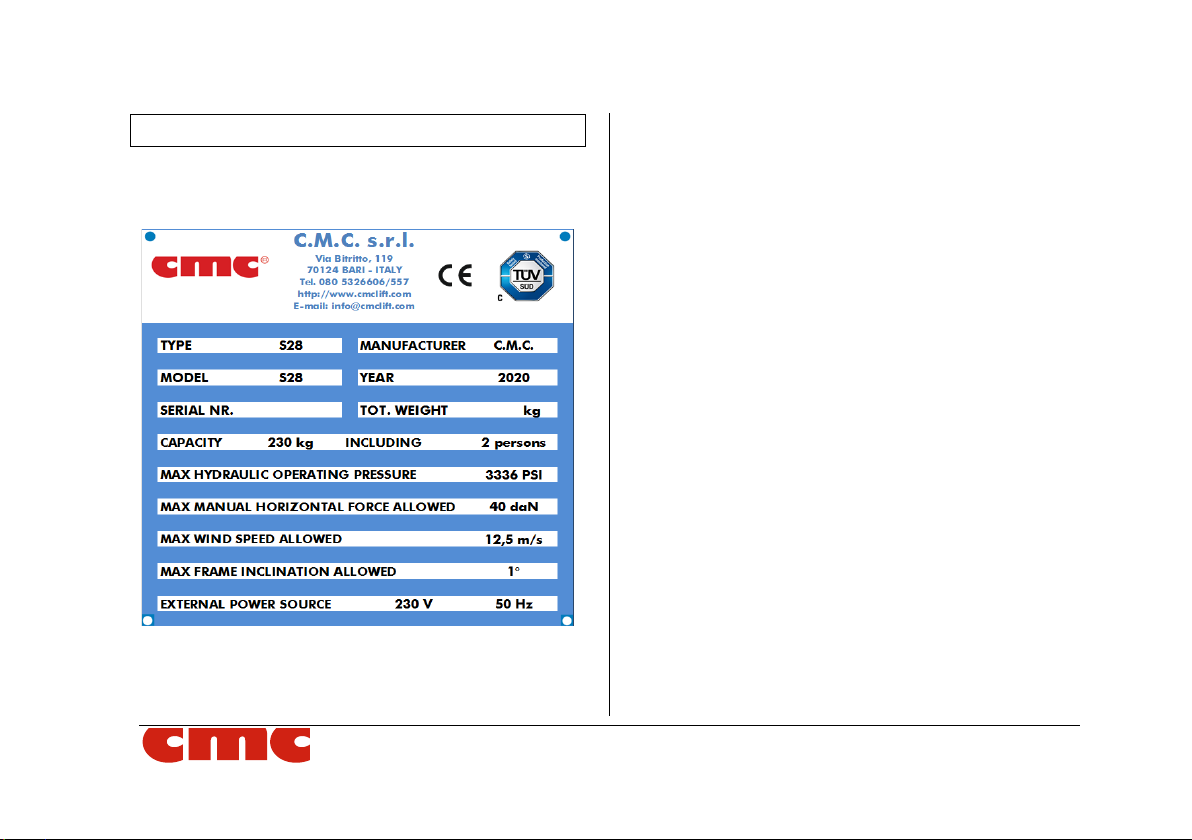

MAN.243 Rev.5 ENG - Use and maintenance manual S28 page 3of 138

➔Only properly trained and authorized personnel

shall be permitted to operate the MEWP. The

employer is obliged to make sure that the

operator has the aptitude requirements

necessary for the correct management of the

machine, that he has carefully read and

understood what is reported in this use and

maintenance manual, and that he has received

adequate training to work in standard and

emergency situations. However, this manual

cannot replace in any way a suitable experience

that the staff in charge must have gained

previously on similar machines or that they will be

able to get on this machine, under the guidance

of an already trained staff.

➔The user must work within the functional limits of

the machine and perform a constant and diligent

maintenance, using only original replacement

parts approved by C.M.C. Any alteration and/or

modification of the original design characteristics

of the machine without prior written approval of

the manufacturer are absolutely prohibited and

make the responsibility for such actions fall

directly on operators.

➔The operator shall carefully know the safety

standards foreseen by national and international

legislations and apply them during all operations

with the MEWP.

➔If an accident occurs (i.e. high height operator’s

suspension), it’s compulsory to replace safety

anchorage components and any damaged parts

of the machine and verify that platform’s structure

is suitable for use making it checked by C.M.C.’s

specialized technicians.

When buying a machine, a warranty certificate

is delivered with the warranty terms clearly

indicated.

The guarantee of proper testing and

functioning of the machine is strictly dependent

on the correct application of all the instructions

contained in this manual.

The non-compliance with the previous

statements automatically invalidates the

warranty.

0.3 Where and how to store the

manual

Original manufacturer's languages: Italian and English.

All other languages are copies of the original

instructions.