic and Spray

Fluid Coolers, Condensers & CO2 Gas Coolers

International Institute of

Ammonia Refrigeration

www.iiar.org

Member of

2

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

3 Introduction

3 Safety Precautions

4 Terminology

4 Receiving

4 Initial Storage and/or Idle Period Recommendations

5 Initial and Seasonal Start-Up and Shut-Down

5 General

5 Initial and Seasonal Start-Up

6 Seasonal Shut-Down

6 Dry, Adiabatic or Spray Fluid Coolers

6 Dry or Adiabatic CO2 Gas Coolers and Dry,

Adiabatic or Spray Condensers

6 Basic eco-Air Series Sequence of Operation

7 Maintenance Instructions

7 Finned Coil Cleaning

7 Cleaning Hydraulically

7 Cleaning with Compressed Air

7 Cleaning with Brushes

7 Cleaning Fans

8 Adiabatic Pad Pre-Cooling System – If Equipped

9 Operation (Adiabatic Pad Pre-Cooling System)

9 Maintenance (Adiabatic Pad Pre-Cooling System)

8 Spray Pre-Cooling System – If Equipped

9 Operation (Spray Pre-Cooling System)

9 Maintenance (Spray Pre-Cooling System)

10 Inlet Water (Adiabatic Pad & Spray Pre-Cooling Systems)

11 Water Quality Guidelines (Adiabatic Pad & Spray Pre-Cooling Systems)

12 Maintenance Checklist

13 Fan System

13 Fan Belt Adjustment - Double Stack Product Line Only

14 Variable Frequency Drives

14 Sequence of Operation for Multi-Fan Units with a VFD During Peak Load

14 Variable Frequency Drive Lockout Notification

15 Cold Weather Operation

15 Unit Layout

15 Freeze Protection

16 Troubleshooting

16 Replacement Parts

17 Replacement Part Drawings

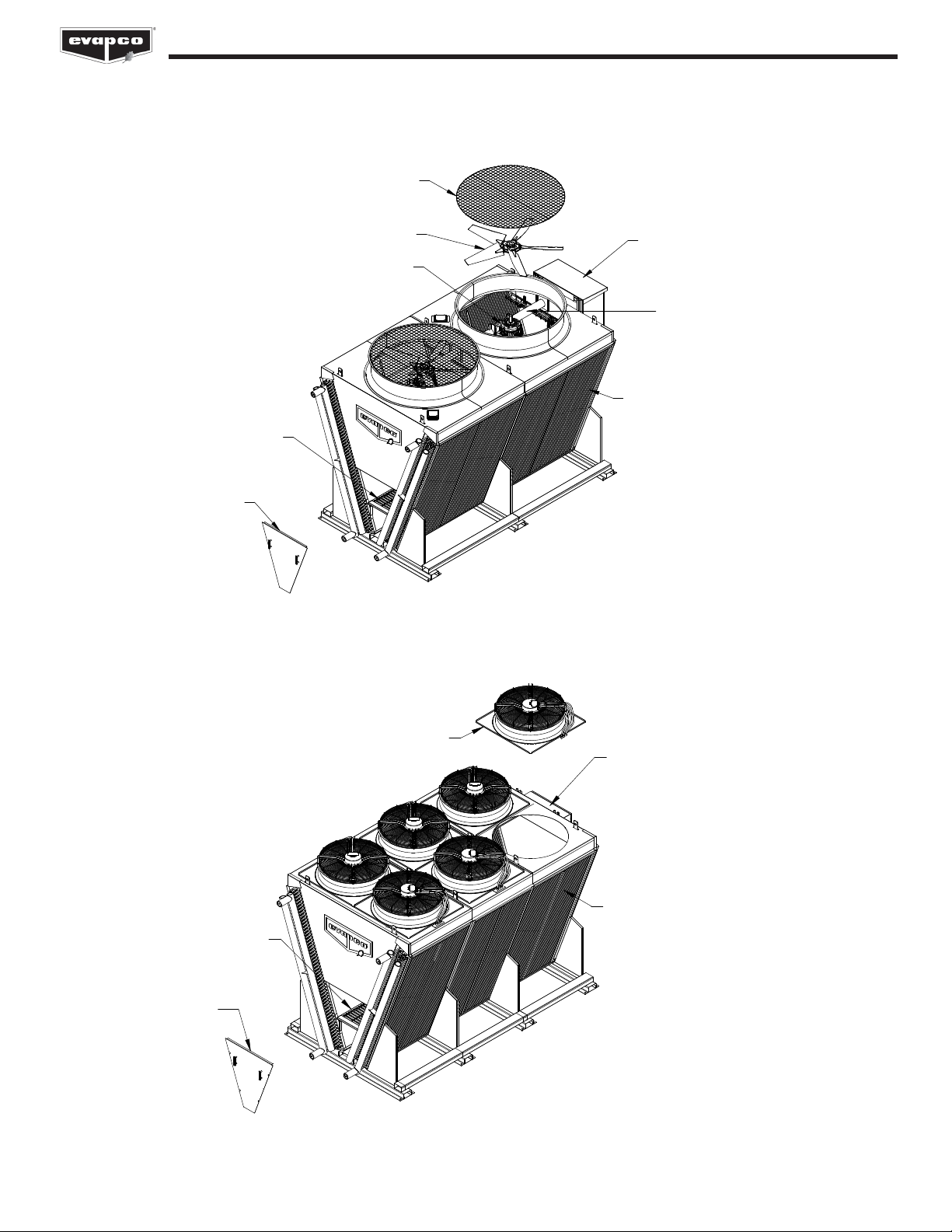

17 eco-Air Flat Coil Configuration with NEMA Fan Motors

17 eco-Air Flat Coil Configuration with EC Fan Motors

18 eco-Air V-Coil Configuration with NEMA Fan Motors

18 eco-Air V-Coil Configuration with EC Fan Motors

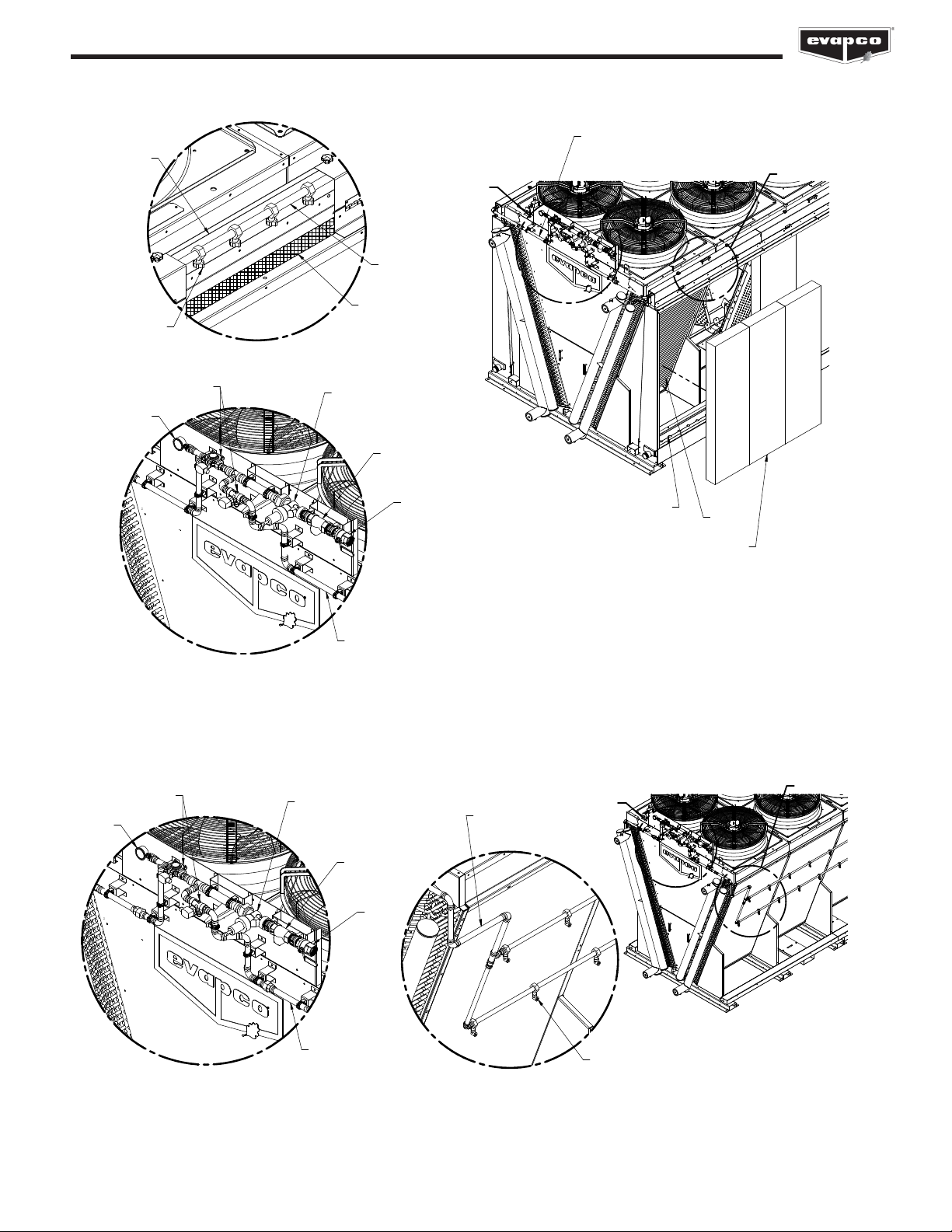

19 eco-Air Adiabatic Pad Pre-Cooling System Components

19 eco-Air Spray Pre-Cooling System Components

20 eco-Air Double Stack Adiabatic Cooler with EC Motors

20 eco-Air Double Stack Adiabatic Cooler with NEMA Motors

21 Notes

Table of Contents

3

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Introduction

Congratulations on the purchase of your EVAPCO air cooled unit. EVAPCO equipment is constructed of the highest quality materials and

designed to provide years of reliable service when properly maintained.

Thoroughly clean road salt, dirt and debris from unit immediately aer delivery. Residue le on product surfaces can cause damage that is

not covered by any warranty. All new cooling equipment and associated piping should be pre-cleaned and flushed to remove grease, oil,

dirt, debris and other suspended solids prior to operation. Any pre-cleaning chemistry should be compatible with the cooling equipment’s

materials of construction. Alkaline formulations should be avoided for systems which include galvanized materials of construction.

Closed hydronic systems connected to a dry fluid cooler should be pre-cleaned and flushed to remove debris, grease, flash rust, oil, and

other suspended solids prior to operation. EVAPCO recommends the use of inhibitor chemistry or inhibited glycol to minimize corrosion

and scale during normal operation.

Air cooled equipment is oen remotely located and periodic maintenance checks are oen overlooked. It is important to establish a

regular maintenance program and be sure that the program is followed. This bulletin should be used as a guide to establish a program. A

clean and properly serviced unit will provide a long service life and operate at peak efficiency.

This bulletin includes recommended maintenance and maintenance intervals for unit start up, unit operation and unit shutdown. Please

note that the maintenance intervals are minimums. Maintenance should be performed more oen when operating conditions necessitate.

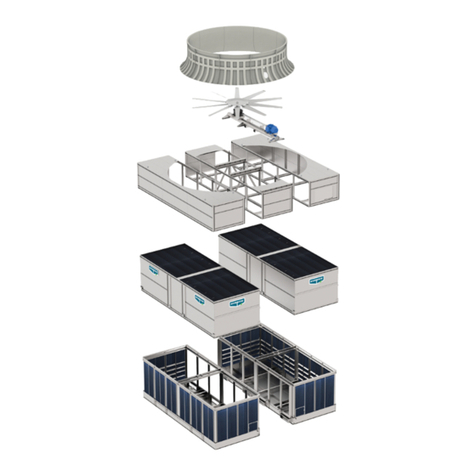

Become familiar with your air cooled equipment. Refer to the isometric drawings located on pages 17-20 for information on the arrange-

ment of components in your equipment.

If you should require any additional information about the installation, operation or maintenance of this equipment, contact your local

EVAPCO representative. You may also visit www.evapco.com or www.mrgoodtower.com for more information.

Safety Precautions

Qualified personnel should use proper care, procedures and tools when operating, maintaining or repairing this equipment in order to

prevent personal injury and/or property damage. The warnings listed below are to be used as guidelines only.

Never operate this equipment without fan screens and access panels properly secured and in place.

Each coil in this unit ships from the factory with a nitrogen charge on the coils. Verify that the nitrogen charge is

still applied before installing unit. Release pressure in each coil before installing heat transfer fluid piping.

An optional factory provided disconnect switch may be located on the unit for each fan motor associated with this

equipment. Before performing any type of service or inspection of the unit make certain that all power has been

disconnected and locked in the “OFF” position.

The top horizontal surface of any unit is not intended to be used as a working platform. No routine service work is

required from this area.

Closed hydronic systems connected to either a closed circuit cooler or dry cooler should be pre-cleaned and

flushed to remove debris, grease, flash rust, oil, and other suspended solids prior to operation. EVAPCO recom-

mends the use of inhibitor chemistry or inhibited glycol to minimize corrosion and scale during normal operation

EVAPCO requires that all external piping and fittings be externally supported, the supplied connections are not

designed to support external piping or fitting weights. Additional weight to the connections or coil in any way

could cause damage to the unit not covered under warranty.

4

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Terminology

Throughout this manual, the terms “Flat Coil,” “V-Coil,” and “Double Stack” are used. Below is a list of EVAPCO eco-Air product offerings

and associated terminology.

eco-Air Series equipment includes the following product models:

<Dry Products

• EAW-FD/EAFWD: Flat Coil Dry Fluid Cooler

• EAW-VD/EAVWD: V-Coil Dry Fluid Cooler

• EAW-DD/EADWD: Double Stack Dry Fluid Cooler

• EAFCD: Flat Coil Dry Condenser

• EAVCD: V-Coil Dry Condenser

• EAVGD: V-Coil Dry CO2Gas Cooler

Receiving

Carefully inspect all units upon arrival to assure that no damage has occurred during shipment. This includes searching for dirt and debris

caused by shipping, as well as inspecting all components and accessories for physical damage. If any units have been damaged during

transit, immediately notify the carrier and file a claim with that carrier.

The coils on all EVAPCO eco-Air Series coolers and condensers are shipped from the factory with a low-pressure nitrogen charge.

Maintain the nitrogen charge until connecting the unit to the system piping.

Each coil is shipped with a pressure gauge to verify the nitrogen charge in the coil. A coil without the factory nitrogen charge may indicate

damage occurred during shipment. In this case, coil(s) should be pressure tested with dry nitrogen gas to assure that it is leak free prior to

installation. Please notify your EVAPCO representative before installing any unit that has lost the factory nitrogen charge during shipment.

Once the nitrogen charge is verified, release the nitrogen charge by opening the valve located on the outlet coil connection.

<Dry Products with Air Pre-Cooling Systems

•EAW-VA/EAVWA: V-Coil Adiabatic Fluid Cooler

• EAW-VS/EAVWS: V-Coil Spray Fluid Cooler

• EAW-DA/EADWA: Double Stack Adiabatic Fluid Cooler

• EAVCA: V-Coil Adiabatic Condenser

• EAVCS: V-Coil Spray Condenser

• EAVGA: V-Coil Adiabatic CO2Gas Cooler

Initial Storage and/or Idle Period Recommendations

If the unit will remain inactive for an extended period of time prior to installation it is recommended that the following be performed in

addition to all component manufacturers recommended maintenance instructions.

• The fans must be turned by hand at least once every three months. This can be accomplished by tagging and locking out the unit’s

disconnect, grasping the fan assembly and rotating it several turns.

• If unit remains inactive longer than one month, insulation test motor windings semi-annually.

• See motor manufacturer maintenance and long term storage instructions for more detailed instructions.

• Thoroughly clean road salt, dirt and debris from unit immediately prior to storage or operation. Residue le on product surfaces

can cause damage that is not covered by any warranty.

5

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Initial and Seasonal Start-Up and Shut-Down

General

1. Verify that the overall installation reflects the requirements of the installation guidelines found in the EVAPCO Equipment Layout

Manual available at www.evapco.com.

2. Verify all safety interlocks work properly.

3. Examine wiring for loose connections or other obvious damage.

4. For units supplied with an EVAPCO control system, refer to The Controller User’s Manual for for motor and controls startup. For

units not supplied with controls see motor manufacturer’s and controls manufacturer’s start up recommendations.

5. If the unit is going to remain inactive for an extended period of time, follow all fan motor guidlines for long term storage. Properly

ventilated plastic sheets or tarps can be used to protect a unit during storage. See your local EVAPCO representative for additional

information on unit storage.

BEFORE BEGINNING ANY MAINTENANCE, BE CERTAIN THAT THE POWER IS TURNED OFF AND THE UNIT IS

PROPERLY LOCKED AND TAGGED OUT!

Initial and Seasonal Start-Up

1. Clean and remove any debris, such as leaves and dirt from the coil face, adiabatic pads (if equipped), and fan screens. Flush the

adiabatic pads to remove any sediment or dirt.

2. If equipped, the factory set flow setter devices on the adiabatic system piping may need to be adjusted to maintain equal

distribution of water flow on both sides of the unit.

3. Fins can be brushed clean with a so bristle brush or pressurized water, not aimed at an angle, but directly onto the fins to clean

accumulated deposits. A fin comb or needle nose pliers can be used to straighten any fins that have become bent. Fins that had

been damaged and straightened with a fin comb may not look like new but will function normally if air spaces remain open.

4. Turn the fan(s) by hand to ensure it turns freely without obstructions.

5. Visually inspect the fan blades. Blade clearance should be approximately 1/4” from tip of blade to the fan cowl.

6. For fluid coolers only, fill the heat exchanger coil with the specified heat transfer fluid and purge air from the system before

pressurizing, using factory supplied coil vents.

NOTE: Dry fluid coolers should only be used on sealed, pressurized systems. Continual aeration of the heat transfer fluid in an open

system can cause corrosion inside the tubes of the cooler leading to premature failure.

Aer the unit has been energized, check the following:

1. Verify fans are rotating in proper direction based on arrow sticker affixed to fan housing.

2. Measure voltage and current on all three power leads of fan motors. The current should not exceed the motor nameplate full load

amp rating.

3. Start the EVAPCO air pre-cooling system if equipped. For adiabatic units, check for proper pad wetting. For spray units, check to

ensure all nozzles are free from debris and have a uniform spray pattern. If the adiabatic pad or spray pre-cooling system is not

operating correctly, consult the troubleshooting guide in this manual.

6

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Seasonal Shut-Down

The below steps should be taken when the equipment is shut down for prolonged periods.

DRY, ADIABATIC OR SPRAY FLUID COOLERS

1. Ensure the process is shut down and the system temperature has reached safe shut down condition.

2. If unit is equipped with an adiabatic pad or spray pre-cooling system ensure that all valves are open and system is completely drained.

3. Switch off the fans and power to the unit.

4. Close the isolating valves by others, if equipped.

5. If the cooler will be subjected to sub-zero temperatures and is not filled with a suitable antifreeze, open the air vent and drain

connection(s) and drain the heat transfer fluid. Applying a positive pressure to the air vent connection(s) will help ensure that there is no

heat transfer fluid retention, which could lead to frost damage.

DRY OR ADIABATIC CO2GAS COOLERS AND DRY, ADIABATIC OR SPRAY CONDENSERS

1. Ensure that the refrigeration load is removed.

2. If unit is equipped with an adiabatic pad or spray pre-cooling system ensure that all valves are open and system is completely drained.

3. Switch off the fans and power to the product.

Basic eco-Air Series Sequence of Operation

NOTE: For units with an EVAPCO control system, refer to The Controller User’s Manual for detailed sequence of operation.

System Off / No Load

The unit’s fans are off. Adiabatic pad or spray pre-cooling systems should be off, if equipped.

System/Condensing Temperature Rises

The fans turn on. For a variable speed controller, the fans are turned on to minimum speed, all fans maintaining the same speed. If the

system temperature continues to rise, then the fan speed is increased as required, up to full speed.

If temperatures continue to rise and an adiabatic pad or spray pre-cooling system is equipped, then the water solenoid valve should open

and completely wet adiabatic pads, or spray water from nozzles. Fan speeds are increased and decreased as needed aer adiabatic pad or

spray pre-cooling system is initiated.

NOTE: If the adiabatic or spray unit is equipped with the two-stage operation accessory, two solenoid valves are provided, and the

pre-cooling systems are actuated in two stages to reduce overall water consumption.

System/Condensing Temperature Stabilizes

Control the leaving fluid temperature (fluid and CO2gas coolers) or condensing pressure (condensers) by modulating the fan speeds with

equipped controls system.

System/Condensing Temperature Drops

Decrease the fan speed, as required. If equipped, shut off adiabatic pad or spray pre-cooling system and continue to modulate fan speed.

System Off / No Load

The system fans turns off. The adiabatic pad or spray pre-cooling system should not be used as a means of capacity control, and should

not be cycled frequently. Excessive cycling can lead to scale build-up on the pads or coils (in case of spray).

NOTE: Minimum control point for process fluid should never be lower than 6º F above process fluid freezing temperature.

7

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Maintenance Instructions

Finned Coil Cleaning

It is essential to understand that fouled or dirty fins reduce heat transfer.

1. Aer operation for a month, check for fouling of the fins. Inspect with a light between the

fins to observe the accumulations of dirt and dust.

2. Dry dust can normally be removed by compressed air, a so brush, or by a suitable

industrial vacuum cleaner. Sweep along the fins and under no circumstances across the

fins.

3. Moist or sticky blemishes or grease should be removed by means of hot water or steam jet

cleaning appliances (against the air direction).

4. Keep the jet of the cleaning appliance at an angle of no more than 15° from vertical

position, to avoid bending the fin edges.

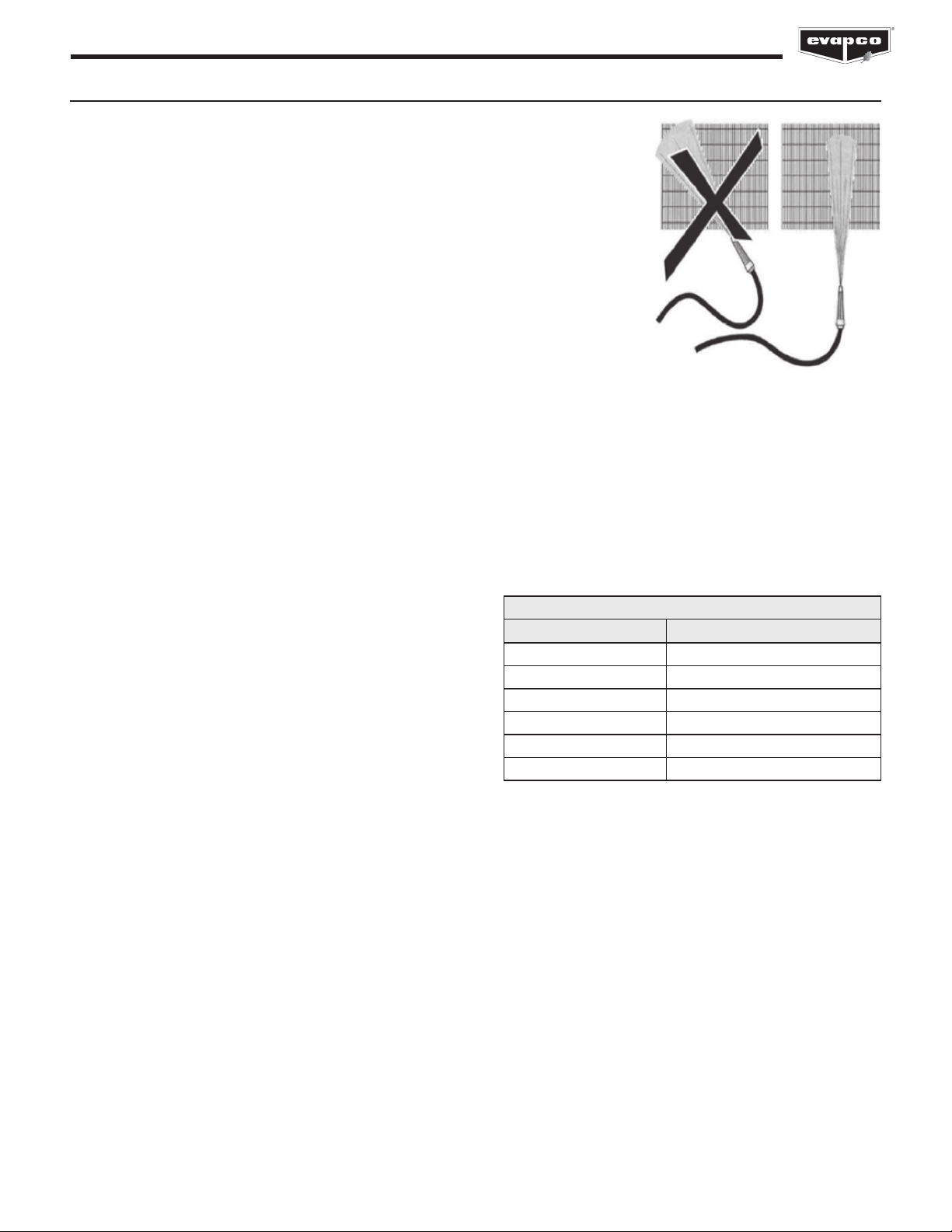

CLEANING HYDRAULICALLY

When cleaning the coil hydraulically, EVAPCO recommends using water only. If cleaning products are used ensure that they are

compatible with the unit materials of construction. When cleaning with water under pressure, use a power washing device designed for a

maximum of 600 psig or less.

Always clean in the vertical direction. Never across the fins, as this will damage the fins. And always from the top down to avoid the water

spray entering the fans (this can short circuit the fan motors).

For oily or otherwise difficult to remove dirt, it is possible to add a chemical cleaning agent to the water used in the power washer. Ensure

that the cleaning agent is compatible with the materials used in the unit and that it is an environmentally friendly agent.

List of recommended cleaning solutions are shown in Table 1.

Figure 1 – Always Clean Fins in

Vertical Direction

STAINLESS STEEL/ALUMINUM COILS

Trade Name Manufacturer

CL-122 NALCO

CL-127 NALCO

LMC-44 LW Chemical

SoilSolv DuChem

FS Process Cleaner Zep

Formula 940 Zep

Table 1 – Acceptable Cleaning Solutions

CLEANING WITH COMPRESSED AIR

When cleaning with compressed air, use a compressor designed for a

maximum of 1,000 psig or less. For the purpose of removing dirt and

debris, please ensure that the air stream is COMPLETELY VERTICAL to

the fins as the compressed air stream can damage the fins.

CLEANING WITH BRUSHES

Dry dust and some dirt can be removed with brushes, possibly in

conjunction with compressed air or an industrial vacuum cleaner.

However, ensure that so brushes are used and when possible all cleaning should be

from the top down. ALWAYS brush along the fins. NEVER across the fins, as this will

damage the fins.

Cleaning Fans

ALWAYS ensure that the power to fans has been locked and tagged out prior to cleaning and ensure that the fans cannot be accidentally

started during maintenance.

It is recommended to clean the fans either by means of brushes or with compressed air. When cleaning with compressed air, use a

compressor designed for a maximum discharge air pressure of 125 psig or less.

8

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

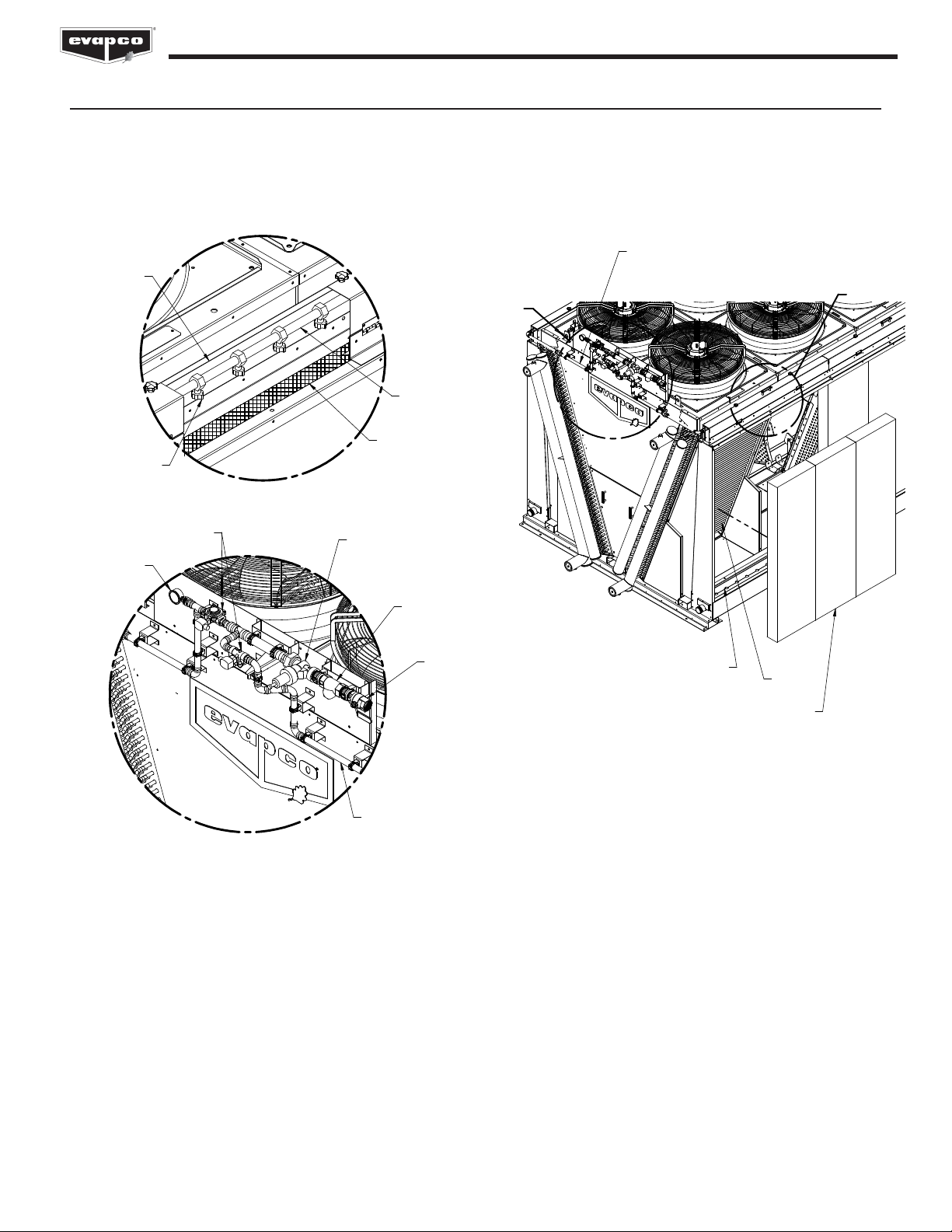

Adiabatic Pad Pre-Cooling System – If Equipped

Adiabatic pad pre-cooling systems are supplied with many dry fluid coolers, CO2gas coolers, and condensers to enhance the

performance of the unit. The below figure shows the major components of the adiabatic pad pre-cooling system.

ADIABATIC WATER

DISTRIBUTION SYSTEM

ADIABATIC DRAIN

COIL

ADIABATIC

PADS

DETAIL A

HAND

VALVE

WATER PRESSURE

REGULATOR

WYE

STRAINER

SOLENOID

VALVE

DISTRIBUTION

PIPE

WATER

BAFFLE

SPRAY BRANCH

SPRAY NOZZLE

PRESSURE

GAUGE

ADIABATIC

DISTRIBUTION

PAD

DETAIL B

AB

Figure 2 – Adiabatic Pad Pre-Cooling System Components

9

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Operation (Adiabatic Pad Pre-Cooling System)

All connecting piping to the unit MUST be externally supported. The piping on the unit is not designed to bear additional piping weight.

EVAPCO recommends visually inspecting adiabatic pads and the distribution system regularly during operation and before seasonal

startup. When in operation the pads should be completely wetted (there will be a noticeable color difference). If portions of the pad are

not wetted, inspect the water distribution system for clogs.

Allow the pads to completely dry once every 24 hours with the fans running.

A water pressure regulator (WPR) is located at the end of each unit as shown in Figure 2. The WPR must be field adjusted to the water

pressure recommended on the unit data sheet/adiabatic pressure nameplate using the provided pressure gauge. The adiabatic pressure

nameplate will be located near the WPR.

When the adiabatic system is in operation and the WPR is set correctly, a small amount of water will be present in the sloped drain

channel. If it becomes necessary to adjust the water flow rate, adjust the WPR until only a small amount of water is in the sloped drain

channel but ensure that the adiabatic pads are completely wetted.

Maintenance (Adiabatic Pad Pre-Cooling System)

Rinse the adiabatic pads to remove loose sediment or dirt. If further cleaning is required use only a mild and environmentally responsible

cleaning agent that is compatible with the unit and pads materials of construction.

To access the distribution system over the adiabatic pads, remove the knobs on the top of the distribution system cover. This allows the

distribution cover to hinge down revealing the water distribution system and the distribution pad.

To remove the adiabatic pads, use the following instructions. Installation is the reverse of removal.

1. Remove the bolts on the top of the distribution system cover. This allows the distribution cover to be repositioned revealing the

distribution pad.

2. Carefully remove the distribution pad, which is the 2” tall pad positioned between the distribution tray and the large vertical

adiabatic pads.

3. Li the large vertical adiabatic pad to clear the lower support (at the bottom) and remove. It is recommended to start with the center

pad per module. This will allow for the pads adjacent to the tube sheets to clear metal brackets attached to the tube sheets.

Ensure the sloped drain channel and outlet connection are free of debris that would impede water flow by removing the adiabatic pads

and then removing the slotted sloped drain channel cover.

The pad material is a bonded cellulose UV resistant material. Refer to local codes and ordinances for disposal methods.

Remove and clean the wye strainer annually to prevent the build up of debris and decreased water flow rate to the adiabatic pads.

10

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Spray Pre-Cooling System – If Equipped

Spray pre-cooling systems are supplied with many dry fluid coolers, CO2gas coolers, and condensers to enhance the performance of the

unit. The below figure shows the major components of the spray pre-cooling system.

DETAIL A

HAND

VALVE

WATER PRESSURE

REGULATOR

WYE

STRAINER

SOLENOID

VALVE

DISTRIBUTION

PIPE

DISTRIBUTION

PIPE

SPRAY NOZZLE

PRESSURE

GAUGE

DETAIL B

B

A

Figure 3 – Spray Pre-Cooling System Components

Operation (Spray Pre-Cooling System)

All connecting piping to the unit MUST be externally supported. The piping on the unit is not designed to bear additional piping weight.

EVAPCO recommends visually inspecting spray system regularly during operation and before seasonal startup. When in operation the

spray nozzles should be spraying outwards and evenly. If any nozzle isn’t operating correctly, inspect the water distribution system for clogs.

A water pressure regulator (WPR) is located at the end of each unit as shown in Figure 3. For units equipped with spray systems, the

discharge water pressure must be set once the unit is installed in the field. Refer to the technical data sheet in the factory submittal for the

WPR setting required for the submitted design conditions. The provided pressure gauge located at the discharge of the solenoid valve

can be used to validate WPR setting. There are no flow setters on the spray system. Inlet water pressure set correctly on the, WPR and a

clean water distribution system will ensure proper operation of the spray system.

NOTE: In addition to the outlined water chemistry guidelines, EVAPCO recommends that dry fluid coolers, CO2gas coolers and

condensers equipped with spray pre-cooling systems limit spray operation to peak ambient and load conditions, about 200 hours a

year, to help limit scale build-up, corrosion and to extend the life of the coil.

Maintenance (Spray Pre-Cooling System)

Clean the finned coils using the recommendations outlined under “Cleaning Hydraulically.”

Remove the spray nozzles, inspect for debris and clean as necessary.

Remove and clean the wye strainer annually to prevent the build up of debris and decreased water flow rate to the spray system.

Inlet Water (Adiabatic Pad & Spray Pre-Cooling Systems)

The water supply temperature and pressure are typically around +50°F and +50 psig, respectively for standard city water main lines. The

adiabatic pad and spray pre-cooling systems require a minimum water pressure of 50 psig at the inlet connection. The adiabatic pad and

spray pre-cooling system piping (see Figures 2 and 3) includes a water pressure regulator to enable the use of high pressure supply water,

up to 140 psig, to be connected. The inlet connection is the highest point on the EVAPCO adiabatic pad and spray pre-cooling systems,

allowing for free drainage of water, aer the soleniod valve, upon system shutoff. Please refer to the “Freeze Protection” section of this

O&M for more information on protecting the adiabatic pad and spray distribution water piping.

Normal municipal and ground water supplies are suitable for use with the adiabatic pad and pre-cooling spray systems. If other water

sources, cleaning agents, or treatments are to be used, ensure that they are compatible with all of the eco-Air product line materials of

construction including PVC, copper, brass, bonded cellulose, galvanized steel and Type 304L stainless steel.

11

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

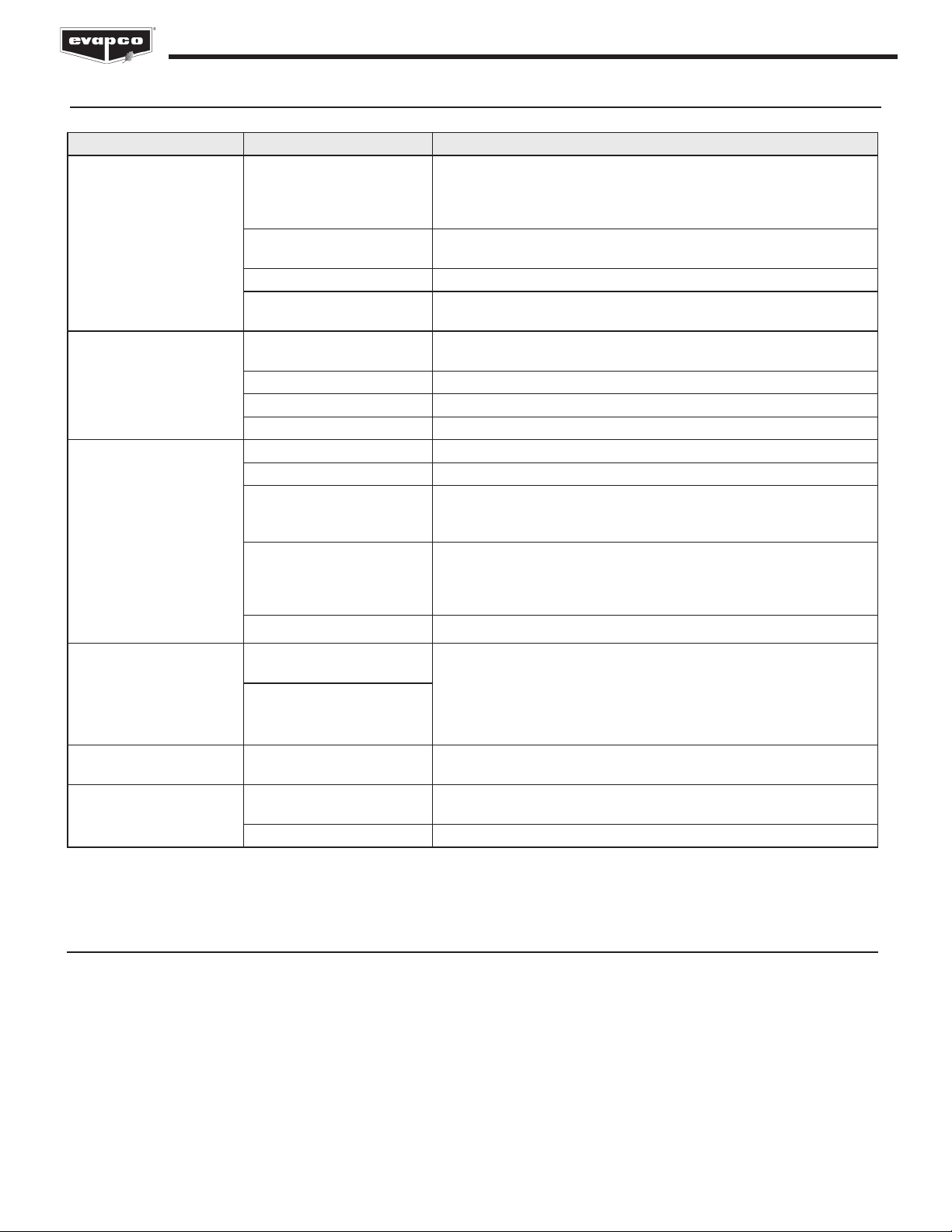

Water Quality Guidelines (Adiabatic Pad Pre-Cooling Systems)

EVAPCO recommends the below outlined water chemistry guidelines applicable to ADIABATIC PAD pre-cooling systems for dry

fluid coolers, CO2gas coolers, and condensers . The water quality guidelines shown below apply to the water which is distributed over

the adiabatic pads. These guidelines are recommended to extend pad life and limit scale build up on the pads.

Property Spray Pre-Cooling System

Scenario 1 Scenario 2

pH 6.0 - 8.5 6.0 - 8.5

Conductivity (mhos/cm) <1,500 <1,000

Alkalinity as CaCO3(ppm) <250 <200

Calcium Hardness as CaCO3(ppm) <350 <250

Alkalinity + Calcium <550 <400

Chloride as Cl (ppm) <175 <150

Sulfate (ppm) <225 <200

Chloride + Sulfate <350 <300

Silica as SiO2 (ppm) <150 <150

Property Adiabatic Pad

Pre-Cooling System

pH 6.0 - 9.0

Conductivity (mhos/cm) <1,500

Alkalinity as CaCO3(ppm) <250

Calcium Hardness as CaCO3(ppm) <300

Alkalinity + Calcium <500

Chloride as Cl (ppm) <250

Sulfate (ppm) <250

Chloride + Sulfate <400

Silica as SiO2 (ppm) <150

Table 2 – Recommended Water Chemistry Guidelines for Inlet Water to Adiabatic Pad Pre-Cooling Systems

Table 3 – Recommended Water Chemistry Guidelines for Inlet Water to Spray Pre-Cooling Systems

Water Quality Guidelines ( Spray Pre-Cooling Systems)

EVAPCO recommends the below outlined water chemistry guidelines applicable to SPRAY pre-cooling systems for dry fluid coolers,

CO2 gas coolers, and condensers. The water quality guidelines shown below apply to the water which passes through the spray pre-

cooling system. Although the spray nozzles spray water away from the coils, the coils and structure of the unit will get wet when the spray

pre-cooling system is on. Thus, the water quality guidelines shown below are recommended to limit scale build-up and corrosion on the

finned tube bundles.

In addition to the water quality guidelines shown below, EVAPCO recommends designing the system for a maximum of 200 hours of

spray operation per year to help limit the possibility for scale build-up and corrosion.

*Scenario 1 applies when the entering Process Fluid or Superheated Refrigerant temperature is equal to or less than 120F.

*Scenario 2 applies when the entering Process Fluid or Superheated Refrigerant temperature is above 120F.

*For Process Fluid and Superheated Refrigerant temperatures in excess of 212F, please consult with EVAPCO.

“Process Fluid” or “Superheated Refrigerant” is the fluid that is circulated and cooled inside the coils. The water chemistry guidelines

outlined for Scenario 2 are more stringent than Scenario 1 because entering process fluid or refrigerant temperatures above 120°F can

accelerate the rate of scale formation and corrosion on the finned coil bundles when the spray pre-cooling system is operational.

If the water chemistry guidelines are not followed or if the spray pre-cooling system is run for prolonged periods of time

(>200 hours per year) or cycled excessively, excessive scale buildup is possible and is not covered under unit warranty.

12

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

PROCEDURE JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

1. Check fins for clogging or debris –

monthly

2. Check unit for damage – quarterly

3. Check unit for leaks – quarterly

4. Clean the coil(s) – semi-annually

5. Check cooler coil connections for

tightness – annually

6. Check the fan blades for cracks, miss-

ing balancing weights, and vibration

– quarterly

7. Examine all wiring for signs of loose

connections or obvious damage –

quarterly

8. Lubricate fan sha bearings - Every

1000 hours of operation (or 3

months)*

9. Check belt tension and adjust

monthly inspect and grease*

10. Sliding motor base - annually or as

needed*

11.Check unit control sequence and

assure proper operation – quarterly

12.Inspect and clean unit surfaces –

annually

a. Galvanized: scrape blemishes and

coat with ZRC

b. Stainless: clean and polish with a

stainless steel cleaner

Adiabatic & Spray Units (During

Operation):

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

1. Check adiabatic pad and water

distribution system for damage or

incorrect pad wetting – monthly

2. Confirm water piping integrity

including flow setter adjustment. The

flow setter can be used to adjust the

amount of water distributed to the

adiabatic pads. Check to ensure holes

are unclogged – bi-monthly

3. Check spray nozzles and water

distribution system for damage and

uniform spray pattern – monthly

4. Remove and clean wye strainer –

annually

MAINTENANCE CHECKLIST

*These procedures are only for the Double Stack product line.

13

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Fan System

Fan motors on the flat and V-coil units have permanently sealed bearings; therefore, no lubrication is required. The Double Stack units

with NEMA motors require their fan sha bearings to be lubricated. Be sure to verify any instructions for special motors that have been

ordered. A motor data sheet and specific motor instructions are shipped with each unit.

Please refer to The Controller User’s Manual for details about control systems.

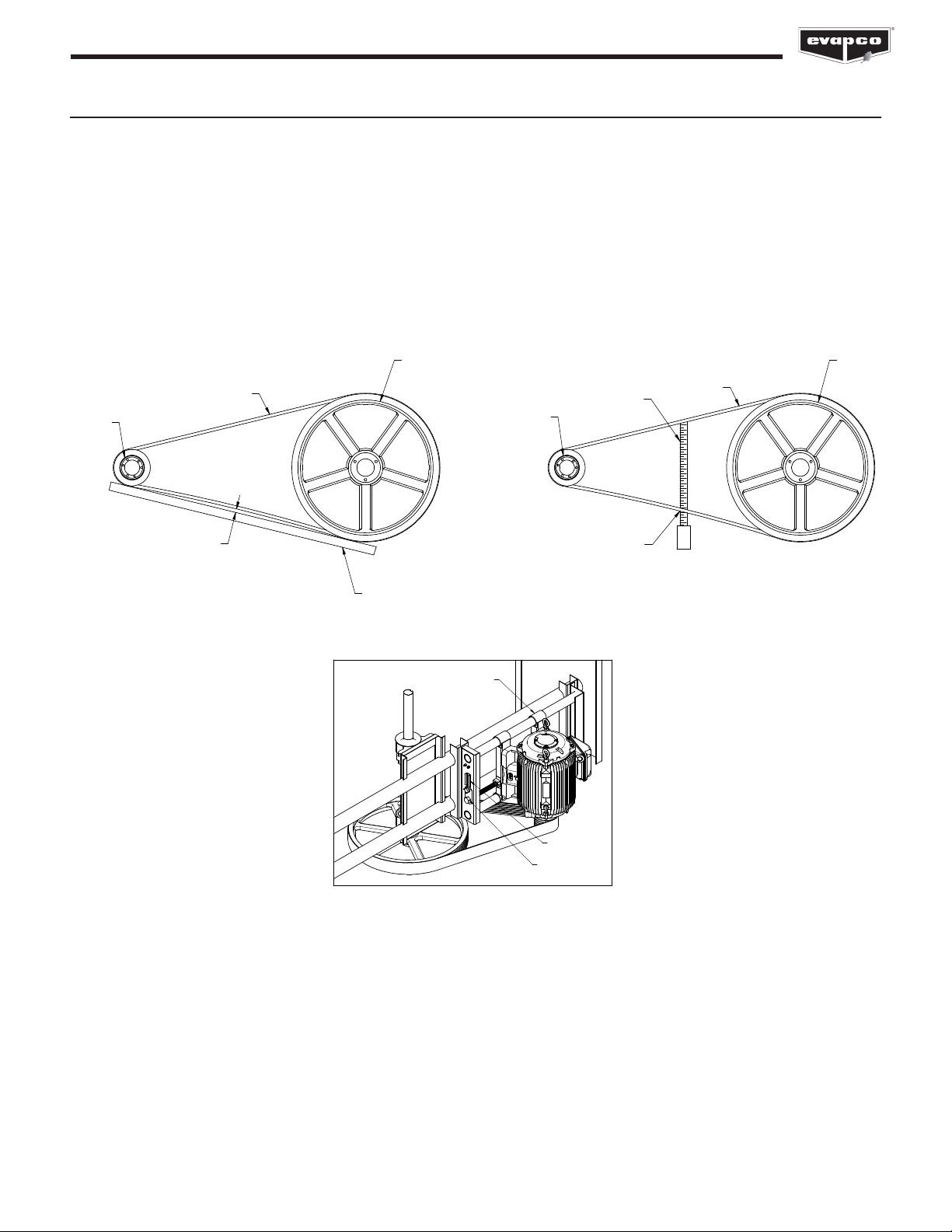

On induced dra belt driven units with internally mounted motors, a motor adjustment tool is provided. The tool will be found on the

adjustment nut. To use, place the hex end over the adjustment nut. Tension the belt by turning the nut in the appropriate direction. When

the belts are properly tensioned, tighten the lock nut

Figure 6 — Internally Mounted Motor, Double Stack

ADJUSTMENT

TOOL

ADJUSTMENT

NUT

SLIDING MOTOR BASE

Fan Belt Adjustment - Double Stack Product Line Only

The fan belt tension should be checked at start up and again aer the first 24 hours of operation to correct for any initial stretch. To

properly adjust the belt tension, position the fan motor so that the fan belt will deflect approximately 1/2” when moderate pressure is

applied midway between the sheaves. Figure 4 and Figure 5 show two ways to measure this deflection. Belt tension should be checked

on a monthly basis. A properly tensioned belt will not “chirp” or “squeal” when the fan motor is started.

Figure 4 — Method 1, Measuring Fan Belt Deflection Figure 5 — Method 2, Measuring Fan Belt Deflection

DRIVEN

SHEAVE

BELT

DRIVER

SHEAVE

STRAIGHT EDGE

1/4" TO 3/8" DEFLECTION =

PROPER BELT TENSION

DRIVER

SHEAVE

BELT

TAPE

MEASURE

DRIVEN

SHEAVE

1/4" TO 3/8" DEFLECTION =

PROPER BELT TENSION

14

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Variable Frequency Drives

The use of a variable frequency drive (VFD) provides the most precise method of capacity control. A VFD is a device that converts a fixed

AC voltage and frequency and changes it into an AC adjustable voltage and frequency used to control the speed of an AC motor. By

adjusting the voltage and frequency, the AC induction motor can operate at many different speeds.

The use of VFD technology can also benefit the life of the mechanical components with fewer and smoother motor starts and built in

motor diagnostics. VFD technology has a particular benefit on evaporative cooling units operating in cold climates where airflow can be

modulated to minimize icing and reversed at low speed for de-icing cycles. Applications using a VFD for capacity control must also use

an inverter duty motor built in compliance with NEMA standard MG-1. This is a standard option from EVAPCO.

The type of motor, manufacturer of the VFD, motor lead lengths (between the motor and the VFD), conduit runs and grounding can

dramatically affect the response and life of the motor. Select a high quality VFD that is compatible with the fan motor(s) in the EVAPCO

unit(s). Many variables in the VFD configuration and installation can affect motor and VFD performance. Two particularly important

parameters to consider when choosing and installing a VFD are switching frequency and the distance between the motor and VFD, oen

referred to as lead length. Consult the VFD manufacturer’s recommendations for proper installation and configuration. The motor lead

length restrictions can vary with the vendor. Regardless of motor supplier, minimizing lead length between the motor and drive is good

practice. The motor lead length restrictions may vary with the motor vendor.

SEQUENCE OF OPERATION FOR MULTI-FAN UNITS WITH A VFD DURING PEAK LOAD

1. The VFD should all be synchronized to speed up and slow down uniformly.

2. The VFD needs to have a preset shutoff to prevent water temperatures from becoming too cold and to prevent the drive from

trying to turn the fan at near zero speed.

3. Operating below 25% of motor speed achieves very little return in fan energy savings and capacity control. Unless otherwise

stated in your factory submittal, 25% is the lowest recommended fan speed.

VARIABLE FREQUENCY DRIVE LOCKOUT NOTIFICATION

Qualified personnel should use proper care, procedures and tools when maintaining the fan/drive system in order to

prevent personal injury and/or property damage.

Identify and lockout harmful resonant frequencies.

A variable frequency drive (VFD) fan system, unlike traditional fixed-speed systems, is designed to operate between 25% (15Hz) and 100%

(60Hz) speeds, which creates an opportunity for operation where resonant frequencies exist. Sustained operation at resonant frequencies

may lead to excessive vibration, fatigue of structural components, and/or drive system noise and failure. Owners and operators must

anticipate the existence of resonant frequencies and lock out frequencies during startup and commissioning in order to prevent drive

system operational problems and structural damage. As a part of the normal start-up and commission processes, resonant frequencies

should be identified and locked out in the VFD’s soware.

The unit’s supporting structure, external piping, and accessories contribute to the overall harmonic make-up and stiffness of the system.

The choice of VFD will also have a significant influence on how the system behaves. Consequently, not all resonant frequencies can be

determined in advance at the manufacturer’s factory during final inspection and testing. Relevant resonant frequencies (if they occur) can

only be identified accurately aer the unit installation in the system.

To check for resonant frequencies in the field, a run-up and run-down test must be performed. Additionally, VFD carrier frequencies

should be adjusted to best align the VFD with the electrical system. Refer to your drive’s start-up procedures for additional information

and instruction.

The procedure of checking for resonant frequencies requires stepping through the VFD’s operating range at (2) Hz intervals from the

lowest operating frequency to full speed. At each step, pause long enough for the fan to reach steady-state. Note changes in unit

vibration during this time. Repeat from full speed to minimum speed. Should vibration-inducing frequencies exist, the run-up and run-

down test will isolate the resonant frequencies which then must then be locked out in the VFD programming.

For more details on the use of variable frequency drives, please reference the “Variable Frequency Drives” document located under

technical references, in the document library on www.evapco.com.

15

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Cold Weather Operation

EVAPCO eco-Air Series air cooled equipment is well suited to operate in cold weather conditions. The lack of required water makes air

cooled equipment ideal for low ambient conditions. When the air cooled unit is going to be used during cold weather conditions, several

items need to be considered including unit layout, adiabatic pad or spray system water distribution piping (if equipped), and unit heat

transfer coils.

Unit Layout

Adequate, unobstructed air flow must be provided for both the intake and discharge from the unit. For additional information on unit

layout, please refer to EVAPCO’s Equipment Layout Manual Bulletin.

Freeze Protection

EVAPCO is not responsible for ensuring that the product is adequately protected against the heat transfer fluid freezing. If the product

has occasion to operate in close to or sub-freezing temperatures then either the heat transfer fluid should be dosed with an adequate

anti-freeze additive or provision has to be made to either manually or automatically drain the fluid from the cooler.

NOTE: Opening the air vent and drain connections as a means to fully drain the fluid from the dry cooler is not sufficient to fully empty

all the fluid and thus prevent freeze damage. In particular for large dry coolers, air pressure assisted drainage is required.

The sequence of control for a unit operating at low ambient conditions is much the same as a cooler or condenser operating under

summer conditions provided that the ambient temperature is above freezing. When the ambient temperatures are below freezing,

additional precautions must be taken to avoid the potential for damaging ice formation.

It is very important to maintain close control of the cooler or condenser during winter operation. EVAPCO recommends that the leaving

heat transfer fluid temperature NEVER be less than 6° F above the fluids freezing temperature.

If the adiabatic (optional) fluid and gas cooler or air cooled condenser is to be located in an area that experiences ice storms and freezing

conditions EVAPCO recommends the removal and dry storage of the adiabatic pads (if equipped).

NOTE: Heat tracing all adiabatic and spray water piping upstream and including the solenoid valve is required, unless the incoming

water supply lines are drained during low ambient conditions and all valves are le open (recommended). Adiabatic pad and spray pre-

cooling systems are not intended to be operated in low ambient conditions.

16

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Problem Possible Cause Remedy

Overamping Fan Motors Electrical issue 1. Check voltage across all three legs of the motor.

2. Verify that the motor is wired per the wiring diagram, and connections

are tight.

3. Refer to EVAPCO’s Controller User’s Manual for further details.

Fan rotation Verify that the fan is rotating in the correct direction using visible arrow

sticker on fan cowl. If not, switch the leads so it runs correctly.

Mechanical failure If fan motor does not turn freely by hand, replace fan/motor assembly.

Motor running single- phase Stop motor and attempt to start it. Motor will not start again if single

phased. Check wiring, controls and motor.

Unusual Motor Noise Motor leads connected

incorrectly

Check motor connections against wiring diagram on motor.

Electrical unbalance Check voltage and current of all three lines. Correct if required.

Fan hitting cowl Replace fan/motor or assembly.

Defective motor Replace fan motor or assembly.

Capacity Not Reached Insufficient fluid flow Check piping system and components.

Heat transfer fluid change Compare with design fluid and adjust if required

De-energized fans 1. Verify motor has power.

2. If motor has power and is still de-energized, replace fan/motor

assembly.

Adiabatic pads not wetted Check for complete wetting of pads

1. If pads are only partially wetted, clean out water distribution pipe and

check distribution holes for clogs.

2. If pads have excessive scale they will need to be replaced.

Fouled heat Transfer surface Carefully clean fins, see page 7 for more details.

Improper Water

Distribution for

Adiabatic Pad or Spray

Pre-Cooling System

Spray nozzles not spraying

water uniformly 1. Check for clogged/fouled nozzles or distribution piping

2. Check pressure gauge to ensure correct incoming water pressure,

pressure requirements can be verified on the technical data sheet of

the submittal.

Uneven water distribution

for adiabatic pad and

pre-cooling system

Fans Not Rotating Damaged or unbalanced fan

blade or motor

Replace fan/motor assembly.

Vibration Loosely attached fan/motor

assembly

Tighten fan/ motor assembly.

Unbalanced fan (NEMA equipped units only) balance fan blade using spacers.

Replacement Parts

EVAPCO has replacement parts available for immediate shipment. Most orders ship within 24 hours from time of order!

The following pages contain exploded view drawings of all current EVAPCO eco-Air closed fluid coolers and condensers. Please use

these drawings to help identify the major parts of your unit. To order replacement parts, please contact your local EVAPCO representative

or Mr. GoodTower Service Center. The EVAPCO representative contact information is located on the unit’s nameplate or can be found

by visiting either www.evapco.com or www.mrgoodtower.com.

Additionally, your local EVAPCO representative or Mr. GoodTower Service Center can provide FREE unit inspections to help ensure your

equipment operates at peak performance regardless of the original manufacturer!

Table 4 — Troubleshooting Guidelines for eco-Air Units

Troubleshooting

17

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

Replacement Part Drawings

eco-Air Flat Coil Configuration with NEMA Fan Motors

eco-Air Flat Coil Configuration with EC Fan Motors

COIL

FAN

SCREEN

FAN ASSEMBLY

NEMA

MOTOR

TERMINAL BOX

OR CONTROLLER

(OPTIONAL)

CASING

PANEL

MECHANICAL

EQUIPMENT

SUPPORT

EC FAN

ASSEMBLY

COIL

CASING

PANEL

TERMINAL BOX

OR CONTROLLER

(OPTIONAL)

18

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

FAN

SCREEN

FAN ASSEMBLY

NEMA

MOTOR

COIL

INSPECTION

PANEL

INTERNAL

STEP DECK

(OPTIONAL)

TERMINAL BOX

OR CONTROLLER

(OPTIONAL)

MECHANICAL

EQUIPMENT

SUPPORT

EC FAN

ASSEMBLY

COIL

INSPECTION

PANEL

INTERNAL

STEP DECK

(OPTIONAL)

TERMINAL BOX

OR CONTROLLER

(OPTIONAL)

eco-Air V-Coil Configuration with NEMA Fan Motors

eco-Air V-Coil Configuration with EC Fan Motors

19

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

eco-Air Adiabatic Pad Pre-Cooling System Components

eco-Air Spray Pre-Cooling System Components

DETAIL A

HAND

VALVE

WATER PRESSURE

REGULATOR

WYE

STRAINER

SOLENOID

VALVE

DISTRIBUTION

PIPE

DISTRIBUTION

PIPE

SPRAY NOZZLE

PRESSURE

GAUGE

DETAIL B

B

A

NOTE: If the adiabatic pad or spray pre-cooling system is provided with the “two-stage” accessory, quantity (2) solenoid valves will

be provided.

ADIABATIC WATER

DISTRIBUTION SYSTEM

ADIABATIC DRAIN

COIL

ADIABATIC

PADS

DETAIL A

HAND

VALVE

WATER PRESSURE

REGULATOR

WYE

STRAINER

SOLENOID

VALVE

DISTRIBUTION

PIPE

WATER

BAFFLE

SPRAY BRANCH

SPRAY NOZZLE

PRESSURE

GAUGE

ADIABATIC

DISTRIBUTION

PAD

DETAIL B

AB

20

DRY, ADIABATIC AND SPRAY FLUID COOLERS, CONDENSERS & CO2GAS COOLERS

eco-Air Double Stack Adiabatic Cooler with NEMA Fan Motors

eco-Air Double Stack Adiabatic Cooler with EC Fan Motors

EC FAN MOTOR ASSEMBLY

CONTROL PANEL

INSPECTION PANEL

COIL

NEMA

MOTOR

FAN

ASSEMBLY

FAN

SCREEN

MECHANICAL

EQUIPMENT

SUPPORT

POWER

DISCONNECT

COIL

INSPECTION

PANEL

This manual suits for next models

17

Table of contents

Other EVAPCO Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

GE

GE HS15-66a-9G-CUL Important safety instructions

LFA

LFA TDP 5 Assembly instructions

Dungs

Dungs FRM-NOC 100 Series instruction manual

JUKI

JUKI AW-3S instruction manual

SCHUNK

SCHUNK NSE mini 90 Assembly and operating manual

Xylem

Xylem McDonnell & Miller PSE-800-M Application, Installation, Operation, and Maintenance Manual

Eaton

Eaton PKE65/AK/XTU-65-SP Instruction leaflet

ABM International

ABM International Innova Longarm 1018 Series manual

Agilent Technologies

Agilent Technologies G1531-67000 instructions

KROHNE

KROHNE SMARTPAT COND 7200 Handbook

Balluff

Balluff BTL6-A/E500/B50 M E2/E28-KA LA Series Condensed guide

Technom

Technom Lokring MTK45 Instruction card